TMPOil Furnaces – Furnace Manual

670-000-004/1010 11

4Venting

General venting requirements

Failure to follow all instructions can result in flue gas

spillage and carbon monoxide emissions, causing

severe personal injury or death.

Inspect existing chimney before installing furnace.

Clean chimney thoroughly. Replace or repair

chimney if visual inspection indicates chimney may

be unsuitable for use. Insufficient draft can cause

flue gas leakage and carbon monoxide emissions.

Failure to clean or replace perforated pipe or tile

lining and/or patch mortar and joints can cause

severe personal injury or death.

Proper draft for these oil furnaces may be achieved using either

a conventional chimney (natural draft) or a power vent (sidewall)

system that has been properly designed for use with oil-fired

equipment. Power vent manufacturer’s instructions must be

followed.

Use vent material approved by local codes for oil-fired burners.

In their absence, refer to:

NFPA 31, Installation of Oil-Burning Equipment.

NFPA211, Standard for Chimneys, Fireplaces, Vents and

Solid Fuel Burning Appliances.

In Canada, refer to CSA B139, Installation Code for Oil-

Burning Equipment.

NFPA-211 requires chimney to be lined before connected to

furnace.

To prevent downdrafts, extend chimney at least 3 feet above

highest point where it passes through roof and 2 feet higher than

any portion of building within 10 feet. Increase chimney cross-

sectional area and height at least 4% per 1,000 feet above sea

level.

Provide minimum clearances from vent (flue) pipe to

combustible material:

Single-wall vent – 18 inches minimum

Type“L”double-wallvent–6inchesminimum

Oversized chimneys, outside masonry chimneys

and/or derated inputs can result in condensation in

chimney.

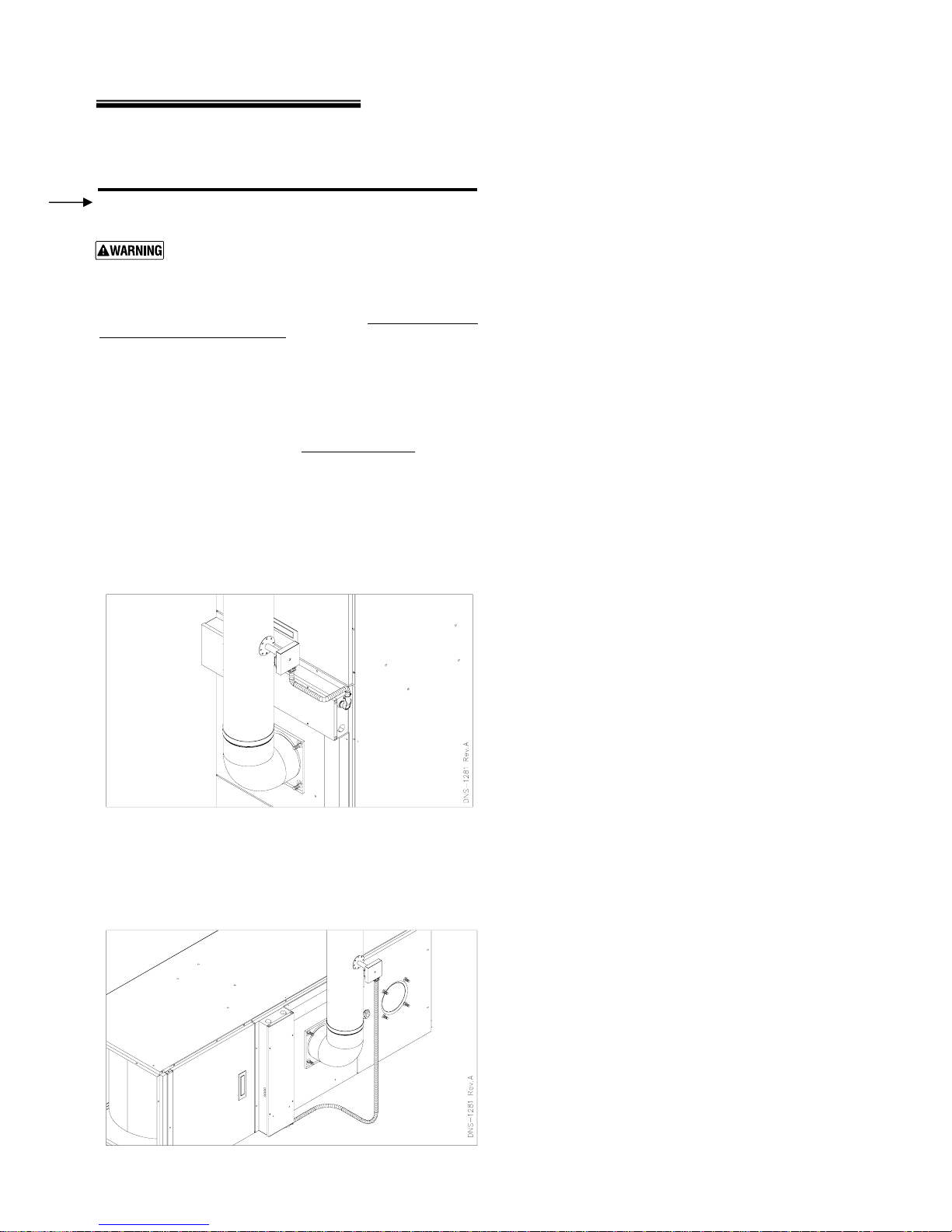

Connect venting

Long horizontal vent runs, excessive number of tees

and elbows, or other obstructions restricting

combustion gas flow can result in the possibility of

condensation, flue gas leakage and carbon

monoxide emissions, which can lead to severe

personal injury or death.

The horizontal vent must slope upwards, away from the furnace,

a minimum of ¼inch per foot.

Connection must be made above bottom of chimney to avoid

blockage. Vent pipe must not enter chimney far enough to cause

obstruction. Use thimble or slip joint where vent pipe enters

chimney to allow removal for cleaning.

When burner and furnace are properly installed, draft overfire

will be approximately –0.01” to –0.02” w.c. Install barometric

Connect venting (continued)

control in vent, per control manufacturer’s instructions, when

excess draft needs to be relieved or to comply with applicable

codes and regulations. Use draft gauge to adjust proper

opening.

An induced draft fan for the chimney may be necessary if:

Excessive resistance to flow of combustion gases can be

expected.

Cross-sectional area of chimney is smaller than minimum

recommended.

Chimney height is less than recommended.

When using induced draft fan seal all vent joints and

interlock burner with fan operation.

Vent dampers

Do not install a thermal-type vent damper on this

furnace. Failure to comply could result in severe

personal injury, death or substantial property

damage.

If a vent damper is required, use only a motorized

one, installed and wired in the furnace according to

the vent damper manufacturer’s instructions.

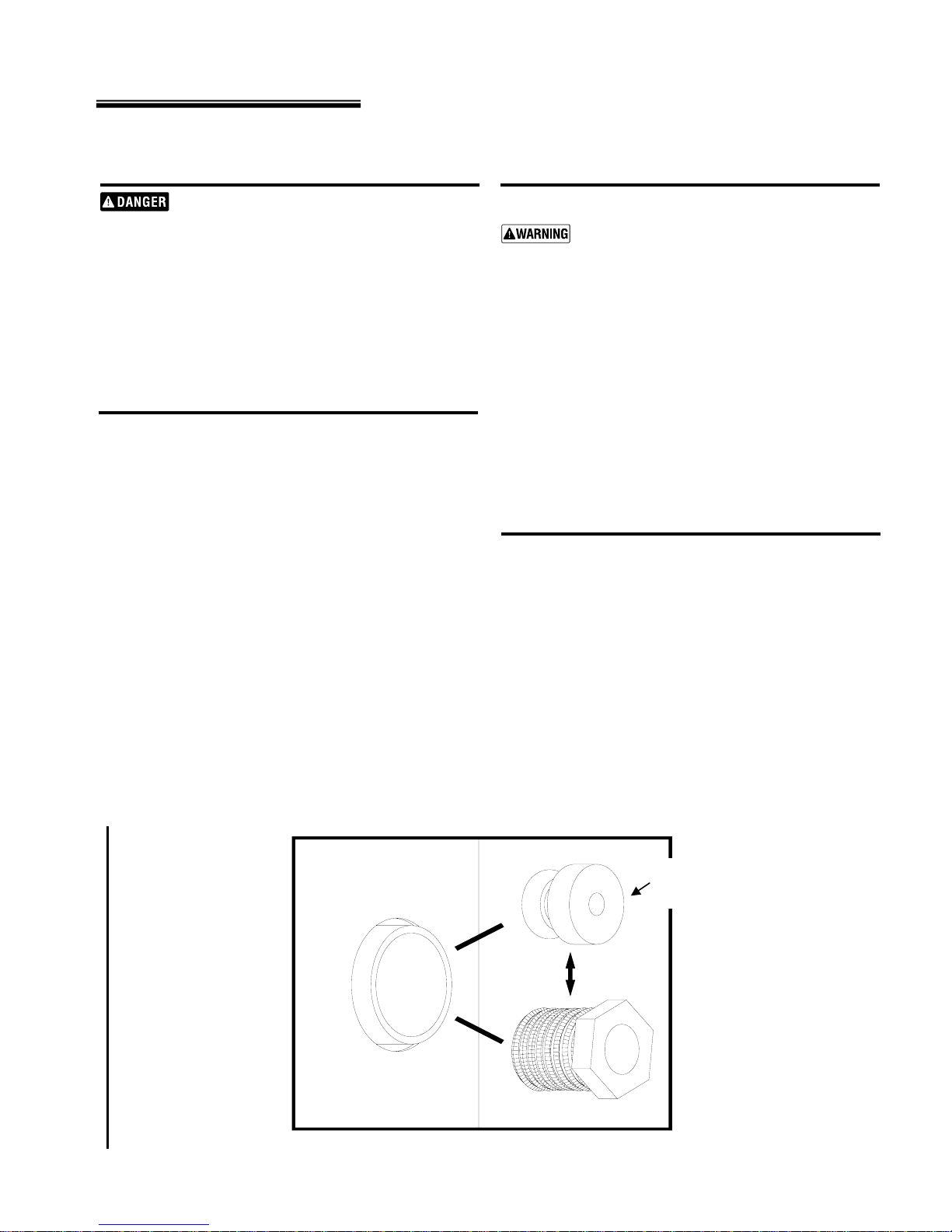

Barometric draft control

Install a barometric control in the vent, per the manufacturer’s

instructions, when excess draft needs to be relieved or to comply

with applicable codes and regulations. Use draft gauge to adjust

proper opening.

Install a barometric draft control in the vent pipe at least one foot

from the furnace vent connection, preferably in the highest part

of the vent pipe before the vent enters the chimney. If headroom

does not provide enough clearance to locate the control at least

one foot from the vent connection, install an elbow at the furnace

and mount the control in an horizontal pipe at least one foot from

the elbow. Install an elbow after the control to turn vertically.

The barometric draft control must be located in the same room

as the furnace to operate correctly.

Ensure that the barometric draft control is accessible. Adjust the

damper to obtain the correct overfire draft, as described in this

manual and the burner manual.