Templari KITA AIR R32 User manual

INSTALLATION INSTRUCTION

AIR TO AIR

Refrigerant gas

THE HEAT PUMP

Summary

1 Introducon ........................................................................................................... 6

1.1 General Notes......................................................................................................... 6

1.2 Suggested tools ...................................................................................................... 6

1.3 Seriesdescripon ................................................................................................... 6

2 Read Carefully before use ....................................................................................... 7

2.1 Importantinformaon............................................................................................ 7

2.2 Importantinformaonregardingtherefrigerantused ............................................ 7

2.3 Proper use.............................................................................................................. 8

2.4 Standards and statutory provisions......................................................................... 8

2.5 Instruconsfordisposal ......................................................................................... 8

2.6 Energecsaving...................................................................................................... 8

3 Expecteduseoftheheatpump .............................................................................. 8

3.1 Operangareaesafedevices ................................................................................. 8

3.2 Allowedoperavezone .......................................................................................... 8

3.3 Heat pump structure .............................................................................................. 9

3.4 Operaonmode ..................................................................................................... 9

4 Equipment supplied................................................................................................ 9

4.1 Main unit................................................................................................................ 9

4.2 Name and serial number ........................................................................................ 9

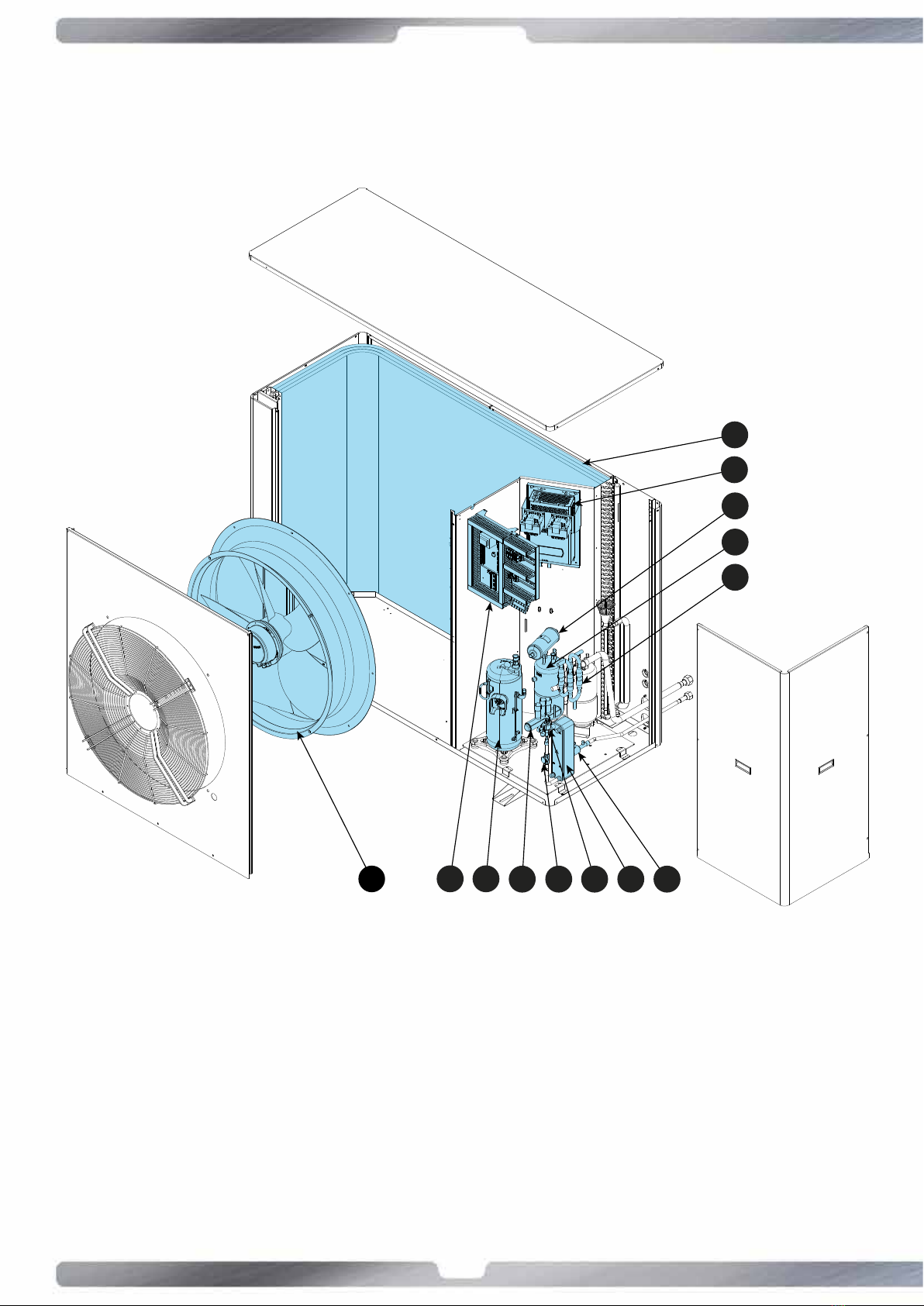

4.3 KITA AIR R32 Templari® external unit components diagram ................................. 11

4.4 KITA AIR Plus R32 Templari® external unit components diagram........................... 12

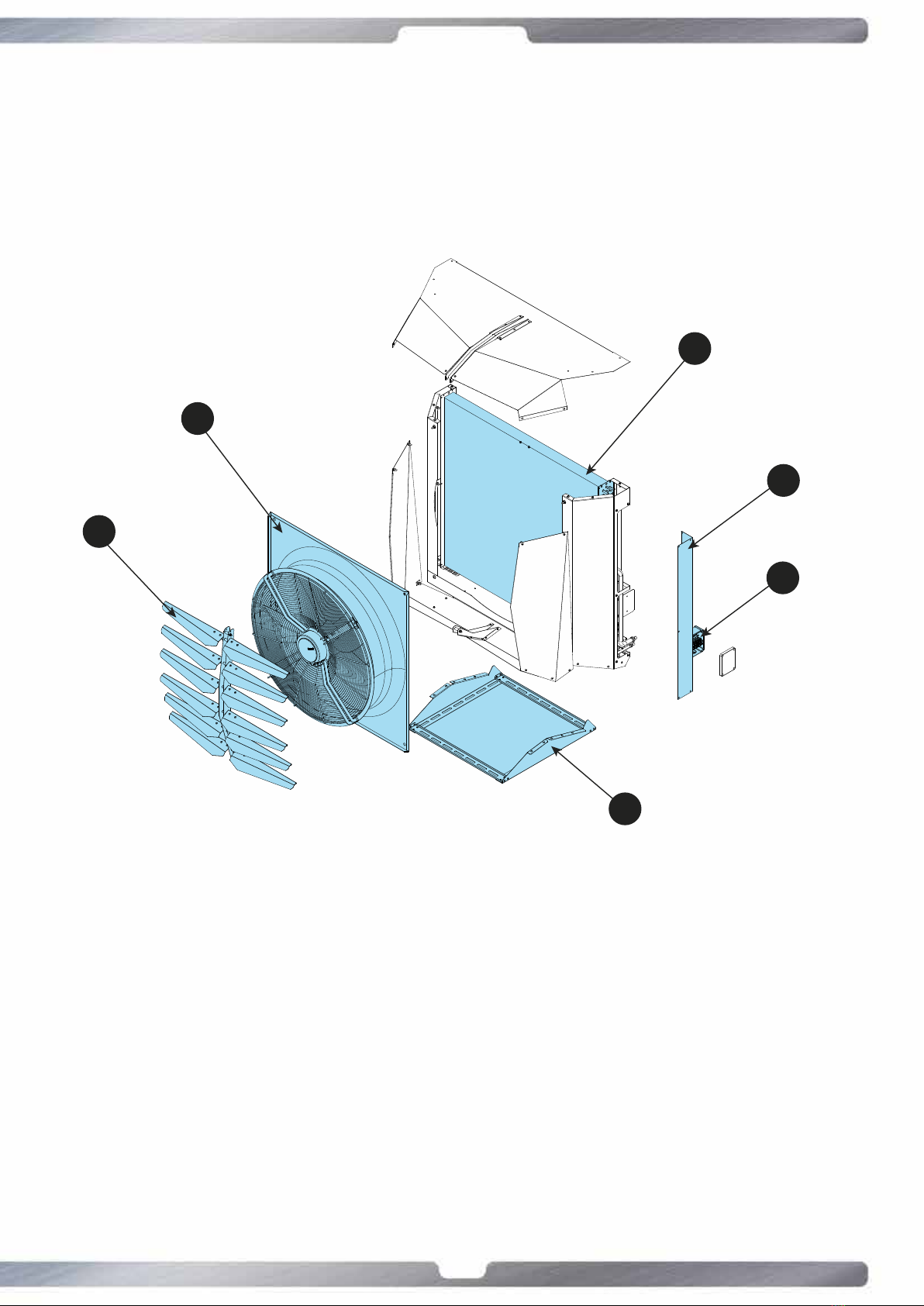

4.5 KITA AIR R32 and AIR Plus R32 Templari® internal unit components diagram........ 13

5 Transport.............................................................................................................. 14

6 Mounngandinstallaon..................................................................................... 14

6.1 Equipmentcheck .................................................................................................. 14

6.2 External unit measurements................................................................................. 14

6.3 Freespacesfortheassembly ................................................................................ 15

6.4 Choiceofinstallaonplace ................................................................................... 15

6.5 Externalunitmounng ......................................................................................... 16

6.6 Condensatedischargepreparaon........................................................................ 16

6.7 Correct alignment................................................................................................. 17

7 Installaonandassemblyoftheinternalunit ....................................................... 17

7.1 InternalunitsizesKITAAIRR32............................................................................. 17

7.2 Generaliesandchoiceoftheinstallaonplace ................................................... 18

7.3 AssemblyinternalunitandcorrectposioningofB2probe .................................. 18

8 Refrigerantcircuitconnecon............................................................................... 18

8.1 Installaonrequirements ..................................................................................... 18

8.2 Setupforinstallaonandrefrigerantpipelinesinstallaon .................................. 19

8.3 Vacuum procedure ............................................................................................... 19

9 Maintenance and cleaning.................................................................................... 19

9.1 Finned coil cleaning .............................................................................................. 19

9.2 Condensatedischargecleaning............................................................................. 20

9.3 Refrigerant circuit maintenance............................................................................ 20

10 Electricconnecon ............................................................................................... 20

10.1 Generalinformaon ............................................................................................. 20

10.1.1Thecustomer/installerhasto: ............................................................................. 20

10.2 Operaonsoflaying ............................................................................................. 20

10.3 Externalunitconnecon....................................................................................... 20

10.4 Internalunitconnecon ....................................................................................... 20

10.5 Probes and remote controller ............................................................................... 20

10.6 Power supplying ................................................................................................... 20

10.6.1Internalunitauxiliaryheater(oponal) ................................................................ 21

10.7 Powerandsignalcablescharacteriscs................................................................. 21

11 Terminal box wiring .............................................................................................. 22

11.1 Mono-phaseinternalterminalboxwiring............................................................. 22

11.2 3-phaseinternalterminalboxwiring .................................................................... 22

12 Electronics(UPC) .................................................................................................. 24

12.1 Digital outputs...................................................................................................... 24

12.2 Digital inputs ........................................................................................................ 24

12.3 Analogical outputs................................................................................................ 24

12.4 Analogical inputs .................................................................................................. 24

12.5 KITAAIRR32andAIRPLUSR32electricdiagram................................................... 25

12.6 Internalunitwiringconnecon............................................................................. 26

12.6.1 Fan....................................................................................................................... 26

12.6.2 4-way valve and carter resistance wiring .............................................................. 26

12.6.3 wiring probe ........................................................................................................ 26

12.7 KITAAIRR32andAIRPLUSR32internalunitauxiliaryheangelement(oponal)

wiringconnecondiagram ................................................................................... 27

13 Commissioning ..................................................................................................... 28

13.1 Preliminary controls ............................................................................................. 28

13.2 Commissioning ..................................................................................................... 28

14 K-TouchPanel ....................................................................................................... 28

14.1 Warnings .............................................................................................................. 28

14.2 ConnecngtotheKitaheatpump........................................................................ 29

14.3 System overview .................................................................................................. 30

14.4 Explodedview:PLanconnecon(7a)orBMSconnecon(7b) .............................. 32

15 Control unit .......................................................................................................... 34

15.1 Fixingofthepanel ................................................................................................ 34

15.2 Control panel measurement ................................................................................. 34

15.3 Control panel structure......................................................................................... 34

15.4 Control panel display............................................................................................ 34

15.5 Main menu........................................................................................................... 35

15.6 ON-OFF menu....................................................................................................... 35

15.7 SETPOINT menu.................................................................................................... 35

15.8 Clock/metablemenu .......................................................................................... 36

15.9 Input/Outputmenu.............................................................................................. 37

15.10Alarmshistorymenu ............................................................................................ 37

15.11Boardchangemenu.............................................................................................. 37

15.12 Assistance menu................................................................................................... 37

15.13 Menu overview .................................................................................................... 41

16 Alarms.................................................................................................................. 42

16.1 Alarmsresoluon ................................................................................................. 44

16.2 Nocaons......................................................................................................... 44

6

www.templari.com

1 Introducon

KITA - AIR Templari® heat pump, from

its start-up and for all its life cycle. The document is divided

procedures to be performed.

gases covered by the Kyoto Protocol. Do not

vent gases into the atmosphere.

take extreme care that there are no sources of

requirements in paragraph 6.4.

1.1 General Notes

the system.

• The unit is directly supplied by the manufacturer with all

pump KITA - AIR Templari® can prevent damages and any

costs for repairs.

• Keep this manual with the necessary diagrams in an easily

accessible place.

control panel, if necessary contact the installer. If necessary,

please request for original parts.

• Voltage and frequency of Power supply of the machine;

• Sound power level;

1.2 Suggested tools

• Set of screwdrivers;

• Scissors;

• Set of wrenches or pipe wrenches;

• Pumber material to seal the threads;

• Testers and current clamp;

1.3 Seriesdescripon

KITA - AIR Templari® heat pump series presents air to air

machines which are composed by an external and internal

KITA - AIR Templari® is full-inverter with high performance and

Another feature is the EVI technology (Enhanced Vapour

a 4-ways valve, pressure transducers, temperature probes,

controlled by the electronics onboard. The user can control the

this control it is possible to change the setpoint and the working

Internal unit

External unit

7

www.templari.com

2 Read Carefully before use

2.1 Importantinformaon

ATTENTION!!

The use and the maintenance of the KITA - AIR Templari®

heat pump, are subjected to the juridical ordinances of the

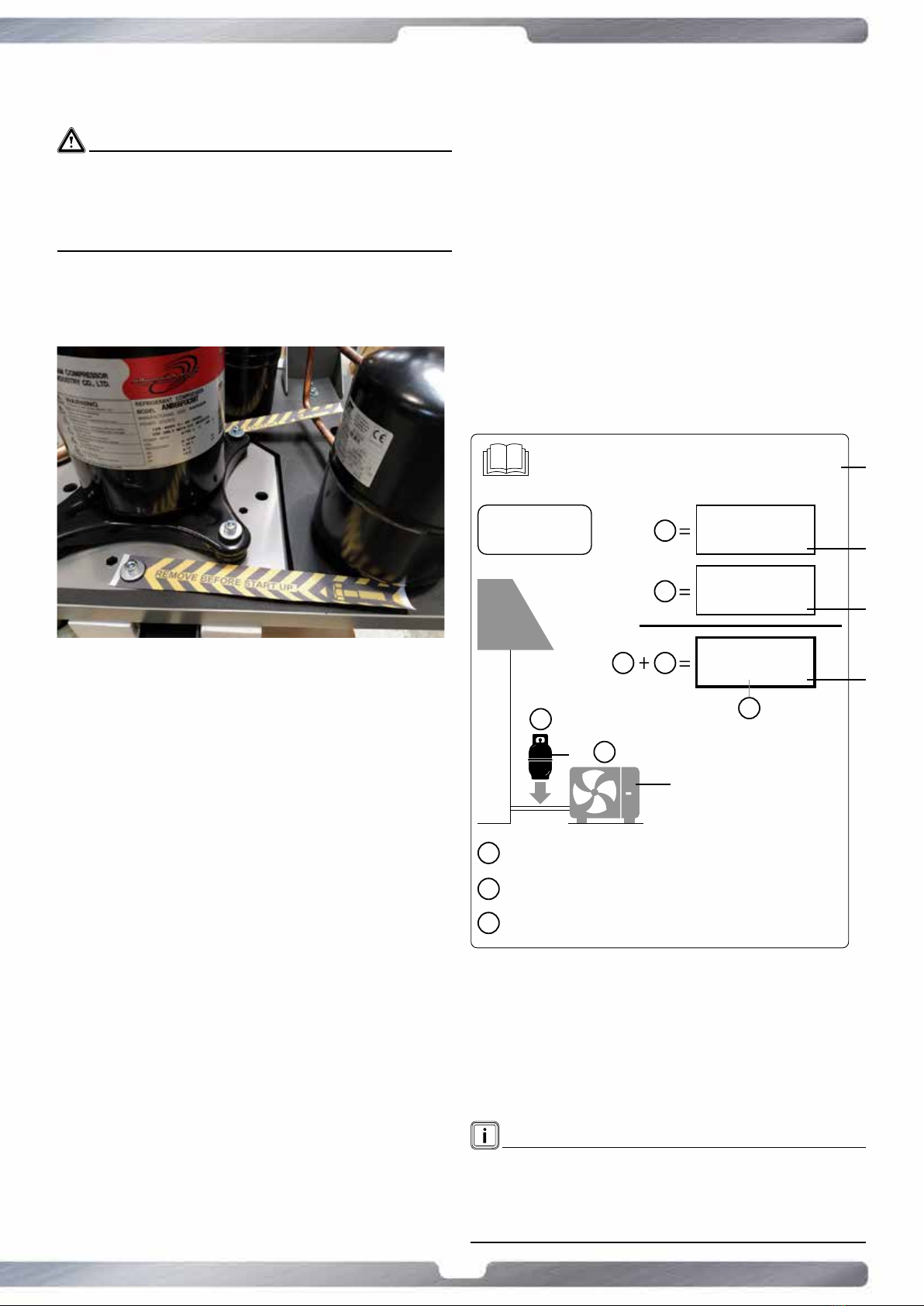

• Transport protecon must be removed before to

commissioning.

countries.

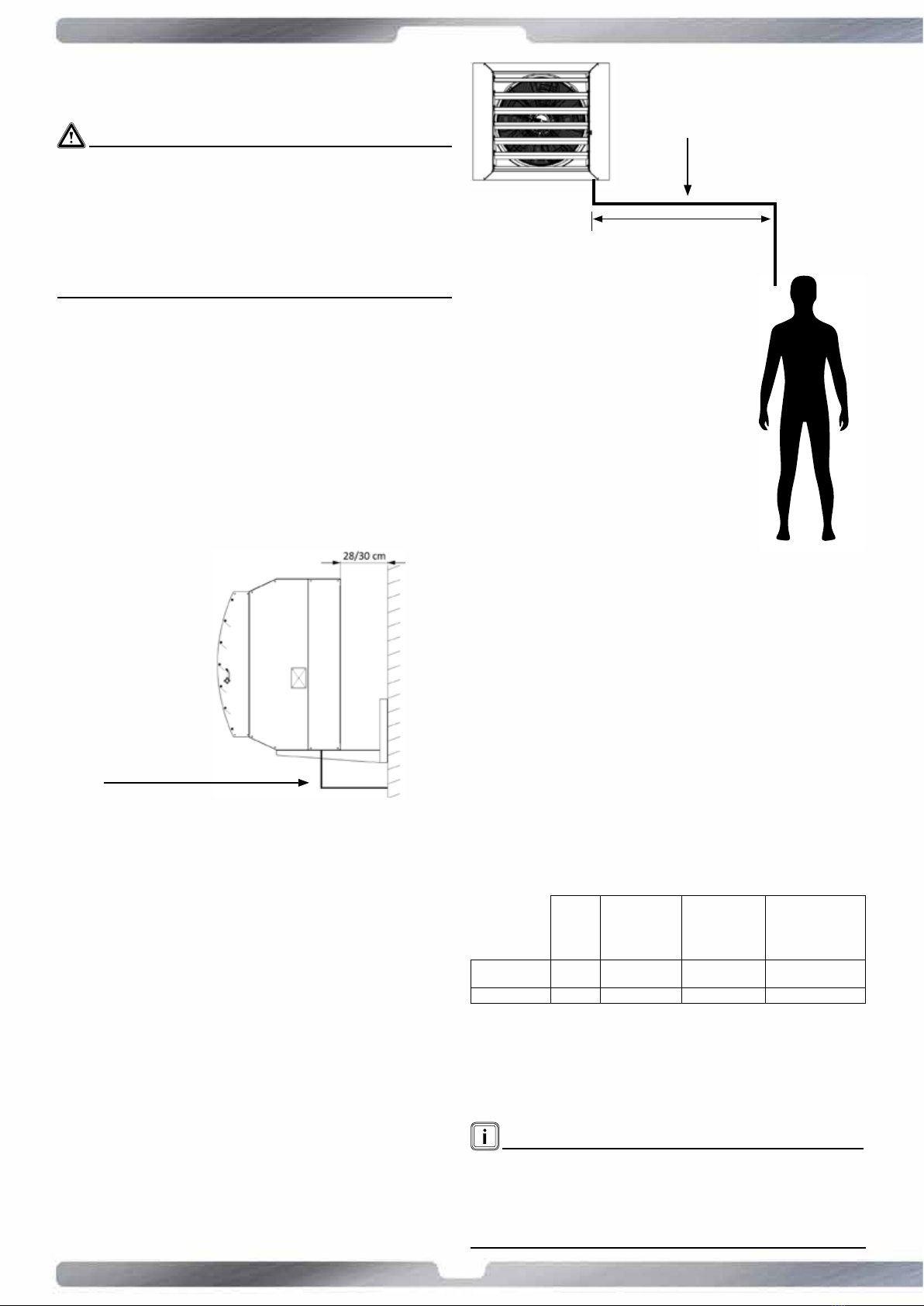

• If the heat pump is installed near the wall, be careful to the

• If the heat pump is installed near a wall, there is a higher

by the heat pump must escape in order to not increase the

building thermal losses.

the monoblock in niches or in interior courtyards, because

the cooled air accumulates on the ground and in the case

pump.

wiring the start of the heat pump is hindered. The unit

presents a phase monitoring that indicates the correct

please see the commissioning procedure explained

forward.

electronics.

the device.

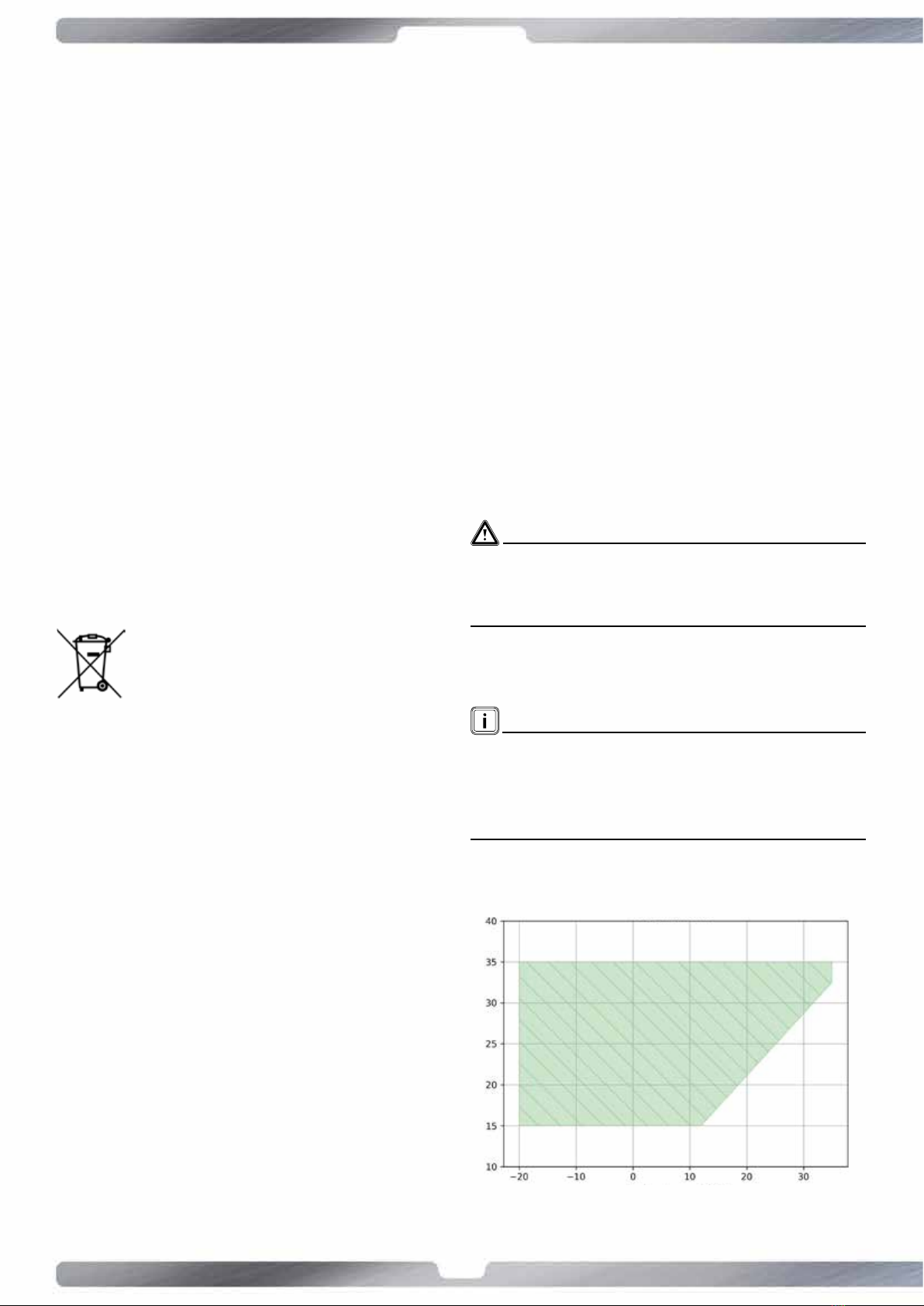

2.2 Importantinformaonregardingthe

refrigerant used

the Kyoto Protocol. Do not vent gases into the atmosphere.

• the factory refrigerant charge of the product,

•

• +the total refrigerant charge

product.

R32

Contiene gas uorurati ad effetto serra inclusi nel protocollo di Kyoto

Contains uorinated greenhouse gases covered by the Kyoto Protocol

Enthält uorierte Treibhausgase, die durch das Kyoto-Protokoll abgedeckt

warden

1

1

2

3

2

Carica di refrigerante di fabbrica del prodotto: vedi targhetta con il nome

dell’unità / Factory refrigerant charge of the product: see unit name plate / Werkseitige

Kältemittelbefüllung des Produktes: siehe Typenschild der Einheit

Quantità di refrigerante aggiuntiva nel campo / Additional refrigerant amount charged in

the eld / Zusätzliche am Montageort befüllte Kältemittelmenge

Carica di refrigerante totale / Total refrigerant charge / Gesamte Kältemittelbefüllung

1

2

2

3

1

Kg

Kg

Kg

A

B

C

D

E

F

A

B

Ctotal refrigerant charge

D

Protocol

Eoutdoor unit

Frefrigerant cylinder and manifold for charging

NOTE!

8

www.templari.com

working environments, which may otherwise lead to deposits on

3 Expecteduseoftheheat

pump

3.1 Operangareaesafedevices

KITA AIR Templari® heat pump has to be used with external air

• Heang

• Cooling

• KITA AIR Templari® heat pump is equipped by a pressure

ATTENTION!

• KITA AIR Templari® heat pump is equipped by a

discharge temperature probe that controls the discharge

temperature.

NOTE!

The device is not suitable for use with an external inverter. If the

periods, do not interrupt the procedure of the oil warming that

starts when the machine is powered once again. This procedure

prevents the compressor breakdown.

3.2 Allowedoperavezone

Heangmode

Outside air temperaturer ± 2 [°C]

Internal air temperaturer ± 2 [°C]

2.3 Proper use

2.4 Standards and statutory provisions

were observed in the design and manufacture of the heat pump

be carried out in accordance with the applicable VDE, EN and IEC

of mains supply network operators must be observed.

Persons, especially children, who on the basis of their physical,

must not use the device without the supervision

or guidance of a competent person. Ensure that

children do not play with the device.

2.5 Instruconsfordisposal

PRODUCT COMPLIES WITH EU DIRECTIVE 2012/19/EU-

LEGISLATIVEDECREE49/2014pursuanttoArt.26ofLegislave

DecreeNo.49of14March2014“ImplementaonofDirecve

2012/19/EU on waste electrical and electronic equipment

(WEEE)”.

The crossed-out wheelie bin symbol on the equipment or its

packaging indicates that the product must be collected separately

from other waste at the end of its useful life.

The removal of the appliance, as well as the retrieval of coolant,

oil or any other parts, must be carried out in accordance with

system, as well as the retrieval of refrigerant, oil or any other

The units must be processed at a facility specialising in material

reuse, recycling and recovery. Proper disposal of the product will

2.6 Energy saving

safeguarding the environment. A prerequisite for reducing

9

www.templari.com

Cooling mode

Internal air temperaturer ± 2 [°C]

Outside air temperaturer ± 2 [°C]

3.3 Heat pump structure

• TheKITAAIRTemplari® external unit contains the refrigerant

circuit;

• KITA AIR Templari®

•

•

3.4 Operaonmode

Heangmode

4 Compressor

5 Electronic expansion

valve

6 Internal unit

exchanger

Cooling mode

4 Compressor

5 Electronic expansion

valve

6 Internal unit

exchanger

4 Equipment supplied

4.1 Main unit

The KITA AIR Templari®

consists of components which are indicated at page 4.

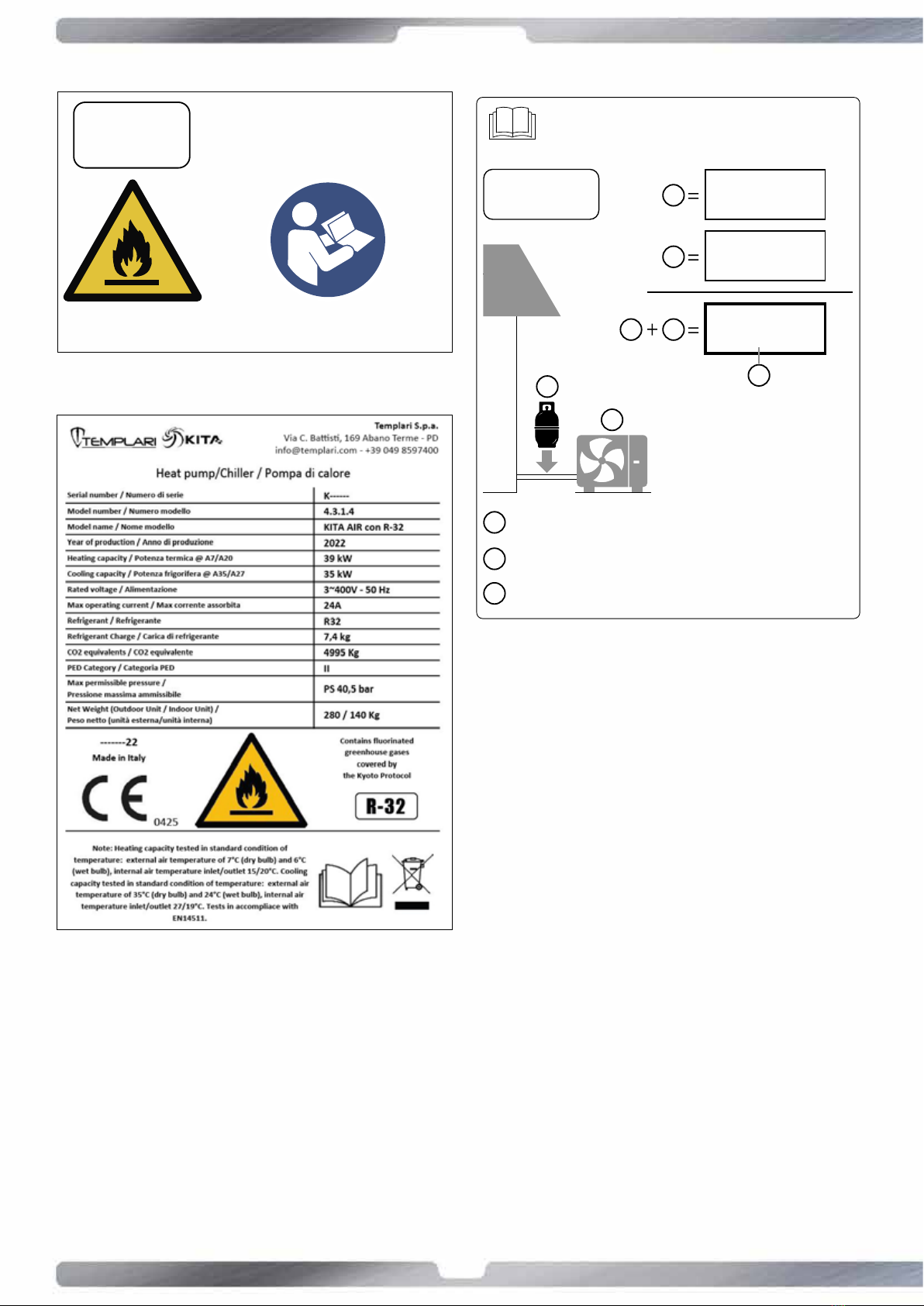

4.2 Name and serial number

The name of the model and the serial number are indicated on

2

1

3

gure 1

10

www.templari.com

R-32 This equipment contains fluorinated greenhouse gases

covered by the Kyoto Protocol.

Read the instruction manual carefully before making any operation.

Leggere attentamente il manuale di istruzioni prima di effettuare qualsiasi operazione.

Questa apparecchiatura contiene gas fluorurati ad

effetto serra inclusi nel protocollo di Kyoto.

R32

Contiene gas uorurati ad effetto serra inclusi nel protocollo di Kyoto

Contains uorinated greenhouse gases covered by the Kyoto Protocol

Enthält uorierte Treibhausgase, die durch das Kyoto-Protokoll abgedeckt

warden

1

1

2

3

2

Carica di refrigerante di fabbrica del prodotto: vedi targhetta con il nome

dell’unità / Factory refrigerant charge of the product: see unit name plate / Werkseitige

Kältemittelbefüllung des Produktes: siehe Typenschild der Einheit

Quantità di refrigerante aggiuntiva nel campo / Additional refrigerant amount charged in

the eld / Zusätzliche am Montageort befüllte Kältemittelmenge

Carica di refrigerante totale / Total refrigerant charge / Gesamte Kältemittelbefüllung

1

2

2

3

1

Kg

Kg

Kg

11

www.templari.com

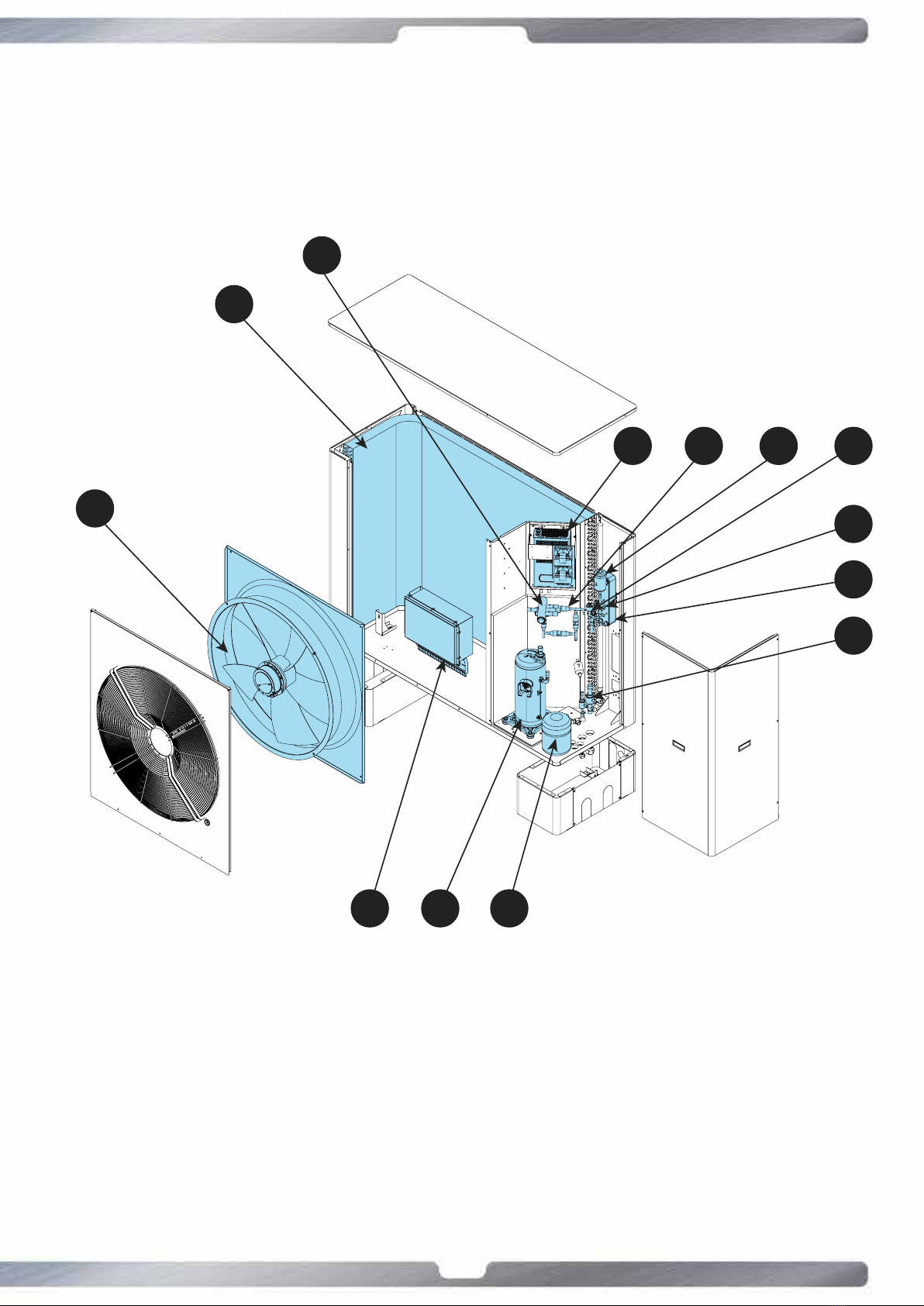

4.3 KITA AIR R32 Templari® external unit components diagram

4

6

9

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

G. Zaccheo

KITA AIR

R32

EXTERNAL UNIT

15/03/2022

This drawing is the property of templari srl, any reproduction and/or distribution without templari srl approval is unlawful.

Il presente disegno è di proprietà di Templari Srl. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguita a norma di legge.

13

1

5 10 3 11

4

8

9

627

12

12

www.templari.com

4.4 KITA AIR Plus R32 Templari® external unit components diagram

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

1

3

6

5

10

13 24

78 91112

4

6

9

13

www.templari.com

4.5 KITA AIR R32 and AIR Plus R32 Templari® internal unit components diagram

1 Deettore

2 Ventilatore

3 Batteria alettata

4 Quadro elettrico

5 Coperchi laterali

6 Basamento

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

G. Bacca

KITA AIR

INTERNAL UNIT

UNITA' INTERNA

15/09/2021

1

2

3

4

5

6

14

www.templari.com

5 Transport

WARNINGS!

than 45°. Contrary you can have anomalies in the refrigerant

consequence a failure inside.

a pallelt. The heat pump KITA AIR Templari® can be transported

KITA AIR R32 Kg. 280 + 130

KITAAIRPLUSR32Kg.320+140

• Protect the sidewalls of the product coming into contact

example.

• Consider the weight of the product riported in the technical

data.

and the provisions in force.

two persons.

6 Mounngandinstallaon

6.1 Equipmentcheck

• sensor probe

oponal

• wall support for internal unit.

6.2 External unit measurements

KITA R32

WITH LEGS

Agas flow / passaggio refrigerante (gas)

outer diameter / diametro esterno : 22mm

Bliquid flow / passaggio refrigerante (liquido)

outer diameter / diametro esterno : 12mm

Ccondensate drain / scarico condensa

outer diameter / diametro esterno: 40mm

Delectrical wiring / passaggio cavi ele�rici

WITH LEGS

CON GAMBE

WITH BRACKETS

CON STAFFE

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

Giovanni B.

KITA L

SPLIT VERSION

06/03/2020

1513

256 1257

325 1133 325

1791

641

88

289

292

1791

61

136

137

C

A B D

1292

35 1257

65

297 1056

65

301

1791

75

1367

678

1791

292

88

3361121

334

61

289

136

137

11 X 36

C

A B D

WITHBRACKETS

Agas flow / passaggio refrigerante (gas)

outer diameter / diametro esterno : 22mm

Bliquid flow / passaggio refrigerante (liquido)

outer diameter / diametro esterno : 12mm

Ccondensate drain / scarico condensa

outer diameter / diametro esterno: 40mm

Delectrical wiring / passaggio cavi ele�rici

WITH LEGS

CON GAMBE

WITH BRACKETS

CON STAFFE

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

Giovanni B.

KITA L

SPLIT VERSION

06/03/2020

1513

256 1257

325 1133 325

1791

641

88

289

292

1791

61

136

137

C

A B D

1292

35 1257

65

297 1056

65

301

1791

75

1367

678

1791

292

88

3361121

334

61

289

136

137

11 X 36

C

A B D

15

www.templari.com

KITAAIRPLUSR32

WITHBRACKETS

Boom view

161

60

80

2018

9393

770

123

124

956

306

1423

248

53

1147

13 X 88

D

C

1414

2021

40

917240

120

CONNECTIONS DETAIL

DETTAGLIO CONNESSIONI

A

gas flow /

passaggio refrigerante (gas)

outer diameter /

diametro esterno

: 28mm

B

liquid flow /

passaggio refrigerante (liquido)

outer diameter /

diametro esterno

: 16mm

C

condensate drain /

scarico condensa

outer diameter /

diametro esterno:

40mm

D

electrical wiring /

passaggio cavi ele�rici

D

A

B

137440

1414

2021

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

G. Bacca

KITA AIR Plus

EXTERNAL UNIT

UNITA' ESTERNA

24/06/2021

This drawing is the property of templari srl, any reproduction and/or distribution without templari srl approval is unlawful.

Il presente disegno è di proprietà di Templari Srl. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguita a norma di legge.

161

60

80

2018

9393

770

123

124

956

306

1423

248

53

1147

13 X 88

D

C

1414

2021

40

917240

120

CONNECTIONS DETAIL

DETTAGLIO CONNESSIONI

A

gas flow /

passaggio refrigerante (gas)

outer diameter /

diametro esterno

: 28mm

B

liquid flow /

passaggio refrigerante (liquido)

outer diameter /

diametro esterno

: 16mm

C

condensate drain /

scarico condensa

outer diameter /

diametro esterno:

40mm

D

electrical wiring /

passaggio cavi ele�rici

D

A

B

137440

1414

2021

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

G. Bacca

KITA AIR Plus

EXTERNAL UNIT

UNITA' ESTERNA

24/06/2021

This drawing is the property of templari srl, any reproduction and/or distribution without templari srl approval is unlawful.

Il presente disegno è di proprietà di Templari Srl. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguita a norma di legge.

161

60

80

2018

9393

770

123

124

956

306

1423

248

53

1147

13 X 88

D

C

1414

2021

40

917240

120

CONNECTIONS DETAIL

DETTAGLIO CONNESSIONI

A

gas flow /

passaggio refrigerante (gas)

outer diameter /

diametro esterno

: 28mm

B

liquid flow /

passaggio refrigerante (liquido)

outer diameter /

diametro esterno

: 16mm

C

condensate drain /

scarico condensa

outer diameter /

diametro esterno:

40mm

D

electrical wiring /

passaggio cavi ele�rici

D

A

B

137440

1414

2021

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

G. Bacca

KITA AIR Plus

EXTERNAL UNIT

UNITA' ESTERNA

24/06/2021

This drawing is the property of templari srl, any reproduction and/or distribution without templari srl approval is unlawful.

Il presente disegno è di proprietà di Templari Srl. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguita a norma di legge.

80

53

117

117

55

155

302

1423 240

93

93

770

956

1148

13 X 88

2027

D

C

1413

40

2027

1373

115

40 72 91

CONNECTIONS DETAIL

DETTAGLIO CONNESSIONI

A

gas flow /

passaggio refrigerante (gas)

outer diameter /

diametro esterno:

28mm

B

liquid flow /

passaggio refrigerante (liquido)

outer diameter /

diametro esterno:

16mm

C

condensate drain /

scarico condensa

outer diameter /

diametro esterno:

40mm

D

electrical wiring /

passaggio cavi elettrici

D

A

B

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

Giovanni B.

KITA L Plus

SPLIT VERSION

06/03/2020

6.3 Freespacesfortheassembly

Distance Measures in millimeters

A

C

D

E

• If the product is installed in areas prone to heavy snowfalls,

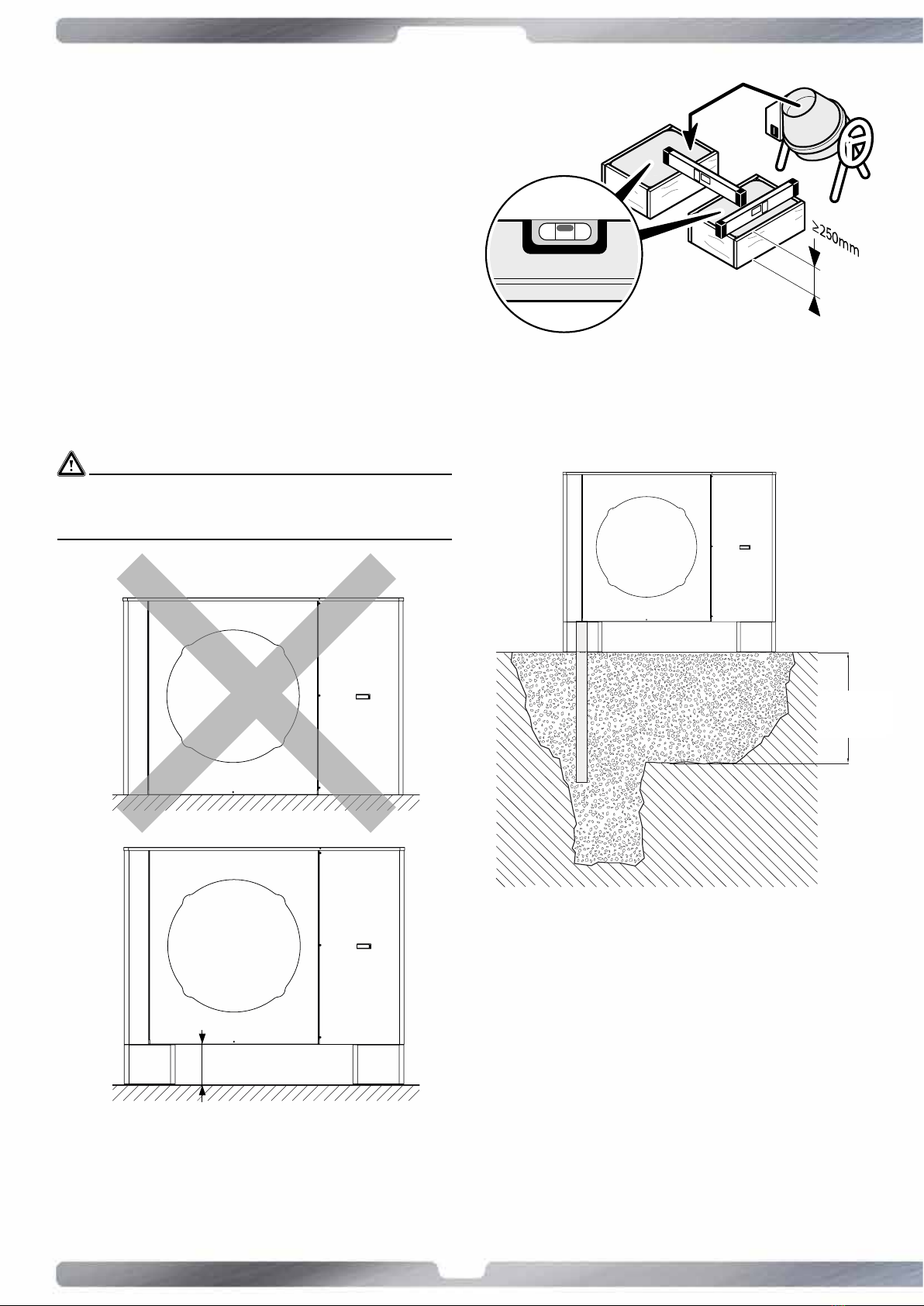

6.4 Choiceofinstallaonplace

• Observe all the rules in force, included the environmental

• Install the product outside the building.

- near a heat source,

- prevailing winds,

- noise of the fan and the compressor,

surrounding environment

could be hit by parallel winds.

installing the heat pump

- Concrete pavement,

- T steal beem

- Concrete block.

16

www.templari.com

• Prepare the laying of electrical cables.

• In places where there are snowfalls, install the heat pump

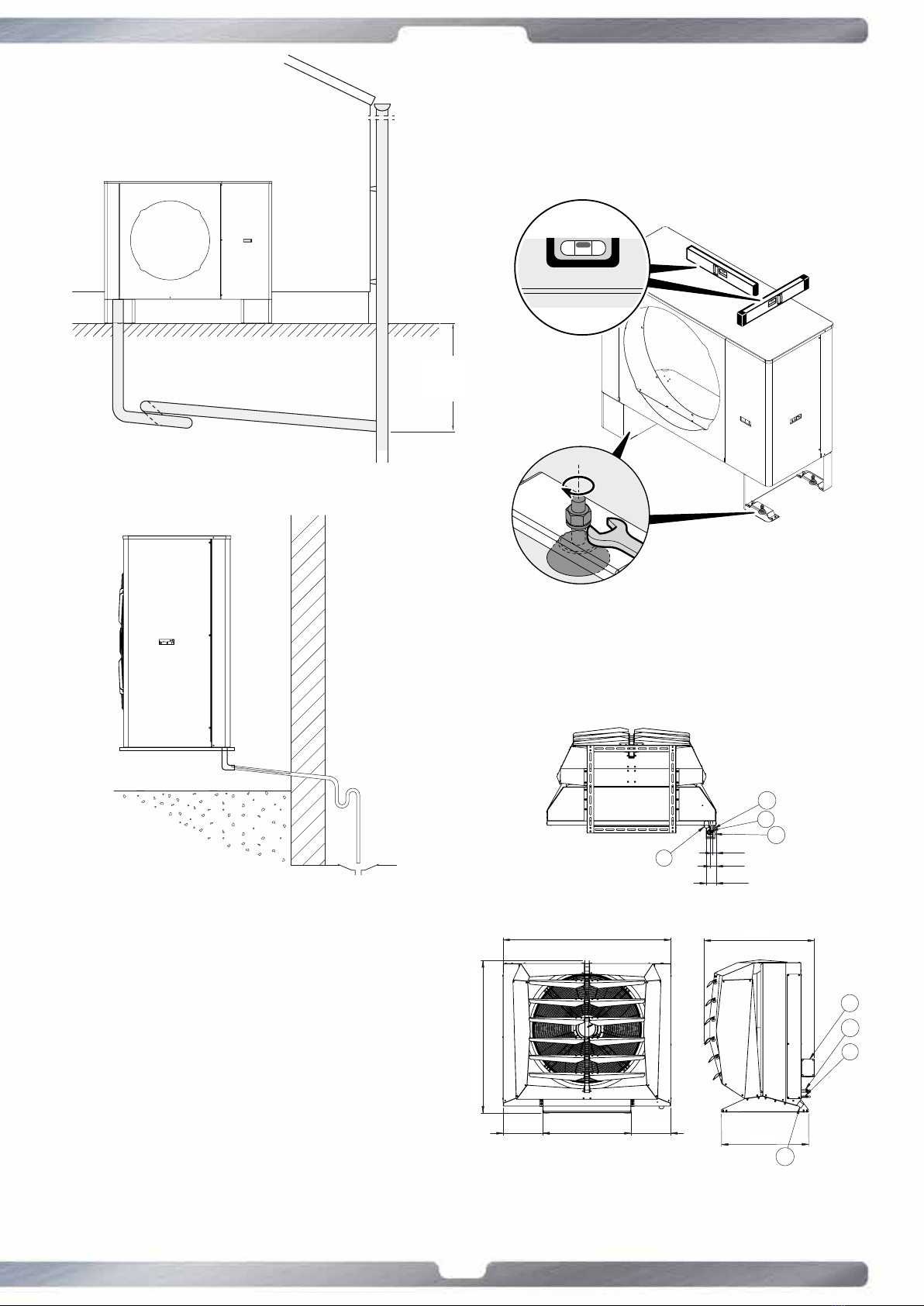

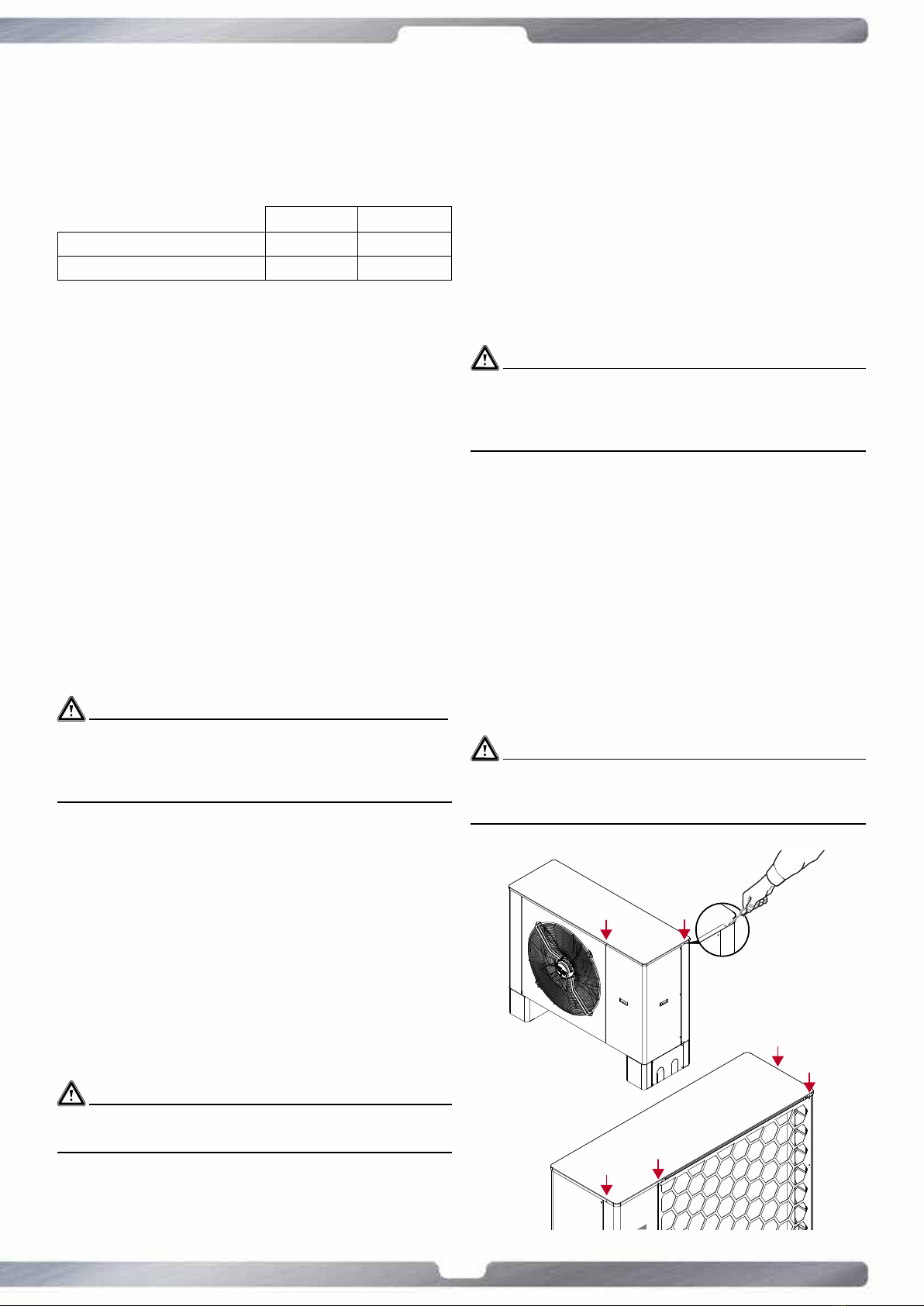

6.5 Externalunitmounng

in this manual.

a wall support.

device.

of the device can absorb condensed water.

6.6

Condensatedischargepreparaon

The condensate is discharged behind the heat pump by a unique

way. Prepare the condensate discharge with a discharge pipe

or with a gravel bed.

WARNINGS!

Frost proof

depth

min 250mm

Frost

proof

depth

Frost proof

depth

min 250mm

Frost

proof

depth

Frost proof

depth

min 250mm

Frost

proof

depth

• Preparaon of the base for condensate drain

Frost proof

depth

min 250mm

Frost

proof

depth

depth

• Example 3 condensate drain (it is recommended to bury the

drain pipe to prevent the formaon of ice in the event that

you do not purchases oponally the heang resistor for

discharge condensate)

17

www.templari.com

Frost proof

depth

min 250mm

Frost

proof

depth

• Example 2 condensate drain

• Example 3 condensate drain with condensate drain element

the evaporator.

drain area.

6.7 Correct alignment

KITA AIR Templari® so that

7 Installaonandassemblyof

theinternalunit

7.1 InternalunitsizesKITAAIRR32

297 660 297

1139

1255

28

41

71

C

A

B

D

827

652

C

D

A

B

12 X 62

610

602

80

652

660

A

gas flow /

passaggio refrigerante (gas)

outer diameter /

diametro esterno:

22mm

B

liquid flow /

passaggio refrigerante (liquido)

outer diameter /

diametro esterno:

12mm

C

condensate drain /

scarico condensa

outer diameter /

diametro esterno:

40mm

D

electrical panel /

quadro ele�rico

BASE BRACKET /

BASAMENTO

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

G. Bacca

KITA AIR

INTERNAL UNIT

UNITA' INTERNA

INNENEINHEIT

12/04/2021

This drawing is the property of templari srl, any reproduction and/or distribution without templari srl approval is unlawful.

Il presente disegno è di proprietà di Templari Srl. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguita a norma di legge.

297 660 297

1139

1255

28

41

71

C

A

B

D

827

652

C

D

A

B

12 X 62

610

602

80

652

660

A

gas flow /

passaggio refrigerante (gas)

outer diameter /

diametro esterno:

22mm

B

liquid flow /

passaggio refrigerante (liquido)

outer diameter /

diametro esterno:

12mm

C

condensate drain /

scarico condensa

outer diameter /

diametro esterno:

40mm

D

electrical panel /

quadro ele�rico

BASE BRACKET /

BASAMENTO

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

G. Bacca

KITA AIR

INTERNAL UNIT

UNITA' INTERNA

INNENEINHEIT

12/04/2021

This drawing is the property of templari srl, any reproduction and/or distribution without templari srl approval is unlawful.

Il presente disegno è di proprietà di Templari Srl. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguita a norma di legge.

297 660 297

1139

1255

28

41

71

C

A

B

D

827

652

C

D

A

B

12 X 62

610

602

80

652

660

A

gas flow /

passaggio refrigerante (gas)

outer diameter /

diametro esterno:

22mm

B

liquid flow /

passaggio refrigerante (liquido)

outer diameter /

diametro esterno:

12mm

C

condensate drain /

scarico condensa

outer diameter /

diametro esterno:

40mm

D

electrical panel /

quadro ele�rico

BASE BRACKET /

BASAMENTO

DATE :

DRAWN BY :

DESCRIPTION:

TEMPLARI SRL - HEAT PUMP TECNOLOGY

Via Pitagora, 20A - 35030 Rubano (PD)

Tel. +39 049 5225929 - www.templari.com

G. Bacca

KITA AIR

INTERNAL UNIT

UNITA' INTERNA

INNENEINHEIT

12/04/2021

This drawing is the property of templari srl, any reproduction and/or distribution without templari srl approval is unlawful.

Il presente disegno è di proprietà di Templari Srl. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, verrà perseguita a norma di legge.

18

www.templari.com

7.2 Generaliesandchoiceofthe

installaonplace

WARNING!

• Install the unit in an internal environment.

• The unit must not to be install near heat or steam sources.

from walls and obstacles for facilitate the assembly and

7.3 Assembly internal unit and correct

posioningofB2probe

be at least in two persons or more, as the excessive weight can

cause serious injuries.

the internal unit

the internal unit, it must alight at man height

with the wall because it is primary that the

the wall.

8 Refrigerant circuit

connecon

use of a weld tool.

8.1 Installaonrequirements

have to respect the below indicated dimensions.

at the base of the bigger piping. If the gap between the

internal and external unit is more than 5 m an u-trap at

medium height will be required.

Nominal

lenght Maximum lenght

of the piping

(m of equivalent

Maximum height

(m of equivalent

refrigerant charge

recommended*

(g/m of equivalent

54

NOTE!

The parameter equivalent lenght has to consider the curves too.

19

www.templari.com

8.2 Setupforinstallaonandrefrigerant

pipelinesinstallaon

• Measure the distance between internal and external units,

• The laying of the pipes must include the minimum number

of bends, because each curve increases the pressure drop

of the circuit and reduce the machine performance.

• Cut the pipes to a length slightly greater than that

measured.

the pipe downward and blowing air into the pipe.

the outer side male anchors. Where is possible, perform

minimum thickness of 6 mm.

WARNING!

Safety valve must be conveyed at a minimum distance of 5 m

8.3 Vacuum procedure

unit.

• At the end of the procedure remove the pump and open

the valve to pour out the refrigerant liquid.

WARNING!

it is recommended to adopt all the safety measures and use the

9 Maintenance and cleaning

and usury of the components. The user decides the maintenance

halfyearly.

polluted places or in the presence of dust that could

more frequent maintenance.

WARNING!

disconnect the power supply in order to avoid any injuries.

9.1 Finned coil cleaning

an adequate distance so as not to risk to fold or damage them.

• Clean the frontal surface;

placed in dusty ambient

WARNING!

service center.

20

www.templari.com

• Pass the power cables and the net control cable of the

machine only trough proper holes.

10.3 Externalunitconnecon

• Connect the power supply to the external unit electric

terminal by the following table named “power supply

apposite holes.

10.4 Internalunitconnecon

•

•

•

WARNING!

10.5 Probes and control panel

internal unit.

extend it, following the shortest path, away from powe cable

resistances that may interfer with the reading signal of the

control board.

the internal one by a bipolar cable.

The control panel gets connected to the external unit by a

6 metres telephonic cable supplied with the heat pump (on

10.6 Power supplying

Connect the power supply to the internal terminal block as

indicated in the diagram below.

9.2 Condensatedischargecleaning

Please make sure that the condensate discharge pipe is in the

9.3 Refrigerant circuit maintenance

The machine is equipped with a safety valve which ensure

and make sure to replace it each 4 years.

WARNING!

The triggering of the safety valve and the consequent expulsion

of the refrigerant gas may cause poisoning and injuries if in direct

contact with the skin.

Do not stand or place any heat source near the safety valve.

any servicing of the heat pump that requires welding.

10 Electricconnecon

10.1 Generalinformaon

make sure that the unit is in stable equilibrium and that there

•

•

• Make sure that upward the power supply line or the

pump requirements.

•

10.1.1Thecustomer/installerhasto:

breaker, CEI approved, as close as possible to the heat

pump, inside an adequate case

manufacturercannot be held liable for any damage caused

according to the layout of the electric wiring in the

10.2 Operaonsoflaying

• Avoid parallel laying with other cables, the arrangement is

Table of contents

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual

Panasonic

Panasonic CS-S18HKQ Service manual

Panasonic

Panasonic CS-E15NKE3 operating instructions

Gree

Gree GWH18TC-K3DNA1B/I Service manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

Daikin

Daikin R32 Split Series installation manual