6484 01 3905 04

Specifications subject to change without notice.

UNIT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

Take precautions to ensure Aluminum tubes do not come in

direct contact or allow for condensate run off with a

dissimilar metal. Dissimilar metals can cause galvanic

corrosion and possible premature failure.

CAUTION

!

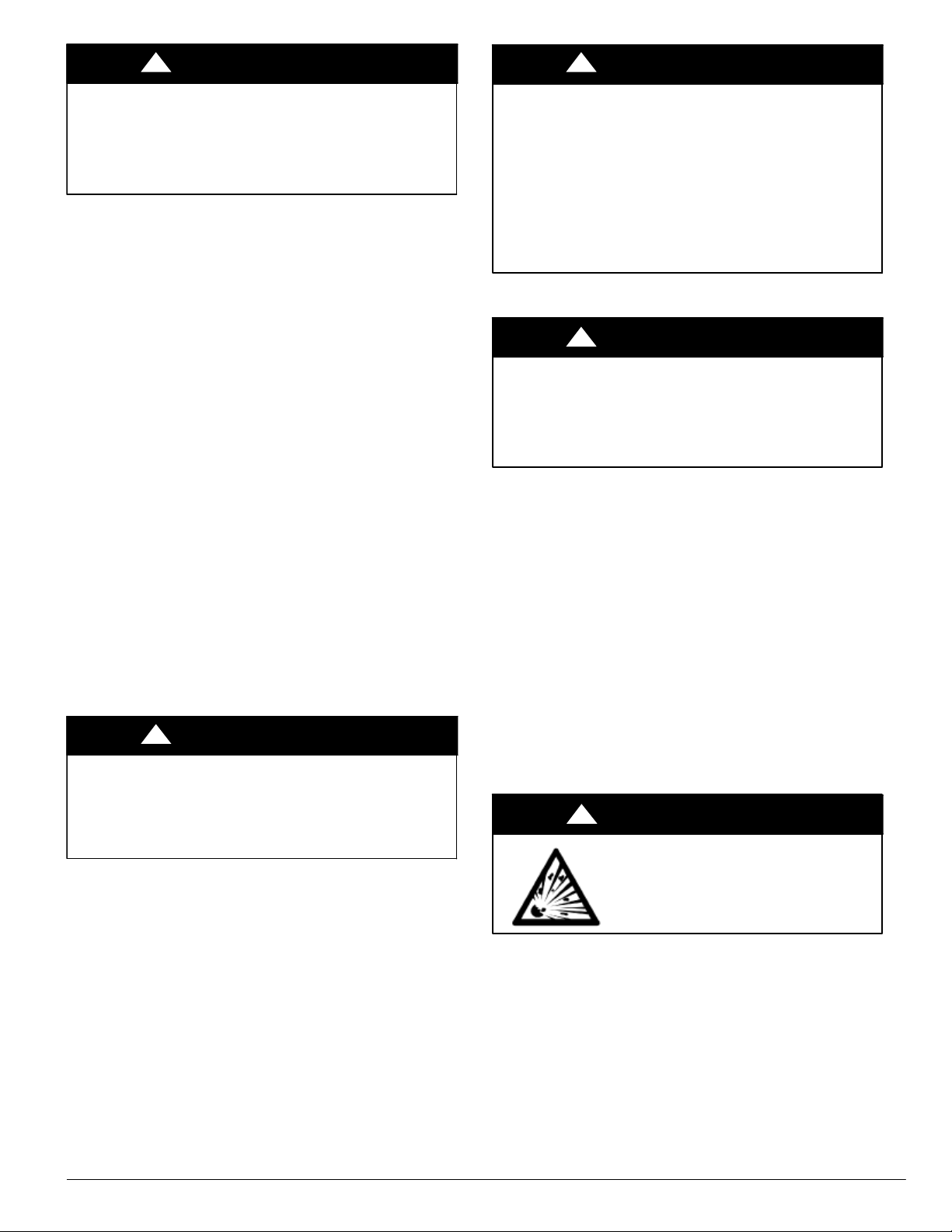

The coil can be connected to outdoor units using field−supplied

tubing of refrigerant grade. Always evacuate tubing and reclaim

refrigerant when making connections or flaring tubing. Leak

check connections before insulating entire suction line.

See Table 1 for coil connection tube size.

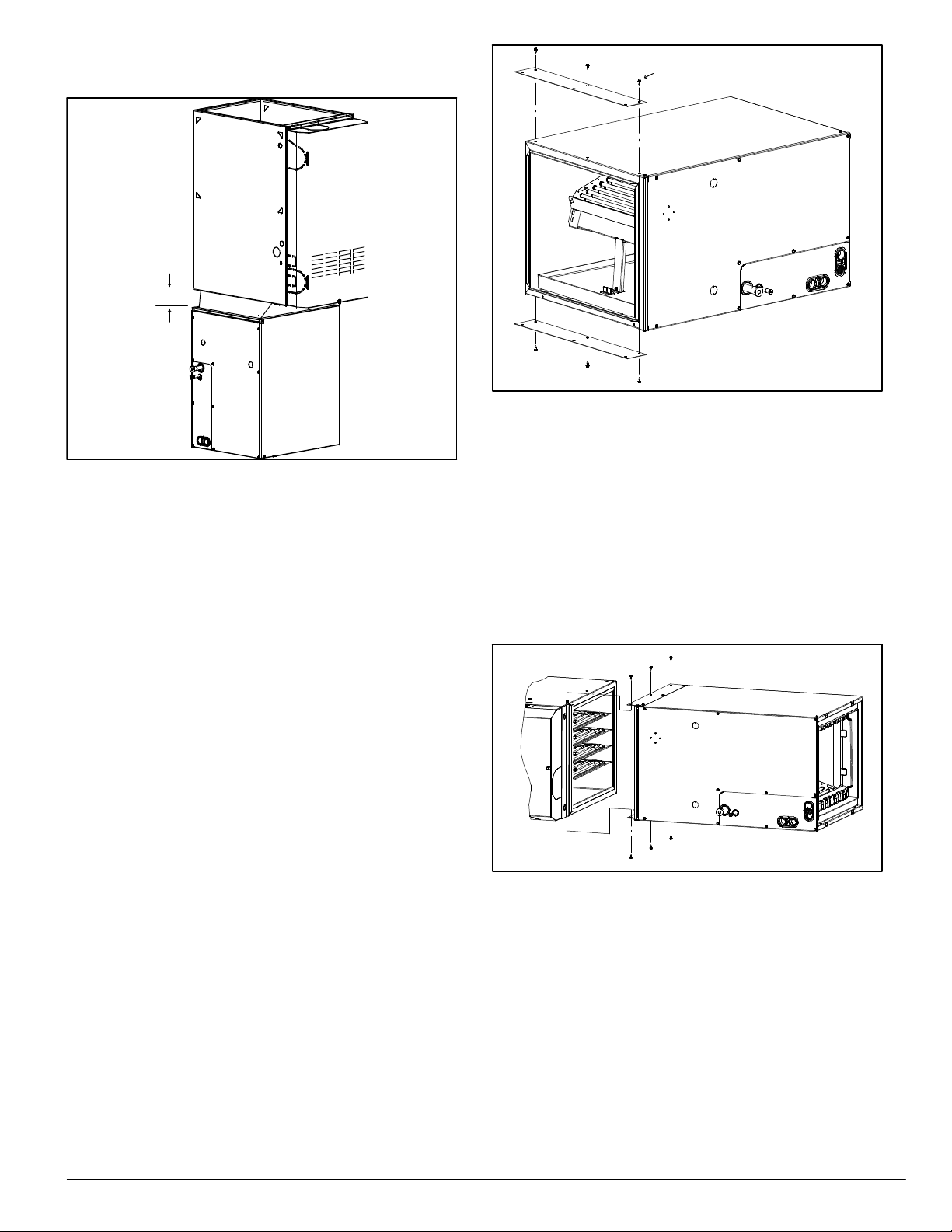

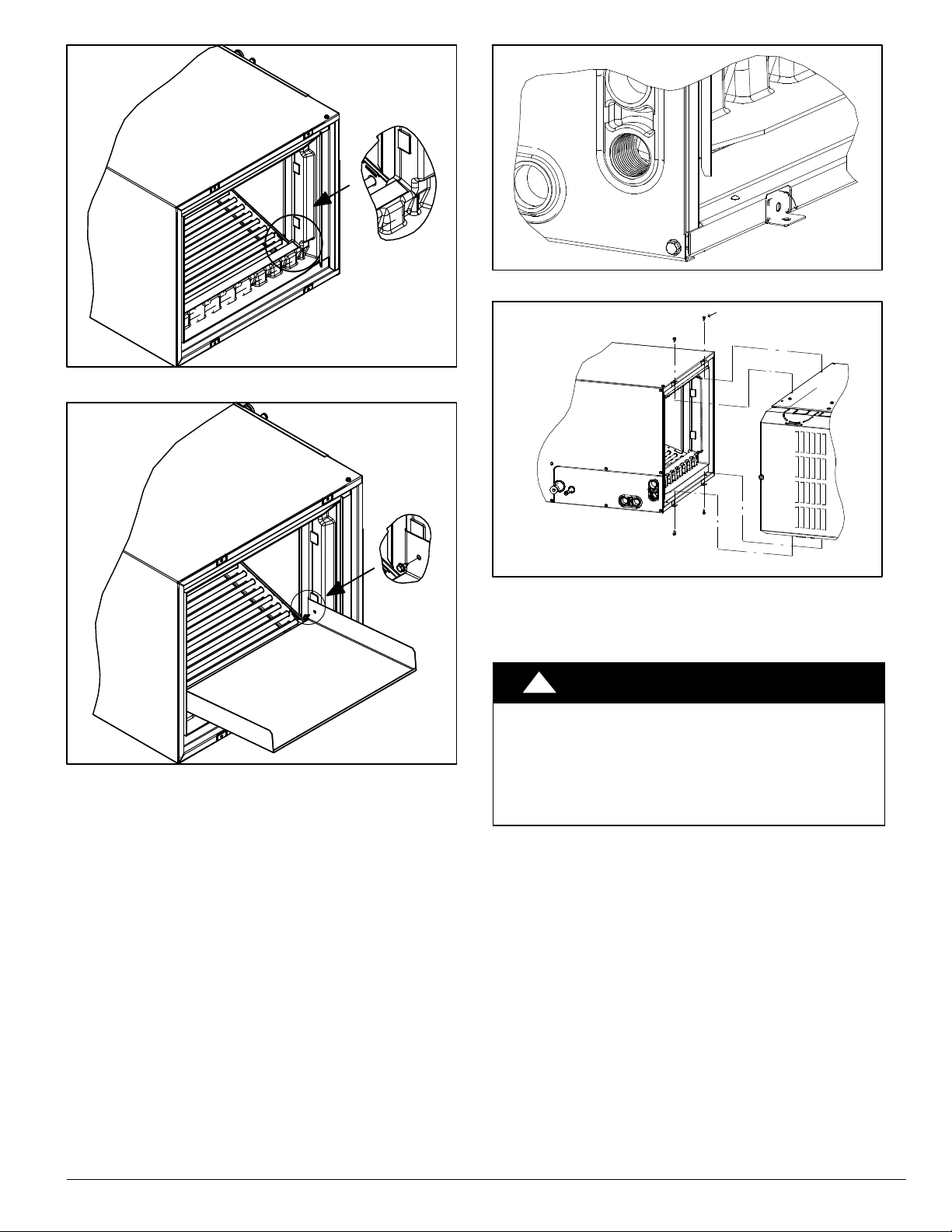

1. Remove cabinet access door.

2. Remove rubber plugs, suction plug then liquid plug, from

coil stubs using a pulling and twisting motion. Hold coil

stubs steady to avoid bending or distorting.

3. Remove tubing plate with rubber grommets and slide plate

with grommets onto the refrigerant lines (field line−set),

away from braze joints.

4. Fit refrigerant lines into coil stubs. Wrap a heat sinking

material such as a wet cloth behind braze joints.

5. Wrap TXV and nearby tubing with a heat−sinking material

such as a wet cloth.

6. Use 1/2 psig Nitrogen purge in the suction and out the the

liquid line.

7. Braze using a Sil−Fos or Phos−copper alloy. Do not use

soft solder.

8. After brazing, allow joints to cool. Carefully remove TXV

bulb insulation and verify that the TXV bulb is securely

fastened with hose clamp. Tighten screw a half−turn past

hand tight with TXV bulb placed in the indentation with full

contact with the vapor line tube. Re−wrap TXV bulb with

insulation.

9. Leak check connections before insulating entire suction

line.

10. Slide tubing plate with rubber grommets over joints.

Position tubing at center of each grommet to ensure an air

seal around the tube. Reinstall cabinet door.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

To avoid valve damage to the refrigerant control device

while brazing, valves must be wrapped with a

heat−sinking material such as a wet cloth.

CAUTION

!

REFRIGERANT METERING DEVICE

These Coils have a factory installed hard shut−off TXV

designed only for use with R−410A refrigerant. Use only with

outdoor units designed for R−410A.

NOTE: ALL TXV’S HAVE PRESET SUPERHEAT SETTINGS

AND ARE FIELD NON−ADJUSTABLE.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

DO NOT BURY MORE THAN 36 IN. OF REFRIGERANT

TUBING IN GROUND. If any section of tubing is buried,

there must be a 6 in. vertical rise to the valve connections

on the outdoor unit. If more than the recommended length

is buried, refrigerant may migrate to cooler buried section

during extended periods of unit shutdown, causing

refrigerant slugging and possible compressor damage at

start−up.

CAUTION

!

CONDENSATE DRAIN LINE CONNECTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

When installing over a finished ceiling and/or living area,

install a field−fabricated secondary condensate pan under

the entire unit.

CAUTION

!

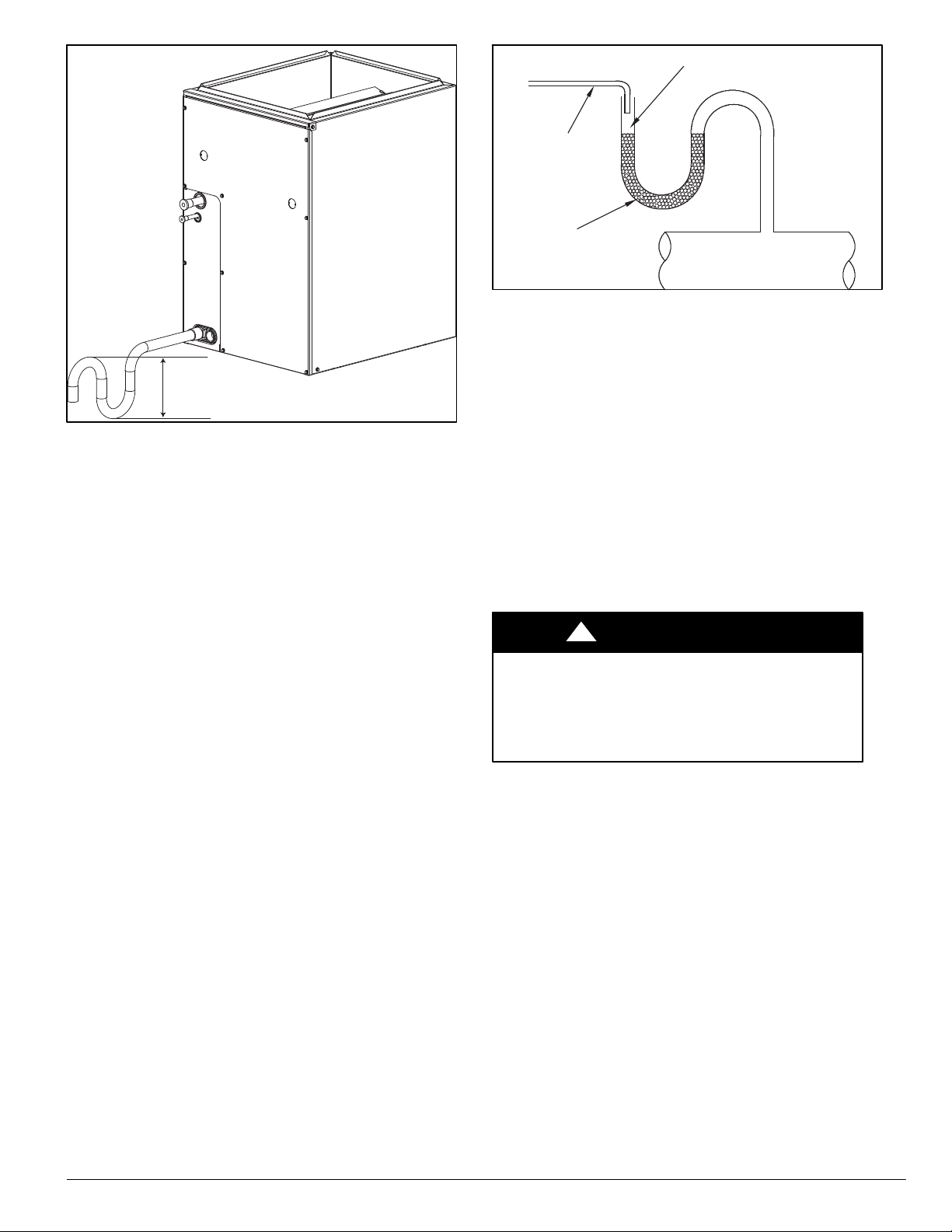

The coil is designed to dispose of accumulated water through

built−in condensate drain fittings. It is recommended that PVC

fittings be used on the condensate pan. Do not over−tighten.

Finger tighten plus 1−1/2 turns. Be sure to install plastic plug in

unused condensate drain fitting. Two 3/4 inch female threaded

pipe connections are provided in each coil condensate pan.

A trap is not necessary on the condensate line if on the supply

air side of furnace. For any modular air handler use

recommended minimum of 4” trap, is required. Consult local

codes for additional restrictions or precautions. If local codes

require a trap then the following guidelines are suggested to

assure proper drainage. Install a trap in condensate line of coil

as close to the coil as possible. Make trap at least 3 inches (76

mm) deep and no higher than the bottom of unit condensate

drain opening (See Figure 10). Pitch condensate line 1 inch

(25.4 mm) for every 10 ft. of length to an open drain or sump.

Make sure that the outlet of each trap is below its connection to

condensate pan to prevent condensate from overflowing the

drain pan. Prime all traps, test for leaks, and insulate traps and

lines if located above a living area.

EXPLOSION HAZARD

Failure to follow this warning could result

in personal injury or death.

Provide trap with air gap in drain line

when connecting to waste (sewer) line.

!WARNING