Tenpilot ECO 600 N User manual

Installation and user guide for the garage drive

for sectional and tilt-up doors.

ECO 600 N

Check other products of our brands on www.sukcesgroup.pl.

Table of contents:

1. Safety recomendations........................................................................4-5

2. Product description and features .......................................................5-6

3. Pre-Installation recommendations........................................................7

4.Montage..............................................................................................8-12

5. Programming instruction.................................................................12-15

6. Optional connectors and connections............................................15-16

7. Manual drive disconnection.................................................................17

8. Maintenance..........................................................................................17

9. Technical data..................................................................................18-19

10. Technical specications................................................................19-22

11. Common faults and solutions.......................................................22-24

4

Read the instructions carefully and follow all installation and safety

instructions.

Keep the instruction. Failure to follow these instructions can present risk to

life and health or damage to property.

Used electrical products should not be disposed of with municipal waste.

Throw them into specially marked containers.

1. Safety

1. The drive is designed and manufactured in accordance with applicable standards and

regulations.

To properly mount the drive, the installer must comply with the standards and

regulations in force in the country where the appliance will be installed.

2. Unskilled personnel or people who do not know the health and safety standards

applicable to the installation of automatic gates and doors may not under any

circumstances perform system installation or commissioning.

3. Persons who install or service the device without complying with all applicable safety

standards shall be liable for any damage, injury, costs, expenses or claims of the injured

person as a result of improper installation of the system.

4. In order to increase safety, we recommended to install the photocells. Although the

drive is equipped with an overload system, added of photocells will signicantly improve

the safety of automatic garage doors.

5. Before leaving or entering the garage, make sure that the garage door is completely

open and stationary.

6. After CLOSE command, make sure that the garage door is completely closed and

stationary.

7. Do not hold your hands near the drive and garage door when operating the drive.

8. The obstacle detection system is designed to work only on stationary objects. When

the garage door contacting with a moving object, it can cause serious personal injury

and / or property damage.

9. This device is not intended for use by children or persons with limited physical,

sensory or mental abilities, unless they have been supervised or trained in the use of the

device by a person responsible for their safety. Children should not play with the device.

10. If the supply cord is damaged it must be replaced by manufacturer, its service agent

or qualied persons in order to avoid a hazard.

11. Do not allow children to play garage door control units. Keep away remotes control

from children.

12. Watch the movable gate until it is fully opened or closed. Make sure there are no

people or animals nearby.

13. Be careful when opening the gate - an open gate that has damaged or weak springs

5

2. Drive description and functions

1. Obstacle detection

Drive stops or retreats if sensing resistance in its path. Thanks to this function, we can

protect children, pets and other things from being crushed by the gate.

2. Soft start / soft stop function

The reduced speed of moving the gate up and down at the beginning and end of each

cycle reduces the stress of the gate and drive to extend the service life and makes for

quieter working.

3. Auto closing

This function provides home security, automatically closing the gate after entering or

leaving the garage.

4. Automatic adjustable opening and closing forces

The drive force for various stages of gate movement is automatically set during the drive

conguration and is constantly updated. The drive force is automatically adjusted in the

appropriate range.

5. Electronic limit positions

Setting the electronic limit positions is quick and easy, you only need to control the con-

guration from the drive panel.

6. Additional connectors

Optionally, we can connect: photocells, additional receivers, wired and wireless wall swi-

tches, signal lamps and pass door protection.

7. LED lighting

The lighting switch on for each cycle for 3 minutes.

8. Connecting emergency power supply

In the event of a power failure, the drive can be powered from the battery.

may fall down sharply.

14. Check the installation regularly, especially wires, springs and mountings for signs of

use and damage. In a situation where it is necessary to repair or adjust the gate - do not

use it. Using an incorrectly balanced or damaged door can cause personal injury.

15. Once a month check obstacle detection function to work properly. Place an obstacle

with a height of min. 5 cm and close the gate - the drive should detect it and the gate

should stop or go back. If necessary, adjust the overload force and check again, as

improper adjustment can pose a hazard when using the door.

16. Familiarize yourself with the instructions before releasing and using the gate

manually.

17. Please check the informations of regulating the gate and drive.

18. Turn power supply off while cleaning or other maintenance.

19. The manual should contain details regarding the installation of the drive and related

components.

6

9. Break gear

The brake gear is a protection against uncontrolled lowering of the gate.

10. Disconnecting the drive manually

The manual release system is used to operate the gate in the event of a power failure.

11. Radio control

Rolling code technology (7.38 x 10 combinations), frequency 433.92 MHz, Transmitter,

eg 4-channel, allows you to control 4 gates using one transmitter.

12. The metal bottom plate provides a strong and safer assembly.

13. UP/DOWN control buttons.

19

GÓRA

DÓŁ

SET UP

CODE DOWN

Fig. 1

7

1. A correctly installed garage door should be manually lifted and closed without much

effort. Good balance of the gate and properly mounted springs are essential for proper

installation.

2. In a situation when the garage door is incorrectly mounted (opening of which requires

to use of large force), the drive should not be installed.

3. Make sure that mounted locking devices have been removed from the gate before

installing the device. In the opposite situation, you can lose your warranty.

4. The power supply socket must be mounted near the place where the drive will be

installed.

5. There should be a gap with a minimum height of 30 mm at its nearest point between

the bottom of the metal rail and the upper part of the garage door (Fig.2).

3. Pre-installation recommendations

As an additional protection for the garage door, we recommend installing

photocells on all installations.

Fig. 2

30 mm minimum

clearance

8

4. Montage

4.1 Installation of wall bracket and handle gate

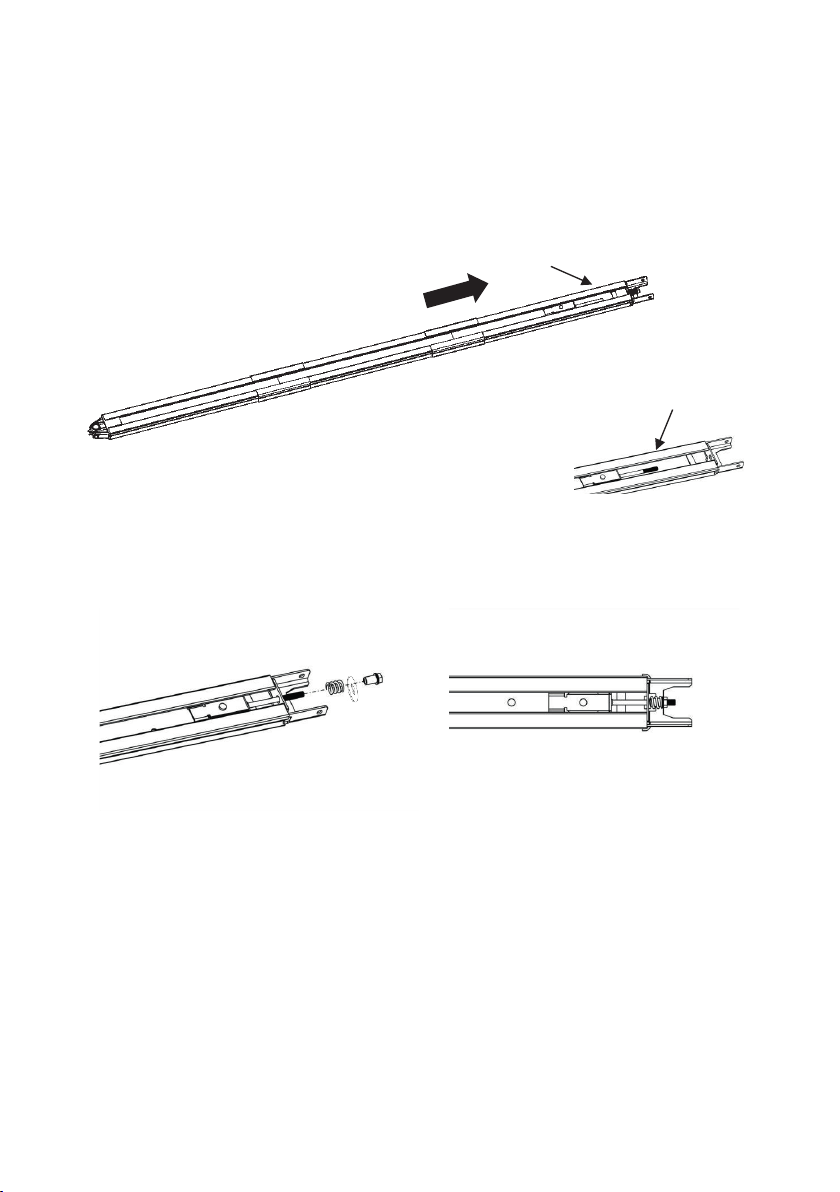

4.2 Folding the rail

1. Wall bracket

Close the garage door, measure its width

at the top and mark the center. Attach and

mount the wall bracket on the inner wall

2cm-15cm above the gate (depending on

the space available).

2. Handle gate

Attach the handle door to the internal side

of the door as close as possible to the top

edge.

2- elements rail

3- elements rail

Fig. 3

Fig. 4

A:1500 mm

B:1500 mm

Łącznik

Rys.3

A: 1500 mm

B: 1500 mm

connector

Fig. 5

D:1000 mm

E:1000 mm

C:1000 mm

Łącznik

Rys.4

Łącznik

C: 1000 mm

D: 1000 mm

E: 1000 mm

connector

connector

9

4. Dokręć nakrę tkę, jak pokazano na rysunku 7,anastępnie przejdź do montażu szyny

Rys.6

Rys.7

Fig. 7 Fig. 8

1. 2- elements rail:

Slide rail A and B in the connector (Fig. 4).

3- elements rail:

Slide the rail C, D and E into the connector (Fig. 5).

2. Pull the screw F with the tensioning element to the end of the rail (Fig. 6).

3. Loosen the nut and spring as in Fig. 7.

4. Tighten the nut as shown in Fig. 8, then go to the rail assembly.

Fig. 6

Rys.5

F

F

10

Fig. 9

4.3 Installation of a metal rail with a drive

STEP 1

Fasten the drive to the rail with two U-shaped handles. Fasten the handles with the 6 mm

nuts included in the set (Fig. 9).

STEP 2

Place the rail with a drive on the garage oor, in the middle of the gate. The side without

the drive should be at the gate. Lift and place the front of the rail in the wall bracket.

Insert the spindle and secure it with the cotter (Fig. 9).

STEP 3

Lift the rail with the drive so that it is position will be horizontal and in the center of the

gate. Mount the drive rail to the ceiling with mounting brackets (Fig. 9, Fig. 10).

STEP 4

Connect with screws the straight arm with the bented arm.

Place and screw the arms to the gate handle located on the upper edge of the gate, using

the screws included in the set (Fig. 9, Fig. 11).

Do not let children stay near a gate, drive or ladder. It can cause serious

injuries and / or damage.

11

4.4. Battery installation (optional)

STEP 5

Open the gate until the latch locks on the belt or chain, and proceed to the drive setting.

Option 1 - Mount at the top of the drive

Mount the battery using the handle and nuts (Fig. 12 i Fig. 13).

Option 2 - Mounting on the side of the drive

Mount the battery using the handle and nuts (see Fig.14 and 15).

Rys.9

Fig. 10

przykręć ramiona do uchwytu bramy na górnej krawędzi za

Rys.10

Fig. 11

Fig. 12 Fig. 13

12

Fig. 14

5. Programming

1. Press shortly UP or DOWN buttons to set precisely limit positions.

2. After setting the limit positions, the gate will automatically open and close.

During this time, the drive force is set. After the movement is completed, the

drive is ready for work.

5.1 Programming of limit positions

Press and hold SET button

untill digit 1 appear.

The drive is in programming mode.

Press and hold UP button

untill the gate will be in

its upper limit position.

Press and hold DOWN button untill the

gate will be in its lower limit position.

Press SET button to conrm

the upper limit position.

Digit 2 appears.

Press SET button to conrm

the lower limit position.

SET UP

CODE DOWN

SET UP

CODE DOWN

SET UP

CODE DOWN

SET UP

CODE DOWN

SET UP

CODE DOWN

Fig. 15

13

SET UP

CODE DOWN

SET UP

CODE DOWN

SET UP

CODE DOWN

5.2 Programming transmitters

5.3 Deleting programmed transmitters

5.4 Regulation of obstacle detection system

Press CODE button.

A dot will appear in the bottom corner.

Press button which will be control the gate

on the remote control. Wait 2 seconds,

press and hold the same button.

Dot will ash several times conrming

transmitter programmed.

Press UP button to increase or DOWN

button to decreases overload force.

Press and hold SET button untill digit 3

appear. The drive is in regulation overload

force mode. The minimum value of the

overload force is 1.

Press and hold CODE button untill C

symbol appear. All programmed

transmitters has been deleted.

Repeat the procedure for

all added transmitters.

Press SET button to conrm settings.

The default value of the overload

force is 3.

SET UP

CODE DOWN

The obstacle detection is set automatically during programming limit

positions. Typically, obstacle detection regulation is not necessary.

SET UP

CODE DOWN

SET UP

CODE DOWN

14

SET UP

CODE DOWN

SET UP

CODE DOWN

SET UP

CODE DOWN

SET UP

CODE DOWN

SET UP

CODE DOWN

5.5 Auto closing

5.6 Photocells

For the automatic closing function to work properly, photocells must be

installed.

Make sure that the photocells are properly connected. Use a NC photocell

(Fig. 15 and Fig. 16). The photocell function should be turned off when they

are not connected. Otherwise, it will not be possible to close the gate.

Press UP button to increase the time or

DOWN to decrease the time. The display

shows numbers from 0 to 9, where:

0 - auto closing function

is turned off,

1 - minimum closing time

it’s 15 seconds,

9 - maximum closing time

it’s 135 seconds.

Press the SET button

to conrm the settings.

Press DOWN button to turn on

the photocells. The digit 11 appear.

Press and hold UP button until the digit

or horizontal bar appears. Press UP button

again to set the automatic closing time.

Press UP button to activate photocells.

The „H” symbol appears in the display.

Press and hold DOWN button

untill digit 11 or symbol „H” appear.

Press the SET button

to conrm the settings.

SET UP

CODE DOWN

SET UP

CODE DOWN

15

The O / S / C input can be used to control the drive using an external switch.

The switch must have normally open voltage-free contacts (Fig. 19).

The power of the caution light should not exceed 25 W.

The external switch should be a „NO”.

5.7 Open/ stop/ close input

6. Optional connectors and connections

Connection of photocells - Fig. 17

Connection of the switch - Fig. 16

Fig. 16

GARAGE DRIVE

O/S/C

Fig. 17

16

Additional connectors:

1. The O / S / C input allows you to connect a switch to control the drive (Fig. 19).

2. The signal lamp (Fig. 18 and Fig. 19).

The drive has a separate output signal lamp. Supplying the signaling lamp it should be in

the 24 V - 28 V DC range and the current consumption must not exceed 100 mA. When

using AC 230 V signal lamps, additional relays should be used.

3. Pass door protection (Fig. 19).

This function does not allow the gate to be opened when the small wicket door is open.

Thanks to this, the door panel will not be damaged.

SD

AC 230 V

IN

FLASH LIGHT

(AC 230 V)

+24 PE PBGND GNDFLASH

Relay

Fig. 18

Fig. 19

GARAGE DRIVE

pass door

protection device caution light O/S/C

SD +24 PE PBGND GND

17

Rys. 20

Rys. 19

Konserwacja

Fig. 20 Fig. 21

7. Manual drive disconnection

The drive is equipped with a mechanism for disconnecting the drive, which allows you to

manually open or close the gate in the event of power failure or drive failure (Fig. 19). To

disconnect the drive, pull the handle. To re-engage the drive, simply close the latch of the

drive disconnect mechanism and then move the gate manually or start the drive until the

latch locks on the belt or chain.

In some cases, it is recommended to bring the drive disconnect handle to the outside so

that the mechanism is accessible from the outside (Fig. 21).

1. No special maintenance of the drive’s electronic system is required. Check at least

twice a year that the gate is properly balanced and that all working parts are in good con-

dition. Also check, at least twice a year, overload force and adjust it if necessary. Make

sure that the photocells, works correctly.

2. Bulb replacement:

Note: Before replacing the lighting, make sure that the power has been turned off and

that the voltage of the new bulb is compatible with its supply voltage and the power does

not exceed 25 W.

Loosen the screws on the lamp cover. Remove the lamp cover and then unscrew the old

LED lamp. Screw the new lighting LED and lamp cover.

8. Maintenance

18

9. ECO 600 N technical data

POWER 230 V | 50 Hz

MAX. PULLING FORCE 600 N

MAX. GATE AREA 10.0 m

MAX. GATE WEIGHT 80 kg

MAX. GATE HEIGHT 2400 - 3500 mm

RAIL chain | belt

OPENING SPEED 160 mm / sec.

LED LIGHT 24 V | 15 pcs. LED

LIMIT SWITCHES electronic

RADIO FREQUENCY 433.92 MHz

CODING FORMAT rolling code (7.38 x 10 combinations)

MEMORY 25 transmitters

LAMP CAUTION OUTPUT yes

OPERATING TEMPERATURE from -40°C to +50°C

SAFETY soft start and stop, the possibility of

connecting photocells and a caution lamp

PROTECTION DEGREE IP20

19

2

19

Max. gate area < 10.0 m Standard gate height: 2400 mm

Max. gate height: 3500 mm

2

10. Elements list

10.1 Table

20

NR

1

2

3

4

5

6

7

8

9

10

11

QUANTITY

1

1

1

1

1

1

1

1

1

1

1

Description

LED lighting housing

Electronic system 1

Electronic system 2

Housing

LED light

DC motor with gear

Motor shaft

Converter

Mounting the transformer

Steel bottom housing

Gearwheel

Table of contents

Popular Garage Door Opener manuals by other brands

Cornell

Cornell SGHNX-5011E Installation instructions and operation manual

Nexx Garage

Nexx Garage NXG-100 installation guide

Automatic Technology

Automatic Technology GDO-6v3 EasyRoller installation instructions

Wayne-Dalton

Wayne-Dalton 44 Double Flush manual

CAME

CAME 801XC-0120 quick start guide

Raynor

Raynor 87504RGD-267 manual

Raynor

Raynor COMMANDER 2000RGD owner's manual

TdA

TdA FBD180 Installation and user manual

Chamberlain

Chamberlain Model MotorLift 1000 owner's manual

Cardin Elettronica

Cardin Elettronica GL112409 Installation

Automatic Technology

Automatic Technology GDO-8 Shed Master owner's manual

Craftsman

Craftsman 139.18595 owner's manual