TERMOSTROJ TERMO-Kombi User manual

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5

ELECTRIC BOILER FOR CENTRAL HEATING

AND WARM WATER PREPARATION

TERMO-Kombi

USER’S INSTRUCTIONS

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5

WE ARE NOT LIABLE FOR

DAMAGES RESULTING

FROM NON-OBSERVING

THESE INSTRUCTIONS

Safety information and warnings

•Keep these instructions in the vicinity of

the boiler!

•The boiler is not allowed to modify.

•Adjusting correctly is important for

economical heating.

•At each contact with the manufacturer or

authorized service call to the factory-a

number that is printed on the identification

label on the boiler.

Children in the household!!!

- Please supervise children who are

retained in the vicinity of the device. Do

not allow children to play with the device.

- User cleaning and maintenance may not

work children unattended.

- The boiler is not intended for the

installation in the open air.

Technical security!!

- Keep the water pressure in the boiler

according to the manufacturer's

recommendations-see section 3.2.

- Do not mount the boiler in the vicinity of

sources of heat (open fireplace, wood stove,

etc.).

- Improper repairs can cause a serious danger

to the safety of the user.

- Defective parts may be replaced only with

original or approved by the manufacturer.

- Turn off the main power before opening or

any work on the boiler.

- The boiler has a built-in protection against

frost damage. If the boiler in winter period

does not use mandatory should be left active

main power (boiler can be turned off on the

control panel) so that the protection was

active.

TERMOSTROJ d.o.o.

10250 ZAGREB – LUČKO, F. Puškarića 1d, PP31

Tel/Fax +385 1 6531008, 6531015,6531016

info@termostroj.com

http://www.termostroj.com

Table of contents

1. Introduction..............................................................1

2. About the product ....................................................1

2.1. Construction .....................................................1

2.2. Integral parts of the TERMO-Kombi Boiler ......2

3. Installation ...............................................................3

3.1. Important warnings...........................................3

3.2. Assembly..........................................................3

3.2. Assembly (Continued)......................................4

3.3. Connection to the power network ....................5

3.4. Connection of room thermostat........................5

4. Use of the product...................................................6

4.1. Use of the boiler ...............................................7

4.2. Manipulation with automatic equipment...........8

4.4. Recommendations for optimal use ................10

5. Maintenance..........................................................10

6. Survey of possible defects and irregularities in

operation ...................................................................11

7. Technical specification ..........................................13

Read this document carefully before

manipulation, any installation, setup,

or service, and follow the instructions

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 1

1. Introduction

Thank you for the confidence you have shown to us

by having purchased our boiler for central heating and

sanitary water preparation.

For correct and safe and above all economic use

of the product, before assembly and connection,

read thoroughly these instructions.

Packing contains the following elements: boiler (1),

suspension support (3), user’s instructions and letter

of guarantee (3), valve for filling and emptying (4),

impurities collector (5), plastic pipe for venting the

system.

The Termo-Kombi boilers meet any and all national

regulations and legal standards. Pursuant to the

mentioned before, the certification of the product was

done according to the valid EN and HRN standards.

You can take insight into the certificates at the point of

sale, authorized service or web sites:

http:/www.termostroj.com.

The firm Termostroj is certified by the quality system

pursuant with the standard ISO 9001:2000.

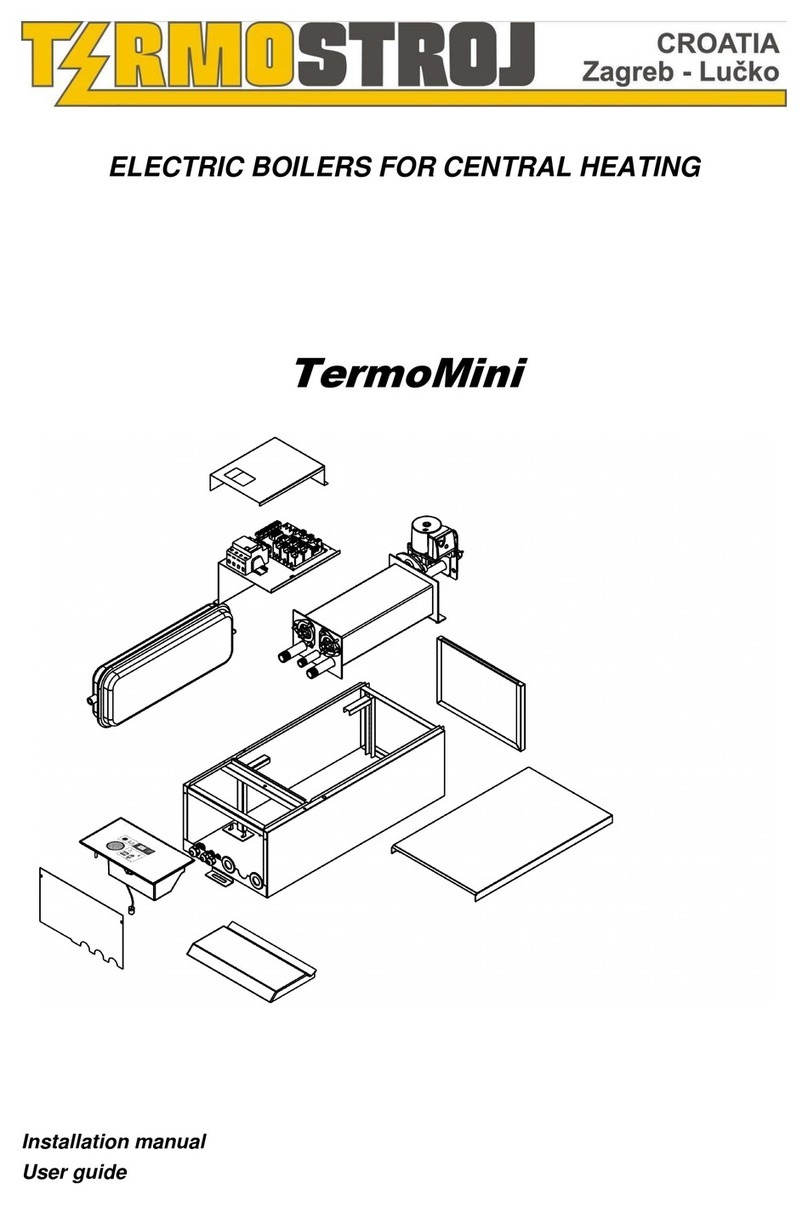

Illustration of unpacked product

2. About the product

TERMO-Kombi is the economic boiler for central

heating and sanitary water preparation that may be

used as the independent source of heat.

The boiler is operated on the principle of rapid heating

smaller water quantities and its energy exploitation is

almost 100%

TERMO-Kombi is suitable for using in smaller

business premises, flats, smaller catering objects etc.,

where it is important that it takes up small space.

Temperature range of operation is for sanitary water

from 30oC up to 55 oC, for central heating from 30oC

up to 90 oC.

Because of its design and noise free operation, the

TERMO-Kombi may easily fit in the living space. The

outer metal sheet is protected by powder coating.

2.1. Construction

The electric boiler TERMO-Kombi is made of quality

boiler metal sheet. The boiler itself is upon welding

sandblasted and protected with quality reactive

fundamental color.

At the bottom side of the boiler there are built in

electric heaters. From the upper side there is the blind

tube for placing the sounding tube of capillary

thermostat, temperature, pressure and thermal fuse

indicator. The boiler is insulated with 19 mm self-

extinguishing insulating material, which is sufficient to

direct all the heat only to the heating and sanitary

water preparation system.

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 2

2.2. Integral parts of the TERMO-Kombi

Boiler

1. Central heating primary flow

2. Central heating return flow

3. External shell of the boiler

4. Boiler

5. Thermal insulation

6. Electric heaters

7. Control panel

8. Boots for el. terminals

9. Contactors

10. Expansion vessel

11. Central heating pump

12. Safety valve at 3 bar

13. Automatic venting valve

14. Filling and emptying valve (in packing, it should

be built in at installation)

15. Valve for boiler venting

16. Sounding tube for air appearance control

17. Distributor

18. Miniature circuit breaker (MCB)

19. Temperature sensor of sanitary water outlet line

20. Exchanger

21. Temperature sensor of sanitary water inlet line

22. Non-return valve

23. Pump for sanitary water preparation

24. Sanitary water intake

25. Sanitary water output

26. Safety valve at 8 bar

27. Automatic venting valve

28. Boiler’s temperature sensor

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 3

3. Installation

3.1. Important warnings

THE GUARANTEE SHALL

NOT BE ACCEPTED IF THE

FOLLOWING WAS NOT

OBSERVED:

•THE BOILER SHOULD BE PUT INTO

OPERATION BY THE AUTHORIZED SERVICE,

•THE ENCLOSED IMPURITIES COLLECTOR

SHOULD BE BUILT IN ON THE STARTING LINE

OF CENTRAL HEATING AND INLET COLD

SANITARY WATER,

•PRIOR TO CONNECTING THE BOILER TO THE

SANITARY WATER LINE, PIPES SHOULD BE

CLEANED IN ORDER TO AVOID THE

BLOCKAGE OF THE EXCHANGER.

THE LIST OF AUTHORIZED SERVICES IS ON THE

BACK OF THE LETTER OF GUARANTEE

THE BOILER SHOULD NOT BE INSTALLED ON

PLACEC WHERE THERE IS A DANGER OF BEING

PORING OVER WITH WATER OR A DANGER OF

SINKING.

IN AREAS WITH STRONG CONCENTRATION OF

LIME IT IS RECOMMENDED TO BUILD IN A

MAGNETIC OR ELECTROMAGNETIC LIME

BREAKER ON THE INLET LINE OF SANITARY

WATER ON THE BOILER.

3.2. Assembly

TERMO-Kombi is foreseen for the wall assembly and

for the easier assembly, on the backside there is

foreseen the suspension support. For the suspension

you may use metal wall plugs with the screw M8 or

M10 or stronger plastic wall plugs – diana screws.

Precise dimensions of boilers are given in the 7.

Technical specification

Filling and emptying valve is delivered together

with the boiler and should be assembled at the

installation.

If possible, the boiler should be assembled to the

lowest point in relation to installation. In this way we

are protecting the boiler from air appearance, which

may leave heaters without water that could result in

their burning through.

Minimum distances at assembly

Disassembly schema

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 4

3.2. Assembly (Continued)

Prior to putting into operation, the system should

be vented and that both central heating and

sanitary water circle.

Illustration of how to correctly vent the water circle on

upper side of Termo-Kombi. Protection cap should be

release on automatic venting pots (1 and 2). Plastic

pipe should be attached to valve (3) prior venting the

water circle.

On the illustration you can see: ground terminal (1),

neutral wire terminal (2), MCB (miniature circuit

breaker) (3), operating current trips (4), relays /

contactors (5) and connection plate (6) for connecting

pumps, room ‘stat and all probes.

Upper side of Termo-Kombi

Connection terminals

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 5

3.3. Connection to the power network

For power supply connection on all Termo-Kombi

boilers, MCB (miniature circuit breaker) is used,

providing same time protection for boiler and

connection point for external power cables.

Note:

When connecting power cable please observe live

and neutral marks inside boiler.

3.4. Connection of room thermostat

The TERMO-Kombi boiler has foreseen clamps for

connecting the room thermostat.

The short circuit is factory installed on the clamps (for

cases when the room thermostat is not used) and if

we connect it, we have to take account of the fact,

which type of a room thermostat is to be connected.

One group of thermostats is connected only serially in

the control voltage circuit, resp. on clamps.

The other group of thermostats has built in

temperature simulation system and therefore should

be constantly under voltage and according to the fixed

temperature in the room, on its outlet we have the

signal for boiler control. In this case the ZERO-line is

connected to the clamp “N”.

Read instructions for connection of a thermostat,

which are enclosed to the thermostat in order to

learn which way of connection is laid down by the

producer.

Power supply connection

Room thermostat terminal

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 6

4. Use of the product

Control panel

1. Multipurpose – temperature indicator (temperature of

boiler, sanitary water, adjustment of temperature)

2. Signalization of operation degree of heaters (1., 2., 3.)

3. Signalization of air appearance in the boiler (red light)

4. Signalization of under voltage protection (red light)

5. Signalization of boiler operation (green light)

6. Adjustment of temperature in boiler

7. Switch for central heating switching on and off

8. Sanitary water temperature adjustment

9. Switch for switching on and off the sanitary water

preparation

10. Signalization of sanitary water preparation and

consumption

11. Indicator of pressure in a boiler

12. Thermal fuse

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 7

4.1. Use of the boiler

First putting on at the beginning of a season

For the first putting on at the beginning of a central

heating season, the first step should be to put on the

boiler by means of the switch for central heating (7),

temperature in the boiler (1) should be adjusted to

30°C (in this was the heaters are disconnected and

only circulation pump is in operation).

Warm water preparation is put on by means of the

switch for sanitary water (9)

If upon putting on the boiler there is no noise of water

or the central heating if warm water pump does not

run (during operation, the pump produces slight

vibrations) the pump should be manually started.

Circulation pumps lubricate bearings with water

flowing through the pump and after stoppage it could

occur that the bearings “burn”.

Starting the pump

For starting the pump it is necessary to turn off the

protection plug on its front side (1) below which there

is the axis with the groove for screwdriver. With the

screwdriver, the pump (2) should be several times

turned in direction of the arrow on the pump head and

the boiler should be put on again.

When the pump starts, the operation temperature of

water in boiler and temperature of sanitary water

should be selected. For central heating the optimal

temperature is between 60 and 70°C, whereas for

sanitary water optimal temperature ranges from 45 to

48°C.

If to the boiler a room thermostat is connected, a

desired room temperature should be adjusted

according to the instructions of the producer of room

thermostat.

Segment of control panel

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 8

4.2. Manipulation with automatic

equipment

Putting on and of the sanitary water preparation

The boiler is switched on by means of the main switch (9),

for switching on, the switch should be put in the position 1.

Upon switching on a desired water temperature in boiler is

displayed for 5 seconds, signalization of sanitary water

preparation is twinkling (10). Upon 5 seconds real

temperature of sanitary water outlet is displayed (1); if there

is no requirement for sanitary water, the signalization lamp

of sanitary water preparation (10) is switched off.

By switching the switch (9) to the position 0, the sanitary

water preparation is put off. The entered desired

temperature of sanitary water shall be stored.

Adjustment of desired temperature of sanitary water

By pressing the key for temperature adjustment (8) the

desired warm water temperature appears, the signalization

lamp of sanitary water preparation (10) is twinkling. By

repeated pressing upwards or downwards it is possible to

increase or decrease the desired sanitary water

temperature. When the temperature is adjusted it is

sufficient to wait for 5 seconds (signalization lamp of

sanitary water preparation (10) does not twinkle) in order

that the boiler memorizes a new temperature.

Use of sanitary water

If there is a need for sanitary water, the signalization lamp of

sanitary water preparation turns on (10) and the

temperature of warm water outlet displays. Signalization of

operation degree of heaters (2) displays and by turning on

lamps it is shown whether one group of heaters is in

operation, two or all three groups.

The boiler automatically controls a heater operation degree.

Putting on central heating

By switching the switch (7) to the position 1, the central

heating system is switched on. Upon switching on a desired

water temperature in boiler is displayed for 5 seconds,

signalization of boiler operation is twinkling (5). Upon 5

seconds real temperature in the boiler is displayed (1); if the

current temperature in boiler meets the desired one, the

signalization lamp of boiler operation (10) is switched off.

Adjustment of desired temperature of central heating

By pressing the key for temperature adjustment (6) the

desired temperature in the boiler appears, the signalization

lamp of boiler operation (5) is twinkling. By repeated

pressing upwards or downwards it is possible to increase or

decrease the desired sanitary water temperature. When the

temperature is adjusted it is sufficient to wait for 5 seconds

(signalization lamp of boiler operation (10) does not twinkle)

in order that the boiler memorizes a new temperature.

Segment of control panel

Segment of control panel

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 9

Parallel operation of central heating and sanitary

water

When both modes of operation are active, central

heating and sanitary water preparation, the boiler

prefers sanitary water.

If there is a requirement for warm water, the boiler

starts with preparation of sanitary water, the lamp (10)

turns on, whereas the boiler operation signalization

turns off (5); temperature indicator (1) displays the

current temperature of warm water outlet.

Air in the boiler (3), red light

If in the boiler the air appears, the signalization of air

in the boiler turns on (3) and the boiler stops the

operation. In this way the boiler is protected against

blowing because of appearance of air. For

continuation of operation, the boiler should be vented.

If the boiler is correctly vented, the operation of boiler

continues automatically.

Voltage drop (4), red light

If the voltage in the network line drops below 175V by

phase, the signalization of under voltage protection (4)

turns on, the boiler automatically switches off in order

to protect electronics and contactors inside the boiler.

The boiler shall automatically continue the operation

when the network voltage reaches values above

185V.

Thermal fuse - turning on

By means of thermal fuse (12) the boiler is protected

against rapid increase of temperature above 115°C.

The fuse turns off the boiler and ejects the MCB

(miniature circuit breaker).

For continuation of operation it is necessary to take off

the protection cover from the thermal fuse and press

the white key, upon which the MCB should be

switched on again.

*If the temperature of water inside the boiler exceeds

90°C, the thermal fuse can not be reset. In order to

reset the thermal fuse, it is necessary to wait for the

water temperature to drop below 90°C.

Segment of the control panel

Segment of the control panel

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 10

4.4. Recommendations for optimal use

Central heating

For optimal use of the boiler and electric power

consumption, we recommend the use of quality room

thermostat connected to the boiler.

Daily temperature should be between 20°C i 22°C (for each

degree above 22°C the consumed energy is increasing

exponentially).

For the night operation we recommend temperature

between 15 i 17 °C. In this way energy saving is higher than

in case of complete turning off the boiler during the night.

If there is no room thermostat, for night operation the

temperature in boiler should be decreased to about 40°C or

turned off completely (9. main switch).

In summer period, valves below boiler should not be

closed (closing valves disables water circulation in

system (10 – 15 seconds) generated by safety

thermostat.

Warm water

Optimal temperature of sanitary water, in boiler, is 42°C up

to 45°C (above 48°C it comes to increased lime separation

that sticks to the exchanger, tubes and pump and may lead

to gradual decrease of boiler effect).

5. Maintenance

We recommend the inspection of a device once a year by

the authorized service (before heating season). This service

is not included in the guarantee. During the inspection all

electric and water connections should be tightened, the

system should be vented and – if necessary – filled up,

valves and general functionality of the device should be

checked.

If you notice a reduced effect of warm water it is necessary

to remove lime accumulated within the plate exchanger (1).

Only authorized service engineer can do removing lime.

Prior to the beginning of cleaning, valves (2) separating

the boiler from the sanitary water installation, should be

closed.

Cleaning tubes should be connected to the foreseen 1/2"

piping (3) (internal thread).

Cleaning solution (5) may be formic acid 2-3%, nitric acid 3-

4% or acetic acid 10%.

The solution should circulate through the system by a pump

(4), as long as there is the sludge in the outlet pipe.

Thereupon the direction of a circulation should be changed

and the process repeated.

Upon finished cleaning the boiler should be washed in

the same way with clear water.

For cleaning the product, it is not permitted to use

aggressive media as e.g. gasoline, kerosene or solvent. For

the external shell and decorative cover media for cleaning

plastics or dish washing media may be used. Control panel

should be cleaned with dry or moist cloth (not wet).

Schematic illustration of lime removal

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 11

6. Survey of possible defects and irregularities in operation

DEFECT CAUSE ELIMINATION

- at switching on, no voltage on

the control panel

-no feed from net on one or

more phases

-fuse 2,5A on the control

panel blown

-MCB (miniature circuit

breaker) ejected

-check on serial clamps of

the boiler whether there is

feeding

-replace the fuse 2,5A and

check the cause of its

blowing

- at switching on, switches

show voltage on the control

board, but the boiler does not

heat

-check the adjustment of a

room thermostat,

-limit thermostat was

activated,

-indicator of air appearance

in the boiler blocked the

operation,

-defective contactor,

-defective operation

thermostat,

-blown heaters

-check the adjusted

temperature on a room

thermostat, replace its

batteries or it is defective,

-vent the boiler till the lamp

“air in boiler”, turns off

- temperature in boiler is at the

desired value, but the radiators

are not warm

-circulation pump is not in

operation,

-air blockage on central

heating installation, that

prevents the circulation

-start the mechanical pump

or replace it with the new

one if it is blown (see 4.1.),

-vent the installation

- the boiler heats poorly

-on the feed one phase is

missing,

-in two-phase thermostats,

second phase is not in

operation,

-second or third phase was

not manually turned on,

-one contactor defective,

-a part of the heater has

blown,

-in three-phase system to

the boiler are not brought

three various phases

-check fuses on the main

panel,

-replace thermostat or, if

necessary, contactor,

-replace the heater,

-measure with the

instrument voltage between

phases, it should be 400V

- in the operation the contactor

can be heard (it is buzzing) and

possibly radio and TV-

interferences

-poor voltage in the network,

-defective contactor

-select with the instrument

the best phase for control

(on the boiler marked with

“R”)

-replace the contactor

- at switching on or off the

operation thermostat radio and

TV-disturbances

-defective operation

thermostat,

-defective blockade (RC –

protection)

-replace the thermostat,

-replace the RC – member

- boiler in operation is roaring

-a system is not good

vented,

-defective heater

-vent the system,

-replace heaters

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 12

- pressure in heating system is

varying

-defective expansion vessel,

-too low or too high pressure

in the vessel

-if there is water on the valve

for pumping the vessel,

replace the vessel,

-pressure in the vessel

should be 0,5 – 0,8 bar

-RCCB switch is ejecting

-defective heater,

-moist on conductors,

-replace the heater,

-check leaking,

-check the cause of

activation

- sanitary water temperature is

varying

-too low pressure or too

small flow in plumbing

installation

-set the warm water

temperature to the desired

temperature without mixing

with cold water

- boiler does not reach a

desired warm water

temperature

-check network fuses

-warm water flow is higher

than boiler capacity

-check in the instructions the

maximum warm water flow

- boiler does not warm up a

water

-pump for warm water

preparation is not in

operation

-air in warm water system

-start the pump manually

according to the instructions

in 4.1.

-vent the warm water system

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 13

7. Technical specification

1. Central heating return line

2. Sanitary water inlet line (cold water)

3. Valve for venting the boiler

4. Central heating starting line

5. Sanitary water outlet line (warm water)

6. Control panel

7. Wall support for suspension

8. Safety valve at 3 bar

9. Safety valve at 8 bar

10. Power and room thermostat inlet

11. Filling valve

TERMO-Kombi Boilers

Type of the device

Characteristics

Units TERMO

Kombi 15

TERMO

Kombi 18

TERMO

Kombi 24

TERMO

Kombi 28

TERMO

Kombi 32

TERMO

Kombi 40

Central heating heat effect

kW

15

18

24

28

32

40

Warm water heat effect

kW

15

18

24

28

32

40

Max. pump supply at 1000 lit/h

m

4,8

Area of central heating temperature

adjustment

oC 40 - 90

Area of warm water temperature

adjustment

oC 30 - 55

Warm water flow at 2 bar

l/min

6,1

6,8

8,5

9,3

10,2

11,50

Warm water flow at 2 bar and 55oC

l/min

2,85

3,10

4,00

4,62

5,10

5,8

Specific flow (at ΔT - 30 K)

l/min

10,2

11,2

12,80

13,30

13,96

15,6

Permitted overpressure, warm water

bar

8

Height

mm

930

Depth

mm

290

Width

mm

480

550

Weight

kg

58

65

We reserve the right of changing these instructions without special prior notification

TMS-UT-0709-Z07-5 14

TABLE OF RECOMMENDED FLOWS

Power range

[kW]

Minimum flow

[l/min]

Optimal flow

[l/min]

Maximum

flow

[l/min]

Recommended

work area

[l/min]

15 820 40 10-35

18 13 26 52 15-40

24 15 34 68 15-55

28 20 40 80

25-70

36 20 45 92

25-80

40 25 57 115

30-100

SUPPLY CHARACTERISTICS

The boiler must be protected by Residual current circuit breaker (RCCB) and appropriate

fuse or MCB (miniature circuit breaker). See table “SUPPLY CHARACTERISTICS”.

POWER Nominal

current

Fuse current Rated short-circuit

breaking capacity

Icn (EN 60898)

Rated short-circuit

breaking capacity

Icn (IEC 947-2)

Min. conductor's

cross-section

Fuse type RCCB switch type

400V 3N ~ 50/60 Hz

15 kW 21,73 A 25 A

10 kA 15 kA

5 x 6 mm2

B25-3p

40 / 0,03 A18 kW 26,09 A 32 A B32-3p

24 kW 34,78 A 40 A B40-3p

28 kW 40,58 A 50 A

5 x 10 mm2

B50-3p

63 / 0,03 A32 kW 46,38 A 63 A B63-3p

40 kW 57,97 A

This manual suits for next models

6

Table of contents

Other TERMOSTROJ Boiler manuals

Popular Boiler manuals by other brands

Lochinvar

Lochinvar Noble NKC 199 user manual

Slant/Fin

Slant/Fin VICTORY II VHS Series Installation and operating instructions

saro

saro ANCONA 5 Translation of the original

Lamborghini Caloreclima

Lamborghini Caloreclima TAURA D 24 MCA Instructions for use, installation and maintenance

Baxi

Baxi COMBI 224 Installation and service manual

Biasi

Biasi Activ A 25S Service manual