The Fire Brick D95 User manual

D95

Brick Oven

D95 PRECUT BRICK OVEN KIT

Instruction Booklet

2

Our Wood Fired Brick

Oven Kits are as

authentic as you can

get. With all the re

bricks cut to size, with

custom formwork and

tooling, building a

quality Brick Oven has

never been so simple.

D95

3

Table of Contents

CONTENTS

INTRODUCTION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

BEFORE YOU BEGIN � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

NOTES & UPDATES� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

SAFETY INFORMATION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

LIMITED WARRANTY � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

LAYOUT DRAWING � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

WHAT’S IN THE KIT � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

ADDITIONAL TOOLS & MATERIALS REQUIRED � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

SUBFLOOR INSULATION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

LAYING THE FLOOR TILES� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

BUILDING THE DOME� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

INSTALLING THE FLUE GALLERY� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 35

INSULATING THE DOME � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

OVEN LANDING & SURROUNDS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 38

PERLITE RENDER � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 39

INSTALLING THE STANDARD FLUE � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 40

FLUE INSTALLATION TIPS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 41

CURING THE OVEN� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 42

PAINTING� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

4

You really don’t need to

be a skilled bricklayer

to put this kit together -

we have done all of the

dicult work for you.

You get the fun part, of

putting it all together.

Introduction

5

Introduction

BEN GUILFORD

DIRECTOR

Firstly, our congratulations and gratitude for the purchase of your D95 PreCut Brick

Oven Kit! We have spent years crafting and perfecting our PreCut Brick Oven Kits,

taking suggestions from customers and mentors, to create a product that we are truly

proud of. We’re very blessed to say that we now have thousands of happy customers

around the world, enjoying time with family and friends over meals cooked in the most

authentic way possible.

That is what it’s all about in the end - you’re not just building a Wood Fired Oven.

You’re building something that’s going to bring your family and friends together in a

shared cooking experience. You’re building something that you will spend quality time

with the people that you love around, where you are forced to slow down and just enjoy

what you’ve built. You’re building something that you can use to love and serve others;

it’s rare to see someone re up their oven just to cook for themselves alone. It’s always

about community, it’s about loving and dare I say, spoiling the people closest to you.

If there’s a piece of outdoor equipment that draws people together more than an

authentic Wood Fired Oven, I’m yet to nd it. May your oven bring you, your family and

friends nothing but joy (and the occasional burnt crust) for many years to come.

Introduction

Introduction

6

Before You Begin

COLD CLIMATES - WARNING

If you’re building a Wood Fired Oven in a region that experiences ‘freeze-thaw’ conditions, where the frost is so

severe that it penetrates deep into the ground, this is something that you need to be aware of when deciding

on where and how to build your Wood Fired Oven.

The refractory bricks and insulation that make up our Wood Fired Oven Kits are very porous, so they will soak

up rain or melted snow that falls on them. This is not a problem in itself - if you re the oven up after the oven

has absorbed some water, the heat will drive the water out and the oven will return to its original state. However,

if your oven has gotten wet and experiences a deep frost, the water held in the re bricks and insulation may

freeze and expand, causing serious damage to the oven.

The sure way to prevent this is to build the oven into an enclosure that keeps it completely dry, so that when

the cold weather comes, it will have no adverse effect on the oven at all. If this is not possible, an alternative is

to re the oven thoroughly before the end of Autumn, then remove the ue and protect the oven with a suitable

weatherproof cover for the winter. The key is to keep the oven completely dry in deep cold conditions.

USING OUR INSTRUCTIONS

Building a Wood Fired Oven is a hugely enjoyable process, providing you take your time and pace yourself.

The best way to prepare for the build is to rst watch through the entire Instructional Video Series, from start

to nish. Then, read through these instructions in full so that you have a clear understanding of the process.

When you actually start building, take 15 minutes and watch the video that covers the part of the build that

you’re up to. These instructions are to help remind you of what you learned and give you more details where

they are needed. Remember, there is information in these instructions that is not in the videos, and vice versa.

That being said, if you’ve watched the videos, read the instructions and still feel even a little bit confused about

something, please call us right away� Part of what you’re paying for when you purchase one of our kits is

quality customer service - we are here to make sure you succeed in your Wood Fired Oven Building adventure!

Before You Begin

7

Notes & Updates

We are on a continuous search for ways to improve our products, so that we’re always giving our customers

the very best product that we can. These changes are always small and incremental - tested by us before being

rolled out to our customers. This is where we will make notes of these changes, where things have evolved

since the instructional videos were recorded.

1. The Refractory Mortar used to lay all of the bricks in the dome of the oven is now a two-part mix (in the

videos it was shown as a one part dry mix). This is to increase the shelf-life of the mortar, by keeping the

active ingredient separate in another bag. Close the tops of these bags after opening to help them keep.

2. The new Refractory Mortar mix used to lay the dome bricks sets far more quickly than its predecessor.

In the video series we suggest waiting until the following day to remove excess mortar from the inside

of the oven dome. We now recommend that you remove excess mortar as soon as possible, as it

will set very hard after 24 hours, particularly if you are building in a warm climate. This is especially

important when you are laying the nal courses of dome bricks on top of the breglass dome

formwork. If you are laying these nal courses over several days, it will be wise to lower the dome

formwork after you lay each course in order to remove excess mortar and clean your brickwork.

3. The D95 PreCut Brick Oven is very similar to its bigger brother - the D105, with one key difference. To

balance the thermal mass of the smaller oven dome with the thermal mass in the oven oor, we have

removed the 25mm Suboor Castable layer, so your 50mm re brick tiles will be mortared down directly

onto the aluminium foil layer that you cover the CalSil board with. This reduces the heat-up time of the

D95, while still giving you more than enough thermal mass in the oor to hold very stable temperatures.

4. If you plan to use your oven at extreme temperatures on a regular basis (in excess of 700°C), or are using

it for commercial purposes, then we recommend using the Refractory Castable to ll in large gaps on the

inside face of the oven. For example, when the dome courses start crossing the Entry Arch there are some

triangular sections that need to be lled in. If you’re using the oven normally, at temperatures below 700°C

then the Refractory Mortar will work perfectly. If you’re going to be using the oven commercially, or running

at extreme temperatures, then replace those sections of Refractory Mortar with Refractory Castable.

Updates

8

Fire Safety

Safety Warning

A MAJOR CAUSE OF UNINTENDED OVEN-RELATED FIRE IS FAILURE TO MAINTAIN

REQUIRED CLEARANCES (AIR SPACES) TO NEARBY COMBUSTIBLE MATERIALS.

IT IS OF THE HIGHEST IMPORTANCE THAT THIS OVEN BE INSTALLED ONLY IN

ACCORDANCE WITH THESE INSTRUCTIONS.

IF THIS OVEN IS NOT PROPERLY INSTALLED, AN UNINTENDED FIRE MAY RESULT.

TO REDUCE THE RISK OF FIRE, FOLLOW THESE INSTALLATION INSTRUCTIONS.

PLEASE READ THIS SET OF INSTRUCTIONS IN FULL AND WATCH THE INSTRUCTIONAL

VIDEOS BEFORE INSTALLING AND USING YOUR OVEN.

FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN FIRE, CARBON MONOXIDE

POISONING OR EXPLOSION LEADING TO PROPERTY DAMAGE, BODILY INJURY, OR

EVEN DEATH.

IF YOU HAVE ANY QUESTIONS AT ALL REGARDING THE SAFE INSTALLATION OF YOUR

OVEN, PLEASE DON’T HESITATE TO CONTACT US, WE’LL BE HAPPY TO ASSIST YOU.

Safety Information

9

Fire Safety

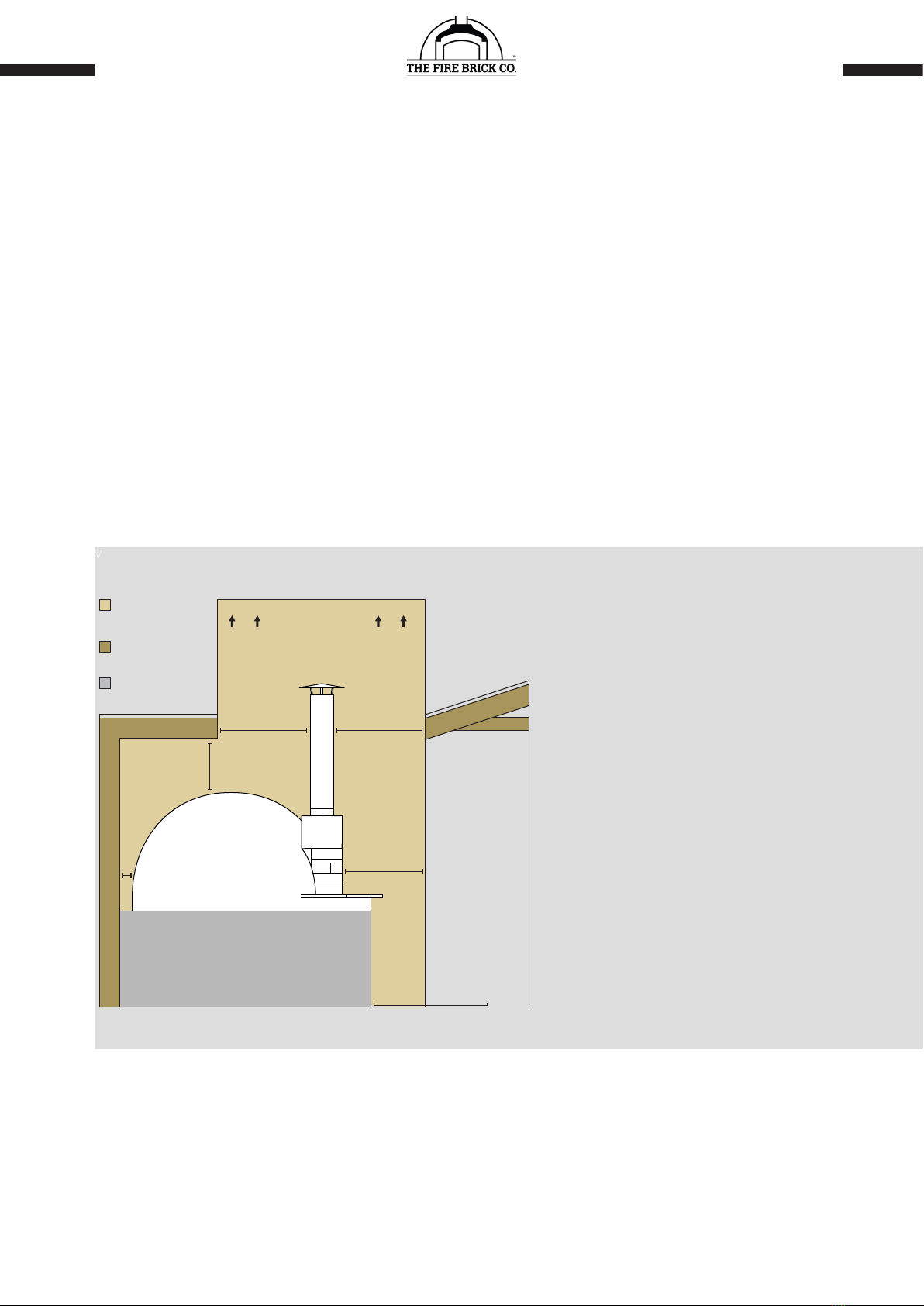

Clearances to Combustible Materials

A major cause of oven-related property re is failure to maintain the required clearances (air spaces) between

the oven and combustible materials. When planning the location for your oven, ensure that you maintain

clearances to all combustible materials, including but not limited to nearby walls, posts, ceiling structures and

vegetation.

If the oven is being built in close proximity to a structure (eg� beneath a pergola), the clearance from

combustible materials to the ue can be reduced by using a twin or triple skin ventilated ue system. If you’re

planning to do this the ue must be specied and installed by a licensed professional to ensure that the ue

system is compliant with the relevant standards and local laws for your area.

If in doubt, contact a qualied plumber or your local re authority for more information.

v

400mm

Above Oven

Clearance

750mm

Flue Clearance

750mm

Flue Clearance

700mm

Vent Brick &

Flue Gallery

Clearance

1200mm

Non Combustible

Floor Material

Clearance Zone

Combustible Material

Non Combustible

Material

Clearance Continues

50mm

Dome

Clearance

MINIMUM CLEARANCES ARE AS FOLLOWS;

50MM CLEARANCE TO COMBUSTIBLES

FROM ALL SIDES OF THE OVEN DOME�

400MM CLEARANCE TO COMBUSTIBLES

ABOVE THE OVEN DOME�

750MM CLEARANCE TO COMBUSTIBLES

FROM ALL SIDES OF THE STAINLESS STEEL

FLUE (UNLESS A MULTI-SKIN FLUE SYSTEM

IS INSTALLED)�

700MM CLEARANCE TO COMBUSTIBLES

FROM ALL SIDES OF THE VENT BRICKS AND

PRECAST FLUE GALLERY�

COMPLETE CLEARANCE ABOVE THE FLUE,

MAINTAINING 750MM RADIUS AROUND IT

(FOR ALL FLUE SYSTEMS)�

NON-COMBUSTIBLE FLOOR MATERIAL

SHOULD EXTEND 1200MM FROM THE

FRONT OF THE OVEN, FOR THE WIDTH OF

THE OVEN DOME, TO PROTECT AGAINST

FALLING HOT EMBERS�

10

Safe Installation Instructions

DUST EXPOSURE – RESPIRABLE CRYSTALLINE SILICA

Inhalation of airborne dust may cause irritation to the mucous membrane and upper airways. Symptoms can include coughing, sneezing

and breathing diculties. Repeated exposure to respirable silica may result in pulmonary brosis (silicosis). Silicosis is a bronodular lung

disease caused by deposition in the lungs of ne respirable particles of crystalline silica. Principal symptoms of silicosis are coughing

and breathlessness.

The following materials in your Wood Fired Oven Kit may contain respirable crystalline silica and a suitable dust mask should be worn

while handling them;

• Hybrid Refractory Bedding Mortar (marked Airset Mortar)

• Refractory Mortar Part A

• Refractory Mortar Part B

• Refractory Castable

• Fire bricks (when cutting or shaping them with a grinder)

• Perlite

• Calcium Silicate Board

While the Ceramic Fibre Blanket does not contain respirable silica, the bers are very irritating to the respiratory tract and can cause

irritation in the nose and throat, and chest discomfort. A suitable dust mask should be worn when working with the ceramic bre blanket,

until the rst layer of Perlite Render has been applied to seal the ceramic bre blanket from the atmosphere.

EYE PROTECTION

This is a very hands-on project and you are advised to wear safety glasses when mixing any of the materials or cutting/grinding bricks.

This also applies to applying the ceramic bre blanket insulation, which is irritating to the eyes. If in doubt, wear safety glasses!

SKIN PROTECTION

The mortar mixture that you’ll use to lay the re bricks in your Wood Fired Oven Kit is quite alkaline, and repeated exposure to your skin can

result in chemical burns. The same goes for the Refractory Castable and Perlite Render mixes. This is compounded by having to handle

wet bricks, which (if done without gloves) makes your skin softer and more vulnerable to being attacked by these materials. IGNORE THIS

AT YOUR OWN RISK! THE AUTHOR HAS PERMANENT SCARRING TO REMIND HIM OF THE IMPORTANCE OF WEARING GLOVES�

To avoid this, wear rubber ‘washing up’ gloves underneath ordinary gardening gloves to protect your skin. Rubber gloves alone may not

work well for long, as handling the re bricks can wear straight through them very quickly. There are some heavy duty rubber gloves

available at some supermarkers and hardware stores that work very well by themselves, as you will see in the instructional videos.

The key is to keep your hands dry, and if you notice a hole in the rubber gloves you would be well advised to replace them immediately.

Avoid rubber gloves with an elastic cuff at the wrist – these can rub your skin and leave it exposed to attack from the alkaline material

you’re handling. If your hands get wet inside the gloves, remove the gloves, dry your hands and put on a new pair of gloves, turning the

others inside out to dry so they can be used later. For this reason it’s worth having two pairs of rubber gloves.

The Ceramic Fibre Blanket can be irritating to the skin, with some people experiencing rash symptoms, so we have provided you with two

large plastic gloves that loop over your neck and cover the length of your arms. Wear these when handling the Ceramic Fibre Blanket.

11

Safe Usage Instructions

WARNING: PLEASE READ ALL OF THE INSTRUCTIONS BEFORE INSTALLING AND USING YOUR WOOD FIRED OVEN� FAILURE

TO FOLLOW INSTRUCTIONS MAY RESULT IN FIRE, CARBON MONOXIDE POISONING OR EXPLOSION LEADING TO PROPERTY

DAMAGE, BODILY INJURY, OR EVEN DEATH� SAVE THESE INSTRUCTIONS�

If your oven is not installed properly, an unintended re may result. To reduce the risk of such a re, please follow our installation instructions

carefully. It is critical to use only the materials specied and provided to construct the oven.

Contact your local Building Authority, or Fire Authority regarding local laws for installation of this oven in your area.

OVEN IS HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE WELL CLEAR. CONTACT WITH UNINSULATED PARTS

OF THE OVEN INCLUDING THE BRICKWORK AND CHIMNEY FLUE MAY CAUSE SKIN BURNS.

DO NOT BURN FLAMMABLE LIQUIDS OR WASTE MATERIALS IN THE OVEN.

DO NOT CONNECT THIS OVEN TO A FLUE ATTACHED TO ANOTHER WOOD BURNING APPLIANCE.

Keep children and pets away from the oven when it is hot, DO NOT leave children near the oven unsupervised.

Use good quality rewood for burning only. DO NOT USE charcoal, pressure treated timber, sappy timber, laminated timber or any material

other than well dried rewood. This does not apply to kindling.

DO NOT USE liquid fuel (relighter uid, gasoline, lantern oil, kerosene or similar liquids) to start or maintain a re.

BEWARE of very high temperatures in the oven and use long oven mitts or welding gloves rated above 400°C to handle pots, pans and

uninsulated tools.

DO NOT put any unprotected part of your body inside the oven while it is hot. The oven can remain hot without a re.

DO NOT close the oven door fully while a re is burning in the oven. Closing the door fully will cut off oxygen to the re, causing the re to

are up violently if the door is then removed. This does not apply to hot coals.

Dispose of ashes using a metal shovel and place in a metal bin with a snug tting lid. The container should be stored on a non-combustible

surface, away from all combustible materials. It is not necessary to empty the ashes from the oven each time it is used, empty as required.

Ensure the ashes are completely cold before disposing of them in an appropriate manner.

VERY IMPORTANT - BEWARE of sparks and embers ying out from the oven opening, as rewood can crackle and pop, sending embers

ying. Ensure no combustible materials are within range of the oven at any time.

DO NOT use water to extinguish the re or cool down the oven.

DO NOT ll the clearance spaces around the oven with sand, insulation or any other material.

Follow the instructions for Curing the Oven with care. Failure to follow these instructions may cause damage to the oven, poses a safety

risk to those nearby, and can void the warranty.

FOR YOUR SAFETY do not store or use gasoline or other ammable liquids or vapours in close proximity to the oven.

Ensure that an able bodied person of suitable age, who’s judgment is not impaired by alcohol, drugs or medication is present to monitor

and control the re from the time that it is lit to the time that it is extinguished.

Ensure that a suitable dry chemical or CO2 re extinguisher is on hand when the oven is lit.

Inspect the ue regularly for any buildup of soot, and remove excess soot if it is found.

If the oven is being built indoors, check with your plumber to ensure that the building has adequate ventilation to feed the re without

lowering the quality of air in the room, or risking a buildup of carbon monoxide.

12

Limited Warranty

The Fire Brick Company, a manufacturer of wood red ovens, warrants its ovens (henceforth referred to as the Oven) to be free from

defects in materials and workmanship for a period of (1) one year from the date of purchase.

QUALIFICATIONS TO THE WARRANTY

The complete Product Warranty outlined above does not apply under the following circumstances:

1. The Oven was not installed in accordance with The Fire Brick Company installation instructions and local building

codes.

2. The Oven has been subjected to non-standard use, such as burning fuels with abnormal burning characteristics including but

not limited to; driftwood, charcoal, plywood and material containing a binder that may burn at excessive temperatures and

cause damage to the Oven.

3. This Warranty does not apply to normal wear and tear.

4. This Warranty does not apply to any cracking caused by over-ring or the failure to follow a proper curing schedule.

5. On parts that would be normally worn or replaced under normal conditions.

6. Normal cracking due to expansion and contraction stress relief in the brickwork, precast ue gallery, render or oor tiles.

LIMITATION ON LIABILITY

It is expressly agreed and understood that The Fire Brick Company’s sole obligation and purchaser’s exclusive remedy under this Warranty,

under any other warranty, expressed or implied, otherwise, shall be limited to replacement, repair, or refund, as specied above, and such

liability shall not include, and purchaser specically renounces any rights to recover, special, incidental, consequential or other damages

of any kind whatsoever, including, but not limited to, injuries to persons or damage to property, loss of prots or anticipated prots, or loss

of use of the Oven.

In no event shall The Fire Brick Company be responsible for any incidental or consequential damages caused by defects in its Ovens,

whether such damage occurs or is discovered before or after replacement or repair, and whether or not such damage is caused by The Fire

Brick Company’s negligence. Some regions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. The duration of any implied warranty with respect to this Oven is limited to the duration of

the foregoing warranty. Some regions do not allow limitations on how long an implied warranty lasts, so the above may not apply to you.

INVESTIGATION OF CLAIMS AGAINST WARRANTY

The Fire Brick Company reserves the right to investigate any and all claims against this Warranty and to decide upon method of settlement.

HOW TO REGISTER A CLAIM AGAINST WARRANTY

In order for any claim under this Warranty to be valid, The Fire Brick Company must be notied of the claimed defect in writing or by

telephone to The Fire Brick Company, Factory 11/167 Princes Hwy Hallam, Victoria 3803, Australia. Claims against this Warranty in writing

should include the date of installation, and a description of the defect.

Limited Warranty

13

D95 Layout Drawing

115 mm

Fire Brick Dome Wall

50 mm

Ceramic Fibre Insulation

50 mm

Perlite Render Insulation

7 inch

Stainless Steel Flue

950 mm

Internal Diameter

500 mm

540 mm

~ 150mm

Center of Flue

1380 mm

Overall Width

1475 mm

Overall Depth

50 mm

Fire Brick Tile Floor

PreCast Flue

Gallery

50 mm

Calcium Silicate Board

50 mm

Ceramic Fibre Insulation

50 mm

Perlite Render Insulation

115 mm

Fire Brick Dome Wall

1050 mm

Flue Height

695 mm

Oven Height

~ 790 mm

External Dome Height

475 mm

Internal

Dome Height

335 mm 345 mm

Layout Drawing

14

All of the bricks come

cut and ground to

size. We provide you

with templates, CNC

machined formwork, a

trammel tool, breglass

dome form and much

more. Your job is to

assemble the kit like a

big Lego set.

Kit Contents

15

Kit Contents

What’s In the Kit

CALCIUM SILICATE BOARD

3 x Calcium Silicate Boards 1000x615x50mm

This is the 50mm thick insulation board layer that you will install underneath your oven; it comes with printed

paper templates & drawing pins so that you can pin the templates onto the CalSil board and cut out the pieces

you need, following the lines shown on the paper templates.

REFRACTORY CASTABLE

1 x Novaref Refractory Castable 25kg bag

Refractory Castable is premixed high temperature concrete, which you’ll use to pour the dome keystone.

FIRE BRICKS - OVEN DOME

All bricks for the Oven Dome are provided, carefully cut to keep the internal gaps on the inside face of the oven

to a minimum. These re bricks are 38% Alumina, rated to 1350°C and are 115mm thick.

FIRE BRICKS - FLOOR TILES

The Floor Tiles are all cut to size and ready to lay; the center tile has a 3mm hole pre-drilled in the center for

the trammel tool to lock into. The re bricks used in the oven oor are 38% Alumina, rated to 1350°C with an

exceptionally hard wearing surface, and are 50mm thick.

FIRE BRICKS - ENTRY & VENT ARCHES

The bricks for the Entry and Vent Arches that form the mouth of the oven are all cut to size from 38% Alumina

re bricks rated to 1350°C, ready to lay.

The Entry Arch Bricks (the opening into the dome) are machine-ground on their back face to follow the curvature

of the dome, to give you a smooth transition from the dome into the opening.

The Vent Arch Bricks are carefully selected as these will be on display at the front of the oven. They are all cut

to size, and are designed to lock into the Entry Arch for strength and stability.

FORMWORK - ENTRY & VENT ARCHES

We provide CNC machined timber formwork with your kit to construct the Entry and Vent Arches around, to

ensure that your brickwork is exactly as per our design. The Formwork is clearly marked to help you position

the arches accurately, and has machined markings showing the location and thickness of each mortar joint.

TRAMMEL TOOL

The trammel is a tool that you will clamp each dome brick into, enabling you to lay the dome bricks in a perfect

hemisphere. It has a hardened pin in the base that ts into the 3mm hole drilled in the center tile.

What’s Inside the Kit

16

What’s In the Kit

FIBREGLASS DOME FORMWORK

To lay the last few rows of bricks in the dome we provide you with a breglass dome form, made to the same

curve as the oven dome. It comes with a round timber support, to spread the load when you jack it into position.

HYBRID REFRACTORY BEDDING MORTAR

Dry Airset Refractory Mortar: 1 x 20kg bag

This is the mortar you will use to lay the re brick tiles that make up the oven oor. Please be aware that you

will need to mix the Airset mortar with General Purpose Cement, Hydrated Lime and Washed Sand* in the ratio

shown on the bag. This makes a smooth hybrid mortar mix perfectly suited to bedding down re bricks for

oven oors.

REFRACTORY MORTAR (TWO PART MIXTURE)

Refractory Mortar Part A: 3 x 25kg bags

Refractory Mortar Part B: 1 x 25kg bag

This is the mortar you’ll use to lay all of the remaining bricks in the kit. It is rated to ll joints up to 80mm width.

PRECAST FLUE GALLERY

The PreCast Flue Gallery is the molded section that ts over the brick arches at the front of the oven. Made

from refractory castable and reinforced with stainless steel bres, it’s tted with 7” Stainless Steel Flue sleeve,

ready to attach the ue section onto. A brushed stainless steel ring covers the ue expansion joint.

CERAMIC FIBRE BLANKET

One full roll and one half roll of 25mm thick Ceramic Fibre Blanket are provided, which will give you two full

layers over your brick dome for 50mm coverage which is precisely what we recommend.

PERLITE RENDER

LiteFill Perlite: 2 x 100L bags

This is the material you will use to cover the Ceramic Fibre Blanket layer, which you will be mixing with GP

Cement, Hydrated Lime and Washed Sand* to make a high-build Render mixture. There is enough Perlite in

the kit to build up a 50mm shell of render over the oven dome, with plenty left in reserve if some is wasted on

accident.

* Sand, Hydrated Lime and GP Cement are available at hardware stores and need to be purchased in addition to the kit.

STAINLESS STEEL FLUE & HAT

1 x 7” Stainless Steel Flue - 900mm Length 1 x 7” Stainless Steel Cowling

Kit Contents

17

Kit Contents

What’s In the Kit

ACRYLIC ROLL-ON BASECOAT RENDER

1 x 5L MAC ‘Rustic Roll-On’ Acrylic Render (White Basecoat)

This is the membrane coating that you will apply over the outer dome, once the oven has been completely

cured and all moisture has been driven out. It gives the dome a good waterproof basecoat which can be rolled

over with more roll-on render, or other similar exterior acrylic coating. It can be tinted at most paint stores.

OVEN DOOR

The nal part of your kit is our Stainless Steel oven door, coated in a satin black nish. The handles are

beautiful oiled hardwood, with solid stainless steel rings top and bottom. The door comes with a vacuum

sealed temperature gauge accurate to 550°C (packed inside the bag of extras within the door box).

EXTRA ITEMS PROVIDED

• Plastic Strips to support the Timber Formwork • 12 x 125mm Nails

• Roll of Chicken Wire & Galv Tie Wire • 25 x 100mm Phillips Head Screws

• 2 x Long Sleeve ‘Vet Examination’ Gloves

OPTIONAL EXTRAS

WATERPROOFING SYSTEM

Roll of 150mm wide Aluminium Flashing and 1 x Cartridge of Sikasil High Temperature Silicone

To prevent rain being drawn into the oven from beneath the outer dome (the perlite render layer), install our

waterproong system around the oven perimeter prior to rendering. Only needed for outdoor installations.

HIGH TEMP SPRAY PAINT FOR PRECAST FLUE GALLERY

Spray can of PPG Temptec 328 in Satin Black. Great for painting the Flue Gallery to make it look sharp.

OVEN WALL TEMPERATURE PROBE WITH THERMOWELL

250mm Temperature Gauge with Stainless Steel Thermowell that can be mounted through the oven wall.

POLISHED GRANITE LANDING

Polished Granite sections cut to t around the Vent area, giving you somewhere to pull out heavy roasting trays

to check on your cooking. Also an important surface to allow you to use your Oven Door as a Draft Door.

STAINLESS STEEL WRAP

2mm thick, brushed Stainless Steel Wrap to cover exposed oor sections around the Vent area.

18

Additional Tools & Materials Required

ADDITIONAL MATERIALS REQUIRED

• 3 x 20kg Bags GP (General Purpose) Cement

• 1 x 20kg Bag Hydrated Lime

• 3 x 20kg Bags Washed Sand

• Household aluminium foil

• Masking Tape

We don’t put these items in the kit for several reasons – they add a signicant amount of weight (which takes

the kits over 1000kg, greatly increasing the cost of freight), they’re available at all good hardware stores, and

we nd that some of our customers already have these materials on hand.

TOOLS REQUIRED

• Trowel

• Small Plastic ‘Flexi’ Tub for mixing Mortar & Castable

• Large Plastic ‘Flexi’ Tub OR a Wheelbarrow for mixing Perlite render

• Jigsaw with wood cutting blade

• Drill/driver for putting in screws

• Level

• Straight Edge (can be a straight piece of timber or metal)

• Stanley knife/scissors

• Car Jack

• Sponges, scourers & rags, old towel

• Angle grinder with masonry grinding disk

SAFETY GEAR REQUIRED

• Safety Glasses

• Ear Muffs

• Heavy duty rubber ‘washing up’ gloves (two pairs recommended, so that you always have a dry pair)

• P2 or equivalent rated Dust Mask

• Suitable clothing

• Safe access to climb onto your oven stand & fall prevention if working at height

Addition Tools & Materials Required

19

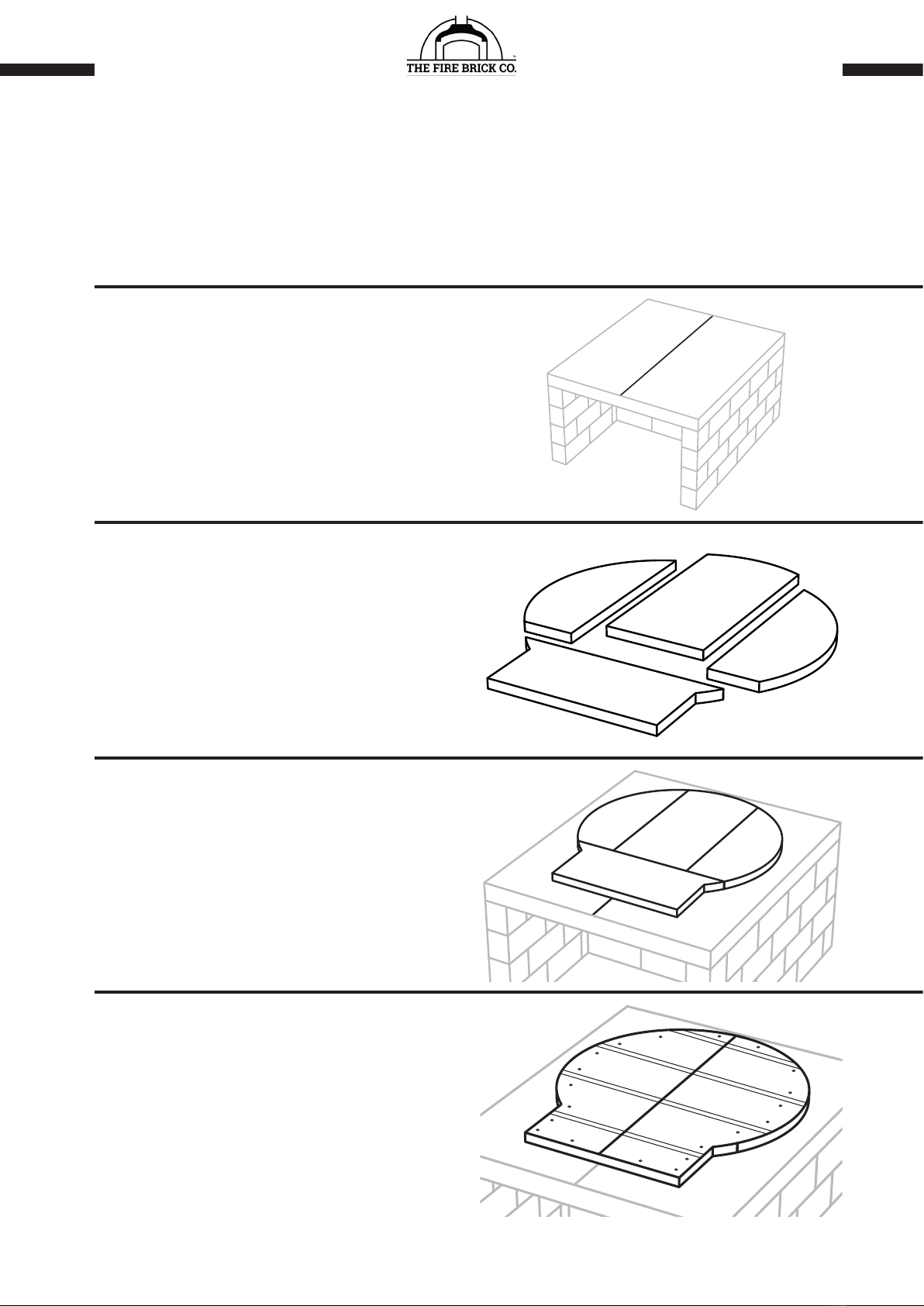

1. Suboor Insulation

The rst step in building your oven is to prevent the heat in the oven oor from being conducted into your

concrete slab, and from there into the surrounding air to be lost forever. We use Calcium Silicate (CalSil) board

to do this, as it has excellent insulating properties, great compressive strength and is easy to work with.

1A: MARK CENTER LINE

Draw a line down the center of your top slab, this is

used to make sure your CalSil board and ultimately

your whole oven is positioned correctly, in the center

of your stand.

1B: CUT OUT CALSIL BOARD USING TEMPLATES

Using the provided paper templates, cut out your

CalSil board pieces using a jigsaw. We have provided

you with thumbtacks to hold the templates to the

CalSil surface.

1C: LAY CALSIL BOARD PIECES ON THE SLAB

Using the center line on your slab and the

corresponding line on the templates, position your

CalSil board pieces on your slab. There is no need to

‘glue’ these pieces down as the weight of the nished

oven will hold them in place.

If your concrete slab is at and level, you can lay the

CalSil directly onto the slab. If your slab is uneven use

a thin layer of brickies sand to bed the CalSil down, to

ensure that it’s uniformly supported.

Suboor Insulation

1D: COVER CALSIL WITH FOIL

Cover the top surface of the CalSil board with

aluminium foil, using the drawing pins provided.

Cover the joins with paper masking tape, this makes

the foil surface stronger and less likely to tear.

Transfer the centerlines that you had previously

marked onto your oven stand onto the foil layer.

20

2. Laying the Floor Tiles

Fire bricks are very porous and will absorb a signicant amount of water, so if you apply wet mortar to a dry

re brick this mortar will dry out and will not develop a good bond. To overcome this, soak your re bricks in

water for at least 10 minutes before you lay them. Take the bricks out of the water shortly before you need

them, then when you grab a brick to lay, give it a dry on a towel or rag to remove any excess surface moisture.

You’ll be using the Hybrid Refractory Bedding Mortar mix shown below to bed the tiles down and get them at.

Remember - WEAR RUBBER GLOVES. This mortar is alkaline and can cause chemical burns!

HYBRID REFRACTORY BEDDING MORTAR MIXTURE

• 2 PARTS AIRSET REFRACTORY MORTAR

• 2 PARTS WASHED SAND

• 1 PART GP (GENERAL PURPOSE) CEMENT

• 1 PART HYDRATED LIME

These measurements are by volume (i.e. 2 cups Airset, 2 cups sand, 1 cup hydrated lime, 1 cup cement). Mix

well while dry, before adding enough water to make a smooth, thick mixture. Take a small trowel of the mortar

and hold it upside down, it should stick to the trowel. The pot life of this mix is around 20 minutes.

Get all of your oor tiles soaking in water, and mix up some mortar. Only prepare one small area at a time,

enough to lay a single tile. If you try to mortar a large area it will dry out before you have a chance to lay the tiles.

Spread a layer approximately 10mm thick on the top of the heat bank. Use your ngers to notch this mortar

mixture, to bed your tile into.

We designed the layout of the CalSil board to be about 20mm larger than the oor tiles all the way around the

perimeter of the oven oor, so that there is some tolerance on the positioning of your oor tiles. The extra area

extending around the dome of the oven will be covered by the insulating blanket and render layers, while the

sections protruding under the front and sides of the oven oor can either be cut back using an angle grinder if

you’re installing a stainless wrap to the exposed edges, or left in place and covered when a landing is installed.

Reminder - you need to watch the instructional videos to get a full understanding of the process, please don’t

rely on these written instructions alone. Don’t feel like you need to watch them all at once - just watch the

section that you’re about to do before you do it, so that it’s fresh in your mind.

Laying the Floor Tiles

Table of contents

Other The Fire Brick Oven manuals