The Greenhouse People Silverline Assembly instructions

Please read all information before you begin, some of the tips and techniques may

save you a lot of time and frustration later on. These help sheets should be used in

conjunction with the manufactures instruction manual.

Safety:

Some of the components in this kit may cause injury if not used sensibly. When

handling any of the metal components and during glazing please take care and

wear gloves, goggles and ear protectors when you judge necessary.

Preparation:

Bear in mind that constructing your greenhouse can take

some time, you may need to leave it and come back to it.

The more space available in which to work the better, a

large clean,clear garage floor is ideal or a flat lawn area.

Tidy your work space prior to assembly. This will reduce

the chances of loosing any of the smaller components.

It is a good idea to find a tub for all your nut and bolts etc...

Organising your components:

On opening your main greenhouse box DO NOT UNWRAP

any of the labelled bundles until they are required.

Assess each component in accordance with the parts list.

Separate like from like components.

Tools advise:

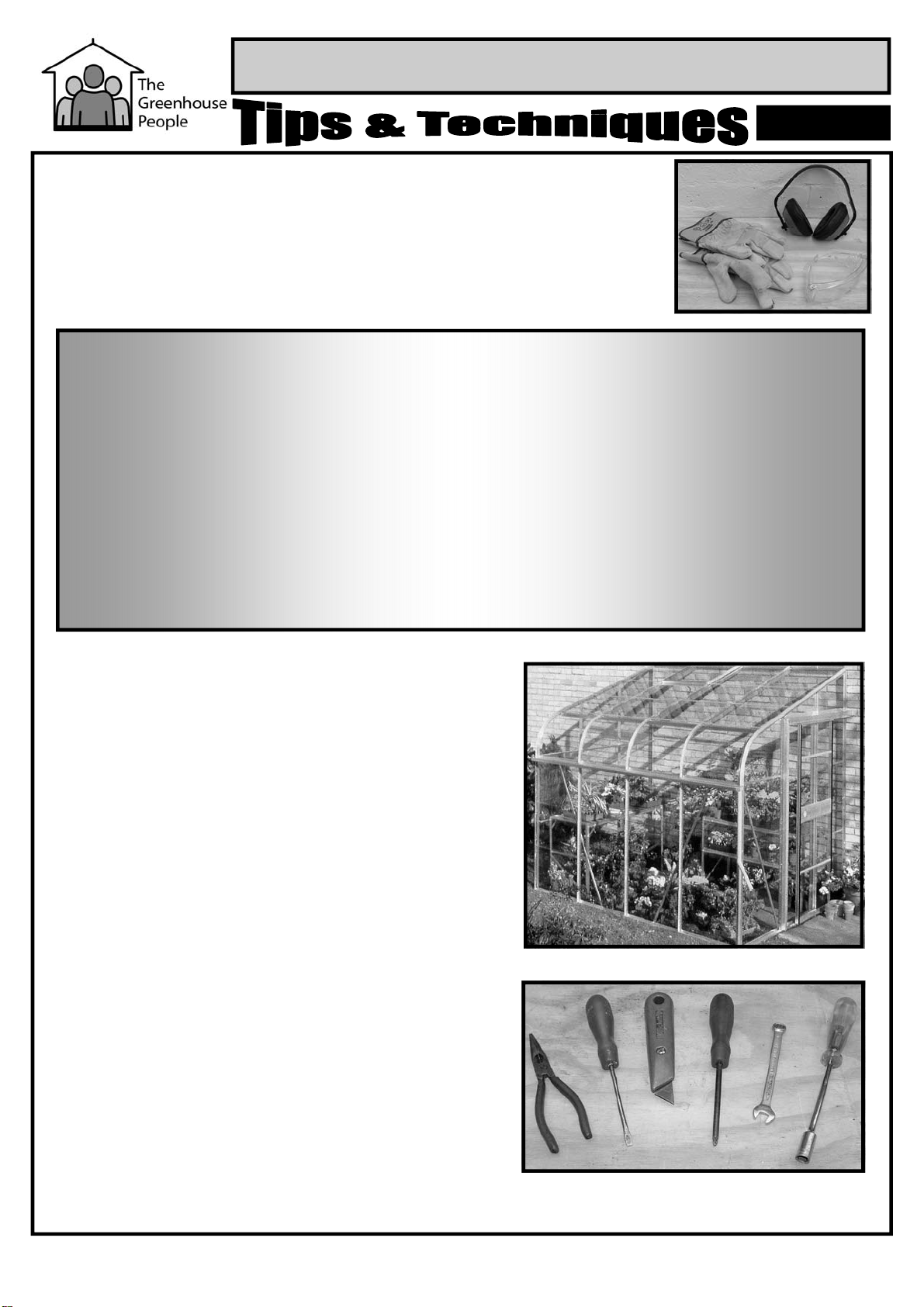

You will save yourself a lot of time by purchasing a 10mm

nut spinner (see picture), it is much quicker and easier to

use than a 10mm spanner (also pictured). You may have

an attachment in a ratchet set that will suit this job.

Other tools that may be may be required are shown in the

picture to the right.

Using the manufacturers manual:

Read the information relevant to each stage of construction

immediately before you begin.

Study each drawing carefully before you begin each stage

of construction.

PTO

Additional help from 'The Greenhouse People'.

Toughened and Horticultural Glass

VERY IMPORTANT INFORMATION:

OUR TOUGHENED GLASS SIZES ARE DIFFERENT FROM THOSE SPECIFIED IN THE MANUFACTURERS

MANUAL. OUR GLAZING PLAN CAN BE FOUND AT THE BACK OF THESE AMENDMENT SHEETS!

Please take extra CARE handling toughened glass. It is extremely vulnerable to BREAKAGE at the edges and in

particular, the CORNERS. When you are MOVING it, please take care not to brush the EDGES of the glass

against concrete etc.. as it can SHATTER or BREAK very easily. Likewise, it should ALWAYS be stacked on

wooden bearers, or cardboard, or carpet, or anything to avoid direct contact with a hard floor.

Once the glass is installed into the frame the whole structure becomes much more RIGID.

The toughened glass in particular is very resilient to face on DAMAGE.

If you are unsure about anything to do with your greenhouse please ring us on 01782 388811.

SILVERLINE

Remember use these hints and tips alongside the manufacturers instruction booklet.

WIND DAMAGE

PREVENTION!

Before you begin to assemble your greenhouse it is a good idea to

workout if any bolts which need to be slid into the glazing bar channels

as instructed in the manual (e.g. bolts for the vertical door bar stiffener

758 shown on page 15 of the manual). This will save you a lot of time

and frustration later on.

Make sure that all of your horizontal and diagonal bracings are located

in the correct holes (see manufacturers manual and internal pictures).

The greenhouse MUST be level and square before you begin glazing.

If not the glass will not fit properly and your door will not slide smoothly.

If you have difficulty inserting the glass try loosening the surrounding

bracings and glazing bars slightly to allow some movement in the

frame.

The black 2' glazing

strips must be used to

fit toughened glass in

the ends not the grey

strips 452 which are

redundant.

The louvre can be

located in either the

back or the side.

Siliconing Tips:

Before glazing it is a good idea to silicone behind

each corner plate 205.

It is also advisable to create a silicone runway where

the curved bars make contact with the gutter. This

helps any water which lands on the roof to run down

the roof glazing bar channels straight into the gutter.

Silicone between each grey glazing strip in your roof.

A bead of silicone should be run across the back

edge of the gutter where it comes in contact with the

curved acrylic panes.

To help prevent your glass from being blown out dur-

ing strong winds it is a good idea to apply some blobs

of silicone around the glazing clips and the corners

of each pane. This will greatly increase the rigidity

of your greenhouse and help it resist more extreme

conditions. In strong winds it is a good idea to shut

roof vents and doors to prevent them being buffeted

and bent out of shape. GUTTER

Silicone =

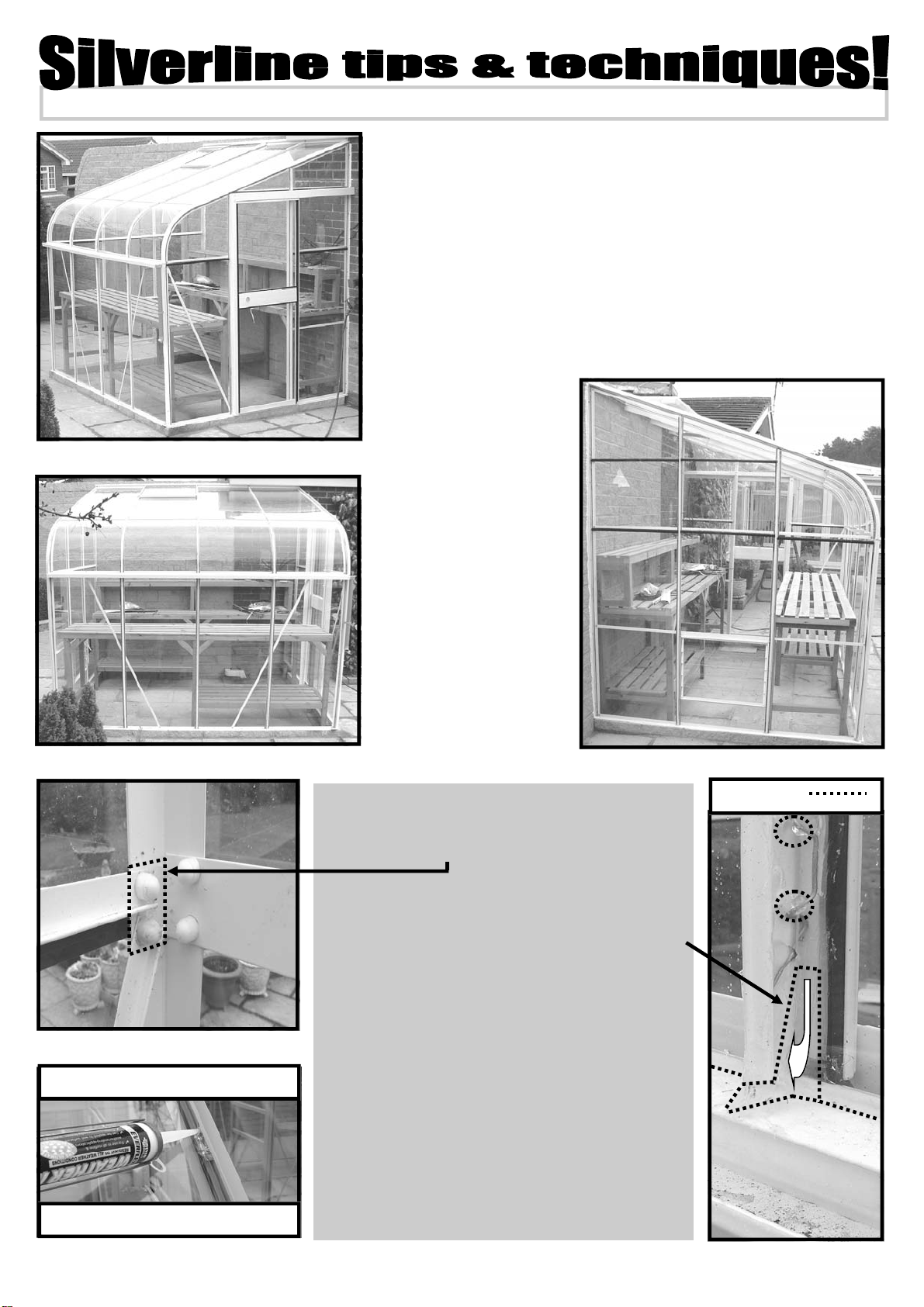

Roof Vent Assembly: (See pictures)

When making the vent it is important to keep flicking between the manual diagrams and the text.

Work a step at a time, studying each diagram closely before you begin.

The rubber can be difficult to insert into the vent frame but using a rubber mallet will help. If you

don't have a mallet available adding some washing-up liquid to the rubber can do wonders.

IMPORTANT Note: For Glass 3.6mm - 4.5mm thick, leave out rubber seal, using silicone as a

replacement on all edges. Erectors tips

Below are some step by step pictures which when used in CONJUNCTION with the manual will

hopefully make assembly a little easier to follow.

Cut rubber seal to fit

each corner when

indicated in the manual.

If you stretch the rubber

from corner to corner cutting each in-turn the

rubber is stretched thinner and there is NO

slack. This allows the vent sides and top to

be pushed on much easier.

Fit roof vent

bottom bar,

centrally

over the

glass and

carefully

knock down

into position.

Fix top bar over glass attach

with screws through the holes in

the left and right vent sides.

Check diagonal measurements

are equal for squareness.

Adjust if necessary and tighten

all screws.

Push the

rubber back

under the

groove with a

flat wooden

edge to tidy up

the rubber

seal.

The vent is now ready to slide into the

ridge. The picture shows the vent as it

will look from the outside of your

greenhouse.

Fit left and

right vent

bars (check

which is which)

over the glass

and screw

corners loosely

at this stage to

the bottom bar.

Each vent

side bar will

extend beyond

the glass and

rubber at the

top so that the

final section of the vent can be put into

place. Cut the seal 138 so that it butts

flush together centrally at the top.

915

896 /897

915 896 / 897

401

138

Glass 610 x 610

C

A

When attaching your window sill bar

into the roof of your Silverline make

sure it is the right way round or

the window will not sit properly. SS

If you have any queries please

do not hesitate to call us on

01782 388811.

www.thegreenhousepeople.co.uk

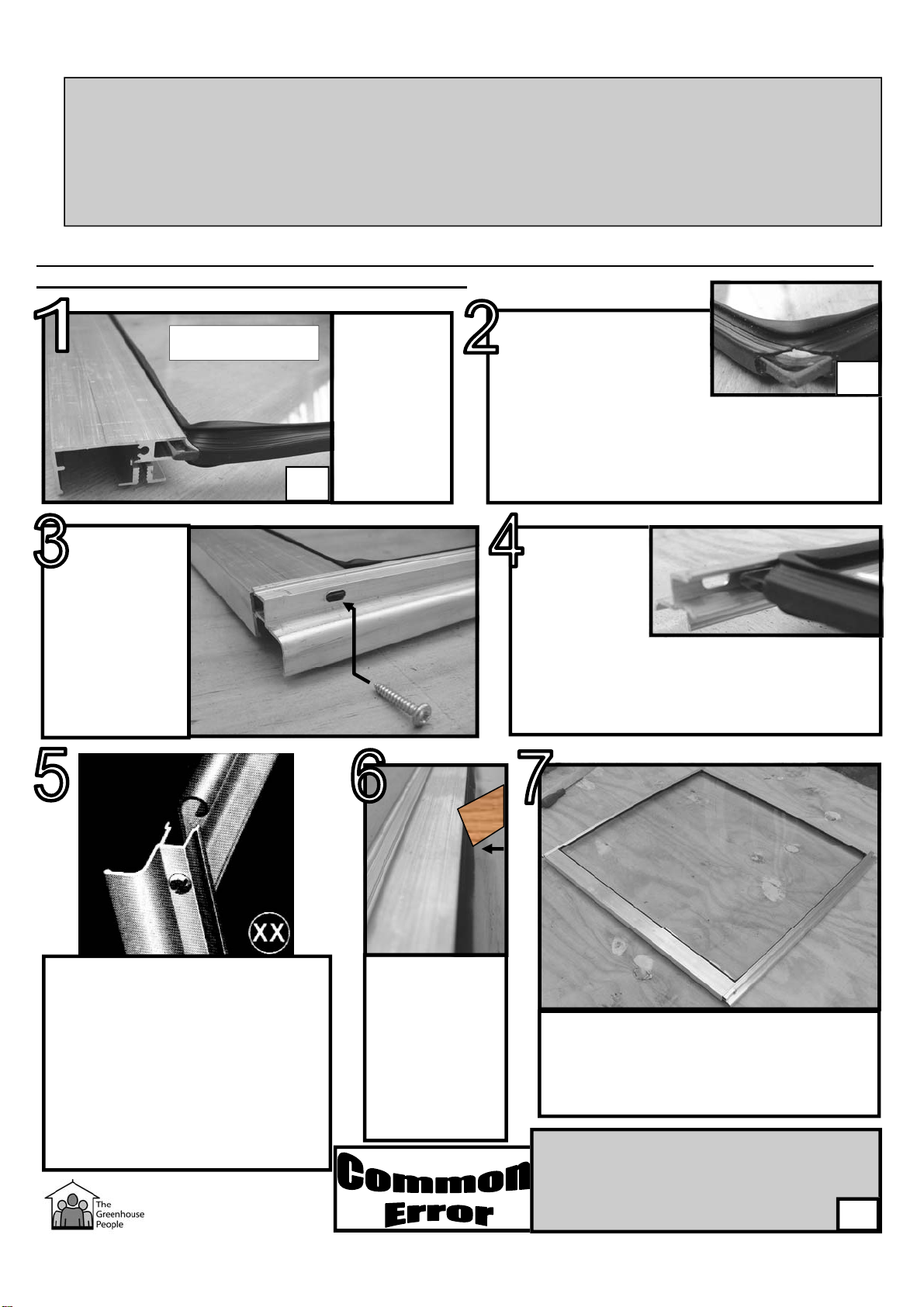

Door assembly and glazing:

The intermediate door bar 986 can be used in

either orientation depending on which end the

door is located.

The glass in the door (toughened glass shown,

note large single panes) is cushioned against the

metal frame by adhesive foam strips. The glass is

stuck onto these strips and secured into position

with the long black plastic 'Door glazing cap' 991.

Each strip needs to be cut to fit the length of the

door. The best way to attach the strips is to lip

them UNDER the outside frame of the door and

press them down onto the surface of the glass

(see diagram to the right). It can be difficult to

insert the strip, a flat screwdriver can be used to

tease the cap into position.

986

Door track:

Part 758 is shown in the manual the wrong way

round because of the door end bracings. It can

only fit on one way and that is opposite to the S

diagram (page 15) the manufacturer has shown.

The Pictures far left show the bar the correct

way up.

It is a good idea to use WD40 in your door track

and door track sill to make the door glide easily.

The door needs to be slid onto the door track

before you attach part 757 which acts as a door

stop and a draft excluder.

991

991

758

757

974

758

Door lock:

The Silverline is primarily

designed to be fitted onto a

wall with a door. Because

of this the lock is designed

to fit on the inside of the

greenhouse to stop access

from the outside.

It is important however to stop the door blowing

open in the wind when unattended. Leaving the

door open in high winds can result in the glass being

blown out. The easiest and cheapest way to secure

the door is to shut the door and drill a hole in the

door track for a padlock to slide through.

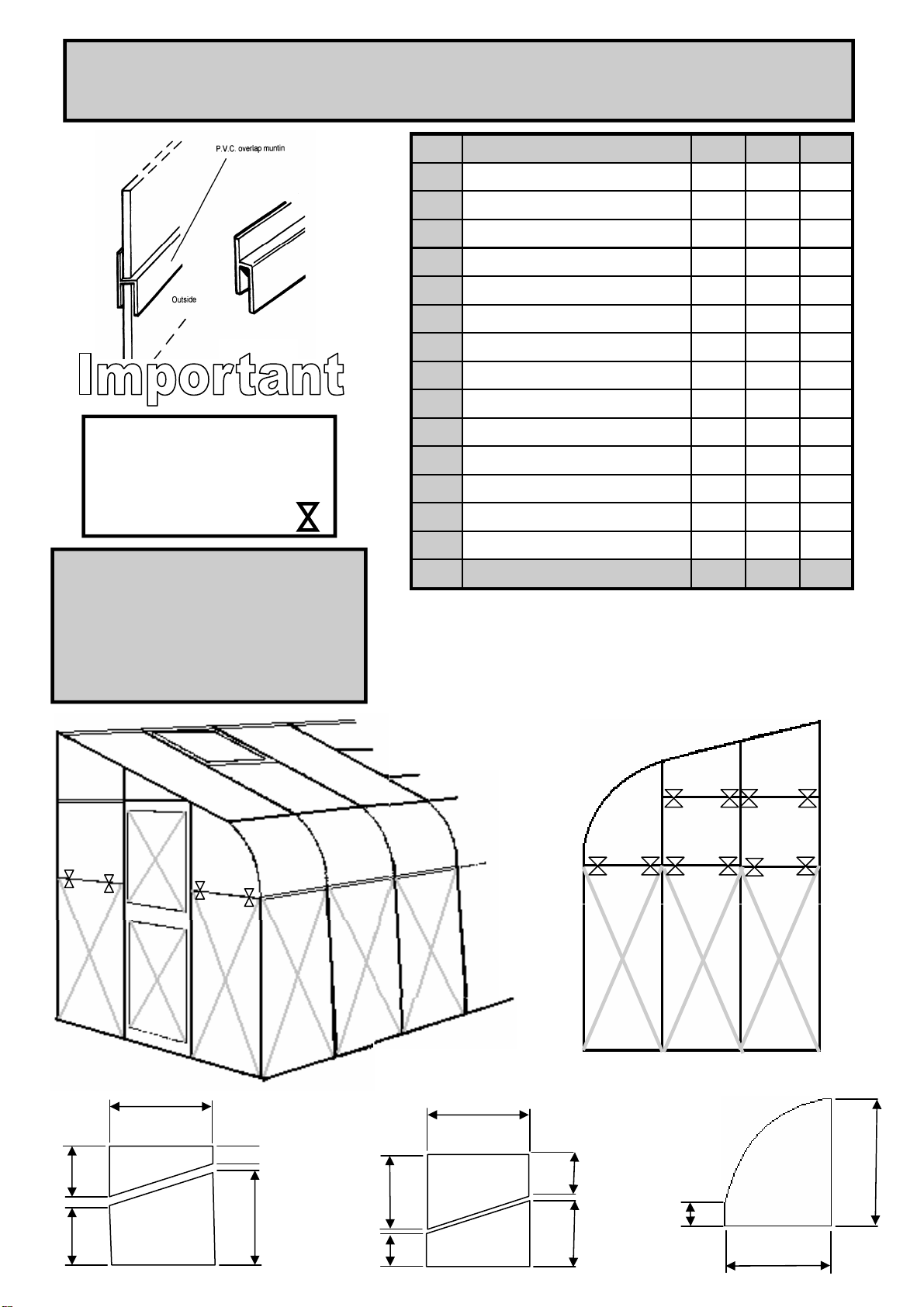

Glazing Plan for Silverline lean-to glazed with large pane

TOUGHENED glass. Use this plan, not the one in your manual.

Code Size (mm) 8x6 10x6 12x6

A 610 x 610 1 2 2

C 610 x 457 2 2 2

D 610 x 525 1 1 1

E As drawing 1 1 1

G As drawing 1 1 1

H As drawing 1 1 1

K 610 x 610 2mm plastic 4 5 6

J Curved Glass 610 x 535 2 2 2

L 610 x 1660 3 3 4

P As drawing 1 1 1

R 610 x 995 1 2 2

BB 610 x 1345 9 10 11

HH 610 x 764 1 1 1

JJ 610 x 916 1 1 1

TOTAL 29 33 36

P

H

288 200

610

6

482

283 195

610

91 389

E

G 610

49

535

J

BB BB BB

C C

G H

J

BB BB BB BB BB

D

JJ

HH

E

K

K

K

L R

A L

J

Pictured above 2’ long black

plastic Muntins. Use these

strips where indicated on the

diagrams to join together panes

of glass. The Muntins are

indicated with a;

FOR LOUVRE WINDOW

REPLACE 1 x BB (610 x 1347)

WITH 1 x A (610 x 700)

+ 1 x 610 x 200

+ 5 x 573 x 100 (Louvre glass)

IMPORTANT: A Louvre MUST go

in-between the two make-up panes.

P

Base

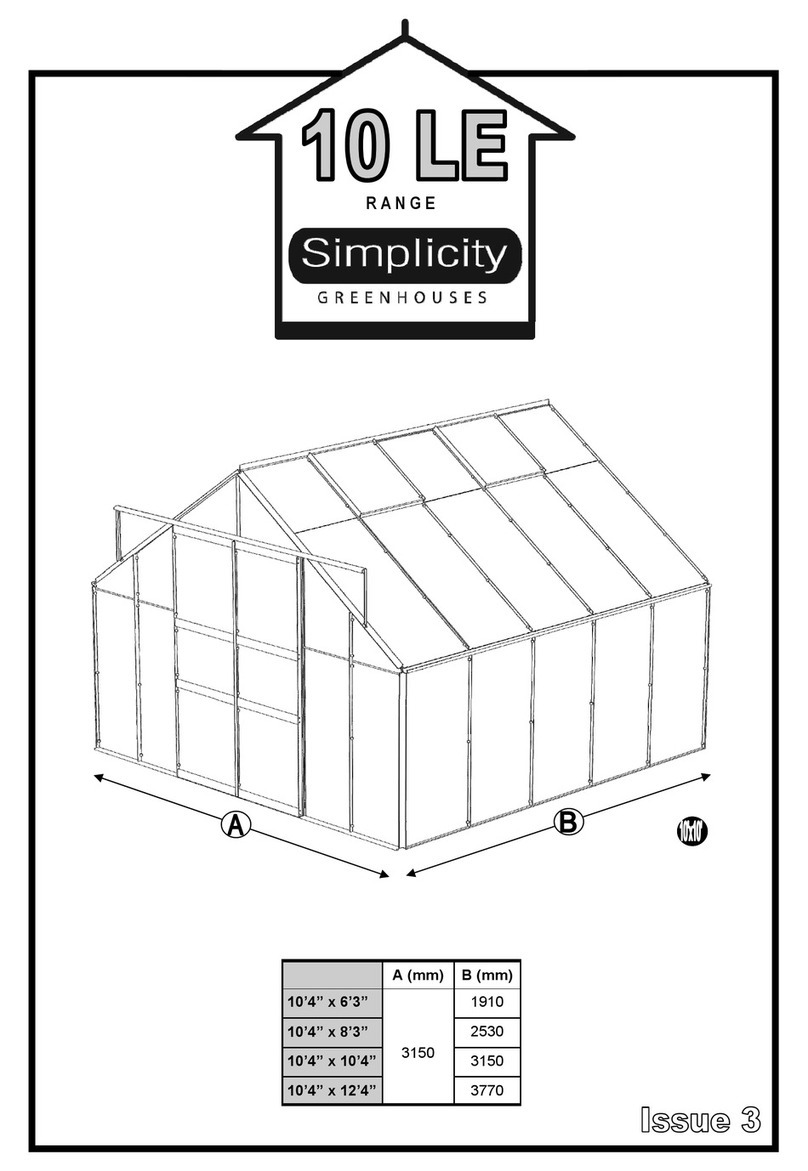

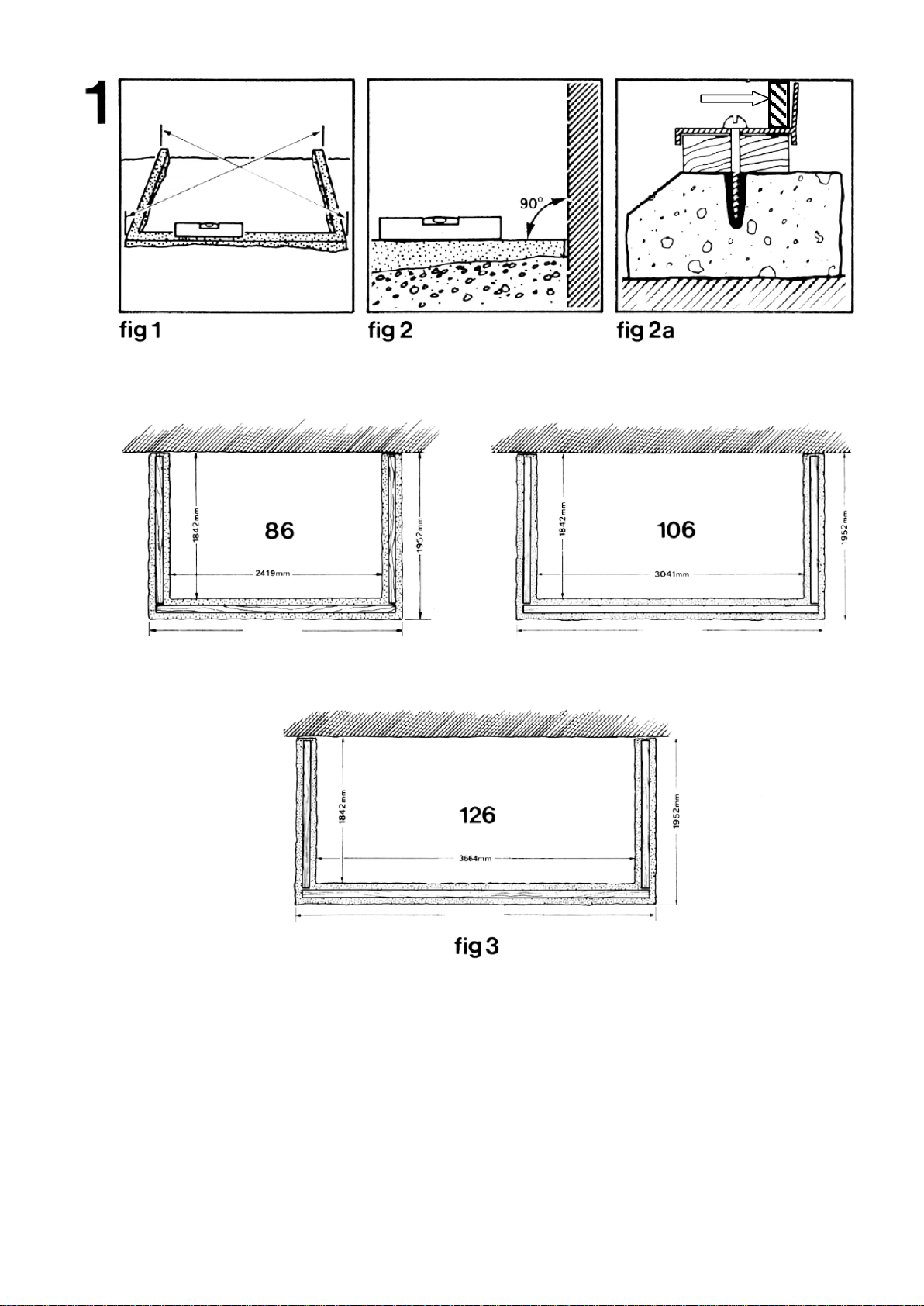

You need a base for your greenhouse to ensure that it is level and rigid. To save time and trouble in laying a

traditional brick or concrete base, Halls can supply a simple-to-assemble prefabricated base as an optional extra.

However, if you want to make your own base you should make it to the dimensions in fig. 3. It is most

important that the base is square and level so check that its diagonal measurements are equal as in fig. 1 and

that the angle between the wall and the base is 90ᵒas in fig. 2. Tanalised timber packing of not less than 12mm

thickness and not more than 30mm width should be made to fit the aluminium section, as shown in fig. 2a.

When the greenhouse has been assembled, it can be screwed to the base with no. 12 screws and rawlbolts (not

supplied) through the sill bar (not pre-drilled) in fig. 2a.

IMPORTANT

If you wish to erect your greenhouse on a solid concrete plinth, you should follow the outside dimensions in fig.

3. However it is important to avoid any possibility of water seeping under the base forming puddles. You should

ensure that the base slopes down towards the outside of the greenhouse. The timber packing will have to be

suitably tapered.

N.B. These diagrams are only if you are building your own base as opposed to buying the

prefabricated optional base, which is the easiest option.

GLASS

2635mm

3880mm

3257mm

4

Other The Greenhouse People Greenhouse Kit manuals

Popular Greenhouse Kit manuals by other brands

ModuLaro

ModuLaro AIGLE GH202020 Assembly instruction

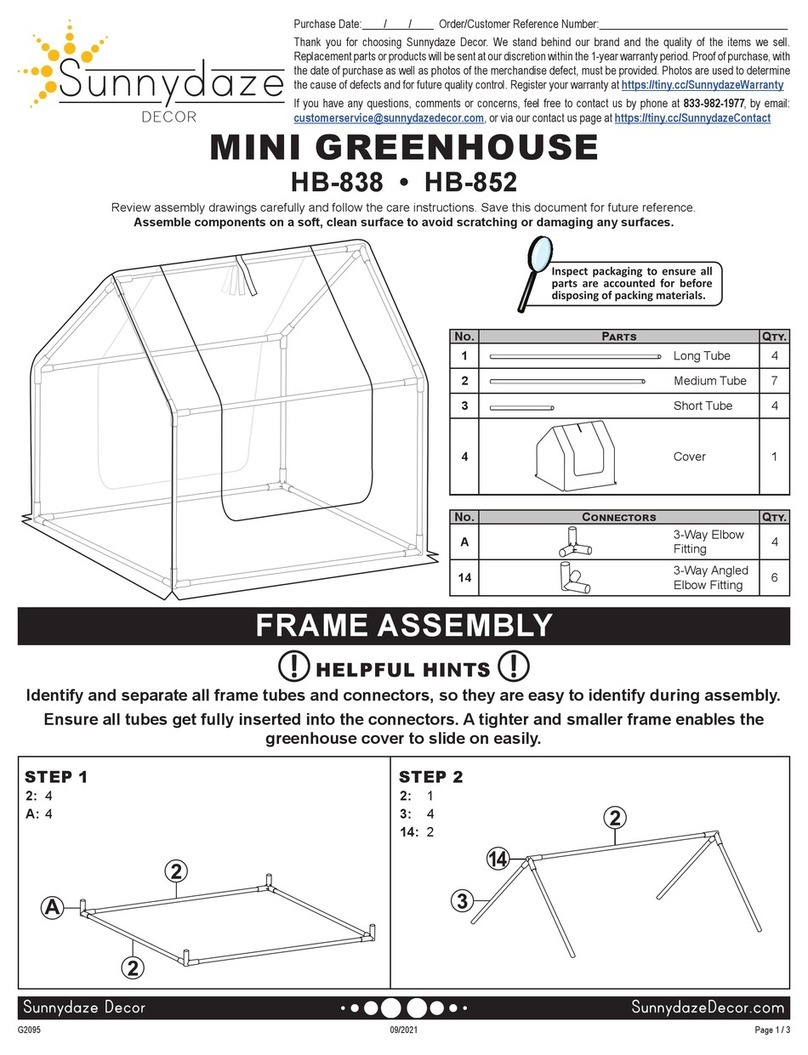

Sunnydaze Decor

Sunnydaze Decor HB-838 Assembly instructions

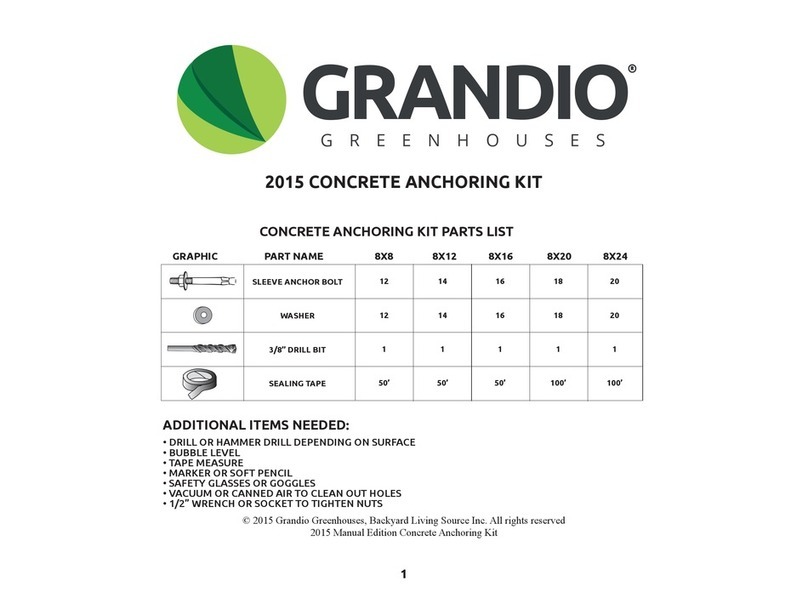

Grandio

Grandio 2015 quick start guide

harvst

harvst Harvster user manual

FarmTek

FarmTek Growers supply GrowSpan Gothic Pro instruction manual

Palram

Palram CANOPIA HARMONY 701634 How to assemble