Thermo Forma 3771 Operating instructions

Millcreek Road, P.O. Box 649

Marietta, Ohio 45750

U.S.A. Telephone: (740) 373-4763

Telefax: (740) 373-4189

Models:

3771 / 3772 3773 / 3774

3775 / 3776 3777 / 3778

3779 / 3780 3785 / 3786

3787 / 3788

Laboratory and Chromatography

Refrigerators

Operating and Maintenance Manual

Manual No. 7003771 Rev. 3

Read this Instruction Manual

Failure to read, understand and follow the instructions in this manual may result in damage to the unit,

injury to operating personnel, and poor equipment performance.

Caution: Any internal adjustments and maintenance must be performed

by qualified service personnel.

51-1483-05 Rev. A

ThermoForma

DoYou Need Information or Assistance on

Thermo Forma Products?

If you do, please contact us 8:00 A.M. to 7:00 P.M. (Eastern Standard Time) at:

1-740-373-4763 Direct

1-888-213-1790 Toll Free, U.S. and Canada

1-740-373-4189 FAX

http://www.forma.com Internet Worldwide Web Home Page

Our Sales Support staff can provide information on pricing and give you quotations. We

can take your order and provide delivery information on major equipment items or make

arrangements to have your local sales representative contact you. Our products are listed on the

Internet and we can be contacted through our Internet home page.

Our Service Support staff can supply technical information about proper setup, operation or

troubleshooting of your equipment. We can fill your needs for spare or replacement parts or pro-

vide you with on-site service. We can also provide you with a quotation on our Extended

Warranty for your Thermo Forma products.

Whatever Thermo Forma products you need or use, we will be happy to discuss your appli-

cations. If you are experiencing technical problems, working together, we will help you locate

the problem and, chances are, correct it yourself... over the telephone without a service call.

When more extensive service is necessary, we will assist you with direct factory trained

technicians or a qualified service organization for on-the-spot repair. If your service need is

covered by the warranty, we will arrange for the unit to be repaired at our expense and to

your satisfaction.

Regardless of your needs, our professional telephone technicians are available to assist you

Monday through Friday from 8:00 a.m. to 7:00 p.m. Eastern Time. Please contact us by tele-

phone or fax. If you wish to write, our mailing address is:

Thermo Forma

Millcreek Road, P.O. Box 649

Marietta, OH 45750

International customers please contact your local Thermo Forma distributor.

SECTION I

General Information

THEMO FORMA MODELS

PART # MODEL # MODEL TYPE CUBIC FEET DOOR TYPE VOLTAGE

52-1996-33 3771 Refrigerator 27.3 1 Glass Hinged 115

52-1996-34 3772 Refrigerator 27.3 1 Glass Hinged 220

52-1996-35 3773 Refrigerator 27.3 1 Solid Hinged 115

52-1996-36 3774 Refrigerator 27.3 1 Solid Hinged 220

52-1996-37 3775 Refrigerator 49.1 2 Glass Hinged 115

52-1996-38 3776 Refrigerator 49.1 2 Glass Hinged 220

52-1996-39 3777 Refrigerator 49.1 2 Solid Hinged 120

52-1996-40 3778 Refrigerator 49.1 2 Solid Hinged 220

52-1996-41 3779 Refrigerator 76.2 3 Glass Hinged 115

52-1996-42 3780 Refrigerator 76.2 3 Glass Hinged 220

52-1996-43 3785 Chromatography 27.3 1 Glass Hinged 115

52-1996-44 3786 Chromatography 27.3 1 Glass Hinged 220

52-1996-45 3787 Chromatography 49.1 2 Glass Hinged 115

52-1996-46 3788 Chromatography 49.1 2 Glass Hinged 220

Except for routine cleaning, these medium tem-

perature cabinets will require little maintenance.

In the unusual event that repair should be neces-

sary, this manual presents information that is

helpful in maintaining, diagnosing, and repairing

these cabinets.

TABLE OF CONTENTS 3

TABLE OF CONTENTS

SECTION I - GENERAL INFORMATION

Handling & Installation ............................................ 5

Condensate Pan Installation .................................... 6

Cabinet Startup ........................................................ 6

Export Models .......................................................... 6

Dimensional Drawings ............................................ 7

Med. Temp., Top Mount, Glass, Pull Door Refrig.

Specifications .......................................................... 8

Med. Temp., Top Mount, Glass, Pull Door Refrig.

Dim. Drawings / Specifications ................................ 9

Med. Temp., Top Mount, Solid, Pull Door Refrig.

Grounding Instructions .......................................... 10

Serial Rating Plates .............................................. 10

COMPONENT IDENTIFICATION

Condensing Unit Assembly Component Ident. ...... 11

Models: 3771 / 3773 / 3777 / 3785 &

Export Models: 3772 / 3774 / 3778 / 3786

Condensing Unit Assembly Component Ident........ 12

Models: 3775 / 3787 &

Export Models: 3776 / 3788

Condensing Unit Assembly Component Ident........ 13

Models: 3779

Export Models: 3780

Evaporator Coil Assembly Component Ident.......... 14

Models: 3771 / 3773 / 3775 / 3777 / 3779 / 3785 / 3787

Export Models: 3772 / 3774 / 3776 / 3778 / 3780 / 3786 / 3788

Evaporator Fan Shroud Assem. Comp. Ident ........ 15

Models: 3775 / 3777 / 3779 / 3787

Export Models: 3776 / 3778 / 3780 / 3788

Electrical Box Assembly Component Ident ............ 16

Models: 3771 / 3773 / 3775 / 3777 / 3779

3787

Export Models: 3772 / 3774 / 3776 / 3778

3780 / 3788

Start Kit Component Ident...................................... 17

Side Light Assembly Component Ident .................. 18

Models: 3771 / 3785 &

Export Models: 3772 / 3786

Mullion Light Fixture Assembly Component Ident.. 19

Models: 3775 / 3779 / 3785 / 3787

Export Models: 3776 / 3780 / 3786 / 3788

SECTION II - ELECTRICAL &

REFRIGERATION INFORMATION

REFRIGERATION SPECIFICATIONS

Med. Temp., Glass & Solid, 1-Door Ref. ................ 23

Models: 3771 / 3773 / 3785 &

Export Models: 3772 / 3774 / 3786

Med. Temp., Glass & Solid, 2-Door Ref. ................ 24

Models: 3775 / 3777 / 3787

Export Models: 3776 / 3778 / 3788

Med. Temp., Glass, 3-Door Ref. ............................ 25

Model: 3779 &

Export Model: 3780

CONTROL ANNUCIATOR PANEL INFORMATION

Control Panel Layout ............................................ 26

General Information / Optional Alarm System ...... 27

Chart Paper Change / Pen Replacement .............. 28

Temp. Recorder Calibration .................................. 29

Battery Backup ...................................................... 29

Alarm/Control Relay .............................................. 29

Set Control Point .................................................... 29

Cobex Model #C-921 ............................................ 30

WIRING DIAGRAMS page .................................. 31

Control Panel page ........................................ 32

Transformer Layout - Export .................................. 33

Temperature Probe Bottle Instructions ....................34

4 TABLE OF CONTENTS

TABLE OF CONTENTS -

continued

SECTION III - MAINTENANCE & REPAIR

General Maintenance & Repair .................................. 37

Service Information ...................................................... 37

Compressor Installation .............................................. 39

COMPONENT REPLACEMENT

Evaporator Drain Pan ............................................ 41

Thermostat ............................................................ 42

Evaporator Fan Motor ............................................ 43

Cam Hinge Doors (Solid Doors Only) .................... 44

Cabinet Center Mullion Heated .............................. 45

Torsion Rod Hinged Doors (Glass Doors Only) .... 46

Door Gasket .......................................................... 47

Metering Device .................................................... 48

Condenser Fan Motor ............................................ 49

Master Power Supply Switch ................................ 50

Light Switch .......................................................... 51

Digital Thermometer Battery Replacement ............ 51

Ballast .................................................................... 52

Fluorescent Bulb .................................................... 53

Touch-up Paint ...................................................... 54

Cleaning ................................................................ 55

TROUBLESHOOTING GUIDES

Machinery .............................................................. 56

Compressor .......................................................... 59

Fluorescent Lamp .................................................. 61

Measuring Starting Lamp Voltage ........................ 63

SECTION IV - PARTS LISTS

Replacement Parts List............................................67

Accessories ............................................................ 69

Lab & Pharmacy Refrigerators/Freezers &

Chromatography Refrigerators Warranty .............. 71

Lab & Pharmacy Refrigerators/Freezers &

Chromatography Refrigerators

International Dealer Warranty ................................ 72

DUE TO CONTINUING PRODUCT IMPROVEMENTS, ALL DATA AND INFORMATION INTHIS MANUAL IS SUBJECT TO CHANGE WITH-

HANDLING & INSTALLATION

GENERAL INFORMATION 5

FREIGHT DAMAGES & SHORTAGES

IMPORTANT

The cabinet was inspected and packaged at the

factory, and should arrive in excellent condition.

The transportation company or other parties

involved in the shipment are responsible for loss

and/or damage. Always make an inspection

before and after uncrating. Inspect the crated

units before locating (preferably at the point of

unloading by the transportation company).

INSPECTING FOR DAMAGES

Note: Always use care when removing shipping

tape, blocks, pads, hardware or other material

until you are satisfied that the unit is completely

operational. Contact Thermo Forma if technical

assistance is required.

Check the cartons or containers.If these are damaged

in any way, open them and inspect the contents in the

driver’s presence. If damage is detected:

1. Have the driver note the nature and extent of the dam-

age on the freight bill.

2. Notify the transportation company at once to request

an inspection. Carrier claim policies usually require

inspections to be made within 15 days of delivery.

3. If damage is noticed, file a claim with the transporta-

tion company.

FILING A CLAIM

File a claim for loss at once with the transportation com-

pany for: A cash adjustment; Repairs; or Replacement.

When filing your claim, retain all packaging materials

and receipts.

HANDLING THE CABINET

Note:

The refrigeration system of the cabinet is

designed to operate with the cabinet located on a level

surface. Do not tilt the cabinet more than 10° to any

side. If the cabinet must be tilted on an angle for han-

dling or moving purposes, allow it to sit in an upright

position 30 minutes prior to starting.

CHOOSING A LOCATION

This model cabinet should be situated to allow proper air

circulation. These cabinets require a 2" minimum clear-

ance behind and 12" between the top of the cabinet and

the ceiling for proper air circulation.

The cabinet must be installed on sturdy, solid, level floor.

The cabinet must be located so it can be plugged into a

properly grounded three-prong electrical outlet of 115

volt, 60 hz.The electrical outlet should not be controlled

by a wall switch which might be turned off accidentally.

UNCRATING THE CABINET

The cabinet should be moved as close as possible to the

operating location before removing crate base. Be sure

to follow the steps in the “INSPECTING FOR DAM-

AGES”instructions.

INSTALLING THE CABINET

(Models with Top Mounted Compressor)

Whenever possible leave the crate base on the cabinet

until it is moved close to the final position.When it is nec-

essary to move the cabinet through a doorway, it may be

necessary to remove the crate base.

Wood runners are provided on the underside of the cab-

inet for ease in sliding. These runners should be left

attached to the cabinet when the crate base is removed

and should remain attached until after the legs are

installed.The cabinet can then be pushed around more

easily without scratching the floor.The runners also pre-

vent damage to the electrical receptacle and conden-

sate pan hardware on the cabinet bottom.

After the cabinet has been moved to the approximate

final location, remove the package containing the legs

from the cabinet interior. Tape the doors to prevent

accidental opening when handling. Raise the sides of

the cabinet high enough to mount the legs at the loca-

tions provided on the bottom of the cabinet.

IMPORTANT:

AFTER REMOVAL

OF WOOD RUN-

NER, REPLACE

BOLT“A”INTO LEG

MOUNTING

BRACKETS.THIS IS

EXTREMELY

IMPORTANTTO

THE SECURE

ATTACHMENT OF

THE CABINET LEG.

THERE MUST BE

FOUR (4) BOLTS

SECURING EACH

LEG.

Level the cabinet by means of the leg adjustments.

Cabinet doors are self-closing, and the cabinet must be

level to operate properly.

6 GENERAL INFORMATION

CONDENSATE PAN

INSTALLATION INSTRUCTIONS

MAKE SURE THE CABINET IS DISCONNECTED

FROM ITS POWER SOURCE

1. Remove and discard protective cover over electrical

receptacle on bottom of cabinet

2. Bend down front part of housing. (See above.)

3. Insert condensate evaporator pan assembly into the

slide supports on the underside of the cabinet by

pushing toward back of cabinet until it stops.

4. Plug supply cord into receptacle in underside of

cabinet.

5. Bend up front part of housing. Line up slot with

rivnut in cabinet bottom and insert thumbscrew

through slot onto rivnut in cabinet bottom. Insert

thumb screw through slot onto rivnut and tighten.

6.The assembly will now operate when power is sup-

plied to the cabinet.

7. Inspect rear of cabinet to ensure that the drain line

from the evaporator is properly positioned over the

condensate pan.

CABINET STARTUP

Once the cabinet has been located in its permanent

location and the proper power and grounding have

been provided, the following items must be checked or

completed:

1. Cut and remove the compressor hold-down band (if

applicable) so the compressor “floats”freely.

2. Check for traces of oil on the compressor pan which

could mean a broken or leaking refrigeration line.

UNDER NO CIRCUMSTANCE SHOULD THE

COMPRESSOR BE STARTEDWHEN OIL IS PRE-

SENT UNTIL INSPECTED BY A SERVICE TECH-

NICIAN.

3. INSPECT THE FACTORY WIRING FOR

TERMINALS THAT MIGHT HAVE VIBRATED

LOOSE IN SHIPPING. TIGHTEN ALL SCREW-

TYPE TERMINALS.

4. Check the refrigeration lines to see that they are

“free”and no damage was done during shipping.

5. Check fan blade(s) for “free”operation.

6.Turn on the main power switch. Once the compressor

starts, the voltage should be checked at the compres-

sor terminals to determine if there is proper voltage to

the compressor. The voltage should not exceed 10%

above or below the rated compressor voltage.

EXAMPLE: If the voltage reads 115 volts with no load

and it drops below 103 volts when the compressor

starts, it may indicate that the supply wiring is too

small or that the wire run is too long.

7. Make sure that the drain line has not been dis-

lodged or broken during shipping and that the drain

trap terminates properly in the condensate pan or

floor drain. (See Condensate Pan on top mounted

compressor.)

8. Listen for any unusual noise such as lines vibrating,

etc. Correct problem by tightening screws, slightly

bending tubing, etc.

9. Check proper tension on doors. (See Door Torque

Adjustment.)

10. Cabinet should not be loaded with product until

cabinet has operated for 24 hours and reached

desirable storage temperature.

EXPORT MODELS

Export model cabinets come equipped with an auto

transformer located in the unit compartment. The

selector switch can be set to various customer voltage

requirements - Factory Setting: Mid position for an

incoming voltage between 212V and 238V.

PRIOR TO STARTING THE CABINET

Supply voltage must be checked in order to determine

the correct position of the variable voltage switch

located on the auto transformer. This will ensure the

cabinet is operating at the correct optimum voltage. In

the event the transformer supply line plug does not

match the electrical outlet, the plug can be changed to

one with equal voltage-amperage rating.

Refer to page 41 for transformer layout.

DRAIN LINE FROM

EVAPORATOR - SEE

NOTE #7.

SUPPLY CORD

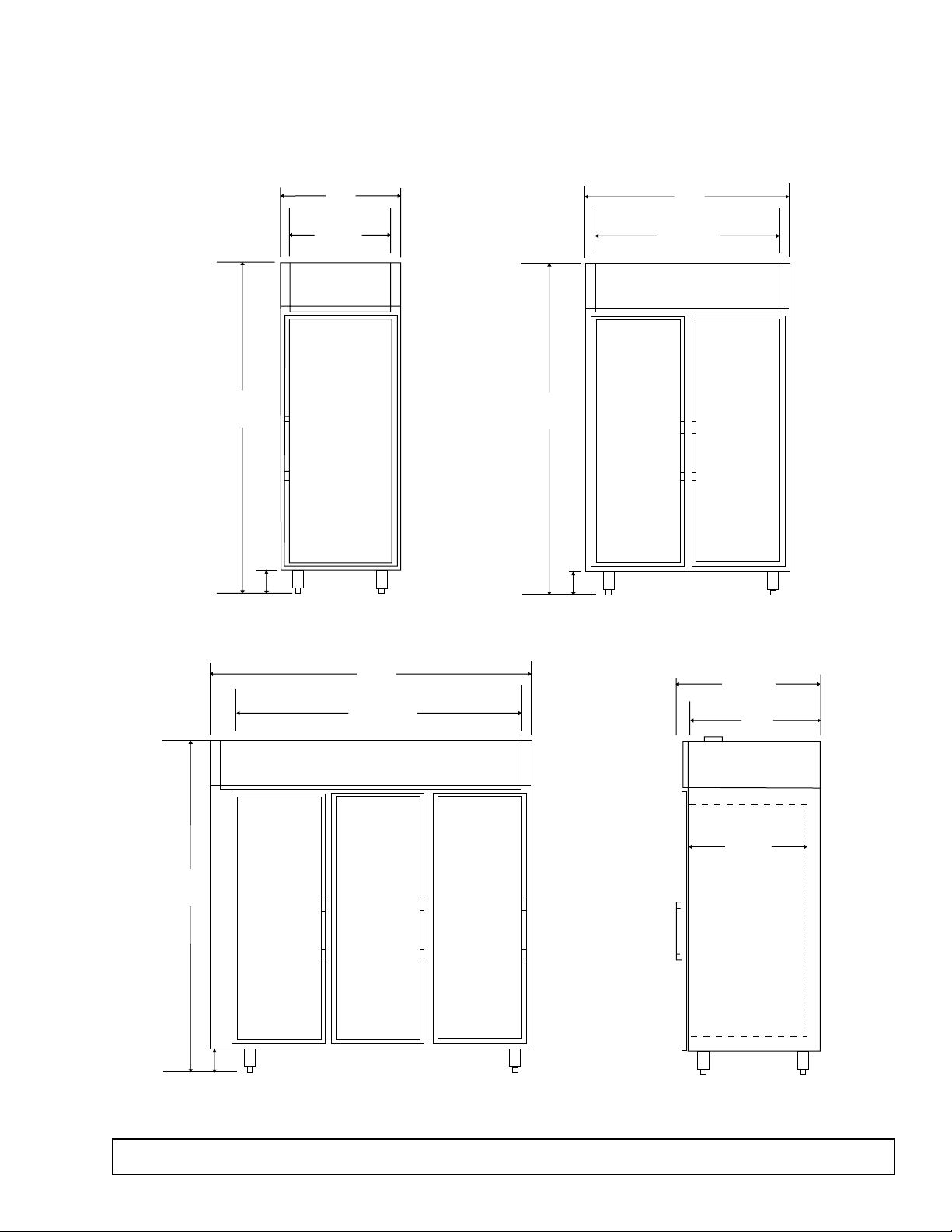

DIMENSIONAL DRAWINGS

MediumTemp.,Top Mount, Glass Pull Door Refrigerators

GENERAL INFORMATION 7

33"

36 1/4"

29 5/8"

SIDE VIEW

31"

26 1/4"

Interior

83 3/4"

6"

83 3/4"

6"

52"

47 1/4"

Interior

83 3/4"

6"

78"

73 1/4"

Interior

8 GENERAL INFORMATION

SPECIFICATION 1-DOOR 2-DOOR 3-DOOR

Compressor Mount Top Top Top

Temperature Range 37°to 55°(3°to 13°C) 37°to 55°(3°to 13°C) 37°to 55°(3°to 13°C)

Number of Doors 1 2 3

Door Construction Double Pane Double Pane Double Pane

Hinge Type Torsion Bar Torsion Bar Torsion Bar

Insulation - CFC-Free Foam-in-Place Urethane Foam-in-Place Urethane Foam-in-Place Urethane

Wall Thickness 2 3/8" 2 3/8" 2 3/8"

Capacity - Gross 27.3 ft.349.1 ft.376.2 ft.3

Shipping Weight (Approx.) 470 lbs. 785 lbs. 1080 lbs.

Compressor Size 1/3 Hp. 1/2 Hp. 1/2 Hp.

Condenser Type Fin & Tube Forced Air Fin & Tube Forced Air Fin & Tube Forced Air

Evaporator Type Fin & Tube Forced Air Fin & Tube Forced Air Fin & Tube Forced Air

Refrigerant Type R404A R404A R404A

Refrigerant Control Expansion Valve Expansion Valve Expansion Valve

Amp Rating - Data Plate 3771: 11.2; 3772: 6.3 3775: 13.8; 3776: 6.1 3779: 16.0; 3780: 8.2

3785: 13.2; 3786: 7.5 3787: 15.8; 3788: 8.8

Electrical Specs.

(V / HZ / PH)

115 / 60 / 1 (Export: 220V/50 Hz) 115 / 60 / 1 (Export: 220V/50 Hz) 115 / 60 / 1 (Export: 220V/50 Hz)

UL & CUL Listed Yes Yes Yes

Interior Finish Powder Coat Finish Powder Coat Finish Powder Coat Finish

Exterior Finish

Lighting

2 Insul. 1500 Milliamp Fluor. Lamps 3 Insul. 1500 Milliamp Fluor. Lamp 4 Insul. 1500 Milliamp Fluor. Lamps

Electrical Information 15 Amp Service Cord 20 Amp Service Cord 20 Amp Service Cord

SPECIFICATIONS

MediumTemp.,Top Mount, Glass Pull Door Refrigerators

MODEL DESIGNATION INFORMATION

NOTE: Export Models use a transformer.

See page 41 for information on how to set transformer during installation.

1-DOOR:

3771

3785

EXPORT MODELS:

3772

3786

2-DOOR:

3775

3787

EXPORT MODELS:

3776

3788

3-DOOR:

3779

EXPORT MODELS:

3780

GENERAL INFORMATION 9

SPECIFICATION 1-DOOR 2-DOOR

Compressor Mount Top Top

Temperature Range 37°to 55°(3°to 13°C) 37°to 55°(3°to 13°C))

Number of Doors 1 2

Door Construction Foam-in-Place Foam-in-Place

Hinge Type Camlift / Spring Assist Camlift / Spring Assist

Insulation - CFC-Free Foam-in-Place Urethane Foam-in-Place Urethane

Wall Thickness 2 3/8" 2 3/8"

Capacity - Gross 27.3 ft.349.1 ft.3

Shipping Weight (Approx.) 440 lbs. 604 lbs.

Compressor Size 1/3 Hp. 1/3 Hp.

Condenser Type Fin & Tube Forced Air Fin & Tube Forced Air

Evaporator Type Fin & Tube Forced Air Fin & Tube Forced Air

Refrigerant Type R404A R404A

Refrigerant Control Cap Tube Cap Tube

Amp Rating (Data Plate) 3773: 8.9; 3774: 5.2 3777: 8.9; 3778: 5.2

Electrical Specs.

(V / HZ / PH)

115 / 60 / 1 115 / 60 / 1

UL & CUL Listed Yes Yes

Interior Finish Powder Coat Finish Powder Coat Finish

Exterior Finish

Compressor Make Americold Americold

Electrical Information 15 Amp Service Cord 15 Amp Service Cord

SPECIFICATIONS

MediumTemp.,Top Mount, Solid Pull Door Refrigerators

MODEL

DESIGNATION

INFORMATION

NOTE: Export Models use a

transformer. See page 41 for

information on how to set

transformer during installa-

tion.

1-DOOR:

3773

EXPORT MODEL:

3774

2-DOOR:

3777

EXPORT MODEL:

3778

33"

34 3/4"

29 5/8"

SIDE VIEW

31"

26 1/4"

Interior

83 3/4"

6"

83 3/4"

6"

52"

47 1/4"

Interior

36 9/16"

DIMENSIONAL DRAWINGS

MediumTemp.,

Top Mount,

Solid Pull Door

Refrigerators

10 GENERAL INFORMATION

SERIAL RATING PLATES

Serial Number Rating Plates on each vertical cabinet are located on the inside upper left hand corner.This plate

contains all technical data necessary to the operation of the cabinet.(Sample below.) Warranty administration is

based on the serial number as printed on the rating plate.

GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong

(grounding) plug for your protection against shock

hazards.The appliance should be plugged directly into

a properly grounded three-prong receptacle.

Where a two-prong wall receptacle is encountered, it

must be replaced with a properly grounded three

prong receptacle in accordance with the National

Electrical Code and local codes and ordinances. The

work must be done by a licensed electrician.

IMPORTANT

Do not under any circumstances cut or remove the

round grounding prong from the equipment plug.

WARNING

Consult a licensed electrician if you have any

doubt about the grounding of your wall recepta-

cle.Only a licensed electrician can determine the

polarization of your wall receptacle. Only a prop-

erly installed three-pronged wall receptacle

assures the proper polarization with the equip-

ment plug.

MODEL SER.

REFRIGERANT VOLTS

TYPE # WIRES PHASE HERTZ

CHARGE TOTAL AMPS MAXIMUM

DESIGN MINIMUM FUSE SIZE

PRESSURE (PSIG) REFRIG. DEFROST LOCKED CIRCUIT OR HACR TYPE

HIGHSIDE CYCLE CYCLE ROTOR AMPACITY CIRCUIT

LOWSIDE

BREAKER

WH

G

RATING: 115V, AC 15 Amp

Plug

5-15 Receptacle

5-15R

RATING: 125V, AC 20 Amp

Plug

FLAMMABLE MATERIAL STORAGE

To meet the requirements for storing flammable material, cabinet has no opening other than

the door, or any electrical components below compressor compartment.

DO NOT MODIFY CABINET OR REMOVE LABEL ON THE FRONT WHICH SPECIFIES STORAGE LIMITS!!

GENERAL INFORMATION 11

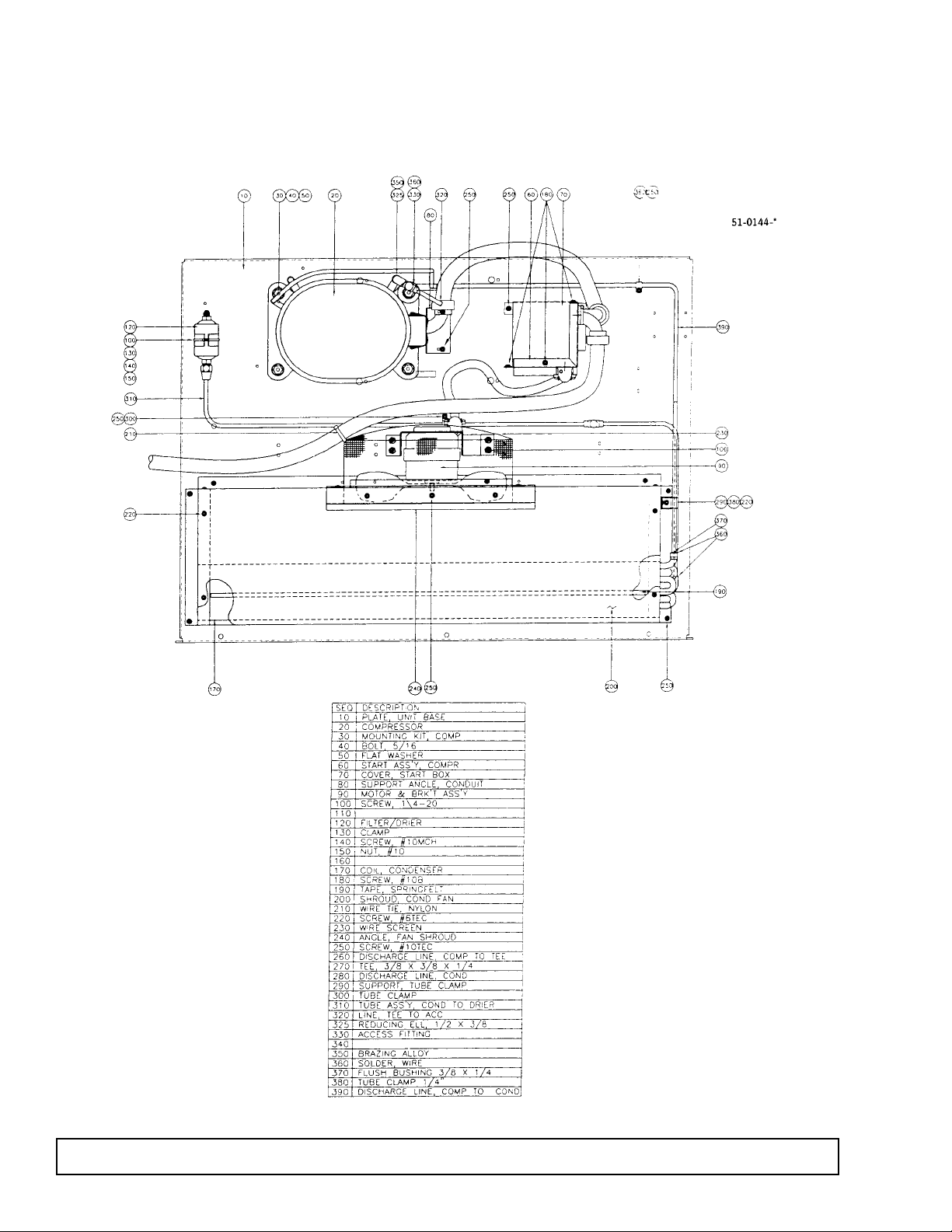

CONDENSING UNIT ASSEMBLY Component Identification

Models: 3771 / 3772 / 3785 / 3786 50-0142-*

Models: 3773 / 3774 / 3777 / 3778

50-0141-*

12 GENERAL INFORMATION

CONDENSING UNIT ASSEMBLY Component Identification

Models: 3775 / 3787

Export Models: 3776 / 3788

NOTE: See Parts Section IV.

GENERAL INFORMATION 13

CONDENSING UNIT ASSEMBLY Component Identification

Models: 3779

Export Models: 3780

14 GENERAL INFORMATION

EVAPORATOR COIL ASSEMBLY Component Identification

Models: 3771 / 3773 / 3775 / 3777 / 3779 / 3785 / 3787

Export Models: 3772 / 3774 / 3776 / 3778 / 3780 / 3786 / 3788

ITEM DESCRIPTION

1 Coil, Evaporator

Coil, Evaporator

2 Expansion Valve

3 Copper Tubing, 1/4

4 Copper Tubing, 1/2

5 Wire Tie, Nylon

9 Brazing Alloy

Note: Glass models shown.

Solid door models captube replacedT.X.V..

GENERAL INFORMATION 15

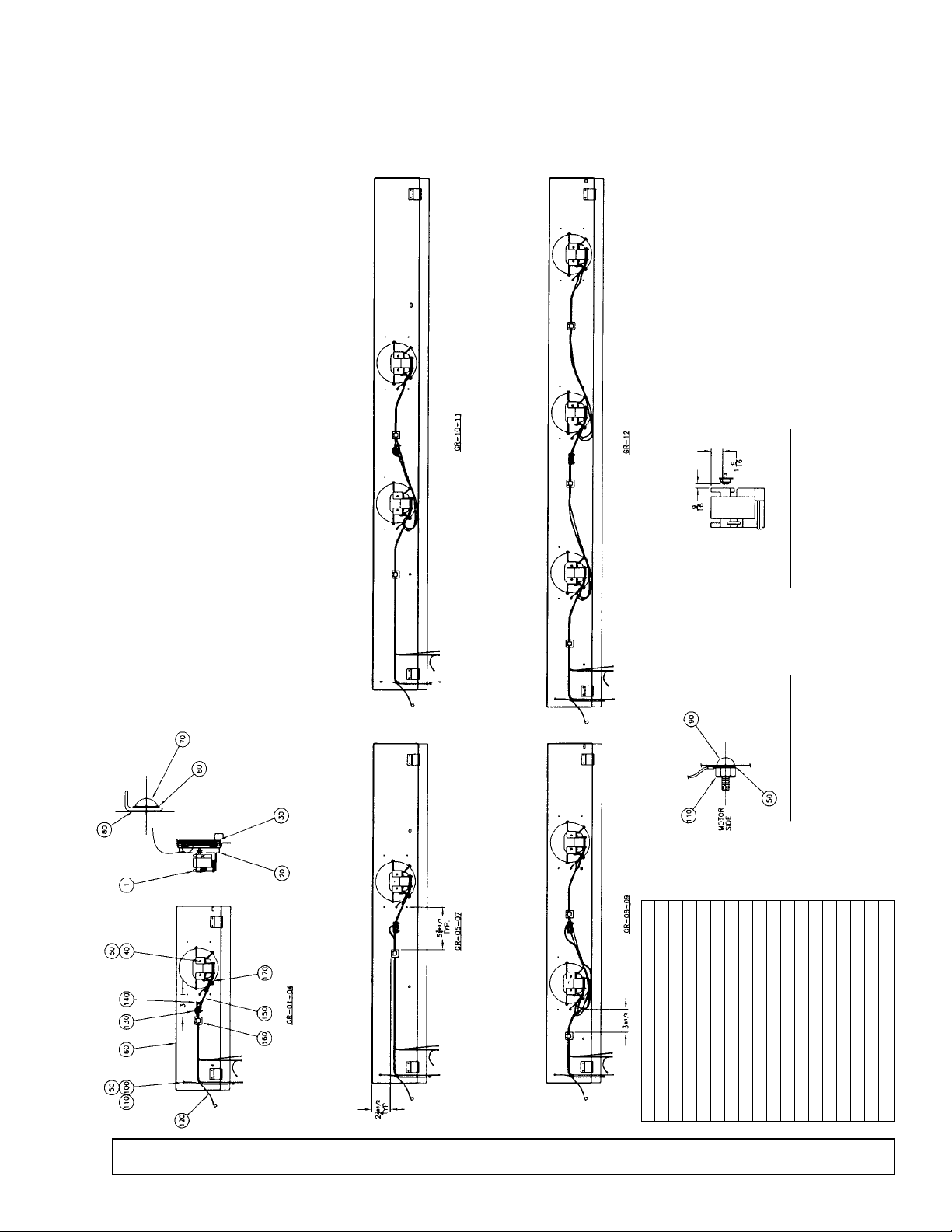

EVAPORATOR FAN SHROUD ASSEMBLY Component Identification

Models: 3771 / 3773 / 3775 / 3777 / 3779 / 3785 / 3787

Export Models: 3772 / 3774 / 3776 / 3778 / 3780 / 3786 / 3788

SEQ DESCRIPTION

10 MOTOR

20 FAN BLADE

30 FAN GUARD

40 SCREW

50 STAR WASHER

60 SHROUD, FAN

70 SCREW

80 WASHER

90 SCREW

100 HEX NUT

110 GROUND LEAD

120 HARNESS, DRAIN HEATER

130 STRAIN RELIEF

140 FAN HARNESS

150 CORD CLIP

160 WIRE TIE

170 BRACKET, HANGER DRAIN PAN

GROUND LEAD DETAIL

TYPICAL 2 PLACES FAN MOUNTING DETAIL

INSTALL FAN BLADE WITH HUB

TOWARD MOTOR LOCATED TO

DIMENSION SHOWN.

16 GENERAL INFORMATION

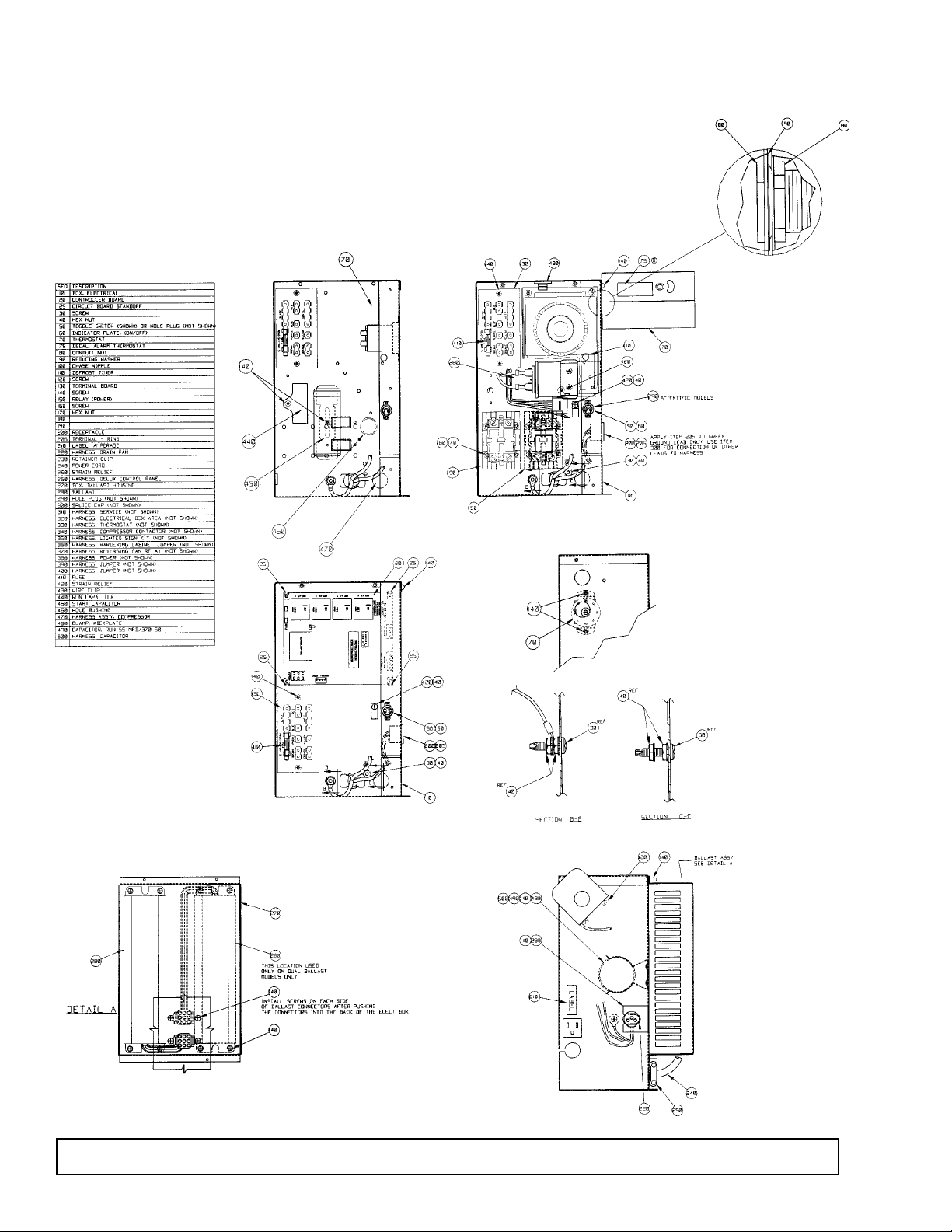

ELECTRICAL BOX ASSEMBLY Component Identification

Models: 3771 / 3773 / 3775 / 3777 / 3779 / 3785 / 3787

Export Models: 3772 / 3774 / 3776 / 3778 / 3780 / 3786 / 3788

GENERAL INFORMATION 17

START KIT Component Identification

If applicable

18 GENERAL INFORMATION

SIDE LIGHT ASSEMBLY

Models: 3771 / 3785

Export Models: 3772 / 3786

ITEM DESCRIPTION

1 Lamp Bracket LH

2 Lampgolder - Top

3 Lampholder - Bottom

This manual suits for next models

13

Table of contents