Thermogenesis MP2200 8-2200-12 Installation instructions

MP2200 Freezer

(Models 8-2200-12, 8-2200-23, 8-2200-31)

Low Temperature Liquid Bath System

for Freezing Blood Components

Operator and

Maintenance Manual

6-07-036.C

© THERMOGENESIS CORP. 2010

Revision History

Rev A: February 2002

Rev B: July 2002

Rev C: May 2010

Table of Contents

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C TOC-1

Table of Contents

Chapter 1 – INTRODUCTION

Intended Use............................................................... 1-1

How to use this manual .............................................. 1-1

Text Conventions......................................................... 1-2

Electrical Safety........................................................... 1-2

Safety Precautions ...................................................... 1-3

Copyright Notice.......................................................... 1-3

Trademarks ................................................................. 1-4

Disclaimer.................................................................... 1-4

Help Line ..................................................................... 1-4

Limited Warranty ......................................................... 1-5

Warranty...................................................................... 1-5

Procedure.................................................................... 1-5

Limitations ................................................................... 1-6

Chapter 2 – OVERVIEW

Specifications .............................................................. 2-1

Operating Environment ............................................... 2-1

Operational Overview.................................................. 2-2

Safety Devices............................................................. 2-2

Major Components of the Freezer .............................. 2-3

Chapter 3 – INSTALLATION

Unpacking And Inspection........................................... 3-1

Vacuum System and Desiccant Filter ......................... 3-2

Placing the Freezer in Position.................................... 3-2

Electrical Installation and Specifications ..................... 3-3

Mounting the Housing ................................................. 3-3

Installing the Control Panel ......................................... 3-4

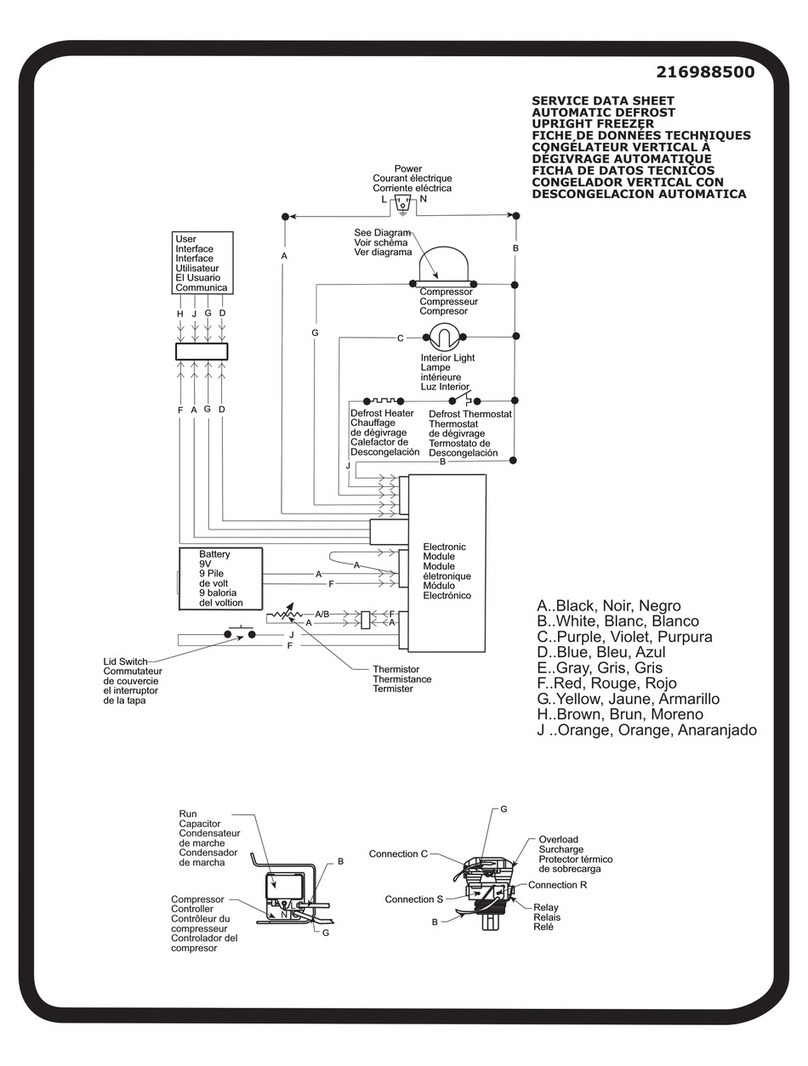

Solenoid Valve Wiring................................................. 3-6

Adding the InstaCoolant IV.......................................... 3-6

Starting the MP2200 Blood Freezer............................ 3-7

Table of Contents

Chapter 4 – OPERATING INSTRUCTIONS

Introduction.................................................................. 4-1

Setting the Operating Temperature............................. 4-1

Verifying Operating Temperature Calibration.............. 4-2

Calibrating the Operating Temperature....................... 4-3

Setting the Freeze Cycle Time.................................... 4-3

Running the Freeze Cycle........................................... 4-4

Running the Night Cycle.............................................. 4-5

Chapter 5 – MAINTENANCE

Maintenance Schedule................................................ 5-1

Checking and Cleaning the Pockets ........................... 5-1

Cleaning the Deck.......................................................5-2

Removing and Replacing a Pocket............................. 5-2

Cleaning the Freezer................................................... 5-2

Checking Desiccant Filters.......................................... 5-2

Checking the Pump Motor Cooling Fans .................... 5-3

Checking the Coolant Level ........................................ 5-3

Checking the Lid Gasket Seals................................... 5-4

Checking the Hinges................................................... 5-4

Checking the Deck Screws ......................................... 5-4

Verifying the Operating Temperature Calibration .......5-4

Defrosting the MP2200 Freezer.................................. 5-4

Running the Defrost Cycle .......................................... 5-4

Running the Filter Cycle.............................................. 5-5

Automatic Defrost and Filter........................................ 5-6

Checking Silica Gel for Coolant Filter ......................... 5-7

Replacing Silica Gel .................................................... 5-7

Replacing the Coolant................................................. 5-9

Chapter 6 – TROUBLESHOOTING

Introduction.................................................................. 6-1

No Power to Unit ......................................................... 6-2

Freezer Display is Lit, but Pumps Do Not Work..........6-2

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

TOC-2

Table of Contents

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C TOC-3

Coolant Chamber Fills Initially, but During the Cycle

the Coolant Level Drops Off...................................... 6-2

Product is not Completely Frozen............................... 6-2

Coolant Temperature is too High ................................ 6-3

Pockets Tearing or Ripping......................................... 6-3

Coolant Filter Pump is not Running ............................ 6-3

Coolant Has Leaked into Housing............................... 6-3

Chapter 7 – PARTS LIST

Parts List...................................................................... 7-1

Ordering Information ................................................... 7-1

Appendix A – FORMS

Installation Checklist....................................................A-1

Daily Maintenance Checklist.......................................A-2

Weekly Maintenance Checklist ...................................A-3

Monthly Maintenance Checklist...................................A-4

Quarterly Maintenance Checklist ................................A-5

Parts Order Form.........................................................A-6

Chapter 1

Introduction

TABLE OF CONTENTS

Intended Use............................................................... 1-1

How to Use this Manual .............................................. 1-1

Text Conventions......................................................... 1-2

Electrical Safety........................................................... 1-2

Safety Precautions ...................................................... 1-3

Copyright Notice.......................................................... 1-3

Trademarks ................................................................. 1-4

Disclaimer.................................................................... 1-4

Help Line .....................................................................1-4

Limited Warranty ......................................................... 1-5

Warranty...................................................................... 1-5

Procedure.................................................................... 1-5

Limitations ...................................................................1-6

1. Introduction

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C 1-1

Intended Use

The THERMOGENESIS CORP. MP2200 Freezer is intended to be used for the

fast, efficient freezing of blood components.

How to use this Manual

This Operator and Maintenance Manual is organized to provide easy access

to setup and maintenance information for the MP2200 Freezer. Please read

this manual in its entirety.

The “Pen-in-Hand” icon means pay close attention to the indicated text.

The “Exclamation” icon is a caution about a hazard that could cause injury

to the operator or others or damage the equipment.

The “Lightning Bolt” icon is a warning about an electrical hazard that

could cause injury to the operator or others or damage the equipment.

The “Flame” icon is a warning about a fire or explosion hazard that could

cause injury to the operator or others or damage to the equipment.

The “Freeze” icon is a caution about a cold hazard or possible frostbite.

The “Biohazard” icon is a warning about a potential biohazard due to

contact with blood components or contaminated coolant.

The “Rotating Hazard” icon is a warning about a potential injury to the

operator from the moving parts of the filtration pump.

1. Introduction

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

1-2

Text Conventions

To convey information readily and consistently, certain text conventions are

used throughout this manual. These conventions are:

Text Convention Used For

Numbered Lists Lists steps to be carried out in order.

For example:

1. Remove the screws from the rear of the

motor box.

2. Remove the screws from the Display

Panel.

Bulleted Lists Indicate items to be carried out, but not

necessarily in sequence.

For example:

Check the fuses.

Make sure all snap connectors are tight.

Bold Typeface,

Uppercase

Calls attention to a CAUTION or DANGER.

Bold Typeface,

Lowercase Emphasizes any term or component that is

being described or referred to.

Italics Refers the user to another section of this

Operator and Maintenance Manual that

should be consulted.

For example:

See Troubleshooting – Chapter 6.

Electrical Safety

CAUTION: The chassis of the system is connected to ground by means of

a cable, and surfaces on the system that the operator may come in contact

with are connected to the chassis by means of screw connections. For

protection against electrical hazards, the system must be directly connected

to a properly grounded electrical source approved by a qualified electrician.

Contact Helmer Technical Service for assistance if you have any questions

concerning the electrical connection for the MP2200 Freezer. When

servicing the MP2200 Freezer, make sure the power switch is turned off and

the unit is unplugged.

1. Introduction

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C 1-3

Safety Precautions

Safety precautions necessary to operate, maintain or troubleshoot the

MP2200 Freezer are outlined below. It is important that these precautions

be carefully read and understood. New employees should also be made

aware of this information.

CAUTION: For proper and safe operation, keep this manual in a place

where it is readily accessible for reference.

CAUTION: Disconnect all power to the freezer before starting any electrical

work.

CAUTION: When replacing fuses, be sure the new fuse has the correct

amperage rating.

CAUTION: Fire hazard occurs if vapors from the InstaCoolant IV are

allowed to reach 42°C (108°F). For operational purposes, THERMOGENESIS

CORP. has set the MP2200 safety thermostat to 27°C (80°F). When

warming the coolant during a defrost operation, DO NOT PLACE AN

ELECTRIC IMMERSION HEATER IN THE COOLANT.

CAUTION: The InstaCoolant IV must be above freezing 0°C (32°F) before

performing any service inside the freezer. Placing your hands in the coolant

when it is below freezing can cause frostbite.

CAUTION: Use of the equipment other than specified by the manufacturer

may cause injury to the operator or others, damage the equipment and

possibly nullify the freezer warranty.

Copyright Notice

©2010 THERMOGENESIS CORP. All Rights Reserved

The material in this manual is intended for use by the purchaser of the

equipment covered by the manual. Permission is granted to the purchaser

to make one copy of the manual for record retention and internal personal

use. This does not create a license to the purchaser under any copyright,

trademark, patent, or other intellectual property right of THERMOGENESIS

CORP. For additional copies of this manual, contact Helmer Technical

Service or the equipment supplier.

1. Introduction

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

1-4

Trademarks

THERMOGENESIS CORP. proprietary trademarks identify products and

services of THERMOGENESIS CORP., are the property of THERMOGENESIS

CORP. and are protected under State and Federal trademark laws, and

under international treaties. Those proprietary trademarks and service

marks may not be used, except as provided by law, without the prior written

consent of THERMOGENESIS CORP. trademarks and service marks:

THERMOGENESIS CORP. Companies own other brand trademarks and

tradenames mentioned in this manual.

Disclaimer

THERMOGENESIS CORP. has thoroughly reviewed the contents of this manual

to make it an informative and easy-to-use guide for the operation of the

equipment and devices described herein. All statements, technical

information and recommendations contained in this manual or related

documentation are current and believed to be reliable as this document

goes to press. For this reason, the contents of this manual are not intended

to be and should not be understood as representations or warranties

concerning the equipment and devices described herein.

All THERMOGENESIS CORP. products, including the products described in this

manual, are covered by specific and limited warranties as described in this

manual.

Contact Information

For questions on equipment or device warranties, call Helmer Technical

Service at 800.743.5637 (U.S./Canada) or +1.317.773.9092 (non-

U.S./Canada) weekdays (except U.S. holidays) from 8:00 a.m. to 5:00 p.m.

Eastern Standard Time.

Helmer Scientific

14400 Bergen Boulevard

Noblesville, IN 46060

Tel: 800.743.5637 (U.S./Canada)

Direct: +1.317.773.9092 (non-U.S./Canada)

Fax: +1.317.773.9082

Web: www.helmerinc.com

1. Introduction

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C 1-5

European Union Authorized Representative:

Medical Device Safety Service GmbH (MDSS)

Schiffgraben, 41

D-30175 Hannover

Germany

Web: www.mdss.com

Limited Warranty

THERMOGENESIS CORP.(“THERMO”) products are designed and

manufactured to provide reliable, trouble-free performance when properly

maintained and used in accordance with the operating instructions provided

with each unit. Each unit is carefully inspected, tested and found to be in

good working order prior to shipping.

Warranty

THERMO warrants to the original purchaser that the unit will be free from

defects in materials or workmanship for one year from the date of shipment.

THERMO also warrants that spare parts will be free from defects in material

workmanship for a period of ninety (90) days, or the maximum time required

by applicable local law, from the date of shipment of the spare part.

Equipment failure due to reasons other than manufacturing defects such as

accident, misuse or failure to timely perform scheduled maintenance in

accordance with the maintenance schedule included with the operating

instructions for the unit is excluded from Warranty coverage. This Warranty

covers only the cost of parts needed to make Warranty repairs. Labor

charges and shipping charges for replacement parts will be billed to the

purchaser. THERMO reserves the right to replace any malfunctioning unit or

part with a new or refurbished unit in lieu of repairing such unit.

This warranty and THERMO’s obligation to repair or replace defective parts

is the sole and exclusive remedy of purchaser. Under no circumstances

shall THERMO be liable for consequential or economic damages that might

arise from a defective part.

NOTE: The use of coolant, other than what is recommended by

ThermoGenesis Corp., could void product warranty.

THERMO WARRANTIES, AS SET FORTH HEREIN, ARE EXCLUSIVE

AND ARE IN LIEU OF, AND PURCHASER HEREBY WAIVES, ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE OR WARRANTY OF NON-

INFRINGEMENT.

1. Introduction

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

1-6

Procedure

If Warranty repairs are needed, contact Helmer Technical Service, 14400

Bergen Boulevard, Noblesville, IN 46060, Telephone: +1.317.773.5637 or

800.743.5637 in the US; Fax: +1.317.773.9082. For emergency repairs at

night or on weekends or holidays, contact your THERMO Authorized

Service Provider (“Service Provider”) directly and notify Helmer Technical

Service on the next business day. Failure to notify Helmer Technical

Service on the next business day after a request for emergency repairs may

result in denial of coverage for that service call.

When calling for service have available: (1) detailed information about the

problem; (2) the serial number of the unit; (3) the service record for the unit;

(4) the date and place of purchase of the unit.

Limitations

EQUIPMENT OR SPARE PART MALFUNCTIONS OTHER THAN THOSE

CAUSED BY DEFECTS IN MATERIALS OR WORKMANSHIP, INCLUDING

MALFUNCTIONS CAUSED BY MISUSE, ACCIDENT OR FAILURE TO

PERFORM SCHEDULED MAINTENANCE, ARE EXCLUDED FROM

COVERAGE. ANY ALTERATIONS OR MODIFICATIONS MADE TO THE

UNIT (OTHER THAN MODIFICATIONS OR ALTERNATIONS MADE BY

THERMO) RENDER THE WARRANTY NULL AND VOID. THERMO WILL

NOT BE RESPONSIBLE FOR ANY CONSEQUENTIAL OR INCIDENTAL

DAMAGES RESULTING FROM EQUIPMENT MALFUNCTION OR LOSS

OF USE OF THE EQUIPMENT. THERMO MAY AUTHORIZE

INDEPENDENT CONTRACTORS TO PERFORM SERVICE. SERVICE

PROVIDERS ARE INDEPENDENT CONTRACTORS, NOT THERMO

EMPLOYEES, CONSEQUENTLY, THERMO IS NOT RESPONSIBLE FOR

THE ACTS OR OMISSIONS OF THE SERVICE PROVIDERS, INCLUDING

WITHOUT LIMITATION, FAILURE BY A SERVICE PROVIDER TO

RESPOND TO CALLS FOR EMERGENCY SERVICE IN A TIMELY

FASHION.

Chapter 2

Overview

TABLE OF CONTENTS

Specifications .............................................................. 2-1

Operating Environment ............................................... 2-1

Operational Overview.................................................. 2-2

Safety Devices............................................................. 2-2

Major Components of the Freezer .............................. 2-3

2. Overview

Specifications

Height: 105 cm (42 in)

Height with lid open: 185 cm (73 in)

Width: 260 cm (103 in)

Depth: 94 cm (38 in)

Electric Defrost Heater: 1000 W

Unit Weight: 601 kg (1325 lbs)

Coolant Volume: 492 liters (130 gal)

Product Final Core Temperature: -30°C (-22°F)

Line Voltage / Amperage: 200-240 VAC

Current (Max) 12A

Frequency 50/60 Hz

Minimum Circuit Breaker: 20 Amps

Installation Category II

For Indoor Use Only

Mains supply voltage fluctuations are not to exceed 10 percent of the

nominal supply voltage

Operating Environment

Temperature: 15°C to 30°C (59°F to 86°F)

Relative Humidity: 10% to 80%

Altitude ≤2000m

IP 40

Pollution Degree 2

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

2-1

2. Overview

Operational Overview

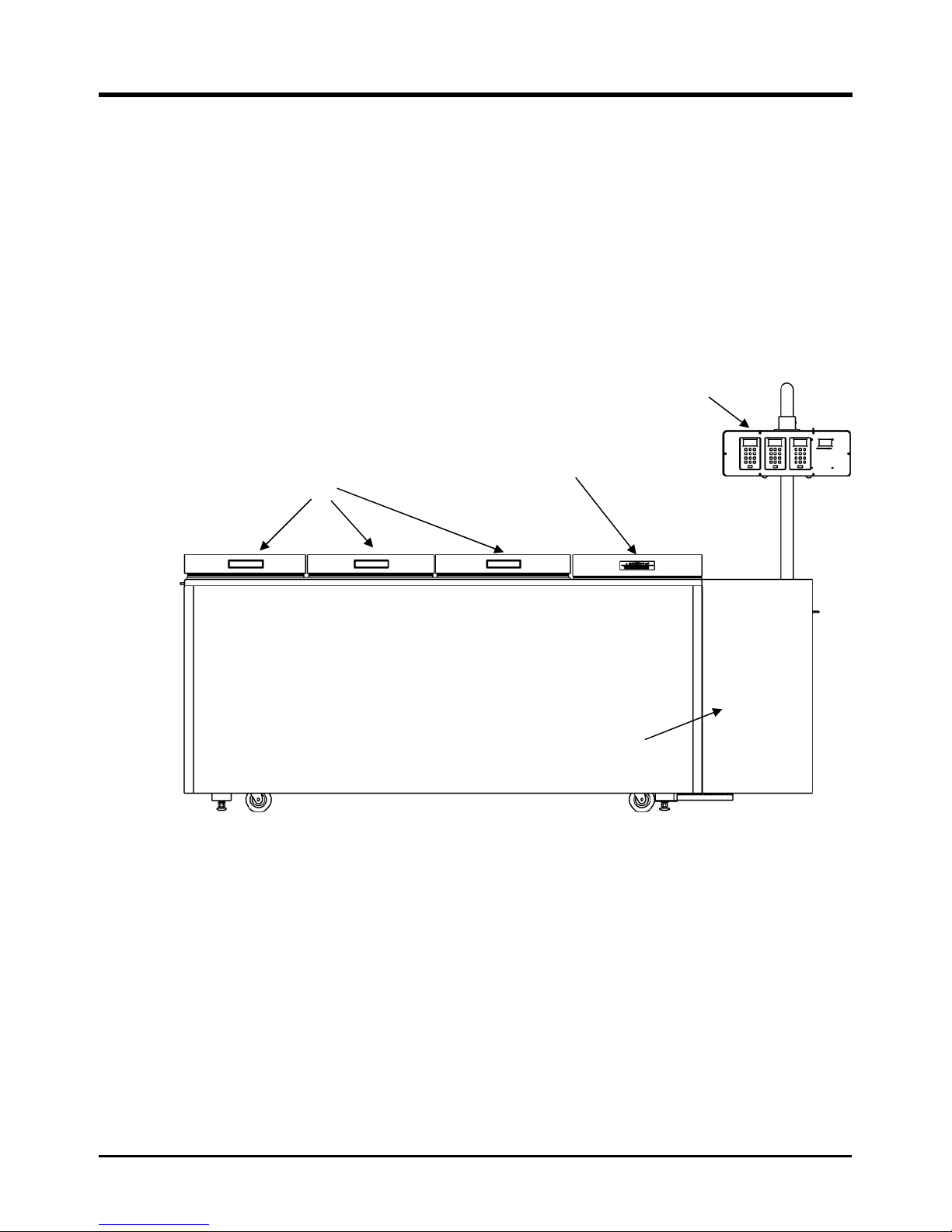

The THERMOGENESIS CORP. MP2200 Freezer (Figure 1) is a low

temperature liquid bath freezer. Blood components are frozen using a low

temperature re-circulating liquid coolant passing outside polyurethane

pockets containing the blood components. One-touch defrost and water

filtration cycles allow for automatic water removal, thus reducing ice build-

up.

Figure 1: MP2200 Freezer

Chamber Lids

Motor Box Cover

Control Panel

Housing

Safety Devices

Safety thermostat

The MP2200 Freezer monitors temperature of the coolant with a

temperature sensor and a thermostat (See Major Components, InstaCoolant

IV, for a description of the coolant). This thermostat cuts all power to the

freezer if coolant temperature exceeds 27ºC (80ºF).

During defrost operation

During a defrost cycle, the heater warms the coolant from its chilled

temperature to about 3ºC (37ºF). If the heater does not shut off at 3ºC and

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

2-2

2. Overview

continues to operate, the thermostat will override the defrost cycle at 27ºC

(80ºF) and shut off power to the unit.

NOTE: A small red light is located on the right side of the freezer, in the

upper left hand corner. When this red light is on, the coolant temperature is

above the safety thermostat temperature setting and all power to the

machine has been shut off.

Major Components of the Freezer

Refrigeration system (sold separately)

The MP2200 Freezer is available with air or water-cooled two-stage remote

condensing unit. Contact Helmer Technical Service for more information.

Motor box

Located at the right side of the freezer, the motor box contains three coolant

circulating pumps, electrical components, safety thermostat, connection for

the electrical defrost heating element and the exhaust fans for cooling the

motorbox compartment.

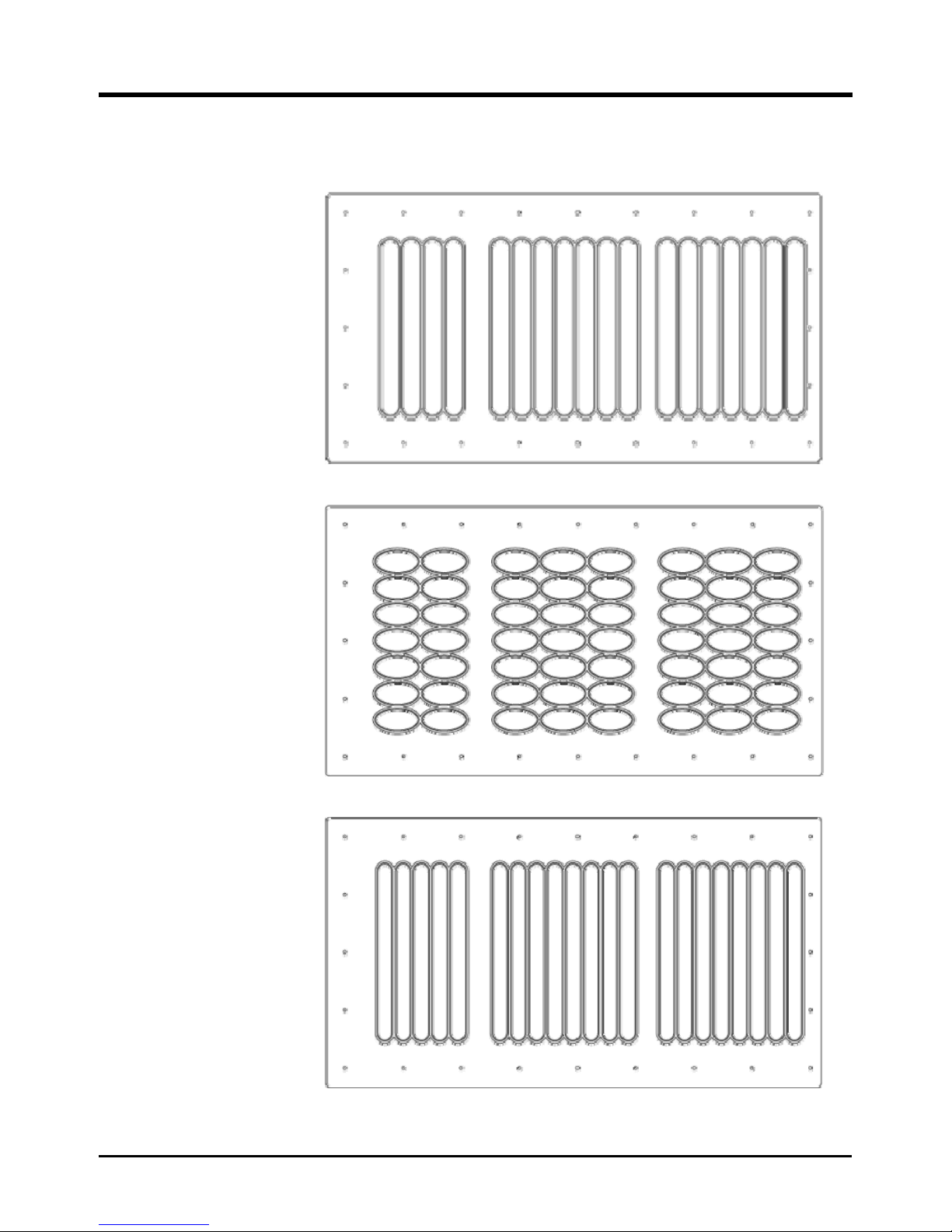

Deck and pockets

The deck of the MP2200 Freezer is located under the three lids and holds

the pockets in which the blood components are placed (Figure 2). The

pockets are made of a polyurethane material capable of maintaining

flexibility at low temperatures. The pockets hang down into the three

freezing chambers. During a freezing cycle, the pockets encapsulate the

blood components during coolant circulation. The deck and pockets provide

a tight seal to insulate the low temperature reservoir from the ambient room

temperature.

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

2-3

2. Overview

Figure 2: Deck and pocket arrangements

8-2200-12, 18-pocket configuration

8-2200-23, 56-pocket configuration

8-2200-31, 21-pocket configuration

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

2-4

2. Overview

Pocket springs

The pocket spring is a metal insert that assists with insertion and removal of

blood components.

Figure 3: Pocket spring

Freezing chambers

Located below the deck are three freezing chambers. During the freezing

cycle, these chambers are filled with low temperature InstaCoolant IV. The

coolant circulates around the pockets, freezing blood components.

Power panels

Located on the housing console at the right side of the freezer, these panels

contain the electronics that operate the freezer (Figure 4). The main power

switch is located on the primary power panel. Fuses for the various

electrical components are located in these two panels.

Figure 4: Power panels

Secondary

Panel

Primary Power Panel

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

2-5

2. Overview

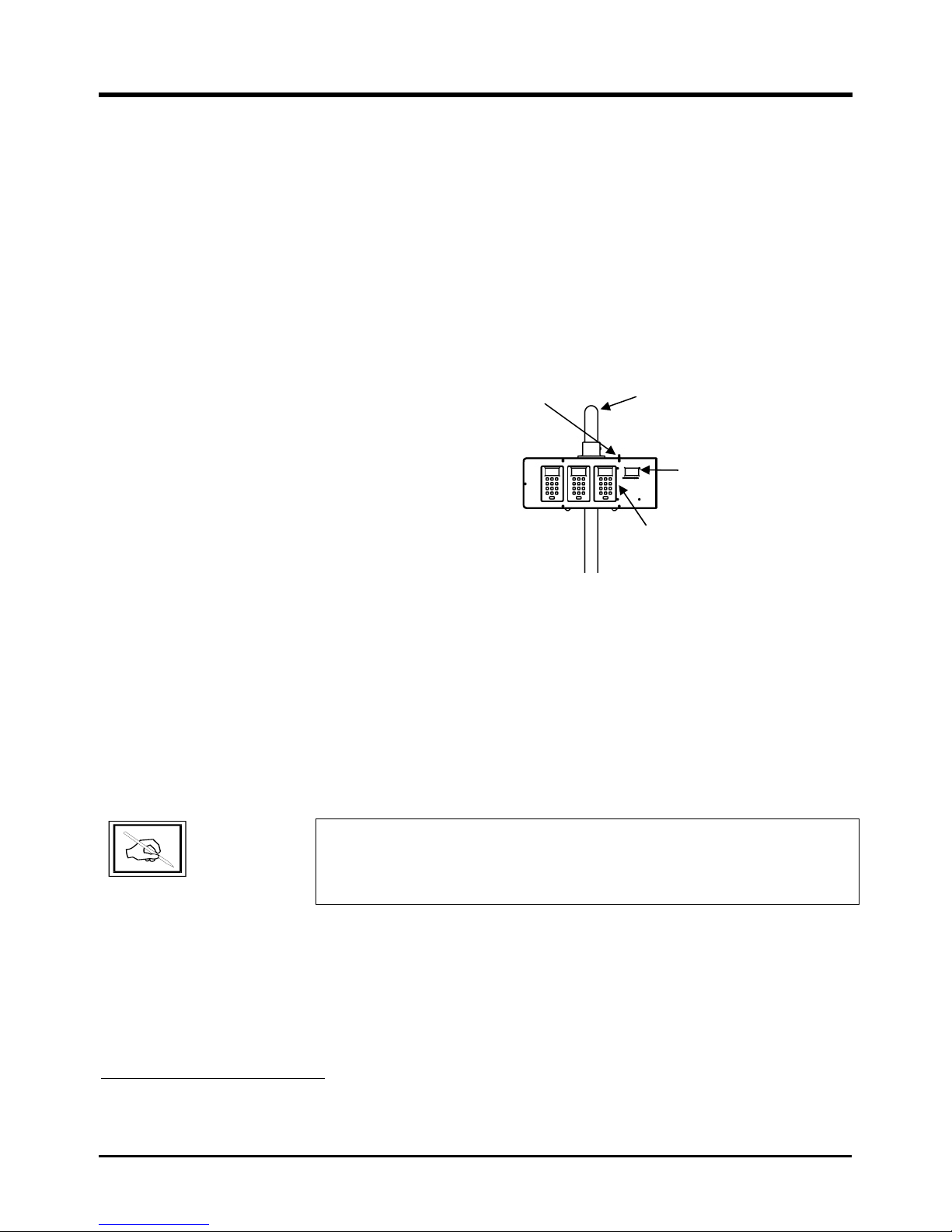

Control panel

The control panel is located on the control arm (Figure 5). The commands

for operation, defrost, calibration and temperature setpoint are entered

using the keypads.

(For model 8-2200-23 only) On top of the control panel is a small, red

vacuum indicator light. When lit, it indicates that the vacuum system has

reached the setpoint where the pockets are expanded. Blood components

may now be inserted or removed from the pockets.

Figure 5: Control arm and control panel

MP2200 Freezer – Operator and Maintenance Manual, 6-07-036.C

2-6

Over temperature indicator light

On the right side of the freezer is a small red light, located in the upper left-

hand corner of the housing. When lit, it indicates that the safety thermostat

has shut off power to the freezer due to high coolant temperature.

InstaCoolant IV

InstaCoolant IV (Dow Chemical Company Syltherm XLT) is a silicone-based

heat transfer fluid specifically designed for use in low temperature systems.

While the fluid operating range is -100ºC to 260ºC (-150ºF to 500ºF), the

vapors of the fluid have a flashpoint1at 42ºC (108ºF).

NOTE: THERMOGENESIS CORP. provides a safety thermostat that

automatically shuts off all power to the freezer when the coolant

temperature exceeds the safety temperature setting. THERMOGENESIS CORP.

sets the safety temperature limit at 27°C (80°F).

1The lowest temperature at which the vapor of a liquid can ignite momentarily in air. This assumes an ignition source

is present such as a flame or an electric heater element.

Vacuum

Indicator Light

Control Arm

(8-2200-23 only)

Temperature

Readout

Keypads

Chapter 3

Installation

TABLE OF CONTENTS

Unpacking and Inspection...............................................3-1

Vacuum System and Desiccant Filter .............................3-2

Placing the Freezer in Position........................................3-2

Electrical Installation and Specifications.........................3-3

Mounting the Housing .....................................................3-3

Installing the Control Panel .............................................3-4

Solenoid Valve Wiring.....................................................3-6

Adding the InstaCoolant IV..............................................3-6

Starting the MP2200 Freezer..........................................3-7

Table of contents