3

2. GENERAL USE

The construction of THERM-EL electric boilers is designed for hot-water heating systems with induced water

circulation. They can be installed in central or individual-storey heating with induced circulation sealed or open

systems and they are characterized by an environmentally friendly operation without requirements for venting of

the combustion product. Service-free operation enables the installation of an external regulator, other external

regulating or controlling components (not included in the boiler delivery package!), simple equitherm regulator or

room thermostat integrated directly in the automatic controlling system which maintains the pre-set room

temperature. The electric boiler can be used as a universal source of heat for heating flats, small family houses,

resort houses and also as an alternative source to another main heat source of heating and hot water preparation

(also for transitional periods) – for heat pumps, accumulation systems or in previously installed central or single-

storey heating systems etc. To attain higher output levels, boilers can be connected into a cascade format.

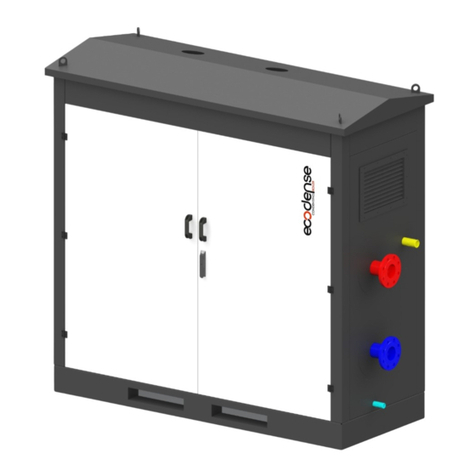

3. GENERAL CHARACTERISTICS OF THERM – EL ELECTRIC BOILERS

Therm-EL electric boilers are wall-mounted appliances designed for water heating in a heating system and

potentially for domestic hot water heating (hereinafter referred to as “DHW”) in an indirect heating storage tank.

THERM EL boilers are produced in three series. The first, lower output series, has three types:

8, 15 and 23 kW

,

in the second

higher output series

there are a further 3 types:

30, 38 and 45 kW

. In terms of the construction and

manner they are controlled and regulated in the same manner as with the output lower series. The latest series are

with touch display boilers in variants

5, 9 and 14 kW

.

The electric boiler is formed by a steel vessel with inbuilt heating bars, heating temperature probe and safety

thermostat (these components are all located under one cover in the upper part of the vessel). The vessel is made

from a varnished steel sheet and it is fitted with thermal insulation. Heating water inlet, on which a circular pump is

mounted, is welded at the bottom part of the boiler. A lug located in the upper part of the vessel is adjusted to the

cup for the boiler temperature sensor and emergency thermostat. Heating water outlet and threaded sleeve pieces

are also located in the upper part of the vessel.

Heating bars

(up to 6) are screwed in the sleeve pieces. In variants

5, 9 and 14 kW there are 3 bars with the output 1.5 kW (each bar has three independent 0.5 kW

heating bodies

), 3

kW (each bar has three independent 1 kW

heating bodies

) and 4.5 kW (each bar has three independent 1.5 kW

heating bodies

), the remaining series of boilers have bars, each with the total output of 7.5 kW (in each

heating bar

there are three independent

heating bodies,

each 2.5 kW). An automatic vent valve is placed at the highest point of

the water heating circuit.The boiler control box enables connection of an external room thermostat, addition of

interface for the boiler cascade connection type, programmable (time) switch and MRC (mass remote control) tariff

switch.

Switching and electric line protection of the boiler and output inlets for the heating bars are not

located in the boiler

but they always form part of the electric distributor of the flat or house. Terminals of the main

wiring are concentrated in the right part of the boiler. A sufficiently rated output line contactor or switch (correctly

marked!) which are used for disconnecting the electric boiler from the power network must be connected right next

to the boiler during its installation.

♦

Boiler operation characteristics:

Operational stage of the boiler is launched when heating system temperature drops below the temperature set

on the boiler control panel or on the room thermostat. Control circuit of the heating bars becomes activated and

heating water inside the boiler body becomes heated gradually. After the required temperature has been reached in

the room (if a room thermostat is applied), the control microprocessor unit starts switching off the heating bodies

one by one and the heating of the water stops. At this moment the function of an adjustable limited pump

deceleration (in terms of time or temperature) becomes activated.

As standard, Therm-EL boilers are also fitted with emergency thermostat which delivers maximum safety. It is

connected to the control circuit of the integrated output contactor. The disconnection of the emergency thermostat

(disjunction of the controlling circuit relay and heating bars) and thus the boiler shut-down occur when the

temperature reaches 105°C. Shall the emergency thermostat become disconnected, the boiler can be only put back

into operation by an authorized service engineer. Another protection of the boiler is assured by a pressure switch