Ecodense ROOF TOP Series Installation guide

14.12.2021 Rev. 03

www.ecodense.com

ROOFTOPSERIES CONDENSING BOILER

INSTALLATION,OPERATING ANDMAINTENANCE

MANUAL

ECODENSE RT-65 One ECODENSE RT-65 Twin

ECODENSE RT-80 One ECODENSE RT-80 Twin

ECODENSE RT-90 One ECODENSE RT-90 Twin

ECODENSE RT-100 One ECODENSE RT-100 Twin

ECODENSE RT-110 One ECODENSE RT-110 Twin

ECODENSE RT-115 One ECODENSE RT-115 Twin

ECODENSE RT-125 One ECODENSE RT-125 Twin

ECODENSE RT-150 One ECODENSE RT-150 Twin

14.12.2021 Rev. 03 1

DEAR USER,

The Roof Top Series Condensing Boilers ECODENSE RT-65 One, ECODENSE

RT-80 One, ECODENSE RT-90 One, ECODENSE RT-100 One, ECODENSE RT-110

One, ECODENSE RT-115 One, ECODENSE RT-125 One, ECODENSE RT-150 One,

ECODENSE RT-65 Twin, ECODENSE RT-80 Twin, ECODENSE RT-90 Twin,

ECODENSE RT-100 Twin, ECODENSE RT-110 Twin, ECODENSE RT-115 Twin,

ECODENSE RT-125 Twin, ECODENSE RT-150 Twin areconstructed andmanufactured

accordingto the most advance technological inventions and the safety rules. It is easy to

use for our customers.

We recommend that you read this manual and safetywarnings thoroughly before the

use of the device in order to ensuresafe, cost effective and environmental-friendly use.

If you encounterany issue that is not explained clearly inthis manual oryou could

not understand, please contact with our service department.

We thank you for choosing ECODENSE brand.

This Operating Manual is an integral partof the device andmust bemaintained in a

plastic dossier and hung at a clearly visible place bythe device.

TERMO ISI S STEMLER SAN.VE T C.A.Ş.

Esentepe Mah.MilangazCad. No:75 K:3

Kartal Monumento Plaza

Kartal/ STANBUL/TÜRK YE

Tel: +90 216 442 93 00

Fax: +90 216 370 45 03

www.ecodense.com

e-mail:servis@ecodense.com

14.12.2021 Rev. 03 2

CONTENTS

1. WARNINGS......................................................................................................................................... 3

1.1. Warning Symbols and Descriptions............................................................................................... 3

1.2. General Safety Rules...................................................................................................................... 4

2. TERMSOFWARRANTY................................................................................................................... 6

2.1. Out of Warranty Conditions........................................................................................................... 6

3. GENERAL CHARACTERISTICSOFCONDENSING BOILER...................................................... 7

3.1. ECODENSE Roof Top Series Condensing Boilers for Outdoor Installation................................ 8

3.2. TechnicalSpecifications................................................................................................................. 8

3.3. Boiler Safety................................................................................................................................... 8

3.4. Standart Equipments....................................................................................................................... 8

3.5. ECODENSE Roof Top Series Boiler Components........................................................................ 9

4. CONDENSING BOILER GAS, FLUE GASAND HEATING WATER SCHEMA........................ 11

5. CLOSED CIRCUIT COMPONENTS................................................................................................ 14

5.1. Balance Tank................................................................................................................................ 14

5.2. Sizing TableFor Expansion Tank................................................................................................ 15

5.3. ExpansionTank............................................................................................................................ 16

5.4. Manometer.................................................................................................................................... 16

5.5. Strainer......................................................................................................................................... 16

5.6. Air Separator................................................................................................................................ 16

6. WATER QUALITY............................................................................................................................ 17

7. TECHNICAL DATA.......................................................................................................................... 18

7.1. Capacity Table.............................................................................................................................. 18

7.2. Condensing BoilerDimensions.................................................................................................... 21

7.3. NoiseLevel................................................................................................................................... 22

8. INSTALLATION................................................................................................................................ 22

8.1. General Controls .......................................................................................................................... 22

8.2. ExternalOutdoor Sensor (Optional): ........................................................................................... 23

9. STACK CONNECTIONS.................................................................................................................. 23

10. ASSEMBLY .................................................................................................................................... 24

10.1. ECODENSE Assembly Instructions......................................................................................... 24

10.2. ECODENSE Single/CASCADE Assembly Instructions ......................................................... 24

10.3. Assembly of Condensing Fluid Drain...................................................................................... 24

11. ECODENSE CONTROL INSTRUCTIONSBEFORE START-UP............................................... 25

12. ELECTRICAL DIAGRAM............................................................................................................. 27

13. COMMISSIONING......................................................................................................................... 28

13.1. BeforeCommissioning............................................................................................................. 28

13.2. Checks During Commissioning................................................................................................ 29

14. ADJUSTING COMBUSTIN PARAMATERS............................................................................... 29

14.1. Adjustment and Measurement Points....................................................................................... 29

15. CONTROL PANEL BUTTON SPECIFICATIONS....................................................................... 30

15.1. Adjusting MinimumCapacity.................................................................................................. 30

15.2. Adjusting MediumCapacity..................................................................................................... 30

15.3. Adjusting MaximumCapacity.................................................................................................. 31

15.4. Adjsuting TimeSchedule......................................................................................................... 31

16. MAINTENANCE............................................................................................................................ 32

16.1. Monthly Maintenance............................................................................................................... 32

16.2. SeasonalMaintenance.............................................................................................................. 32

17. LIST OFERROR CODE................................................................................................................. 33

18. SOLUTION RECOMMENDATIONSFOR SOME OFTHE PROBLEMS.................................. 37

19. AFTER SALESSERVICES............................................................................................................ 38

20. NOTES............................................................................................................................................. 39

14.12.2021 Rev. 03 3

1. WARNINGS

1.1. Warning Symbols and Descriptions

Symbols Symbol Descriptions

Important information and useful hints.

Warning of danger to lifeor property.

Warning of electrical voltage.

Product handling information.

GAZ HATTINI TEM ZLEY NZ.

CLEAN GASLINE.

ЧИСТАЯ ЛИНИЯ ГАЗ.

"Cleanthegas line"warning on gas line.

Carry in an upright position. FragileItem.Protectagainst water.

14.12.2021 Rev. 03 4

1.2. General Safety Rules

•All personnelengagedininstallation, disassembly,commissioning, operation,control,

maintenance and repair should havereceivedthenecessary training andfully readand understood

this manual.

•No changesthatmight damagethesafety of thedevicemust bemadebypersons and/or

organizations on thedevice.

•All operation, commissioningand installation works (except for burning adjustment) should be

carriedout whenthedeviceis notoperatingand afterdisconnecting thepowersupply.

Noncompliancewiththeserulesmayleadtoserious bodilyinjuriesand evendeathby electrical

shocks or uncontrolled flameformation.

•Repairs concerned with safety elements should becarried outonly by themanufacturing company.

•Thedeviceshould never beused by children, mentally handicappedand inexperienced persons.

•Childrenmust not beallowedto play with thedevice.

•Keep thedeviceaway fromexplosiveand flammablematerials.

•Device must intakeair, and ventilation and air dischargeholesmust notbeclosed.

If yousensegas leakage;

•Shut down valves of all gas devices.

•Open all doors and windows.

•Do not turn on electricdevices or do not turn themoff if theyareworking.

•Do not useburner derivedtools such as match and lighter.

•Informthegas company.

Do not storeany inflammablematerials in boilerroom.

Wear hearing protectors if thereis noisein boiler room.

Incaseof fıre orother emergency;

Switch off themain switch

Closethemain fuel shut-off valveoutsidetheplant.

Takeappropriateactions

14.12.2021 Rev. 03 5

Beforecommissioning and If thereis pressureloss in thesystemdueto seasonalmaintenance;

Afterwateradditionprocess, it is necessary to carry out that airremoval process and must be

observedthatthereisabsolutely noair in thesystem. If there is airin thesystemrepeatthe

deaerationprocess.

If you receieve 110 (Lock-out) failure on thecontrol panel, pleasedo no reset theboiler, Call

AuthorisedService company.

Preventing damagecaused by thepresence of particles suchas dirt, sediment, metal burrs on the

heating circuit installation and condensing boiler, for thecomfortableand longerservice lifeof

theboilers, It is recommended that theinstallation circuit is separated by plateheat exchanger as

primary and secondary circuit

For TheHigh-riseBuildings, If height ofstructuremorethan 25 mt. Or morethan 10 th floor, in

order to ensurethatcondensing boilercascadesystemoperates comfortably atlow pressures, a

plateheatexchangermust beinstalled inorder to distinguish thehigh pressurebetween 2nd

circuit andthePrimary circuit. thestaticpressureappearanced dueto theheight of building,theboiler

systemis not allowed to operateundertheinfluence of high pressure.

BOILER ROOM

Condensing Boilers must beinstalled in asuitableroom/floor with minimumexternal air openings

and sufficient to ensureoptimumgas-air mixturecombustion, in compliancewiththeregulations.

Air openings of theboilerroom, burner fan intakevents or air ductsmust stay open to the

atmosphereand Birdcageshould beinstalled in order to prevent any Bird, foreignbody entrance

a.Thebuild up of toxic/explosivegasmixtures in theboiler room,

b. Combustion with insufficient air,resulting in hazardous, anti-economical and polluting ope-

ration.

TheCondensing boiler must bealways protected fromrain, snow and frost to prevent corrosion and

paint deformations.

Keepthecondensing boiler roomclean and free of solidvolatilesubstances,which could besucked

into thefan and clogtheinternal boiler or combustion air ducts.

Every 6-12 months, afterfirst commissioning of boiler, theboiler devices should becleaned with

protectivechemicals to prevent calcification and resultant blocking and corrosion on themetallic

surfaces.

Flushing;

On theCurrently operating systems, appropriatechemical solution with thepH rangeof 4-6 should be

selected for cleaning thepipelineinstallation for safety commissioning thecondensing boiler.

In thenewbuilding installations and boiler heat exchangers, maintenance should beappliedwith

chemicals with neutral pH (neutral) effectand preventivemaintenance must becarried out periodically.

14.12.2021 Rev. 03 6

2. TERMSOF WARRANTY

Main andauxiliary equipment and allcomponents usedin ECODENSERT-65One,ECODENSE

RT-80 One,ECODENSERT-90 One,ECODENSERT-100 One,ECODENSERT-110 One,

ECODENSERT-115One,ECODENSERT-125One,ECODENSERT-150 One,ECODENSERT-65

Twin, ECODENSERT-80 Twin, ECODENSERT-90 Twin, ECODENSERT-100 Twin, ECODENSE

RT-110 Twin, ECODENSERT-115 Twin, ECODENSERT-125 Twin, ECODENSERT-150 Twin Roof

Top SeriesCondensing Boilersareguaranteedfor 1yearby TERMOISIS STEMLER A.Ş. starting

fromthedateof commissioning underthemaintenance,adjustment,operatingconditionsand relevant

mechanic,chemicaland thermal effects explainedherein.

Pleasenotethatthis warranty isonly validif thedevice(s) is commissionedand maintainedby our

authorizedservices.

Our company reservestheright to makeanymodifications on theproductand all instructions

thereof forimprovement purposes.

2.1. Out of Warranty Conditions

•Any damagearisingout of orin relation to customers’ non-compliance to their responsibilities

with regards to installation, commissioning, operation and maintenance,

•Any damagearising out of or in relation to commissioning, repairs and maintenance carriedout by

unauthorized services,

•Any damagethatmay occur during transportation or storageof theproduct,

•Not preserving theproduct in its originalpackaging until theinstallation stage,

•Incorrectand poor electricalconnections, Failuresdueto incorrectvoltageapplications,frequent

repetition of voltagefluctuations,

•Any damagethatmayoccur asaresultof incorrectfuelusageor, foreign substancesinthefuel

used or using of theproduct without anyfuel,

•Any damagethatmayoccur dueto foreign particlesenteredinto theproductduring installation

and operation,

•Failures dueto incorrect deviceselection,

•Any damageto unit dueto natural disasters,

•Devices without anywarranty certificates,

•Warranty Certificates without thestampand signatureof theauthorizeddealer or service,

•Deviceswith any falsification on thewarranty certificateorwithout an originalserial number.

•Therisks during transportation of device undertheresponsibilityof customerbelong to the

customer.

•Presence of misusefaults areindicatedinthereports issuedby authorizedservicestations or our

authorizedagent, dealer, representativeor our factory incaseof unavailability of authorized

service stations.

•Customersmayapply consumerprotection arbitrator committee withregards to this report and

request for an expert report.

14.12.2021 Rev. 03 7

3. GENERAL CHARACTERISTICSOF CONDENSING BOILER

ECODENSERT-65 One,ECODENSERT-80 One,ECODENSERT-90 One,ECODENSERT-100

One,ECODENSERT-110 One,ECODENSERT-115 One,ECODENSERT-125 One,ECODENSERT-

150 One,ECODENSERT-65 Twin, ECODENSERT-80 Twin, ECODENSERT-90 Twin, ECODENSE

RT-100 Twin, ECODENSERT-110 Twin, ECODENSERT-115 Twin, ECODENSERT-125 Twin,

ECODENSERT-150 Twin areheating devicesoperating with naturalgasor LPGwith avery low suction

power, andequippedwith high-duty, premix condensing control systemwith micro-processor. Theboiler

is composedof aheatexchangerwith aluminumcooling fins and asteelpremix burnerequippedwith

ignitionand ionization flamecontrol,modulating fanand gasvalve.ECODENSERT-65One,

ECODENSERT-80One,ECODENSERT-90 One,ECODENSERT-100 One,ECODENSERT-110

One,ECODENSERT-115 One,ECODENSERT-125 One,ECODENSERT-150 One,ECODENSERT-

65 Twin, ECODENSERT-80 Twin, ECODENSERT-90 Twin, ECODENSERT-100 Twin, ECODENSE

RT-110 Twin, ECODENSERT-115 Twin, ECODENSERT-125 Twin, ECODENSERT-150 Twin are

designed for useas standaloneas well ascascade.

14.12.2021 Rev. 03 8

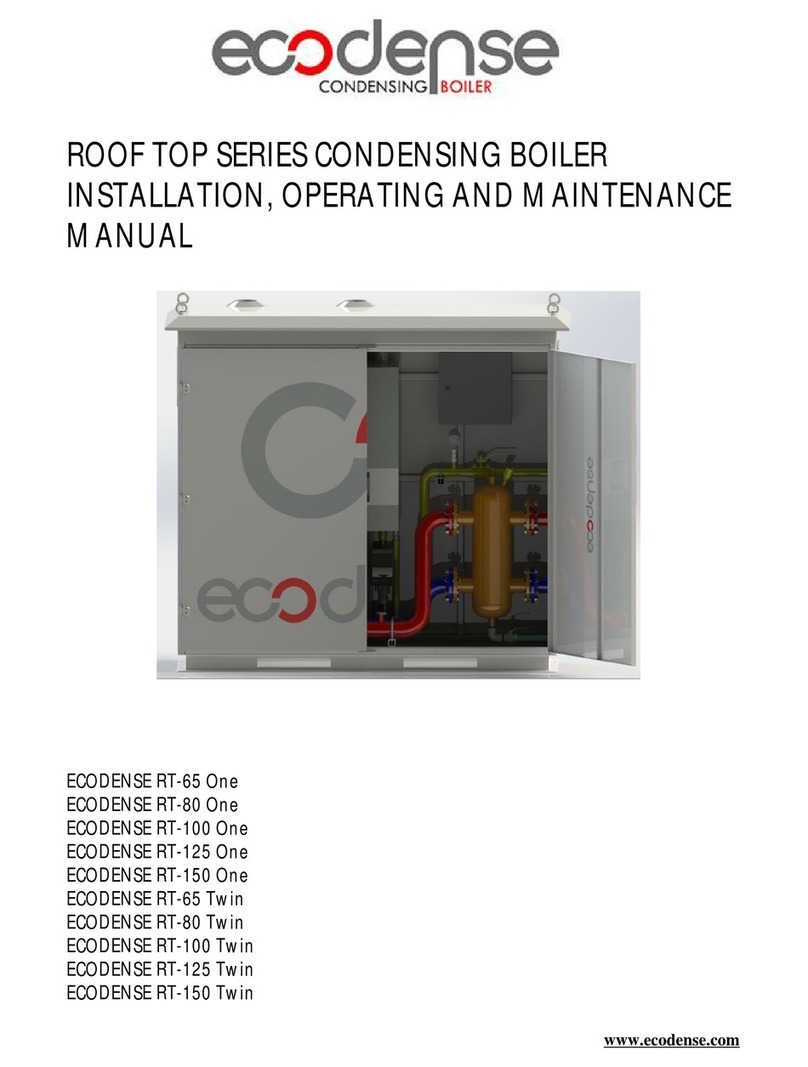

3.1. ECODENSE RoofTopSeries Condensing Boilers forOutdoorInstallation

ECODENSERoof Top seriescondensing boilersoffersolution in hot waterproduction for rooftop

outdoor installation inmany applications suchas shopping centers, office buildings, hospitals and hotels.

ECODENSEcondensing boilers, whenusedasCASCADE, meethigh-capacity energy requirements with

line-up operation and also expand thelife-cyclebyensuring equalaging in boilers.

3.2. TechnicalSpecifications

•High efficiency withpremix condensing technology and micro-flamemetal fiber coated steel burner,

•Provides energy saving through 5:1 modulating operation,

•10 different capacity option between 65kW-300 kWin ECODENSERT One/Twin series,

•Operation option with naturalgas and LPG,

•Easy hydraulicand gas circuitconnections,

•WhenusedasCASCADE, thepanelon theboilers allows controlling 16 unit control for

ECODENSE RT Oneand 8 unit control for ECODENSE RT Twin series condensing boilers,

•Allows simplecontrol withilluminatedLCD panelwhichprovideseaseof use;and error codesand

boilerinformation can bedisplayed on this panel,

•Daily and weekly operation schedulecan beprogrammed,

•Seasonalheat programcan bepreparedduring summer and winter times,

•Operation in lower noisevalues,

•Environmentally-friendly withlower NOx and CO emission rates,

•Easy installation, operation andmaintenance.

3.3. BoilerSafety

•Whenoutdoor temperaturegoesbelow +4 °C, theboilerautomaticallyprotects itself and prevents

fromfreezing.

•Theboilerprotects itself, whenthetemperatureof fluegas exceeds theset valueduring operation,

•Theboilerprotects itself during unexpectedhigh temperatureswithcombustion space safety

thermostat.

3.4. StandartEquipments

•Primer hydrauliccircuit circulating pump,

•Inletand return collectors in size according to installed totalpower,

•Checkvalvein inletlineand safety valvein returnlineof theboiler,

•Ball valves in both inletand return lines of theboilers,

•Balance containerwith residue,dirtandair separator returncollectors in sizeaccordingto total

installed power,

•Gas detector for thegas leakagecontrol,

•Pressuregaugeand ball valvein gas line,

•Thermometerin hydrauliccircuits,

•Drain trapfor each boiler,

•Ventilation grills fortheair inlet and outlet,

•Eyebolt for easy transport.

14.12.2021 Rev. 03 9

3.5. ECODENSE RoofTopSeries BoilerComponents

ECODENSE WT 65 – ECODENSEWT 80– ECODENSE WT 90– ECODENSEWT 100

AssemblyNo

Part Name

AssemblyNo

Part Name

1

Venturi 11

Gas Inlet

2

Fan 12

Heater circuit return

3

Gas valve 13

Water flow sensor

4

Control panel 14

Heater circuit supply

5

Control card 15

Water pressuresensor

6

Boiler 16

Condensing unit

7

Bulls eye 17

Condensing water releaseoutlet

8

Ionizationelectrode 18

Condensing water trap

9

Automaticair reliefcock 19

Burner

10

Flueoutlet 20

Ignition transformer

14.12.2021 Rev. 03 10

ECODENSE WT 110 – ECODENSEWT 115 - ECODENSE WT 125- ECODENSEWT 150

AssemblyNo

Part Name

AssemblyNo

Part Name

1

Venturi 11

Gas Inlet

2

Fan 12

Heater circuit return

3

Gas valve 13

Water flow sensor

4

Control panel 14

Heater circuit supply

5

Control card 15

Water pressuresensor

6

Boiler 16

Condensing unit

7

Bulls eye 17

Condensing water releaseoutlet

8

Ionizationelectrode 18

Condensing water trap

9

Automaticair reliefcock 19

Burner

10

Flueoutlet 20

Ignition transformer

14.12.2021 Rev. 03 11

4. CONDENSING BOILER GAS, FLUE GASAND HEATING WATER SCHEMA

WT

14.12.2021 Rev. 03 12

WT-S45/55/65

14.12.2021 Rev. 03 13

WT-S100/120/145

14.12.2021 Rev. 03 14

5. CLOSEDCIRCUIT COMPONENTS

5.1. Balance Tank

Balance Tank (Separator) mustbevertical.

Advantages:

ØNo hydraulicresponseoccurs betweentheboiler circuit and theheating circuit.

ØBoilers and heating zones operateundersuitablewater flow.

Sizing of Balance Tank:

ØIn order toensurehealthy operation of thebalancetank, accuratesizingmust bemade.

ØTheboiler’s exit water temperatureshould bemeasured on theupper part of balance tank.

ØFor this, a½”muff should bewelded onto tank, and also an air reliefcock should bemounted.

ØDimensions shown in thepicturerepresent minimumdimensions required to beapplied.

14.12.2021 Rev. 03 15

5.2. Sizing TableForExpansionTank

SYSTEM

CAPACITY

ABHEXPANSION

TANK

DIAMETER(D)

INLET &

OUTLET

DIAMETER(Ø)

kw

cm cm cm mm mm

65 33 38 48 100 50

90 38 44 55 125 50

115 42 47 59 125 50

130 47 54 68 150 65

170 54 62 77 150 65

230 59 67 84 200 80

345 72 82 103 200 80

460 83 95 119 250 100

575 93 106 133 250 100

690 102 116 145 300 125

805 110 126 157 300 125

920 118 134 168 350 150

1035 131 150 188 350 150

1150 138 157 197 400 200

1265 144 164 206 400 200

1380 150 171 214 450 200

1495 155 178 222 450 200

1610 162 185 230 450 200

1725 169 192 238 450 200

14.12.2021 Rev. 03 16

5.3. ExpansionTank

Expansiontank forepressures must beadjusted according tosystem. Expansion tank should be

placed parallel to circuit returnline.

5.4. Manometer

Amanometer with capacity of at least 0 to 6 barmust beconnected to system. Manometer should be

placed to easily visiblespot fromfilling point, preferably samepoint as expansion tank.

5.5. Strainer

Any dirt or residuein circuitwatercausesdamagegot boilerand circuit components and decreases

efficiencyby reducing heattransfer. Inorderto prevent this problemastrainermust beconnectedto

circuit.

5.6. AirSeparator

Theair inthewaterdissolvesdueto increasing temperatureand flowin thecircuit. Dissolvedaircauses

cavitation,sound and efficiency loss. By using an air separator air is removed fromthesystem.

Thehydraulicsystemdesign must comply with thecircuit diagramsspecified in theusermanual to ensure

that thesystemoperates smoothly and that installation errors do not result in loss of efficiency. The

hydraulicsystemmust haveabalance vessel, sediment trap, air separator and expansion tank in

accordancewith thesystemcapacity andspecifications.

In ordertokeepthepH valuein balance,passingthewatercirculatingin thesystemthrough asoftening

step (Reverseosmosis systems)will beuseful in thecontinuity of thewater quality.

14.12.2021 Rev. 03 17

6. WATER QUALITY

1. Beforeconnection of condensing boilers any dirt and residuein circuit must becleaned.

2. Water Hardness and pH measurements should bemadeby theauthorized or central servicein the

field wheretheboiler will becommissioned before thecommissioning, and it should bedecided

whether thewater can beusedin theboiler water installation.

3. Refined water must beused whileadding water to heating circuit duetoany loss in closed circuit.

4. Permittedwaterhardness for thewaterusedin watercircuit must comply with Frenchor German

(VDI 2035) hardness degree standards.Thelimedissolvedin water,settlesonhot surfacesand

formsaninsulationlayerwhenwatertemperaturerises. This prevents heattransferand high

temperaturemight damagetheheatexchanger.If boilerwatercyclesthroughwatercircuit, all

circuit watermust meetaboverequirements.If aplateheatexchangerseparatesboilerwaterand

heating circuitwater, onlythewaterbetweenboilerand heatexchangermust meetthese

requirements.

In ordertoprevent sedimentation, propertiesof thewatertobeusedor to bereinforcedin the

water lineshould not exceed thefollowing tablevalues according to below mentioned capacities.

BoilerType Capacity (Total Hardness)

ppm (°F) French VDI German

SingleBoiler 0-50 kW 250

<

25

<

14

SingleBoiler 50-200 kW 110

<

11

<

6,16

SingleBoiler 200- 600 kW 40

<

4

<

2,24

Single/ Cascade >600 kW/ All capac.

2

<

0,2

<

0,112

*Volumeto capacityratio ofwaterin circuitmustbehigherthan20 I/kW.Totalvolumeof first filled

waterand additionalwatermust beless than volumeof system.

5. thecustomer or contract company should analyzethewater to beused in thewater lineby an

accreditedorganization prior tocommissioning and awater quality report should provided

containingMinimumHardness, pH and conductivity values, total dissolved solid values .

6. pHvalueof unrefinedwater must be7<pH<9. This pHvaluecanbeachieved after fillingthe

circuit withmaincircuit water withpHvalueof 7andairseparation.pHvalueof refined

water must bebetween7-8,5 pH.

7. In newbuilding installations,periodic preventivemaintenance must becarriedout byusing

organicsolutions with achemical pH effect [neutral].

8. Prior to commissioning of condensing boilers inold buildingwaterinstallations,asuitabletypeof

organicsolution with apH value(acidic)between4 and 6 should bewashed.

9. Theboilerwaterpipelineandheatexchangershould betreatedwith asuitabletypeoforganic

solution overaperiod of 6to 12 monthsto preventcalcification and deposits thatmayoccur over

timein theinstallation.

14.12.2021 Rev. 03 18

7. TECHNICAL DATA

7.1. Capacity Table

TYPE CAPACITY BOILER

NUMBER

GAS INLET

PRESSURE

MAX.

OPERATING

PRESSURE

kW - mbar bar

ECODENSERT-65 One 65 1 21 6

ECODENSERT-80 One 80 1 21 6

ECODENSERT-90 One 90 1 21 6

ECODENSERT-100One 100 1 21 6

ECODENSERT-110One 110 1 21 6

ECODENSERT-115One 115 1 21 6

ECODENSERT-125One 125 1 21 6

ECODENSERT-150One 150 1 21 6

ECODENSERT-65 Twin 130 2 21 6

ECODENSERT-80 Twin 160 2 21 6

ECODENSERT-90 Twin 180 2 21 6

ECODENSERT-100Twin 200 2 21 6

ECODENSERT-110Twin 220 2 21 6

ECODENSERT-115Twin 230 2 21 6

ECODENSERT-125Twin 250 2 21 6

ECODENSERT-150Twin 300 2 21 6

14.12.2021 Rev. 03 19

Unit WT65 WT80 WT90WT100WT-110WT115WT125WT150

kW 65 80 90 100 110 115 125 143

kW 14 14,1 14,1 14,2 20 20 20 20

kW 63,4 76,4 88 98 108,5 112,7 122,5 138

kW 13,7 13,8 13,8 13,9 19,4 19,4 19,5 19,5

kW 69 85,6 95,2 105,0 114,9 121,0 131,0 151

kW 15,1 15,3 15,3 15,4 21,3 21,3 21,5 21,5

%97,5 95,5 97,8 98,0 98,6 98,0 98,0 96,5

%97,9 97,9 97,9 97,9 97,0 97,0 97,5 97,5

%106,2 107,0 105,8 105,0 104,5 105,2 104,8 105,6

%107,9 108,5 108,5 108,5 106,5 106,5 107,5 107,5

%108,6 108,8 108,4 108,3 108,6 108,4 108,9 108,5

°C 10-65 10-65 10-65 10-65 10-65 10-65 10-65 10-65

°C 90 90 90 90 90 90 90 90

L5 5 5 7 7 7 7 9

bar 6 6 6 6 6 6 6 6

bar 1 1 1 1 1 1 1 1

-G20-G31G20-G31G20-G31G20-G31G20-G31G20-G31G20-G31G20-G31

mbar 20 20 20 20 20 20 20 20

mbar 37 37 37 37 37 37 37 37

Nm³/h 6,78 8,34 9,38 10,42 11,47 11,99 13,03 14,91

Nm³/h 1,46 1,47 1,47 1,48 2,08 2,08 2,08 2,08

°C 42 42 42 43 45 45 45 45

°C 65 65 65 65 65 65 65 65

-6 6 6 6 6 6 6 6

V/Hz 230/50 230/50 230/50 230/50 230/50 230/50 230/50 230/50

IP X4D X4D X4D X4D X4D X4D X4D X4D

W100 100 100 200 200 200 200 300

A6 6 6 6 6 6 6 6

inch 1/2" 3/4'' 3/4'' 3/4'' 3/4'' 3/4'' 3/4'' 3/4''

inch 11/2'' 11/2'' 11/2'' 11/2'' 11/2'' 11/2'' 11/2'' 11/2''

kg 65 75 75 75 75 85 88 92

mm 80/125 80/125 80/125 80/125 80/125 80/125 80/125 100/150

Efficiency@Pmin.(80°C /60°C)

ECODENSE WTNG SERIES WALLTYPECONDENSINGBOILER

TECHNICALSPECIFICATIONS

ThermalCapacity

Maximum HeatingCapacity

MinimumHeatingCapacity

Maximum HeatOutput(80°C /60°C)

MinimumHeatOutput(80°C/60°C)

Maximum HeatOutput(50°C /30°C)

MinimumHeatOutput(50°C/30°C)

ThermalEfficiency

Efficiency@Pmax.(80°C /60°C)

GasType

Efficiency@Pmax.(50°C /30°C)

Efficiency@Pmin.(50°C /30°C)

Efficiency@%30 (30°C)

Domestic HotWaterCircuit

Temperatureadjustmentrangewithexternalstorage

tankusage

CentralHeatingCircuit

Maximum OperatingTemperature

WaterVolume

Maximum OperatingPressure

MinimumOperatingPressure

GasSpecifications

EnergyConsumption

GasInletPressure(G20)

GasInletPressure(G31)

Maximum gasconsumption

Minimumgasconsumption

CombustionSpecifications

Maximum FlueGasTemperature(50°C /30°C)

Maximum FlueGasTemperature(80°C /60°C)

NOxEmissionClass (EN15502-1+A1)

ElectricalSpecifications

ElectricalSupply

ProtectionClass

FlueDiameter(Ø)

G20 NaturalGas,G31 LPG

FuseCurrent

CircuitSpecifications

GasConnectionDiameter

CentralHeatingCircuitInlet/OutletDiameter

GeneralSpecifications

NetWeight

This manual suits for next models

16

Table of contents

Other Ecodense Boiler manuals

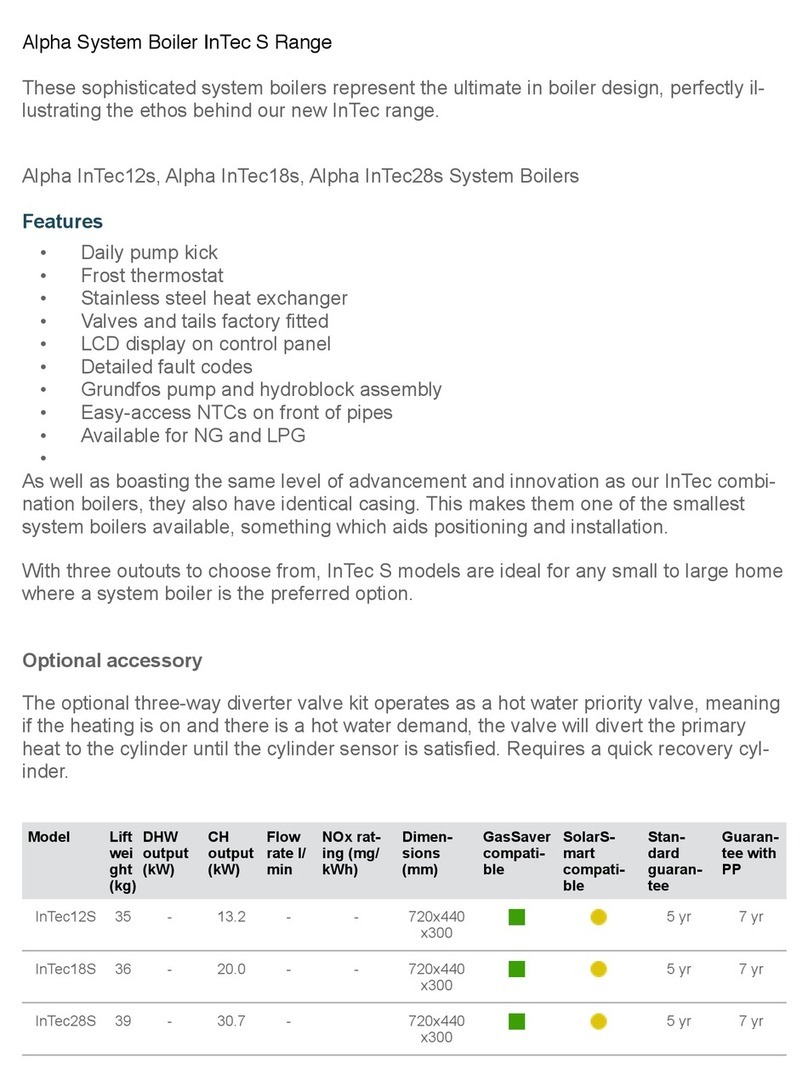

Popular Boiler manuals by other brands

IDEAL

IDEAL Elise H15 user guide

Well-mcLain

Well-mcLain 68 Series manual

THERMO 2000

THERMO 2000 MINI Ultra 6 Installation & operating manual

WarmFlow

WarmFlow U Series User instructions

Riello

Riello Residence PRO 32 KIS User's information manual

Columbia

Columbia CSFH-3 WATER Installation, operation & maintenance manual

Sime

Sime SOLO 20 OF manual

CHAFFOTEAUX

CHAFFOTEAUX PIGMA GREEN user manual

Raypak

Raypak 0133-4001 Installation and operating instructions

Worcester

Worcester Greenstar utility 32-50kW instruction manual

ElectraStream

ElectraStream BEL 130 user manual

Westinghouse

Westinghouse WBRC 140 Series Installation, start-up, maintenance, parts, warranty