1. USAGE

THERM DUO 50 FT is an advanced wall-mounted source of heat energy for premises with the

maximum heat loss of 45 kW. It can be used separately or in a cascade for large buildings. The demanded

output of the boiler room will be acquired by using more Therm Duos in a cascade, which is controlled by

its own expansion regulation including weather compensated regulation. In this easy way you can acquire

a heat source with high efficiency. The construction of boilers in a cascade lowers the operational costs

and losses compared to standard boiler rooms. The boilers are designed as appliances with maximum

efficiency and minimal emissions to the air, their operation is economical and it does not harm the

environment. The boiler output is adjustable within 50 and 100 % and it adapts itself to the current needs

depending on heat losses.

The high technical standard is guaranteed by the use of top components from the best world

producers.

Important: The boiler is designed for heating systems equipped with an open expansion vessel with

min. height of 8 m above the boiler.

2. GENERAL DESCRITPTION OF THERM DUO 50 FT

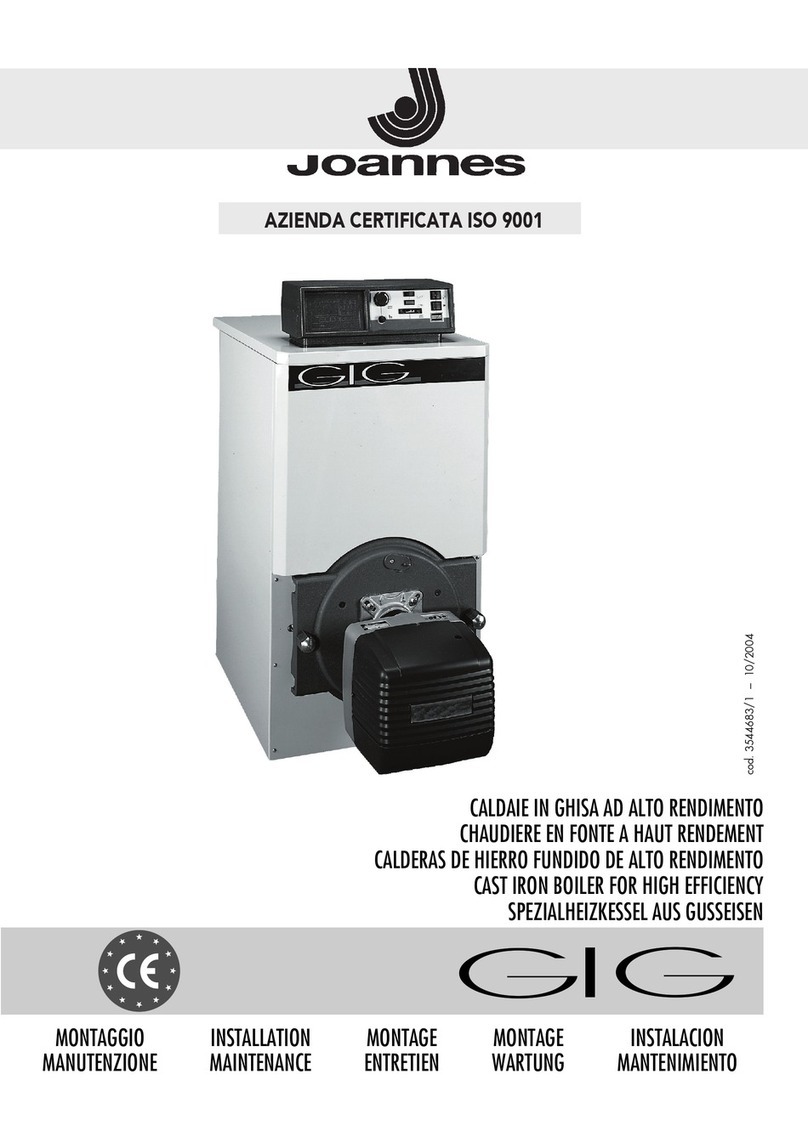

All functional parts of THERM DUO 50 FT are fixed to a metal supporting frame. There are two

copper flue exchangers in its upper part. Their surface is protected by an aluminium and silicone mixture.

Inside the tube sheet there are turbulators, which have to be protected against blocking by dirt from the

heating system. Therefore, it is necessary to install a filter at the return water inlet in the boiler. To

maintain the minimum losses of heat transfer it is essential to keep exchanger lamellas clean. The

exchanger usually gets dirty when dust particles are burned (the boiler operates in a dusty environment).

There are automatic deaerating valves on the inlet and safety contact thermostats on the outlet of the flue

exchanger.

The combustion chamber is made of aluminium plated metal sheet and it is inlaid by a heat

insulation. The front wall is removable. Above the exchangers there is an exhaust rectifier.

There is an eighteen-armed, water-cooled, low NOX gas burner in the lower part of the combustion

chamber. The burner is a product of POLIDORO. It has an advanced modular construction and it is fitted

with three electrodes. Two of them (ignition electrodes) ignite the burner; the third (ionization electrode)

checks the burning

SIT gas fitting is connected to the burner by a grommet and screwing. The fitting includes a gas

pressure regulator and two solenoid valves controlled automatically.

There is also a modulating electromagnet. The magnetic coil core of the modulator has an adjustable

lift so gas pressure into burner can be adjusted within the set range.

There is a Grundfos pump on the return water inlet. The pump drives the water through the boiler.

The sufficient through-flow is watched over by a through-flow switch. Moreover, there is a safety valve

connected to in front of the pump to protect the boiler against excess pressure.

The control panel is made of plastic. The control elements are placed on the front of the plastic

control panel (see the operational rules). There is a DIMS01-TH01 microprocessor automatics for boiler

control inbuilt inside

THERM DUO boilers work without an ignition burner and they are ignited with an electric spark,

which means greater gas savings.

The ventilator and the components engaged in gas combustion and power transformation are inbuilt

in a closing chamber. The sufficient supply of combustion air and the forced flue exhaust are usually

ensured by the coaxial tubes that go horizontally through the perimeter wall or vertically through the roof

construction out into the open space. The coaxial tubes must be installed in such a way that any

penetration of rainwater or condensed water into the boiler can be averted. It is therefore necessary that

the vertical tubes be finished with a stack, whereas the horizontal tubes must be installed with a moderate

fall in the direction from the boiler to the flue exhaust. Should these instructions be disregarded, the

components inside the closing chamber, in particular the flue ventilator, are easily liable to damage.