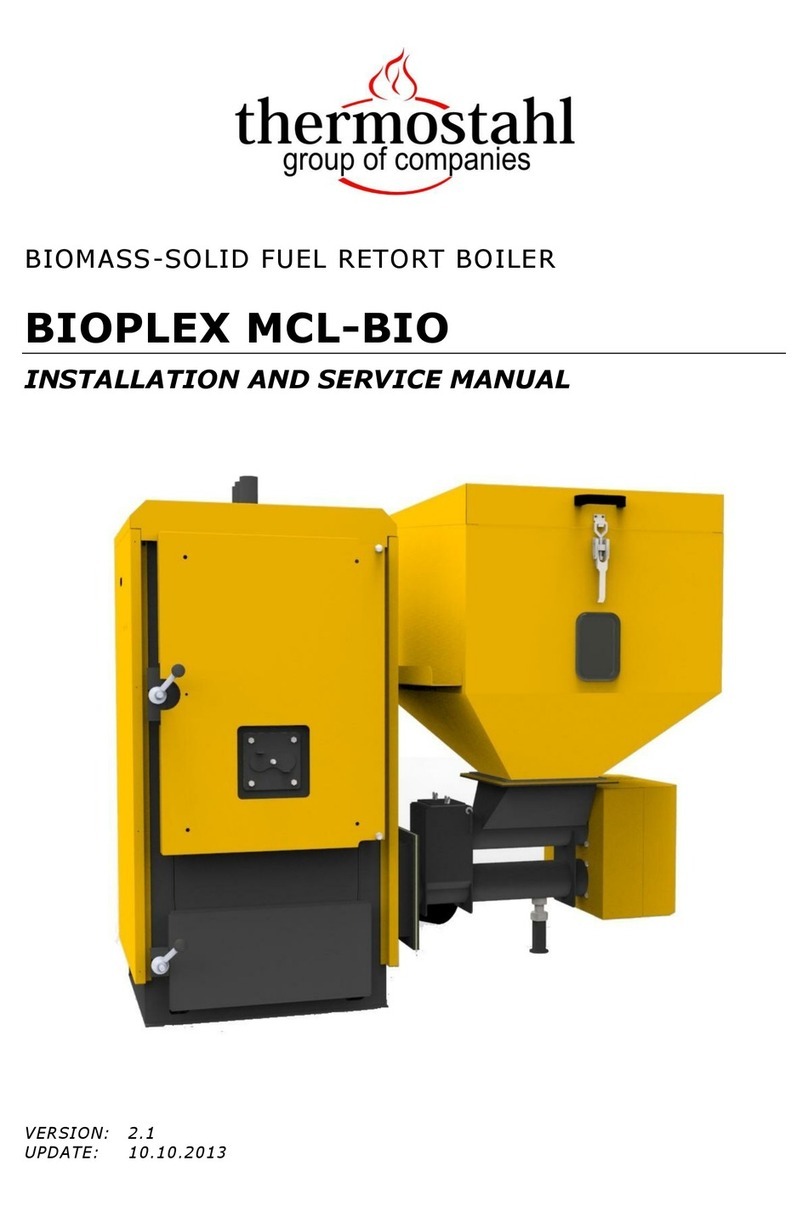

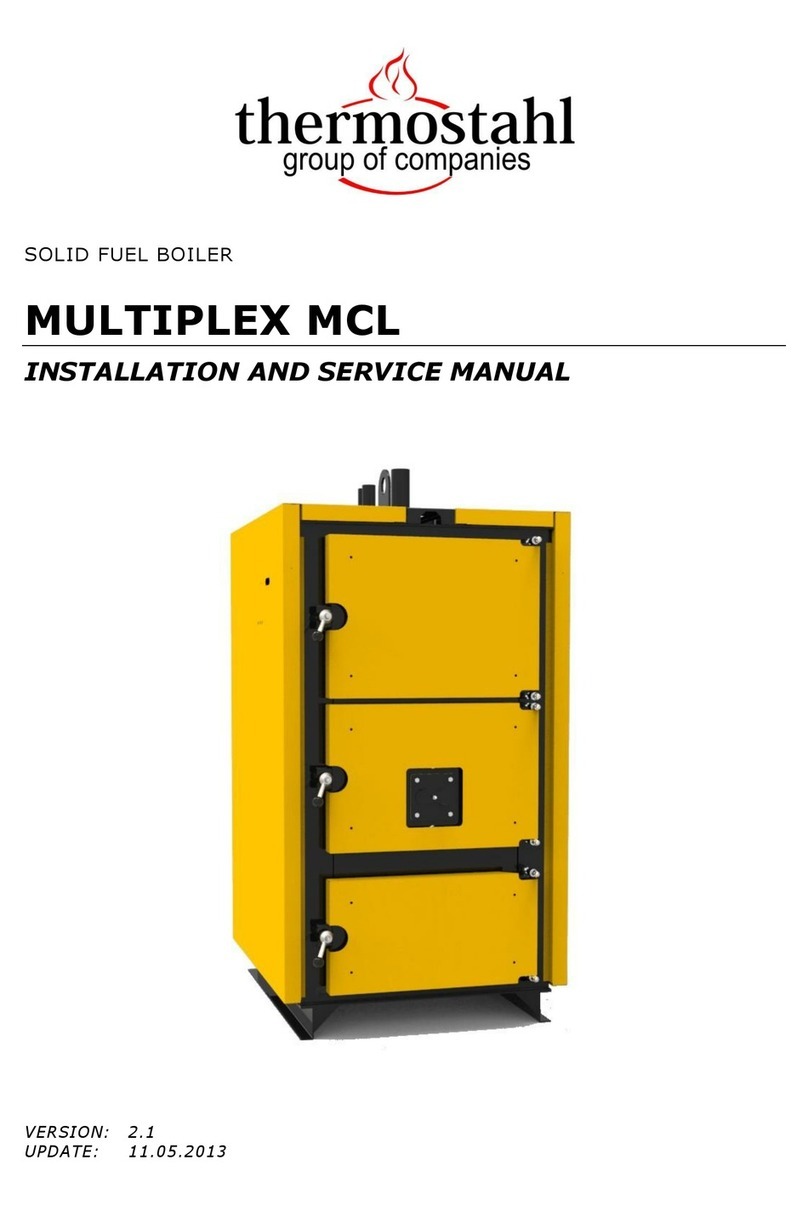

3.4.1 BOILER BODY

PELLETSTAR boiler is horizontal with smoke tubes.

The principal body of the boiler is made from hot laminated steel sheet St 37.2 STAS 500/2-

80~S235 JR SR EN 10025/90 according DIN 17100. Cutting is made with an automatic

plasma-cutting machine. The boiler is designed in such a way that all its parts touched by fire

to be cooled by water. Section, number and length of smoke tubes are specially designed for

a maximal exploitation of the burnt gases.

Welding are made according the 288-1 and 288-3 and DIN 50120, 50121-50145, SR EN

1011.1/2001 standards, by using of electric welding equipment (MIG-MAG) after the sock

currents method, for realizing the penetration of the material intended to be welded on all the

iron sheet thickness. The quality of the welding cords is checked according DIN 8563. The

welding process is according 131-ISO 4063.

The smoke box is screwed and has a special door for cleaning, insulated with a fireproof

plate, which works also as an explosion door (safety). The chimney of the smoke box is wide

enough to insure the exhaust of the smoke resulted after the burning process.

For increasing the efficiency, a delay of the exhaust smoke is made by using special

turbulators that will increase the thermal transfer factor.

Every boiler is separately tested at a hydraulic pressure of 4-5 bars (according the type) for

checking the tightness and strength. A thick insulation covers the whole boiler body.

The access door at the smoke pipes and burning chamber is protected inside with refractory

material for a good resistance against high temperatures. It is also provided with a glass fiber

braid for a very good tightness against NOx from the burning chamber. The door is provided

with an eye slit for an optical control of the burning process.

The door is also provided with a special flange adapted for mounting a pellet or a diesel

burner, if so is desired. Meanwhile it is compulsory that this flange to be well fitted so there

will be no smokes coming out from the burning chamber.

4. Boiler installation

Jackets assembling:

Jacket (covers) assembling on the boiler body is done easy and fast respecting the following

instructions.

Fitting order is the following:

a. Fit first the insulation and the side covers.

b. Fit the upper cover.

c. Screw in the upper front of the side covers the control panel and in the back the

cover for the smoke box.

d. Fit the insulation and cover for the front door by screwing first the connecting

screws between the door and jacket.

The boilers can be installed in their own room, in the basement, ground floor or the upper

floors of the production buildings from category C, D and E of fire danger warehouses of

incombustible materials and civil buildings, according the valid legislation.

ATTENTION! It is prohibited to install a boiler in a room with a common wall with rooms with

people that cannot evacuate themselves (hospitals, shops, kindergardens, daycare centers,

etc) or under the evacuation ways of those.

BOILER LOCATION must be separate of the joined rooms by walls, incombustible doors and

without window holes.

Space dimensions:

We advise that the boiler installation must be made in such a way that there is enough space

for easy cleaning and maintenance.

Boiler must be installed on horizontal plan and if possible easy to be accessed on all sides.

Burner must be installed on the front door and fastened with the screws on its special flange.

The auger must make an angle of 45 degrees with the floor.

The distance between the front wall and the boiler: at least 1,5 m.

The distance between the front wall and the boiler: the adequate distance that allows an easy

access for checking and maintenance.

The distance between the side wall and the boiler: at least 0,6 m.

The high of the boiler room: –at least 2,5 m.