INSTALLATION INSTRUCTIONS

MALIBUOIL FIRED CAST IRON BOILER

MODELS M-100THROUGH M.250.

LOCATION: Mount the baler near tho ch~mneyto keep the

flue plpec js short as poss~ble.Bo~lermust be mounted

on a level Il?ur,dat~onInstall on non-combust~blefloor

only

3.

Removeobstructions.

4

Replace worn sections of metal stacks.

5.

Seal bad masonry jolnts.

6

Repa~rdamaged linings

AIR SUPPLY: C. Where more than one appliance vents into a com-

monchimney, the area of the common flue should

A.

Enclosed boiler room having normal tight

construe-

at least equal the area of the largest flue plus 50%

tlon requlres two unobstructedopenings for passage of the add~tionalflueareas.

of air into the boiler room. D. Ch~mneyheight shall extend at least

3

feet above

1.

Air drawn vertically from outdoors; One openlng

on floor and one opening on ceiling each w~tha where

~t

passes through the roof of a building, and

minimum free air passagearea of 1square Inch at least 2 feet above any r~dgewithin 10 feet of the

per

4000

Btuh of total system ~nput. Ch~mney.

2.

Air drawn

horizontally

from outdoors through an

outslde wall; One louvredopenlng near the floor

(below burner air ~nlet)and one louvredopening

near the ceiling (abovethe highest draft regula

tor or draft hood rellef open~ngs),each opening

with a minimum free air passage area of 1

square inch per

2000

Btuh of total system input.

3.

Alr drawn from Insidethe bu~ldlng;One opening

near the floor (below burner air inlet)and one

openlngnear the celling (abovethe highest draft

regulator or draft hood relief open~ngs),each

openlng with a mlnlmum free air passage area of

1square inch per 1000 Btuh of total system

input

B.

If

boilers are installed adjacent to other fuel burning

equipment, the area of free openings must

be

appropriately increased to accommodate the addi.

tional load

E. Vent connector lnto chimney must be same size as

breeching outlet.

F. Vent connector should be Inserted into, but not

beyond Inside of chimney liner.

Q.

CAUTION-UNIT SHALL BE CONNECTEDTO A

FLUE HAVING SUFFICIENT DRAFT AT ALL TIMES,

TO ASSURE SAFE PROPER OPERATION OF THE

UNIT.

ELECTRICALSUPPLY: Electrical wlring and equ~pment

should be installed in accordance with CSA Standard

C22.1,

and Canadian

Electrical

Code, part 1and any

local codes having jur~sdiction

FUEL OIL SUPPLY:

011

piping should be a minimum of

tube A manual shut-off valve must be installed as

close as posslble to the oil storage tank. An oil filter of

C. Unless properly controlled, avo~dthe use of forced capaclty larger than the fir~ngrate of the burner should

ventilation, since it can create an undesirable pres-

be

Installed

011

plplng should be protected

:rcv

k~nk~ng

sure differentla1between boiler room and air source. or other damage

'For further details refer to C.G.A.Standard B 149.1

InstallationCode For Gas.

FLUE CONNECTION: Connect flue p3pebetween top of

the boiler and chimney.

Horizontal

sectlons of the flue

pipe must

be

pltched upward to the ch~mneyat least

'/r"

per foot. The breech~ngshould not exceed 10 ft. of how

zontal length The flue pipe should be cemented lnto the

thimble uslng asbestos shorts The thlmble should be

flush with the lns~desurfaceof the flue l~nerand the

flue pipe should not extend beyond th~spolnt Install

the draft regulator In the fluep~pe.as shown In the

separate ~nstructlonssheet lnslde the draft regulator

carton

CHIMNEY REOUIREMENTS

6

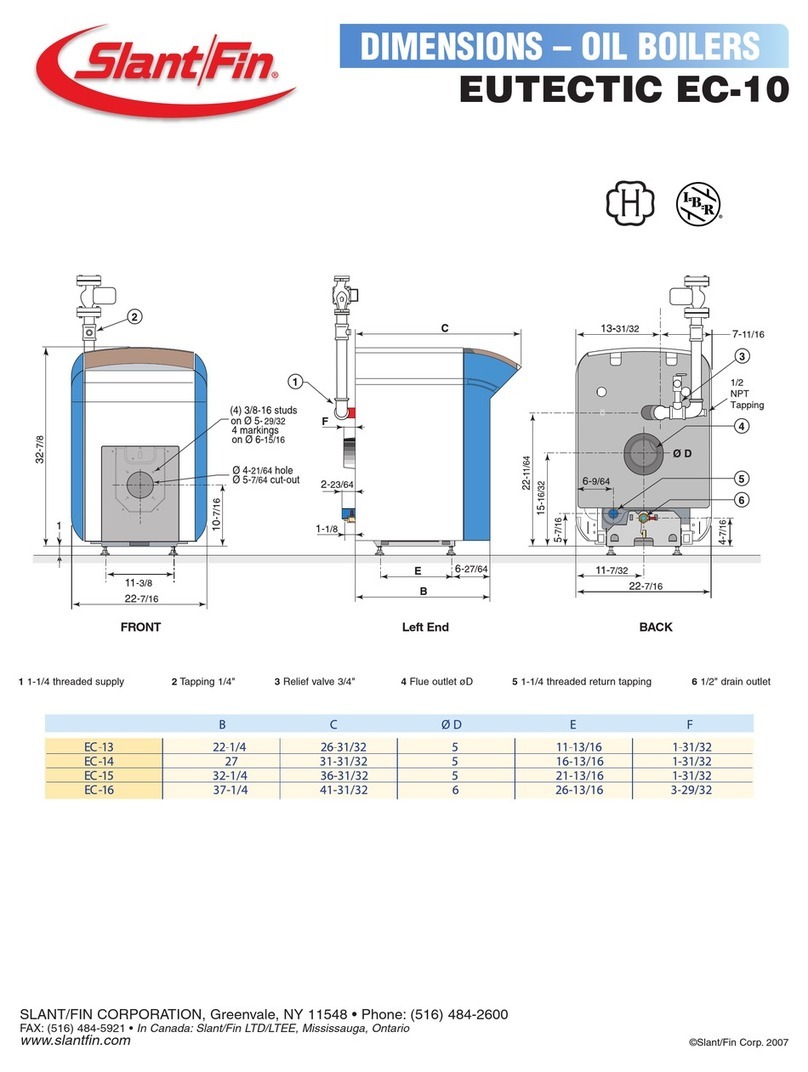

DIMENSIONS:Refer to

data on page

2

of

this

manual

A.

A vitreous tile lined ch~mneyof the slze shown on

Page

2

is recommended Local codes apply.

B.

Check ch~mneycond~tron

Exist~ngch~mneysand stacks may have deterlorat.

ed; without repalrs the11use would be hazardous

Before

connecting

to an oid ch~mneyor stack

1 Clean

11

2.

Inspect

~t

thorodgh!y

If the oil tank

IS

~nstalledabove or on level with the

burner,a one pipe s~nglestage o~lsystem may be used.

If the

011

tank

IS

~nslalledbelow the burner,a two pipe

s~nglestage

011

system may have to be used. If the total

lift is more than

8

feet, a two plpe,two stage fuel system

must be used.

If

a boosler pump

IS

used care should be taken to see

that the pressure orr the Inlet s~deofthe burner fuel un~t

does not exceed

8

PS I

G

FLOW CONTROL VALVE: When domest~chot water

tankless healer

IS

used a flow control valve should be

Installed In the supplv plplng as shown In the ~llustra-

t~on

MINIMUM CLEARANCES: Above

30"

Front

24"

Rear

18"

S~des

18"

Flue Plpe 18 inches

AOUASTAT SETTINGS: Low

ltrnlt

should be set at least

20" below

Ihe

htgh llmlt sett~ng

PRESSURE CONTROL SETTING: Recommended h~gh

l1m11sett~ng1s

10

P

S

I

G

The h~ghl~m~tsett~ngshould

never exceed

15

P

S

I

G

3