Thiele Streamfeeder Tagger 125 Series User manual

Manual

Series 125 Tagger

© 2016 Thiele Technologies, Inc. - Streamfeeder. All rights reserved.

No part of this publication may be reproduced, photocopied, stored on

a retrieval system, or transmitted without the express written consent of

Thiele Technologies, Inc. - Streamfeeder.

Thiele Technologies, Inc. - Streamfeeder

315 27th Avenue NE

Minneapolis, MN 55418 USA

Tel:(763) 502-0000

Fax:(763) 502-0100

e-Mail: service@streamfeeder.com

Web: www.streamfeeder.com

Printed in the USA.

1Tag Feeder Manual

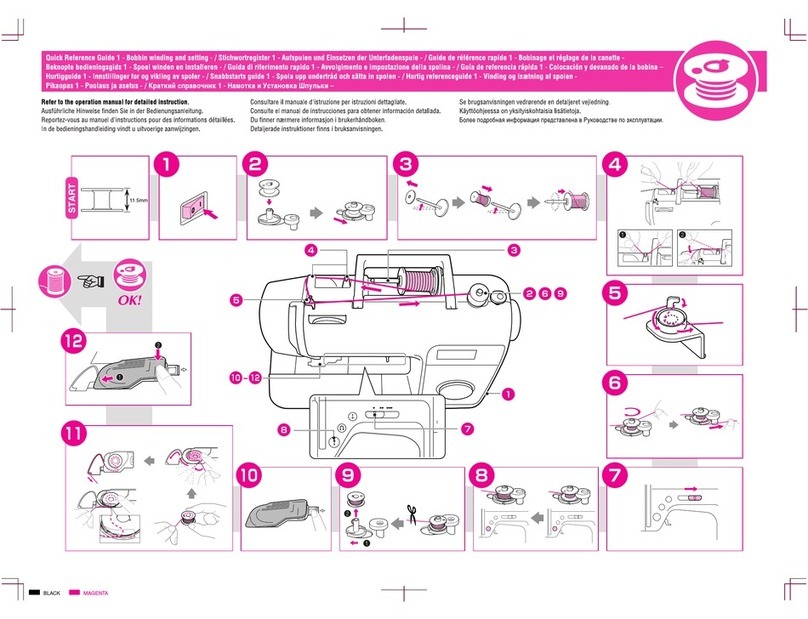

Review the main assemblies below to become familiar with names

and locations of feeder parts and adjustments. This will help to prepare

you for initial setup.

1About the Machine

Main Assemblies

Feed

Belts

Wedge

Assembly

Roller Wedge

Assembly

Pressure Plate

Product

Hold Down

Product

Tray

Discharge

Assembly

Product

Staging

Sensor

Controller

Mounting

Stand

Gate

Assemblies

2

Tag Feeder Manual

Feature Description

Main Assemblies Feature Descriptions

Feed Belts Provide the friction necessary to drive the tags through the separator and into the discharge.

Wedge Assembly Provides a light lift of the rear of the tag stack when loaded. This is critical to ensure that the

tags ow smoothly around the separators.

Product Tray Where the stack of tags are loaded.

Product Hold Down Applies pressure to the stack of tags as they ow through the product tray to ensure separation

of the tags are consistent.

Gate Assemblies Provide a gap between them and the feed belts to allow one tag to feed out at a time while

retaining the rest of the stack.

Discharge Assembly Receives the tags one at a time, accelerates it to create a gap, and positions the tag at the tag

detect sensor mounted at the end of the discharge. The discharge has spring loaded wheel

assemblies that require no adjustment and is covered by a guard to keep excessive dust out.

Controller Provides the logic and controls to operate the machine.

Product Staging Sensor Detects the leading edge of each piece to "stop" each cycle.

Pressure Plate Provides consistent stack pressure of the product onto the feed belts.

Mounting Stand The stand supports the feeder.

3Tag Feeder Manual

2Preparing for Operation

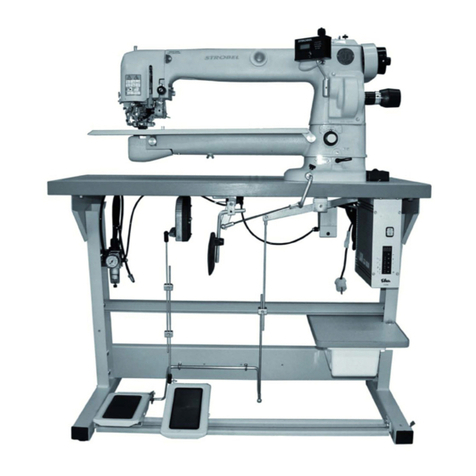

Below you will see the two main types of sewing machine congurations

for which we offer a Single Stage or a Dual Stage conguration.

Installation Use the single-stage discharge for infeeds like this

Use the dual-stage discharge for infeeds like this

Direction of

bag travel

Direction of

bag travel

Single stage

tagger feed

position

Dual stage tagger

feed position

4

Tag Feeder Manual

Depending on available locations, the trigger sensor and reector should

be mounted in an area along the conveyor that will allow it to detect

the bags as they come into the sewing machine. It is important that the

location is not interfered with by operators which could result in miss-

feeds. The provided mounting hardware will allow you to mount the

sensor and reector directly on the sewing machine frame.

Slide and set the pressure plate at the full rear/up position. Secure in

place with the detent knob.

Raise the gates a couple turns off the belt by turning the knob clockwise.

Insert a single tag between the separators and feed belts. Begin turning

one of the separator knobs counter clockwise while you slide the tag

back and forth until a slight drag is made. Then repeat with the second

separator. Once both are equally set, turn both knobs additionally

counter clockwise ¼ turn.

With a tag in position at the separators, add another 1-2” of tags to the

stack. Move the wedge in just so it makes contact with the rear of the

tags.

Continue loading product in the product tray. When loaded, release the

detent knob and allow the pressure plate to make contact with the stack.

Make sure the detent knob is in the full up position so that the pressure

plate slides freely.

Plug the machine into a properly grounded 120V outlet and release the

Estop button.

Mounting

Trigger Sensor

Set the Gates

Set the Wedge

Load Product

Turn on Power

5Tag Feeder Manual

HMI Displays User Interface

Upon power up the machine will default to Screen 1: RUN SCREEN

Press F4 to advance to screen 2:SETUP SCREEN

3Operation

6

Tag Feeder Manual

HMI Displays

Press the F1 key to jog the feed motor. – This will incrementally advance

tags from the stack and into the discharge and eventually out of the dis-

charge. While jogging, ensure that only one tag is coming out at a time and

that there is at least 1” spacing between each tag.

If tags are coming out in doubles, lower the separators CCW another ¼ turn.

Press the up arrow key to increase the delay time for the start of the tag feed

after the trigger sensor is made. – This value will vary based on the speed of

the system. When running slow, the value will be higher than when running

fast.

With Miss FLT on, the machine will go into an error state when multiple

triggers have come into the machine before the rst cycle was completed.

Press F2 to turn on or off.

Press ESC to return to RUN SCREEN.

7Tag Feeder Manual

HMI Displays Ready Indicator: The indicator turns black when the tagger is ready to ac-

cept trigger signals.

The fault indicator turns black on any error that stops the tagger from ac-

cepting trigger signals.

Press the F1 key to stage/start the tagger.

Press the F2 key to put the tagger in a paused state.

Press the F3 key to reset a faulted condition.

Test cycle Manual. For further setup testing, press and release the F1 key to

cycle the machine. One tag should be dispensed and the next one staged to

the tag detect sensor. Repeat as necessary.

Test cycle Automatic. To automatically test the machine, it will need to be

put into ready mode rst. Press F3 and then F1. The indicator next to the

word READY should change to black.

Run a bag through the conveyor and into the sewing machine. The bag

should trip the sensor and turn on the feeder to dispense a tag into the sew-

ing machine which will bring the tag onto the bag.

To set the position of the tag on the bag, use the up / down arrows to either

increase or decrease the trigger delay.

Repeat until tag is in desired position. Please note that relocation of the

trigger sensor and reector may be needed if you run out of adjustment

either way.

8

Tag Feeder Manual

For proper operation of the machine, periodic maintenance is required and

only takes a few minutes to complete.

Clean the feed belts and discharge belts as needed, no more than weekly

using a rag and isopropyl alcohol. Isopropyl alcohol is the best solution for

refreshing the belts and cleaning the dust off them. It can be purchased at

any Walgreens / CVS type stores.

As you are cleaning the belts, visually check the condition of the timing

belts to look for fraying or cracking – replace as needed.

Gate o-rings will need to be rotated as they develop at spots on them. The

best way to determine if they need to be rotated is that the machine will start

feeding doubles.

To adjust, simply loosen the screw and rotate the o-ring spool 1/8”.

Finally, a clean machine is a happy machine. Make sure to blow off dust

and contaminants on a regular basis.

4Maintenance

9Tag Feeder Manual

5Mechanical Components

ASSEMBLIES

Assembly # : 311-1439

10

Tag Feeder Manual

ASSEMBLIES

Assembly # : 311-1439

ITEM QTY. PART NUMBER DESCRIPTION

1 1 311-1285 ASSY, TAG FEEDER BASE

2 1 311-1341 ASSY TAGER WEDGE

3 1 311-1389 ASSY, TAG FEEDER DISCHARGE

4 1 311-1343 ASSY, TAG FEEDER CARRIAGE

5 1 904528 SIDE GUIDE TAG FEEDER

6 1 904669 FEEDER MOUNT ANGLE

7 1 311-1387 ASSY, TAG FEEDER HOPPER

8 1 311-1292 ASSY TAGGER SLIDING WEDGE

9 1 311-0940 EZ ADJUST STAND, TALL W/WIDE BASE

10 1 904395 ENCLOSURE BRACKET

11 1 904526 GUIDE RAIL

12 3 901571 MAGNET, BUTTON

13 1 44640021 BRACKET, PHOTO EYE

14 2 23500091 PRESS-FIT KNOB HEAD FOR #10 SHCS 5/8

15 2 102688B26 SHCS BLACK OXIDE 10-32 X .31

16 1 904533 SPACER PLATE

17 1 311-1392 ASSY, TAG FEEDER HOLD DOWN

18 2 903338 REFLECTIVE TAPE PAD

19 1 904670 BRACKET

20 7 102938B05 SHCS SSL 1/4-20 X .50

21 4 102913B03 FHCSS SST 6-32 X .50

22 4 103108B05 HEX NUT SST 6-32

23 2 102937B03 SHCSS SST 10-32 X .50

24 1 311-1440 ASSY SENSOR CLAMP

25 1 904458 GRAPHIC SET, TAG FEEDER

26 1 611-0433 CONTROLS, TAG FEEDER

11 Tag Feeder Manual

ASSEMBLY, BASE

Assembly # : 311-1285

12

Tag Feeder Manual

ASSEMBLY, BASE

Assembly # : 311-1285

ITEM QTY. PART NUMBER DESCRIPTION

1 1 904187 BASE PLATE

2 1 904188 SHELL

3 1 23511290 ASSY, BELT TENSIONER

4 2 44675004 BACK BASE PLATE MOUNT

5 2 44675003 MOUNT, FRONT

6 1 44500071 LABEL, BELT ROUTING

7 1 43555302 PULLEY, TIMING 12T XL 1/2 BORE

8 1 44500061 PLUG, 2 INCH HOLE COVER

9 1 44642023 DC MOTOR

10 1 904248 PROTECTIVE COVER

11 2 904400 MOTOR, MOUNT BRACKET

12 8 102937B03 SHCSS SST 10-32 X .50

13 1 102937B02 SHCSS SST 10-32 X .38

14 8 102637B03 FHCS BLACK OXIDE 10-32 X .50

15 4 102638B05 FHCS BLACK OXIDE STEEL 1/4-20 X .75

16 2 102689B01 SHCS BLACK/OXIDE 1/4-20 X .25

17 4 903357B07 BBHCS BLACK OXIDE ¼-20 X 1.00

13 Tag Feeder Manual

ASSEMBLY, WEDGE

Assembly # : 311-1341

14

Tag Feeder Manual

ASSEMBLY, WEDGE

Assembly # : 311-1341

ITEM QTY. PART NUMBER DESCRIPTION

1 1 901490 PLATE, WEDGE BASE

2 1 44633016 ROUND T-NUT

3 1 904507 WEDGE TAG FEEDER

4 2 23500091 PRESS-FIT KNOB HEAD FOR #10 SHCS 5/8 DIA

5 2 102688B02 SHCS BLACK OXIDE 10-32 X .38

15 Tag Feeder Manual

ASSEMBLY, DISCHARGE

Assembly # : 311-1389

16

Tag Feeder Manual

ASSEMBLY, DISCHARGE

Assembly # : 311-1389

ITEM QTY. PART NUMBER DESCRIPTION

1 1 903886 SHAFT, DISCHARGE

2 1 904190 RAIL, LH SIDE

3 1 904191 RAIL, RH SIDE

4 1 904193 SIDE GUIDE DISCHARGE RH

5 2 53500609 LABEL, WARN INJURY 2.7 X 1.4

6 1 904194 DECK, TRANSPORT CONVEYOR

7 2 44846050 HOLDER, R4 BEARING

8 2 23500032 HOLDER, R8 BEARING CUP

9 1 903889 DRIVE SHAFT, DISCHARGE

10 3 44450008 CROWN PULLY VACUUM

11 1 43560097 PULLEY, TIMING 16T XL 1/2 BORE

12 3 904394 BELT, EXT DISCHARGE

13 6 23500089 O-RING, STANDARD GATE

14 2 44963102 KNOB, 5 LOBE WITH 10-32 THREADED INSERT

15 2 44681021 THUMB KNOB W/10-32 INSERT

16 2 44582021 BEARING, BALL R4 .25 BORE

17 2 23500094 BEARING BALL R8 .500 BORE

18 1 904196 DECK, TRANSPORT COVER

19 2 102732B11 SSSCPPT BLACK OXIDE 10-32 X 1.00

20 2 44854033 SCREW SHOLDER SH/SS Ø.25 X .25

21 8 102937B03 SHCSS SST 10-32 X .50

22 4 102732B07 SSSCPPT BLACK OXIDE 10-32 X .50

23 2 102733B07 SSSCPPT BLACK OXIDE ¼-20 X .50

24 2 102732B03 SSSCPPT BLACK OXIDE 10-32 X .25

25 2 102937B01 SHCSS SST 10-32 X .25

17 Tag Feeder Manual

ASSEMBLY, CARRIAGE

Assembly # : 311-1343

18

Tag Feeder Manual

ASSEMBLY, CARRIAGE

Assembly # : 311-1343

ITEM QTY. PART NUMBER DESCRIPTION

1 1 44630019 DRIVE SHAFT

2 1 43555047 IDLER SHAFT

3 1 44630004 DRIVEN TUBE

4 1 44841056 VACUUM CARRIAGE SHAFT

5 1 44630003 BELT SUPPORT TUBE

6 1 44485005 HOLDER, CARRIAGE

7 1 44485006 HOLDER, CARRIAGE

8 6 23500094 BEARING BALL R8 .500 BORE

9 2 23500095 BEARING BALL R6 .375 BORE

10 1 23500097 PULLEY, 20T TIMING .50 BORE

11 1 43500096 BELT, TIMING XL 85 TEETH

12 1 43560098 PULLEY, TIMING 24T XL 1/2 BORE

13 1 23560078 BELT, TIMING XL, 39 TEETH

14 7 23500162 FEED BELT TAN GUM

15 2 103296B18 1/8 X 3/8 WOODRUFF KEY

16 5 104308B02 E-TYPE, STEEL CLIP FOR 1/2 SHAFT

17 2 104308B04 E-TYPE, STEEL CLIP FOR 3/8 SHAFT

18 10 102732B04 SSSCPPT BLACK OXIDE 10-32 X .31

19 6 102688B03 SHCS BLACK OXIDE 10-32 X .50