SAFETY

TRIPLE Safety Section 1-2

© 2015 Alamo Group Inc.

SAFETY

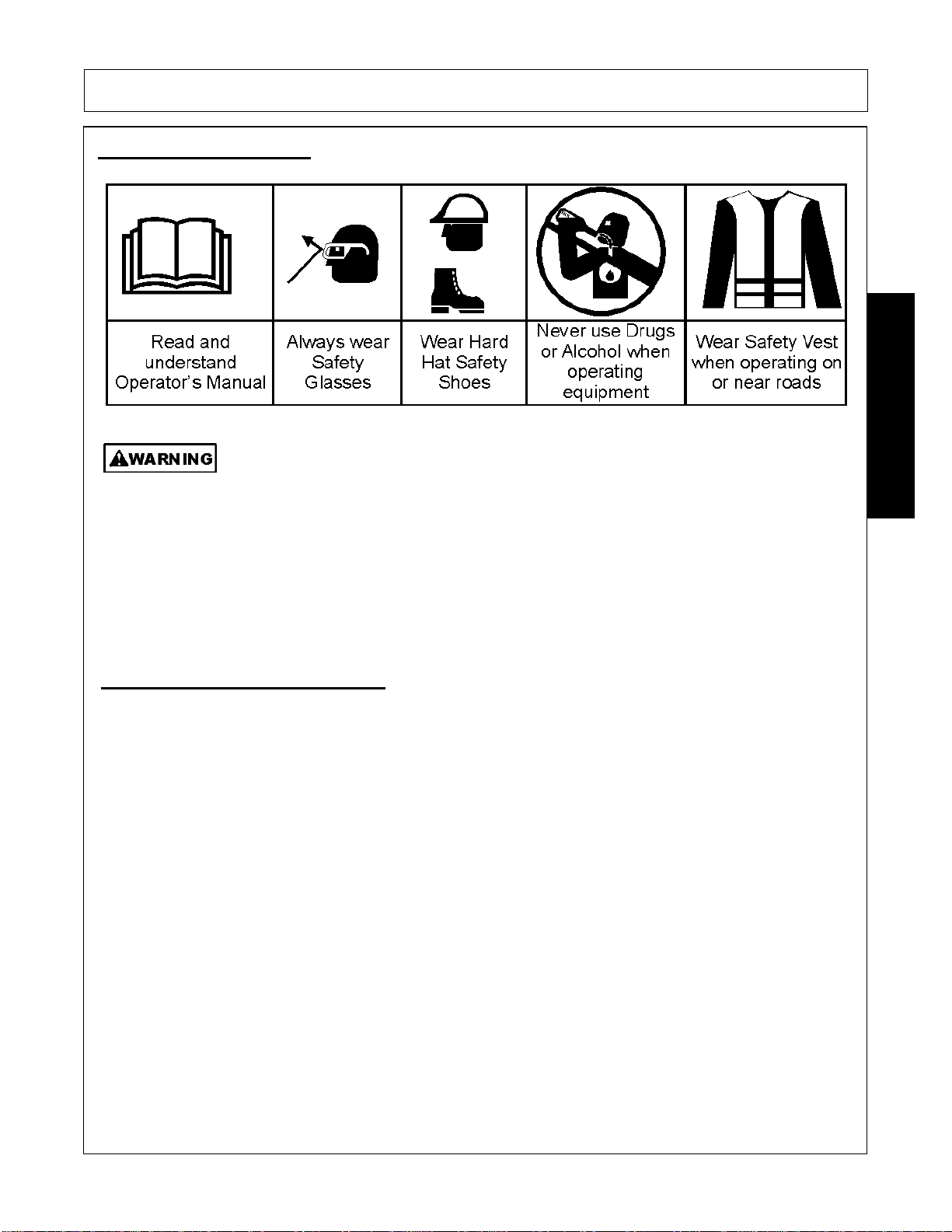

GENERAL SAFETY INSTRUCTIONS AND PRACTICES

A careful operator is the best operator. Safety is of primary importance to the manufacturer and should be to

the owner/operator. Most accidents can be avoided by being aware of your equipment, your surroundings,

and observing certain precautions. The first section of this manual includes a list of Safety Messages that, if

followed, will help protect the operator and bystanders from injury or death. Read and understand these

Safety Messages before assembling, operating or servicing this Implement. This equipment should only be

operated by those persons who have read the manual, who are responsible and trained, and who know how

to do so responsibly.

The Safety Alert Symbol combined with a Signal Word, as seen below, is used throughout this

manual and on decals which are attached to the equipment. The Safety Alert Symbol means:

“ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!” The Symbol and Signal Word

are intended to warn the owner/operator of impending hazards and the degree of possible injury

faced when operating this equipment.

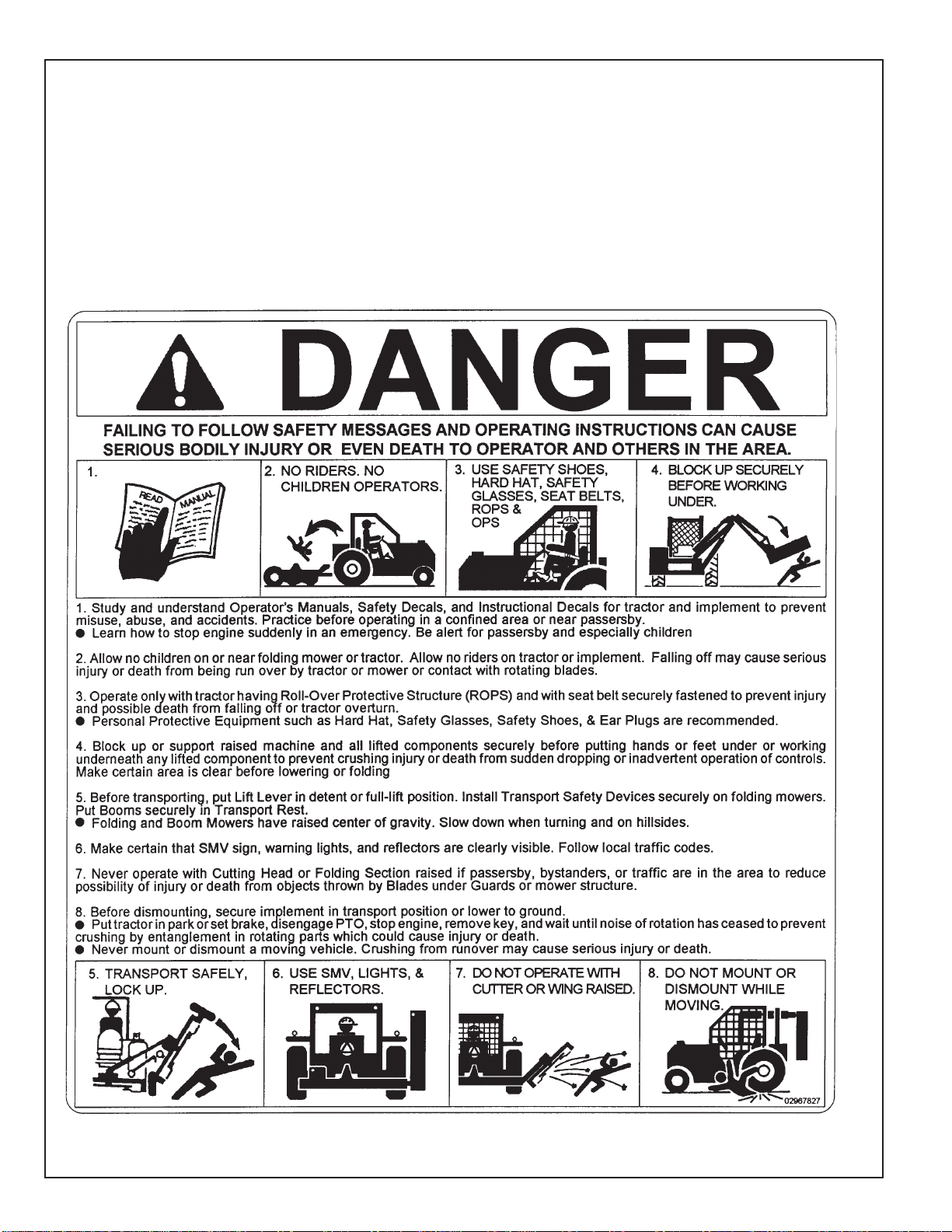

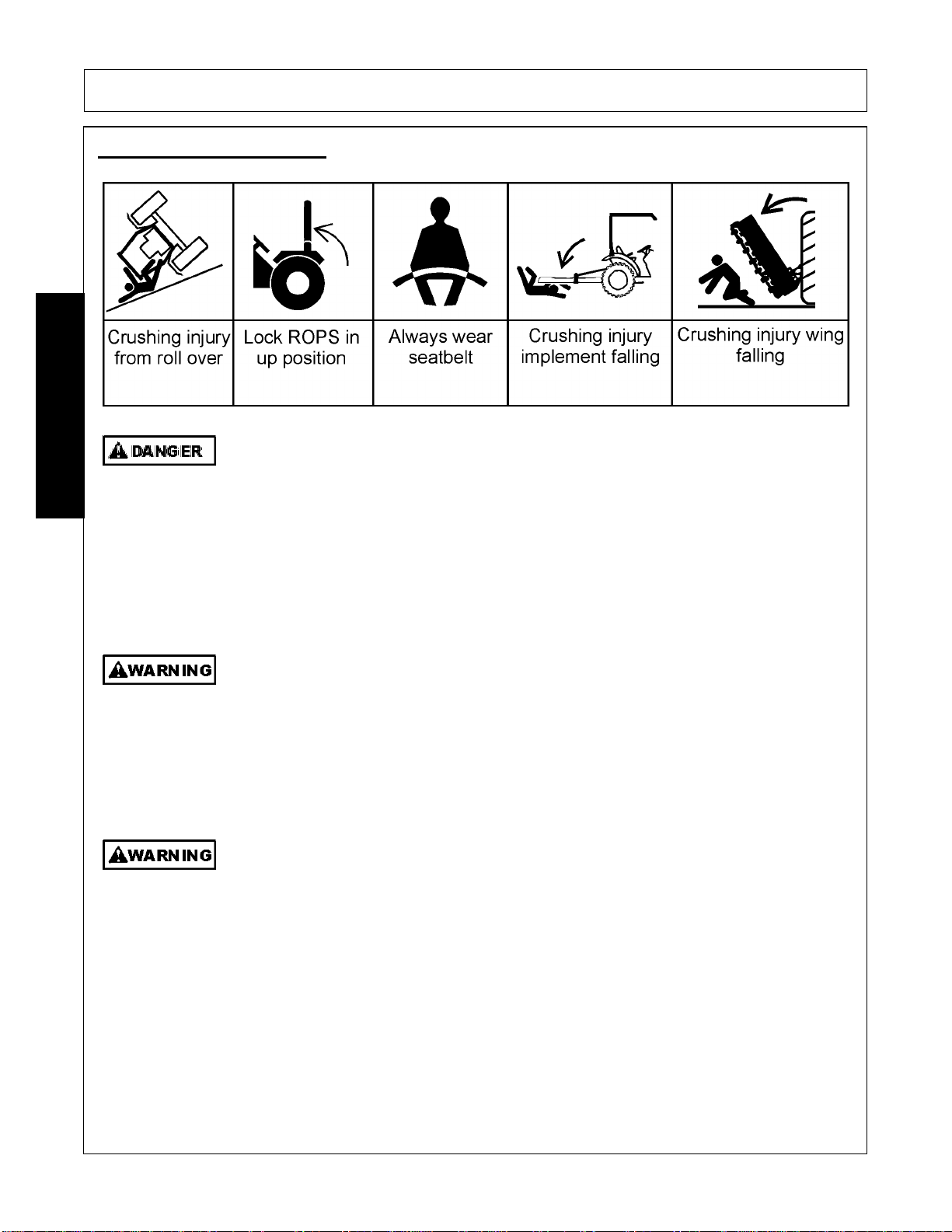

Indicates an imminently hazardous situation that, if not avoided, WILL result in DEATH OR

VERY SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, COULD result in DEATH

OR SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, MAY result in MINOR

INJURY.

Identifies special instructions or procedures that, if not strictly observed, could result in

damage to, or destruction of the machine, attachments or the environment.

NOTE: Identifies points of particular interest for more efficient and convenient operation or repair.

READ, UNDERSTAND, and FOLLOW the following Safety Messages. Serious injury or

death may occur unless care is taken to follow the warnings and instructions stated in this

Manual and in the Safety Messages on the implement. Always follow the instruction in this

manual and use good common sense to avoid hazards.

NOTE: If you want a translation of this safety section in one of the following Languages, please contact:

Translations at 1502 E. Walnut Street Seguin, TX 78155; Fax: (830) 372-9529; Safety Section Translations

are available in Spanish, Portuguese, French, German, Russian. PN GS01

Practice all usual and customary safe working precautions and above all---

remember safety is up to YOU. Only YOU can prevent serious injury or death

from unsafe practices.