Timber Tuff Tools TMS-20TLS User manual

20 TON Gas Powered Hydraulic

Log Splitter

OWNER’S MANUAL

Model# TMS-20TLS

WARNING:

Carefully read and understand all ASSEMBLY AND OPERATION INSTRUCTIONS

before operating. Failure to follow the safety rules and other basic safety precautions

may result in serious personal injury.

02232023

Thank you very much for choosing this product! For future reference, please complete the owner’s record below:

Model: # TMS-20TLS Purchase Date: _______________

Save the receipt, the warranty, and these instructions. It is important that you read the entire manual to become familiar with this

product before you begin using it.

This product is designed for certain applications only. The manufacturer cannot be responsible for issues arising from modification. We

strongly recommend that this product not be modified and/or used for any application other than that for which it was designed. If you

have any questions relative to a particular application, DO NOT use the product until you have first contacted us to determine if it can,

or should, be performed on the product.

For technical questions, please call 1-218-943-6290.

TECHNICAL SPECIFICATIONS

GENERAL SAFETY RULES

WARNING: Read and understand all instructions.Failure to follow all instructions listed below may result in

serious injury.

WARNING: Do not allow persons to operate or assemble this log splitter until they have read this manual

and have developed a thorough understanding of how the log splitter works.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot cover all

possible conditions or situations that could occur. It must be understood by the operator that common sense and

caution are factors that cannot be built into this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep work area clean, free of clutter, and well lit. Cluttered and dark work areas can cause accidents.

• Keep children and bystanders away while operating log splitter. Distractions can cause you to lose control, so visitors should

remain at a safe distance from the work area.

• Be alert of your surroundings. Using log splitter in confined work areas may put you dangerously close to sharp tools and

rotating parts.

• Do not operate in poor lighting.

Maximum Exerted Splitting Force

Engine Specifications

Starter Type

Cycle Time

Gear Pump

Control Valve

Hydraulic Cylinder Stroke Length

Max Log Length

Max Log Width

Hydraulic Fluid Type

Hydraulic Fluid Tank Capacity

Engine Oil Guide

Engine Oil Capacity

Fuel Type

Fuel Tank Capacity

Wheel Diameter

Net Weight

Overall Dimensions(L x W x H)

Low Oil Shut-off

Emissions

20 (US tons)

7.0HP / 209CC

Recoil Start

7.5 Seconds

11GPM

Detent (auto-return)

16"

20.5"

16"

AW32, AW46

2.1Gallon (8L)

SAE 10W-30 is recommended for general use.

Other viscosities shown in the chart may be

used when the average temperature in your

area is within the indicated range.

0.145Gallon (0.55L)

87 octane gasoline with NO ethanol content

NOTE: If using an ethanol blended fuel, a fuel stabilizer, mixed to manufacturer

specifications recommended (See engine manual)

0.74Gallon (approx. 2.8L)

10"

132LB

46.38" x 25.59" x 34.05"(Assembled)

Yes

EPA/CARB

2 of 12

SYMBOL MEANING

Read Operator’s Manual in its entirety.To reduce the risk of injury, user must read

and understand operator’s manual before using this product.

Eye and Ear Protection. Always wear safety goggles or safety glasses with side

shields, and as necessary a full face-shield as well as full ear protection when

operating this product.

Footwear. Always wear safety shoes or work boots when operating the machine.

Sandals and slippers or open toe shoes or any type are strongly discouraged.

Gloves. Always wear non-slip, heavy-duty protective work gloves when operating

this product.

Safety Alert. Precautions that involve your safety.

Risk of Fire. Fuel and its vapors are extremely flammable and explosive. Fire can cause

severe burns or death. Do not add fuel while the product is operating or still hot. Shut

down the unit and wait for unit to cool before refilling the fuel, oil, or hydraulic fluid tanks.

Skin Injection Hazard. Hydraulic oil under high pressure can penetrate your clothes and

skin. Make sure all fittings are fully seated and tightly secured before applying pressure.

Relieve system pressure before servicing.

Always keep hands away from the wedge and the ram.

Moving parts can crush or cut.

SAFETY DEFINITIONS

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations,

deserve your careful attention and review. The safety warnings do not by themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper accident prevention measures and care while using the product.

SAFETY SYMBOLS

Some of the following symbols are used on this product. Please study them and learn their meanings. Proper interpretation of

these symbols will help you to operate the product in a safe and responsible manner.

3 of 12

SYMBOL MEANING

Always keep feet away from the wedge and the ram. Moving parts can crush

or cut.

Hot Surface. To reduce the risk of injury or damage, avoid contact with any hot

surface.

Open Flame alert. Gas and its vapors are extremely flammable and explosive.

Keep gas away from open flames, sparks, pilot lights, heat, and other potential

ignition sources.

Hold logs on sides when loading. Keep hands and feet away from cylinder,

wedge, and partially split logs.

Never place hands or any part of the body between a log and any part of the

log splitter.

Do not split logs against the grain. Split logs end to end in the direction of the

grain only.

Toxic Fumes. The engine exhaust from this product contains chemicals known

to the state of California to cause cancer and birth defects and other

reproductive harm.

Risk of Asphyxiation. This engine emits carbon monoxide, an odorless, colorless

poison gas. Breathing carbon monoxide can cause nausea, fainting or death.

Use only in a well ventilated area. DO NOT use indoors (garage or shed or any

enclosed area).

Clearance. Keep all objects including others at least 10 feet (3m) from this

machine.

Only one person should operate the log splitter and load the logs.

Never operate on an incline. Make sure the splitter is on a level surface. Block

tires and ensure support leg is secure to prevent unintended movement of the

log splitter during operation.

4 of 12

DANGER indicates a hazardous situation which, if not avoided,will result in serious injury and possibly death.

WARNING indicates a potential hazardous situation which, if not avoided, could result in serious injury or death.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE indicates information considered important, but not hazard-related (e.g., messages relating to property

damaged).

SAFETY GUIDELINES

Cancer and Reproductive Harm – www.P65Warnings.ca.gov

Log splitter engine exhaust contains carbon monoxide, a colorless, odorless, poison gas. Breathing carbon monoxide will

cause nausea, dizziness, fainting or death.

If you start to feel dizzy or weak, get to fresh air immediately.

Using an engine indoors CAN KILL YOU IN MINUTES. Engine exhaust contains carbon monoxide. This is a poison you

cannot see or smell.

NEVER use inside a home or garage, EVEN IF doors and windows are open.

ONLY use OUTSIDE and far away from windows, doors, and vents.

Install battery-operated carbon monoxide alarms or plug-in carbon monoxide alarms with battery back-up according to the

manufacturer’s instructions to protect your home and loved ones from possible harm.

Moving parts can entangle hands, feet, hair, clothing and/or accessories. Traumatic amputation or severe laceration can result.

Keep hands and feet clear moving parts. Tie up long hair and remove jewelry before operating the device. Operate equipment

only fully assembled and with guards in place.

DO NOT wear loose-fitting clothing, dangling drawstrings or items that could become caught.

Operation of this equipment may create sparks that can start fires around dry vegetation.

Spark arrestor may be required. The operator should contact local fire agencies for laws or regulations relating to fire preven-

tion requirements.

Running engines produce heat. Severe burns can occur on contact. Combustible material can catch fire on contact.

DO NOT touch hot surfaces.

Avoid contact with hot exhaust gases.

Allow equipment to cool before touching.

Maintain at least 3 ft. (91.4 cm) of clearance on all sides to ensure adequate cooling.

Maintain at least 5 ft. (1.5 m) of clearance from combustible materials.

Crush Hazard

Wedge can cut through skin and break bones and in extreme cases amputate limbs and digits. Keep all limbs away from

wedge and endplate at all times.

Skin Injection Hazard. High pressure hydraulic oil can break skin and cause severe injury.

Make sure all fittings are seated firmly and tightly secured before applying pressure. Relieve system of pressure before

servicing.

5 of 12

Rapid retraction of the starter cord will pull hand and arm towards the engine faster than you can let go. Unintentional startup

can result in entanglement, traumatic amputation or laceration. Broken bones, fractures, bruises or sprains could result.

When starting engine, pull the starter cord slowly until resistance is felt and then pull rapidly to avoid kickback.

Parts of the hydraulic circuit (cylinder, pump, valve-body, hoses) can become very hot during operation.

This product IS NOT intended to to be towed behind a vehicle of any sort. The handle and wheels of the product are intended

for the sole purpose of easily moving the log splitter on your work site. Any modification or changes to allow moving of this

product by any other means other than by hand will render all warranties null and void.

Improper treatment or use of the log splitter can damage it, shorten its life and void your warranty.

Use the log splitter only for intended uses.

Operate only on level surfaces.

DO NOT expose log splitter to excessive moisture, dust, or dirt. Cover with a tarp or store in a shed when not in use.

DO NOT allow any material to block the cooling vents.

DO NOT use product if you observe engine if:

– Equipment sparks, smokes or flames from the motor

– Equipment vibrates excessively.

– Hydraulic Fluid is leaking from the unit

GAS SAFETY

GASOLINE AND GASOLINE VAPORS ARE HIGHLY FLAMMABLE AND EXPLOSIVE.

Fire or explosion can cause severe burns or death.

When adding or removing gasoline:

Turn the engine off and let it cool for at least two minutes before removing the gasoline cap. Loosen the cap slowly to relieve

pressure in the tank.

Only fill or drain gasoline outdoors in a well-ventilated area.

DO NOT pump gasoline directly into the engine at the gas station.

Use an approved container to transfer the gas to the engine.

DO NOT overfill the gasoline tank.

Always keep gasoline away from sparks, open flames, pilot lights, heat and other sources of ignition.

DO NOT light or smoke cigarettes while fueling.

When starting the engine:

DO NOT attempt to start a damaged engine.

Make certain that the gasoline cap, air filter, spark plug, gas lines and exhaust system are properly in place.

Allow spilled gasoline to evaporate fully before attempting to start the engine.

Make certain that the log splitter is resting firmly on level ground.

When operating the log splitter:

DO NOT move or tip the log splitter during operation.

DO NOT tip the log splitter or allow fuel or oil to spill.

When transporting or servicing the log splitter:

Make certain that the gas valve is in the OFF position, the gasoline tank is empty.

Disconnect the spark plug wire.

When storing the log splitter:

Store away from sparks, open flames, pilot lights, heat and other sources of ignition.

Do not store log splitter or gasoline near furnaces, water heaters, or any other appliances that produce heat or have automatic

ignitions.

NEVER use a gasoline container, gasoline tank, or any other gas item that is broken, cut, torn or damaged.

6 of 12

10

6

1

2

9

8

7

5

4

3

11 16

12

15

13 14

Engine Primary Beam Kit Bottom Plate Supporting Bar Wheels

Control Valve

Handle

Hydraulic Cylinder Handle Oil Hose Outer hexagon bolt

M10x 30mm

Hexagon Flange

Bolt M6x12mm

Hexagon Flange

Bolt M8x35mm

Hose Clamp Flat Washer R pin Spring Washer M8 Nut Oil Dipstick

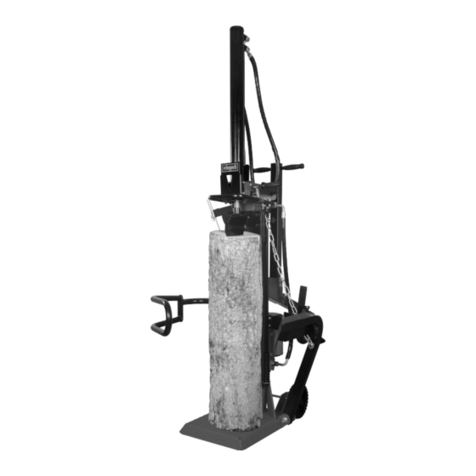

CONTROLS AND FEATURES

1. Handle

2. Splitting Wedge

3. Support Leg – Supports log splitter while operating.

4. Splitting Support Beam---DO NOT PUNCTURE The hydraulic tank is inside.

5. Hydraulic cylinder base.

6. 10" Wheels

7. Hydraulic Oil Dipstick – Add or check Hydraulic oil level.

8. Hydraulic Cylinder – Converts hydraulic pressure into linear force.

9. Control Valve Handle – Controls the movement of the thrust plate.

10. Engine 209cc 4-stroke, air cooled.

11. Hydraulic Oil Return (Low Pressure) Hose – returns hydraulic oil back into the hydraulic tank.

12. Suction Hose – Draws hydraulic oil from the tank into the pump.

13. Hydraulic Pump – Pumps hydraulic oil through the system.

14. Engine Oil Fill Cap / Dipstick – Add or check the motor oil level.

15. Hydraulic Oil Inlet (High Pressure) Hose – Feeds hydraulic oil into the hydraulic cylinder.

16. Fuel tank cap.

PARTS LIST

Hexagon Flange

Bolt M6x45mm

Hexagon Flange

Bolt M6x35mm

M6 Nut

7 of 12

Recommended tools: Needle nose pliers

M6 Nut,

Hexagon Flange Bolt M6x45mm

Hexagon Flange Bolt M6x12mm Tightening torque:9-12 N.m

Recommended tools: Ratchet Wrench (10mm)

Recommended tools: Ratchet Wrench (10mm)

STEP #1

STEP #2

STEP #3

STEP #4

Recommended tools

ASSEMBLY

8 of 12

STEP #5

STEP #6

STEP #7

STEP #8

STEP #9

STEP #10

Spring Washer φ8

Hexagon Flange Bolt M8x25mm

Tightening torque:45-60 N.m

Hose connector recommend tightening torque:80 N.m

M8 Nut,

Hexagon Flange Bolt M8x35mm

Tightening torque:25-30 N.m

Hose connector recommend tightening torque:80 N.m

M6 Nut,

Hexagon Flange Bolt M6x35mm,

Recommended tools: Wrench (27mm 22mm)

Recommended tools: Wrench (27mm 22mm)

Recommended tools: Wrench (13mm)

Recommended tools: Wrench (10mm)

Recommended tools: Wrench (16mm)

Add gas, oil and hydraulic fluid before first Use.

9 of 12

OPERATION

1. Read the Operator’s Manual completely before attempting to use this log splitter.

2. Do not allow anyone to operate your log splitter who has not read the Operator’s Manual or has not been instructed on the

safe use of the log splitter.

3. Never allow children or untrained adults to operate this machine.

4. Never leave the machine unattended with the engine running.

5. Never operate the machine when under the influence of alcohol, drugs or medication

6. Many accidents occur when more than one (1) person operates the log splitter. If a helper is assisting in loading logs to be

split, never actuate controls until helper is clear of the area.

7. Never allow anyone to ride on the machine during use or during operation.

8. Never transport cargo on the log splitter.

9. Always operate the log splitter with all safety equipment in place and all controls properly adjusted for safe operation.

10. High fluid pressures are contained in hydraulic log splitters.

Pressurized hydraulic fluid escaping through a pin hole opening can puncture skin and cause severe bleeding and result in

blood poisoning. Therefore, the following instructions should be heeded at all times.

– Be sure to confirm all hose connections and hose clamps are tight before each use. It is possible for connections to

vibrate loose over time

– Do not operate the unit with frayed, kinked, cracked or damaged hoses, fittings, or tubing.

– Stop the engine and relieve hydraulic system pressure before changing or adjusting fittings, hoses, tubing, or other

system components.

– Do not adjust the pressure settings of the pump or valve. The factory presets are tested for optimal system performance.

Tampering with or modifying these settings will render your product warranty nu,, and void.

– Do not check for leaks with your hand. Leaks can be detected by passing cardboard or wood over the suspected area.

Look for discoloration. If injured by escaping fluid, see a doctor at once. Serious infection or allergic reaction can develop

if proper medical treatment is not administered immediately.

11. Keep the operation zone and adjacent area clear for safe, secure footing.

12. Always keep hands and feet clear of moving parts.

13. If your log splitter is equipped with an internal-combustion engine and intended for use near any unimproved forest, brush,

or grass covered land, the engine exhaust should be equipped with a spark arrestor. Make sure you comply with local,

state, and federal codes. Take appropriate fire-fighting equipment with you.

14. Log splitters should be used only for splitting wood. Do not use for other purposes unless the manufacturer provides

attachments and instructions for such purposes.

15. When loading a ram-type log splitter, place your hands on the sides of the log, not the ends. Never place your hands or any

part of your body between a log and any part of the log splitter

16. Only split wood WITH the grain. NEVER split perpendicular to the grain.

17. On ram-type log splitters, never attempt to split more than one log at a time unless the ram has been fully retracted and a

second log is needed to complete the splitting of the first log.

18. On ram-type log splitters when the logs are not squared, the longest portion of the log should be rotated down and the

most squared end placed against the ram.

19. Use only your hand to operate the log splitter controls, never kick the handle with your feet.

20. Do not refuel the engine until it has cooled for several minutes.

* Please read Alphaworks "Gasoline Engine Manual" for engine operation requirements and precautions.

Add Hydraulic Oil

DO NOT remove the hydraulic oil fill cap when the engine is running or hot. Hot oil can escape causing severe burns.

Always allow the log splitter to cool completely before removing the hydraulic oil cap.

High fluid pressure and temperatures are created in the hydraulic log splitters. Hydraulic fluid will escape through a pin-size

hole opening and can puncture skin.

Inspect hydraulic system regularly for possible leaks.

Never check for leaks with your hand while the system is pressurized.

Seek medical attention immediately if injured by escaping fluid.

To check hydraulic oil level, insert the dipstick into fill neck until it stops.

Remove and read level. Do not thread dipstick into fill neck when checking oil.

When the outdoor temperature is below 32°F , Dexron III transmission fluid can be used.

1. Make sure the log splitter is on a flat, level surface.

2. Remove the dipstick from the oil tank.

3. Add 1.6gallon of hydraulic oil - AW32 / AW46

4. Check hydraulic oil level with oil dipstick. The oil level should be on the dipstick.

5. Tighten the dipstick.

6. Start engine (see Starting the Engine in the Operation section).

7. Extend and retract the cylinder to purge air from the hydraulic system. Cylinder motion should be smooth and continuous.

10 of 12

8. Shut-off engine (see Stopping the Engine in the Operation section).

9. Hydraulic oil can be added appropriately when the cylinder thrust is insufficient.

For safety reasons, hydraulic oil, oil and fuel are not included in the package.

MAINTENANCE AND STORAGE

1. Always shut off the power source while repairing or adjusting the splitter except as recommended by the manufacturer.

2. Clean debris from the engine cylinder, cylinder head fins, recoil starter cover, and muffler areas. If the engine is equipped

with a spark arrestor muffler, clean and inspect it regularly (follow manufacturer’s service instructions). Replace, if damaged.

3. Never store the unit indoors with fuel in the tank. Fumes might reach an open flame spark. Allow the engine to cool before

storing in any enclosure.

4. Clear debris from movable parts, but only when the power source is shut off.

5. Check to be sure all nuts and bolts are tight to assure the equipment is in safe working condition prior to each usage, and

periodically during usage. Engine motor vibration may shake screws and bolts loose during operation.

TROUBLE SHOOTING

Problem

Engine will not start.

Engine will not start.

Engine starts but runs roughly.

Engine shuts down during operation.

Engine cannot supply enough power

or overheating.

Wedge movement is slow or erratic.

Oil leak from cylinder.

Wedge will not extend or retract.

The hose is twisted after tightening.

The valve stem springs back multiple

times.

Cause

No gas.

Faulty spark plug.

Unit loaded during start up.

Low oil level.

Choke in the wrong position.

Spark plug wire loose.

Out of gas.

Low oil level.

Insufficient ventilation.

Air in the hydraulic oil system.

Debris lodged in beam guides.

Low hydraulic oil.

Hydraulic oil is not continuous.

Faulty cylinder rod seal.

Scored or bent cylinder rod.

Loose hydraulic fitting.

Faulty combination washer seal

on cylinder hydraulic fitting.

Faulty control valve.

Faulty hydraulic pump.

Low hydraulic oil.

The hose rotates.

There is air in the hydraulic hoses.

Solution

Add gas.

Replace spark plug.

Remove load from unit.

Fill crankcase to the proper level.

Place log splitter on a flat, level surface.

Adjust choke.

Attach wire to spark plug.

Fill gas tank.

Fill crankcase to the proper level. Place log

splitter on a flat, level surface.

Check for air restriction. Move to a well

ventilated area.

Purge air by extending and retracting the wedge

several times until motion is smooth.

Clear debris from beam.

Check oil level and add as needed.

Add hydraulic fluid.

Contact Customer Service.

Contact Customer Service.

Tighten hydraulic fitting.

Contact Customer Service.

Contact Customer Service.

Contact Customer Service.

Check oil level and add as needed.

Clamp the hose sleeve with pipe pliers and tighten

the joint with a wrench

Unscrew oil dipstick to vent.

11 of 12

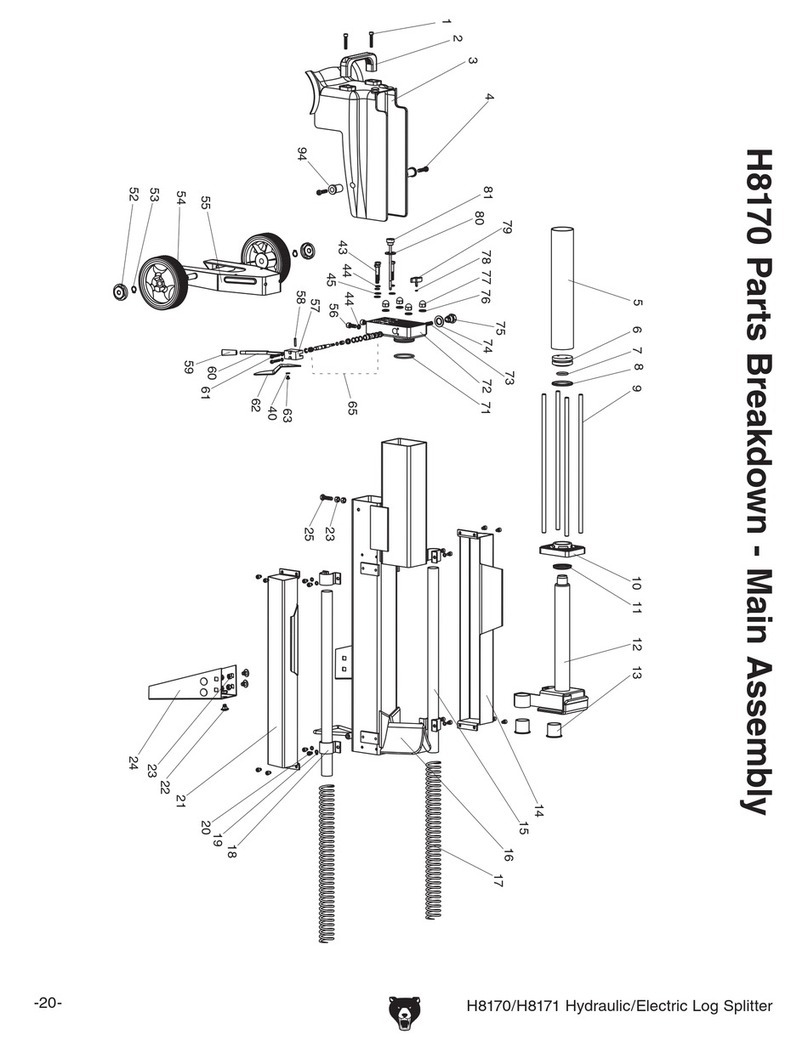

DIAGRAM & PARTS LIST

This unit is not returnable.Please call 1-218-943-6290, for replacement parts and technical assistance.

WARRANTY

One-year limited parts warranty.

Part No.

1

2

3

4

5

6

7

8

9

10

11

Description

R Pin 2x40mm

Flat Washer 16mm

10 " Wheel

Flange Nut M8

Hexagon Flange Bolt M8x40mm

Bottom Plate

Hexagon Flange Bolt M8x20mm

Hose Clamp 32mm

Oil Hose

Elastic Ring 22mm

Filter

Q’ty

2

2

2

4

4

1

4

2

1

1

1

Part No.

12

13

14

15

16

17

18

19

20

21

22

Description

Hydraulic Cylinder Kit

Oil Dipstick

Spring Washer 10mm

Outer hexagon bolt M10x 30mm

Primary Beam Kit

Flange Nut M6

Handle

Hexagon Flange Bolt M6x35mm

Hexagon Flange Bolt M6x45mm

Supporting Bar

Engine

Q’ty

1

1

4

4

1

3

1

1

2

1

1

(17)

1

2

4

3

56

7

8

9

10

11

(8)

12

14

13

15 16

17

18

19

20

21 22

Size: 210x285mm REV 02/23/23157克双铜 3.02.01.268.C001

12 of 12

BAC Industries

PO BOX 155

Miltona, MN 56354

Made in CHINA

Table of contents

Popular Log Splitter manuals by other brands

Wallenstein

Wallenstein 3652A300 installation instructions

Wallenstein

Wallenstein WXR720 Operator's manual

Kity

Kity PV 8000 Translation from the original instruction manual

ATIKA

ATIKA ASP 6 N Original instructions

Craftsman

Craftsman 247.34625 owner's manual

White Outdoor

White Outdoor 24AA570H190 Operator's manual

Scheppach

Scheppach HL1050 Translation of original instruction manual

Hard Head

Hard Head 009669 operating instructions

The Handy

The Handy THLSS-B Operator's manual and parts list

Greyhound

Greyhound 65076 Set up, operating, and servicing instructions

Texas A/S

Texas A/S MPC 1500 user manual

Grizzly

Grizzly H8170 Parts Breakdown