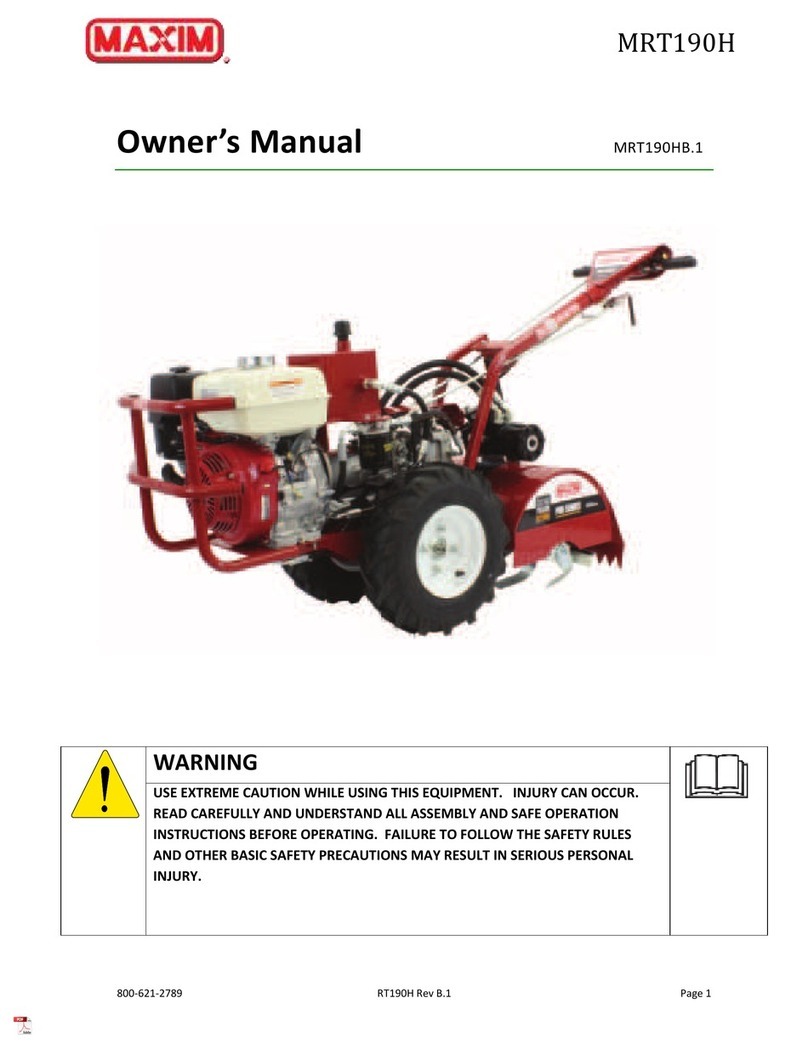

Titan Pro TP 700 User manual

SAFETY

SAFETY

SAFETY

SAFETY

OWNER

OWNER

OWNER

OWNER’

’

’

’S

S

S

SRESPONSIBILITY

RES PONSIBILITY

RESPONSIBILITY

RESPONSIBILITY

Accurateassemblyandsafeandeffectiveuseofthe

Rototilleristheowner

’

sresponsibility.

�Readandfollowallsafetyinstructions.

�Carefullyfollowallassemblyinstructions.

�Maintainthetilleraccordingtodirectionsand

ScheduleincludedinthisEarthquakeoperator

’

smanual.

�Ensurethatanyonewhousesthetilerisfamiliarwith

Allcontrolsandsafetyprecautions.

SPECIAL

SPECIAL

SPECIAL

SPECIALMESSAGES

MES SAGES

MESSAGES

MESSAGES

Yourmanualcontainsspecialmessagestobringattentionto

Potentialsafetyconcerns,machinedamageaswellashelpful

Operatingandservicinginformation.Pleasereadalltheinformation

Carefullytoavoidinjuryandmachinedamage.

NOTE:

NOTE:

NOTE:

NOTE:General

Ge neral

General

Generalinformation

in formation

information

informationis

is

i s

isgiven

gi ven

given

giventhroughout

th roughout

throughout

throughoutthe

th e

the

themanual

ma nual

manual

manualthat

th at

that

that

May

May

May

Mayhelp

he lp

help

helpthe

th e

the

theoperator

op erator

operator

operatorin

in

i n

inthe

th e

the

theoperation

op eration

operation

operationor

or

o r

orservice

se rvice

service

serviceof

of

o f

ofthe

th e

the

themachine.

ma chine.

machine.

machine.

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANTSAFETY

SA FETY

SAFETY

SAFETY

PRECAUTIONS

PRECAUTIONS

PRECAUTIONS

PRECAUTIONS

Please

Please

Please

Pleaseread

re ad

read

readthis

th is

this

thissection

se ction

section

sectioncarefully.

ca refully.

carefully.

carefully.

Operatethetilleraccordingtothesafetyinstructionsandrecommendations,

Outlinedhereandinsertedthroughoutthetext.Anyonewhousesthistiller

Mustreadtheinstructionsandbefamiliarwiththecontrols.Yourtilleris

Equippedwithasafetydevicethatenablesyoutostopthewheels

andtinesquicklyinanemergency.

Learnhowthesafetycontrolleveroperatesandhowtocontrolthetiler

atalltimes.

This

Th is

This

Thissymbol

sy mbol

symbol

symbolponts

po nts

ponts

pontsout

ou t

out

outimportant

im portant

important

importantsafety

sa fety

safety

safetyinstructions

in structions

instructions

instructionswhich

wh ich

which

whichif

if

i f

ifnot

no t

not

notfollowed

fo llowed

followed

followedcould

co uld

could

could

Endanger

Endanger

Endanger

Endangersafety.

sa fety.

safety.

safety.Read

Re ad

Read

Readand

an d

and

andfollow

fo llow

follow

followall

al l

all

allinstruction

in struction

instruction

instructionin

in

i n

inthis

th is

this

thismanual

ma nual

manual

manualbefore

be fore

before

before

attempting

attempting

attempting

attemptingto

to

to

to

O perate

Op erate

Operate

Operatethis

th is

this

thisequipment.

eq uipment.

equipment.

equipment.

2

�Donotallowchildrentooperatethisrototiller.Keepsmallchildrenawayfromthearea

beingtilled.Donotallowadultstooperatethetillerwithoutproperinstruction.

PREPARATION

PREPARATION

PREPARATION

PREPARATION

�Dressappropriatelywhenoperatingthetiller.Alwayswearsturdyfootwear.Neverwear

sandals.Sneakers,oropenshoes,andneveroperatethetillerwithbarefeet.Donotwear

looseclothingthatmightgetcaughtinmovingparts.

�Carefullyinspecttheareatobetilledandremoveallforeignobjects.Donottillabove

undergroundwaterlines,electriccables,orpipes.Donotoperatethetillerinsoilwithlarge

rocksandforeignobjectswithcandamagetheequipment.

�Disengageallclutchesandleaveallcontrolleversintheneutralpositionbeforestartingthe

engine.

�Handlefuelwithcare:itishighlyflammable.

a.Useandapprovedfuelcontainer.

b.Neveraddfueltoarunningengineorhotengine.

c.Fillfueltankoutdoorswithextremecare.Neverfillfueltankindoors.

d.Replacegasolinecapsecurelyandcleanupspilledfuelbeforerestarting.

�Neverattempttomakeanyadjustmentswhiletheengineisrunning.

OPERATION

OPERATION

OPERATION

OPERATION

�Neveroperatethetillerwithoutguards,covers,andhoodsinplace.

�Neverstarttheengineoroperatethetillerwiththewheelhubsandwheelaxle.Thewheels

actasbraketokeepthetilleratacontrolledspeed.Disengagewheellockpintopermit

free-wheelingonlywhenengineisstopped.

�Keephands,feet,andclothingawayfromrotatingparts.Keepclearoftillertinesatalltimes.

�Tinesandwheelsrotatewhentillerisengagedinforwardorreverse-inforward,tinesand

wheelsrotatewhenthedrivesafetycontrollever(FORWARD

FO RW ARD

FORWARD

FORWARD),ispusheddowntowardthe

handlebar.Inreverse,wheelsandtinesrotatewhenthedrivesafetycontrollever

(REVERSE

REVERSE

REVERSE

REVERSE),ispulledbacktowardtheoperator.Releasingthereversehandletotheneutral

positionstopsthewheelsandtines.Donotoperatebothdrivesafetycontrolleversatthe

sametime.

�Beextremelycautiouswhenoperatinginreverse.

Takeextracaretoavoidslippingorfalling,

andkeephandsandfeetclearoftines.

�Useextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.

Stayalertforhiddenhazardsortraffic.

3

�Afterstrikingaforeignobject,stoptheengine,removethewirefromthesparkplug,

thoroughlyinspectthetillerforanydamage,andrepairthedamagebeforerestartingand

operatingthetiller.

�Ifvegetationclogsthetines,raisethehandlebarstoelevatethetines,andrunthetillerin

reverse.Ifthisdoesnotcleancloggedvegetationfromthetines,STOP

STO P

STOP

STOPTHE

TH E

THE

THEENGINE

EN GINE

ENGINE

ENGINEAND

AN D

AND

AND

DISCONNECT

DISCONNECT

DISCONNECT

DISCONNECTTHE

TH E

THE

THESPARK

SP ARK

SPARK

SPARKPLUG

PLU G

PLUG

PLUGWIRE

WIR E

WIRE

WIREbeforeremovingvegetationbyhand.

�Enginemufflerwillbehotfromoperation.Donottouchinwithbareskinoraseverebum

mayresult.

�Iftheunitshouldstarttovibrateabnormally,stoptheengineandcheckimmediatelyforthe

cause.Vibrationisgenerallyawarningoftrouble.

�Donotruntheengineindoors,exhaustfumesaredeadly.

�Donotoverloadthemachinecapacitybyattemptingtotilltoodeepattoofastarate.

�Neveroperatethemachineathightransportspeedsonslipperysurfaces.Lookbehindand

usecarewhenbacking.

�Neverallowbystandersneartheunit.

�Useonlyattachmentsandaccessoriesapprovedbythemanufacturerofthetiller.

�Neveroperatethetillerwithoutgoodvisibilityorlight.

�Becarefulwhentillinginhardground.Thetinesmaycatchinthegroundandpropelthetiller

backward.Ifthisoccurs,letgoofthehandlebarsanddonotrestrainthemachine.

�Takeallpossibleprecautionswhenleavingthemachineunattended.Disengageallcontrol

levers,stoptheengine,waitforallmovingpartstostop,andmakecertainguardsandshields

areinplace.

�Whenleavingtheoperatingpositionforanyreason:

�shutofftheengine

-waitforallmovingpartstostop

-

-

-

-MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCEAND

AN D

AND

ANDSTORAGE

STO RAGE

STORAGE

STORAGE

�Keepmachine,attachments,andaccessoriesinsafeworkingcondition.

�Checkshearbolts,enginemountingbolts,andotherboltsatfrequentintervalsforproper

tightnesstobesuretheequipmentisinsafeworkingcondition.

�Topreventaccidentalstarting,alwaysdisconnectandsecurethesparkplugwirefromthe

sparkplugbeforeperformingtillermaintenance.

�Neverruntheengineindoors.Exhaustfumesaredeadly.

�Alwaysallowmufflertocoolbeforefillingfueltank.

�Neverstoreequipmentwithgasolineinthetankinsideaclosedbuildingwherefumesmay

reachanopenflameorspark.Allowtheenginetocoolbeforestoringina nybuilding.

�Alwaysrefertotheoperator

’

sguideinstructionsforimportantdetailsifthetilleristobe

storedforanextendedperiod.

4

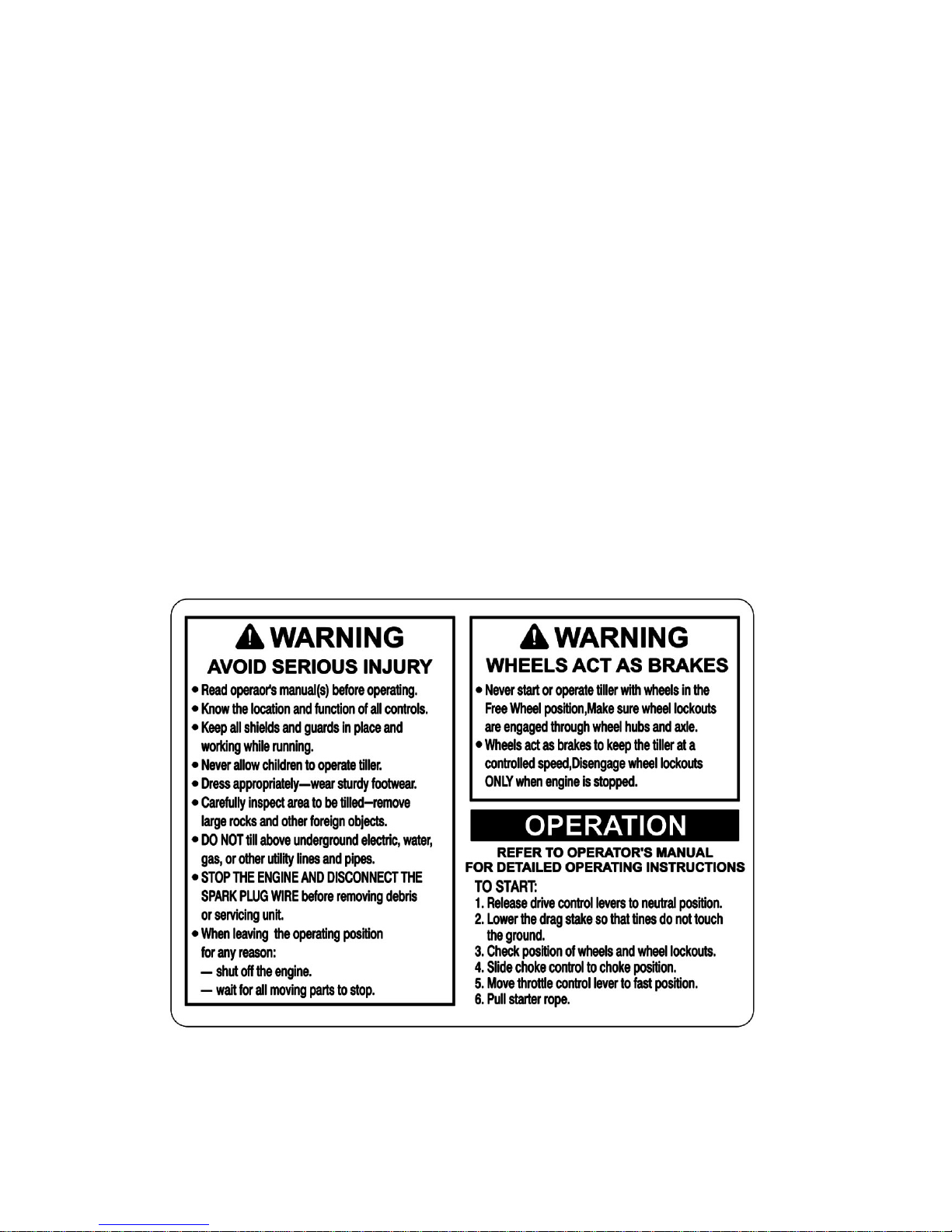

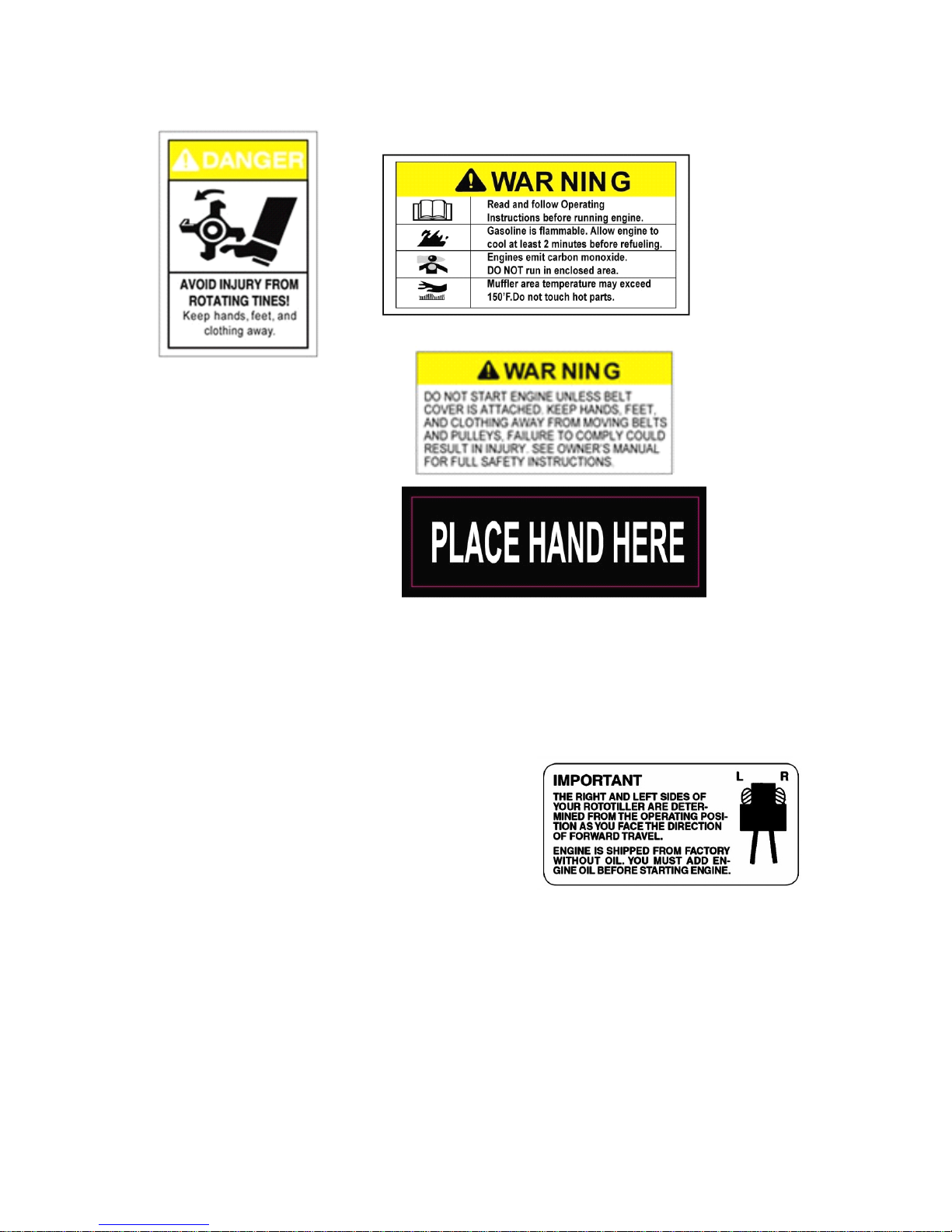

SAFETY

SAFETY

SAFETY

SAFETYDECALS

DEC ALS

DECALS

DECALS

�

�

�

�Thisrototillerunithasbeendesignedandmanufacturedtoprovideyouwiththesafetyand

reliabilityyouwouldexpectfromanindustryleaderinoutdoorpowerequipment

manufacturing.

�

�

�

�Althoughreadingthismanualandthesafetyinstructionsitcontainswillprovideyouwith

�

�

�

�thenecessarybasicknowledgetooperatedthisequipmentsafetyandeffectively,wehave

placedseveralsafetylabelsonthetillertoremindyouofthisimportantinformationwhile

youareoperatingtheunit.

�

�

�

�Theseimportantsafetylabelsareillustratedbelow,andareshownheretohelpfamiliarize

youwiththelocationandcontentofthesafetymessagesyouwillseeasyouperform

normaltillingoperations.Pleasereviewtheselabelsnow.Ifyouhaveanyquestions

regardingtheirmeaningorhowtocomplywiththeseinstructions,rereadthecomplete

safetyinstructiontextontheprecedingpages,orcontactyourlocaldealer.

�

�

�

�Shouldanyofthesafetylabelsbecomeunreadablebecauseofbeingworn,faded,or

otherwisedamagedduringtheuseofyourtiller,pleaseusethepartnumberinformation

providedtoorderareplacementlabelfromyourlocalauthorizeddealer.

�

�

�

�Thesafetylabelsareeasilyapplied,andwillactasaconstantvisualremindertoyou,and

otherswhomayusetheequipment.Followthesafetyinstructionsnecessaryforsafe,

effectiveoperationofyourrototiller.

5

ASSEMBLY

ASSEMBLY

ASSEMBLY

ASSEMBLYINSTRCTIONS

IN STRCTIONS

INSTRCTIONS

INSTRCTIONS

Therototillercomesfullyassembledexceptforafewparts.

Thefollowinginstructionswillhelpyouassembleand

adjustthetiller

’

sdepthregulator,cabletension,

andhandlebarheight.

You

willneedtwo9/16

’’

wrenches

tocompletetheassembly.

STEP

STEP

STEP

STEP1

1

1

1Install

In stall

Install

Installthe

th e

the

theDepth

De pth

Depth

DepthRegulator

Re gulator

Regulator

Regulator

1.

1.

1.

1.InstallthedepthregulatorintothetopofthedepthregulatorBracketwithhandlefacing

rearward.

2.

2.

2.

2.Insertdepthregulatorpinthroughdepthregulatorbracketandtopholeofdepth

regulator-tinesshouldcleartheground.

6

STEP

STEP

STEP

STEP2

2

2

2Attach

Atta ch

Attach

Attachex-arm-rest

ex -arm-rest

ex-arm-rest

ex-arm-reststems

ste ms

stems

stemsto

to

to

toth e

th e

the

theTiller

Ti ller

Tiller

Tiller

1.Theex-arm-reststemsonoutsideoftheTransmissioncoverandalignthelowerboles.

2.Insertone3/8

’’

-16x1

’’

boltforeachsideinlowerholes.

3.Start3/8

’’

-16nutsoneachbolt.

4.Insertone3/8

’’

-16x1

’’

boltforeachsideinUpperholesatdesiredhandlebarheight.

5.Tightenthenuts.

7

STEP

STEP

STEP

STEP3:Attach

3:A ttach

3:Attach

3:Attachhandle

ha ndle

handle

handlebar

ba r

bar

barto

to

to

toth e

th e

the

theTiller

Ti ller

Tiller

Tiller

1.

1.

1.

1.Insertfourfastnessboltsforeachsideineveryholes.

2.

2.

2.

2.Startfastnessnutsoneachbolt.

3.

3.

3.

3.Tightenallthenuts.

STEP

STEP

STEP

STEP4

4

4

4Fill

Fi ll

Fill

FillEngine

En gine

Engine

EngineCrankcase

Cr ankcase

Crankcase

Crankcase

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

Engineisshippedfromfactorywithoutoil.Engineoilmustbeaddedbeforestartingengine.

1.Addoilaccordingtoenginemanual.Donotoverfill.Useclean,highqualitydetergentoils.

Donotmixoilwithgasoline.Oillevelmustbefull.Checktheoillevelbyremovingoilfill

plug.

2.Alwayscheckoillevelbeforestartingengine.Refertoenginemanualforcapacityandtype

ofoiltouse.

8

OPERATION

OPERATION

OPERATION

OPERATION

PRE-START

PRE-START

PRE-START

PRE-STARTINSPECTION

IN SPECTION

INSPECTION

INSPECTION

1.Makesureallsafetyguardsareinplace

andallnutsandboltsaresecure.

2.Checkoillevelinenginecrankcase.Seeyour

enginemanualforprocedureandspecifcations.

3.Inspectaircleanerforcleanliness.Seeyourengine

manualforprocedure.

4.Checkthefuelsupply.Fillthefueltanknocloser

than1inchfromtopoftanktoprovidespacefor

expansion.Seeyourenginemanualforfuel

recommendations.

5.Besuresparkplugwireisattachedandspark

plugistightenedsecurely.

6.Checkpositionofwheelsandwheellockouts.

7.Checkdepthregulatorleverposition.

8.Examineundermeathandaroundengine

forsignsofoilorfuelleaks.

9.Inspectfuelhosesfortightnessandfuelseepage.

10.Lookforsignsofenginedamage.

11.Removeexcessivedebrisfrommuffler

areaandrecoilstarter.

START-UP

START-UP

START-UP

START-UP

Thecontrolsrequiredtostartandruntherototillerarelocatedontheengineandare

marked”choke”and“Throttle”.

Amoredetaileddescriptionofengineoperationandallrelatedprecautionsandprocedurescanbe

foundintheenginemanufacturer

’

smanualthataccompanieseachtiller.

COLD

COLD

COLD

COLDSTARTS

ST ARTS

STARTS

STARTS

1.Movechokelevertofullchokeposition.

2.Movethrottleleverto“start”.

3.Pullstartingropeoutslowlyonetimeandallowtoreturnnormally.

4.Pullstartingropeoutrapidly,andallowropetoreturnnormally.

5.Whenenginestarts,graduallymovechokeleverto“nochoke”positionandincreasethrottle

speed.

9

RESTATING

RESTATING

RESTATING

RESTATINGA

A

A

AWARM

WA RM

WARM

WARMENGINE

EN GINE

ENGINE

ENGINE

Restartinganenginethatisalreadywarnfrompreviousrunningdoesnormallyrequireuseofthe

choke.

1.Movethrottleleverto“start”position.

2.Pullstartingropeoutrapidlyuntilenginestarts.Allowropetoreturnnormally.Repeatuntil

enginestarts.

3.Adjustthrottlespeedto“high”forbesttilleraction.

IDLE

IDLE

IDLE

IDLESPEED

SP EED

SPEED

SPEED

Usethe“low”positiononthethrottleleverto

reducestressontheenginewhentillingis

notbeingperformed.Loweringtheengine

speedto“idle”willhelpextendthelifeof

themotor,aswellasconservefueland

reducethenoiseleveloftheequipment.

OPERATING

OPERATING

OPERATING

OPERATINGSPEED

SP EED

SPEED

SPEED

Fornormaltilling,setthethrottleleverto“fast”.

SHUTTING

SHUTTING

SHUTTING

SHUTTINGDOWN

DO WN

DOWN

DOWN

Tostoptheengineatanytime,turnengineON/OFFswitchtotheoffposition.Tostopwheelsand

tinesatanytime,releasedrivesafetycontrolleverstoneutralposition.

TILLING

TILLING

TILLING

TILLING

1Adjustthedepthregulatorlevertodesiredtillingdepth.

NOTE:

NOTE:

NOTE:

NOTE:Raise

Ra ise

Raise

Raisedepth

de pth

depth

depthregulator

re gulator

regulator

regulatorlever

le ver

lever

leverup

up

u p

upone

on e

one

onehole

ho le

hole

holeat

at

a t

ata

a

a

atime,

ti me,

time,

time,testing

te sting

testing

testingtiller

ti ller

tiller

tilleroperation

op eration

operation

operationafter

afte r

after

aftereach

ea ch

each

each

raise.

raise.

raise.

raise.Raising

Ra ising

Raising

Raisingdepth

de pth

depth

depthregulator

re gulator

regulator

regulatorlever

le ver

lever

levertoo

to o

too

toohigh

hi gh

high

highcan

ca n

can

canresult

re sult

result

resultin

in

i n

inloss

lo ss

loss

lossof

of

o f

ofcontrol

co ntrol

control

controlof

of

o f

oftiller

ti ller

tiller

tiller!

!

!

!

2

2

2

2Movethethrottlecontroltofast.

3Placethetillerinforwardbypushingdownonthedrivesafetycontrollever(FORWARD)—this

willengagethewheelsandtines.

NOTE:

You

canslowthetiller

’

sforwardadvanceatanytimebyputtingslightdownwardpressure

onthehandlebars.

You

canstopthetillerbyreleasingthedrivesafetycontrolleverstotheneutral

position.

DRIVE

DRIVE

DRIVE

DRIVESAFETY

SA FETY

SAFETY

SAFETYCONTROL

CO NTROL

CONTROL

CONTROLLEVERS

LEV ERS

LEVERS

LEVERS

FORWARD

FORW ARD

FORWARD

FORWARDLEVER

LEV ER

LEVER

LEVER

10

Engageswheelsandtinesintoforward.

Pushingdownthedrivesafetycontrol

Lever(FORWARD

FO RW ARD

FORWARD

FORWARD)towardthe

handlebarengagesthewheelsandtines.

Releasingtheleverstopsthewheelsand

tinesandbringsthetillertoacompletesstop.

REVERSE

REVERSE

REVERSE

REVERSELEVER

LE VER

LEVER

LEVER

Engageswheelsandtinesintoreverse

Pullingthedrivesafetycontrollever

(FORWARD)backtowardtheoperator

tiller.releasingtheleverstopsthewheelsand

tines.

Forwardhandle

Reverse

handle

ADJUSTMENTS

ADJUSTMENTS

ADJUSTMENTS

ADJUSTMENTS

WHEEL

WHEEL

WHEEL

WHEELLOCK

LO CK

LOCK

LOCKPINS

PI NS

PINS

PINS

Placewheelsintillingposition.

1.Removeclockpin.Alignholeinaxlewithholeinwheelhub.

2.Insertlockpinthroughholes,foldlockpintosecurepintoaxle.

3.Firmlylockwheelandaxletogetherbeforetilling.

4.Repeatforotherwheel

11

�Setthedepthregulatorleverwiththedetentpininoneofthehigherholes.This

willallowforshallowcultivationnecessarytoturnoverweeds,andbreakupand

aeratethesoil.

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCEAND

AN D

AND

ANDSTORAGE

ST ORAGE

STORAGE

STORAGE

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE

Keepingthetillerintoprunningconditionwillprolongthetiller'slife,andhelpit

obtainoptimumperformancewheneveryouwishtostillyourgarden.

To

helpyouproperlycarefortherototiller,thefollowingpagesincludeamaintenance

schedule,routineinspectionprocedures,andsimplemaintenanceproceduresusing

basichandtools.Otherservicetasksthataremoredifficult,orrequirespecialtools,

arebesthandledbyprofessionalsandarenormallyperformedbyaqualified

mechanic.

�Goodmaintenanceisyourresponsibility,poormaintenanceisaninvitationto

trouble.

Followgoodshoppractices.

Keepserviceareacleananddry.

Bessureelectricaloutletsandtoolsareproperlygrounded.

Useadequatelightforthejobathand.

�Makesuretheengineisoffbeforeyoubeginanymaintenanceorrepairs.Thiswilleliminate

severalpotentialhazards:

Carbon

Carbon

Carbon

Carbonmonoxide

mo noxide

monoxide

monoxidepoisoning

po isoning

poisoning

poisoningfrom

fr om

from

fromengine

en gine

engine

engineexhaust.

ex haust.

exhaust.

exhaust.

Besurethereisadequateventilationwheneveryouoperatetheengine.

Neveroperatetheengineinaclosedbuilding.

Burns

Burns

Burns

Burnsfrom

fr om

from

fromhot

ho t

hot

hotparts.

pa rts.

parts.

parts.

Lettheengineandexhaustsystemcoolbeforetouching.

Injury

Injury

Injury

Injuryfrom

fr om

from

frommoving

mo ving

moving

movingparts.

pa rts.

parts.

parts.

Donotruntheengineunlessinstructedtodoso.

�Readtheinstructionsbeforeyoubegin,andmakesureyouhavethetoolsandskillsrequired.

�Toreducethepossibilityoffireorexplosion,becarefulwhenworkingaroundgasoline.Use

onlyanonflammablesolvent,notgasoline,tocleanparts.Keepcigarettes,sparksandflames

awayfromallfuel-relatedparts.

�Alwaysusepersonalprotectiondevicessuchaseye,handandhearingprotectorswhen

performinganyserviceormaintenance.

�Frequentlychecktillertines.Theyshouldbefreeofnicksandcracksandsecurelyfastenedin

place.

�Periodicallytightenallbolts,buts,screws,andcheckthatallpinsareproperlyinstalledto

makecertainunitissafetooperate.

�Whencompletingmaintenanceorservice,makesureallsafetyguardsanddevicesare

12

NOTE:

NOTE:

NOTE:

NOTE:Always

Al ways

Always

Alwayshave

ha ve

have

haveboth

bo th

both

bothwheel

wh eel

wheel

wheellock

lo ck

lock

lockpins

pi ns

pins

pinsin

in

i n

inor

or

o r

orout.

ou t.

out.

out.Do

Do

D o

Donot

no t

not

notoperate

op erate

operate

operatetiller

ti ller

tiller

tillerwith

wi th

with

withonly

on ly

only

onlyone

on e

one

onewheel

wh eel

wheel

wheel

locked.

locked.

locked.

locked.

Toplacewheelsinfree-wheelposition.

1.Removelockpin.Slidewheelinwardtowardmachine.

2.Insertpininaxleonly

3.Wheelshouldturnfreelyonaxle.

HANDLEBAR

HANDLEBAR

HANDLEBAR

HANDLEBARHEIGHT

HEI GHT

HEIGHT

HEIGHTADJUSTMENT

AD JUSTMENT

ADJUSTMENT

ADJUSTMENT

Adjusthandlebarheight.

Theidealheightofthehandlebarvarieswithoperatorheightandthedepthoftilling.Toadjust

handlebarheight:

1.Unscrewnutsandremovetopandbottomboltsoneachside.

2.Alignhandlebartodesiredholesonthelowerhandlebarmount.

3.Installboltsandnuts.Retighten

13

DEPTH

DEPTH

DEPTH

DEPTHREGULATOR

REG ULATOR

REGULATOR

REGULATORLEVER

LEV ER

LEVER

LEVER

Tillingdepthiscontrolledbytheheightof

thedepthregulatorlever.Toadjusttillingdepth:

1.Removedetentpin.

2.Raisethedepthregulatorlevertoposition

tinesatchosentillingdepth.

3.Alignholeindepthregulatorleverwithhole

indepthregulatorbracketandreplecedetentpin.

Depth

Depth

Depth

DepthRegulator

Re gulator

Regulator

RegulatorLever

Le ver

Lever

LeverDown

Do wn

Down

Down=

=

=

=Shallower

Sh allower

Shallower

Shallowertilling

ti lling

tilling

tilling.

.

.

.

Placethedetentpininthetopholeofthedepthregulatorleverforshallowesttilling.

Depth

Depth

Depth

DepthRegulator

Re gulator

Regulator

Regulatorlever

le ver

lever

leverUp

Up

U p

Up=

=

=

=Deeper

De eper

Deeper

Deepertilling.

ti lling.

tilling.

tilling.

Placethedetentpininthebottomholeofthedepthregulatorleverfordeepesttilling.

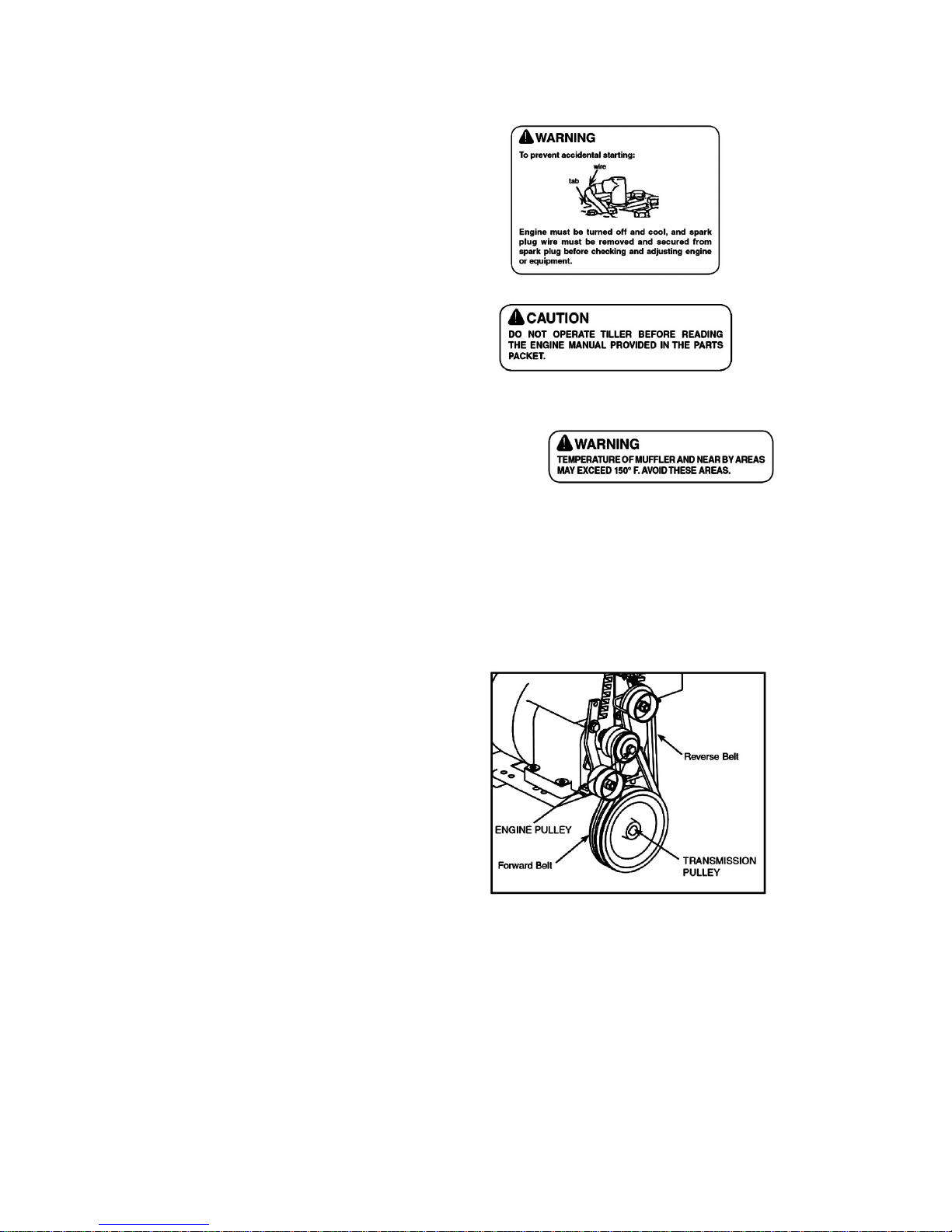

BELT

BELT

BELT

BELTTENSION

TEN SION

TENSION

TENSIONADJUSTMENT

AD JUSTMENT

ADJUSTMENT

ADJUSTMENT

Properbelttensioniscriticaltogoodperformance.After1/2hourofoperation.Allcables

mayhavetobeadjustedduetoinitialstretch.Thereafter,checktensionafterevery2hours

ofoperation.

To

To

To

To

increase

in crease

increase

increasebelt

be lt

belt

belttension

te nsion

tension

tension:

:

:

:

1.Loosenupperjamnut.Turnnutupcablein1/8''increments.

2.Tightenlowerjamnut.

3.Checkadjustment.

Thisprocedurecanberepeateduntilconduitadjustmentboltsarefullyadjusted.Ifnomore

adjustmentcanbe,beltmayhavetobereplaced.

14

TILLING

TILLING

TILLING

TILLINGTIPS

TI PS

TIPS

TIPS

Thekeytosuccessfultillingistobeginwithashallowcutonthefirstpast,andthenworkaninch

ortwodeeperoneachsuccessivepass.

�Tillingdepthwillvarywithgroundconditions.

�Whenbeginningtotillinunbrokengroundor

inextremelyhardsoil,setthedetentpininthe

highestholeofthedragstake(followinstructions

undertillingsection).Thiswillallowforshallow

tilling.Withthedragstakeinthisposition,

makeseverallightpassesovertheareatobetilled.

Tresetfordeeperdepthswithsuccessivepasses.

�Iftillerjumpsorskidsuncontrollably,lowerthedragstakebyplacingthedetentpinina

higherhole.Thiswillallowfoshallowtillingholdfirmlytothehandlebarstocontrolsudden

lurches.

�Ifweeds,tallgrasses,vines,orothermaterialsclogorjamthetines,reversethetillerto

unwindvegetation.

Immediatelyreleasethedrivecontrolleversifthetinesjamoryoustrikeaforeignobject.With

drivecontrolleversinneutralposition,pushthrottlecontroltostroppositiontostroptheengine,

disengagethesparkplugwire,whentineshavestopped,removeforeignobjectsandcheckfor

damage.

15

CULTIV ATING

CULTIV ATING

CULTIV ATING

CULTIV ATINGTIPS

TI PS

TIPS

TIPS

Ifyouplantouseyourtillerforcultivating:

�Plantrowson20

’’

--22

’’

centersforeaseofturning.Installedbeforeusingtherototiller.

�Wherereplacementpartsarenecessaryforperiodicmaintenanceandserving.Useonlynew,

originalreplacementpartsortheirequivalentsforrepairandreplacementtorestoreyour

equipmenttooriginalspecifications.

�Themanufacturerand/ordistributorwillnotberesponsibleforinjuriesordamagescausedby

useofunapprovedpartsand/oraccessories.

�Afirstaidkitshouldbekeptreadilyaccessiblewhileperformingmaintenanceonthis

equipment.

MAINTENACE

MAINTENACE

MAINTENACE

MAINTENACESCHEDULE

SC HEDULE

SCHEDULE

SCHEDULE

Yourrototillerhasbeendesignedandproducedbytheindustry

’

sleadingmanufacturerofoutdoor

powerequipmenttoprovideyouwithyearsofreliableoperation.

Keepingyourtillerintoprunningconditionwillprolongitslife,andhelpyouobtainoptimum

performance.

Pleasereadthisnormalcareschedule,andnotetherecommendedcareoperatingintervalsto

extendthelifeofyourunit.

1)Servicemorefrequentlywhenusedindustyareas.

SERVICING

SERVICING

SERVICING

SERVICINGTHE

TH E

THE

THEROTOTILLER

RO TOTILLER

ROTOTILLER

ROTOTILLER

Thefollowinginformationwillhelpyoumakethenecessarychecksandperformtheprocedures

requiredtofollowthenormalcarerecommendationsmadeforyourrototillerunit.

Ifyouprefer,yourlocalauthorizeddealercanmakethesechecksandperformtherequiredfor

you.

16

CHANGE

CHANGE

CHANGE

CHANGEFORWARD

FO RW ARD

FORWARD

FORWARD/

/

/

/REVERSE

REV ERSE

REVERSE

REVERSEBELT

BEL T

BELT

BELT

1.

1.

1.

1.Turnoffengine.Enginemustbecool.

2.

2.

2.

2.Removespeakplugwireandsecure

fromsparkplug.

3.

3.

3.

3.Removebeltguard.

�

�

�

�Removetheforwardbeltfromthe

forwardenginepulley:

-

-

-

-gentlypulltheenginerecoilropetorotate

thepulley.

-withthepulleyturning,forcetheforward

beltoutoftheV-groove.

-slidethebeltfreeoftheenginepulley.

-pulltheforwardbeltdownandoutoftheway.

-removethereversebeltfromthereverseenginepulley:

-gentlypulltheenginerecoilropetorotatethepulley.

-withthepulleyturning,forcethereversebeltoutofthe

V-groove.

-slidethebeltfreeofenginepulleysandreversebeltgudes.

-pullbeltdownandawayfromtransmissionpulley.

�Installnewreversebelt:

-threadbeltupfrombottom.

-placebeltunderreversebeltguides.

-gentlypullenginerecoilropewhileforcing

ThebeltovertheedgeoftheenginepulleyintotheV-groove.

�Installnewforwardbelt:

-placeforwardbletintransmissionpulley

Groove.

17

-gentlypulltheenginerecoilropetorotatethepulleywhileforcingtheforwardbeltinto

theV-groove.

4.Replacebeltguard.

5.Attachsparkplugwire.

ENGINE

ENGINE

ENGINE

ENGINEMAINTENANCE

MAIN TENANCE

MAINTENANCE

MAINTENANCE

Refertotheenginemanualincludedinyourpartspacketforinformationonenginemaintenance.

Yourenginemanualprovidesdetailedinformationandamaintenancescheduleforperformingthe

followingtasks:

1.Checkoillevelbeforeeachuseorafterevery8hoursofoperation.

2.Changeoilafterfirst5-8hoursofoperation.Changeoilwhileengineiswarm.Refillwithnew

Oilofrecommendedgrade. SAE 15/40

3.checksparkplugyearlyorevery100hoursofoperation.

4.Serviceaircleaner.

5.Keepengineandpartsclean.

6.Checkengineandequipmentoftenforloosenutsandbolts,keeptheseitemstightened.

CHECK

CHECK

CHECK

CHECKOR

OR

OR

ORFILL

F ILL

FI LL

FILLENGINE

ENGI NE

ENGINE

ENGINECRANKCASE

CRAN KCASE

CRANKCASE

CRANKCASE

1.Addoilaccordingtoenginemanual.Do

Do

Do

Donot

n ot

no t

notover

over

o ver

overfill

fill

f ill

fill.

.

.

.

Useaclean,highqualitydetergentoil.Do

Do

Do

Donot

not

no t

notmix

mix

mi x

mixoil

oil

oi l

oil

With

With

With

Withgasoline.

gaso line.

gasoline.

gasoline.Oillevelmustbefull.Checktheoillevel

Byremovingoilfillplugopening.

2.Alwaycheckoillevelbeforestartingengine.Refertoenginemanualforcapacityandtypeof

oiltouse.

CHECK

CHECK

CHECK

CHECKTILLER

TILLER

TI LLER

TILLERTRANSMISSION

TRAN SMISSION

TRANSMISSION

TRANSMISSION OIL

Checkthe oillevelannually.Tocheckthe oil

Level:

1.movetillertolevelground.

2.Remove oilleveldipsticklocatedbetween

Th ehandlebarmountsontheenginemount.If

The oillevelcouldn’ttouchthedipstick.

Pl easefillthe oil.

3.Replace oilleveldipstickinthefillerhole.

4. Notethatthefrontwheeltransmissionandrear

tinetransmissionareonecommonreservoirwhen

18

youaddtothefronttransmission,youmustwaitashortperiodoftimeforthe oiltofollow

re arwardandequalizeinbothfrontandrear.Thedipstickwillreadcorrectlyonlevelgroundfor

bothgearunits.

CHECK

CHECK

CHECK

CHECKTIRE

TIR E

TIRE

TIREPRESSURE

PRES SURE

PRESSURE

PRESSURE

Recommendedtirepressureis20PSI,iftiresdonothaveequalpressure,tillerwillpulltoone

side.

LUBRICATION

LUBRICATION

LUBRICATION

LUBRICATION

Properlubricationofmovingmechanicalpartsiscriticalforpropercareandmaintenance.Oilthe

movingpartsshownat10hoursintervalsusingaSAE30weightoil.

C LEAN

CLEAN

CLEAN

CLEANTINE

TIN E

TINE

TINEAXLE

AXLE

A XLE

AXLESHAFT

SHA FT

SHAFT

SHAFT

1.turnoffengine,enginemustbecool.

2.Removesparkplugwireandsecurefromsparkplug.

3.3.tipthetillerforward.blockthetillerinpositionsothatitrestsontheenginemountandthe

tinesareexposed.

4.Removeallvegetation,string,wire,andothermaterialthatmayhaveaccumulatedontheaxle

betweentheinsidesetoftinesandthesealonthetransmissionhousing.

5.Tipthetillerbacktoalevelpositon.

6.Replacesparkplugwire.

STORAGE

STORAGE

STORAGE

STORAGE

PREPARE

PREPARE

PREPARE

PREPAREFOR

FOR

F OR

FORSTROAGE

STR OAGE

STROAGE

STROAGE

Followthestepsbelowtoprepareyourtillerforstorage.

1.protectwheelsandaxlesfromrust:

2.-Removelockpinandslidewheeloffhub.

-coattheaxleslightlywithaxlegrease.

-slidewheelbackonhubandinsertlockpin.

-Drainfuelsystemcompletelyfollowingenginemanufacturer

’

sinstructionsoraddfuel

stabilizertopreventfuelfromgummingupduringextendedstorageperiod.

3.Whileengineisstillwarm,draintheoilfromtheengine.Refillwithfreshoilofthe

recommendedgrade.

4.Cleanexternalsurface,engineandcoolingfan.

5.Removingsparkplug,pouroneounceofSAE30oilintosparkplughole.

6.Plugholeandpullstartercordslowlytodistributeoilevenlyincylinderheadarea.

7.Reinstallsparkplug.

8.Transportunittosuitablestoragelocation.Ifyouhavechosentouseafuelstabilizer

19

Andhavenotdrainedthefuelsystem,followallsafetyinstructionsstorageprecautionsinthis

manualtopreventthepossibilityoffirefromtheignitionofgasolinefumes.Remember,gasoline

fumescantraveltodistantsourcesofignitionandignite,causingriskofexplosionandfire.

Ifthereisanypossibilityofunauthorizeduseortampering,removethesparkplugandstoreitin

asafeplacebeforestoringtherototillerunit.Besuretoplugthesparkplugholetopreventforeign

materialfromentering.

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTINGAND

AN D

AND

ANDREPAIR

REP AIR

REPAIR

REPAIR

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTINGGUIDE

GU IDE

GUIDE

GUIDE

Whilenormalcareandroutinemaintenancewillextendthelifeofyourrototiller,prolongedor

constantusemayeventuallyrequirethatservicebeperformedtoallowittocontinueoperating

properly\.

Thetroubleshootingguidebelowliststhemostcommonproblems,causesandremedies.

PROBLEM

PROBLEM

PROBLEM

PROBLEMREMEDY

RE MEDY

REMEDY

REMEDY/

/

/

/ACTION

AC TION

ACTION

ACTION

Enginewillnotstart

�Addgastogastank.

�Connectsparkplugwiretosparkplug

�Throttlemustbepositionedatchokeforacold

start

Enginerunsrough,foodsduringoperation�Cleanorreplaceaircleaner

Engineishardtostart

�Drainoldfuelandreplacewithfresh.Usegas

stabilizeratendofseason

�Makesuresparkplugwireissecurelyattachedto

sparkplug

�Drivesafetycontrolleversmustbereleasedto

neutralpositiontostartthe

engine

Enginemissesorlackspower

�Raisethetinesforshallowtillingbyloweringthe

depthregulatorlever

�Removeandcleanfueltank

�Cleanorreplaceaircleaner

�Impropercarburetoradjustment,taketo

authorizedengineservicecenter

�Replacesparkplugandadjustgap

�Drainandrefillgastankandcarburetor

Enginewillnotstopwhenthrottlecontrolispositioned

atstop

Seeenginemanualtocheckandadjustthrottlelinage

Tillermovesforwardduringstarting(machine

jumpsorlurchesforward)

�Lockwheelsintillingposition

�Raisethetinesforshallowertillingbylowering

thedepthregulatorlever

Tillerisdifficulttocontrolwhentilling(machine

jumpsorlurchesforward)

�Lockwheelsintillingpositon

�Raisethetinesforshallowertillingbylowering

Depthregulatorlever

Table of contents

Other Titan Pro Tiller manuals

Popular Tiller manuals by other brands

Echo

Echo ProThatch 99944200563 Operator's manual

EarthQuake

EarthQuake CRT series Operator's manual

SNOWJOE

SNOWJOE SUNJOE TJ599E-RM Operator's manual

EarthQuake

EarthQuake 3300V Operating instructions & parts explosions

Brinly

Brinly SA-400BH owner's manual

MTD

MTD World Tiller - Series 240 Operator's manual