TMEIC TMdrive-XL Series User guide

power

generation

solar

inverters

oil & gastestingminingcranes cementmetals

TMdrive®-XL Series Family

Product Application Guide

TM

drive

®

-XL

S

eries Family

Product Application Guide

2

TMdrive-XL Series

TheTMdrive XL series family of variable frequency drives (VFD) provides

the high power levels and speed required to drive large motors that power

rotating machinery used in the Oil & Gas industry. Important VFD features

common to the family include:

• Common architecture, pulse width modulation and control, water

cooling, I/O modules, andTMdrive-Navigator programming software

• Multi-level VFD output for smooth waveform to the motor

• 24-36 pulse diode converter rectifier for low harmonic distortion

• High VFD reliability and availability with MTBFs in excess of 20 years

and MTTR of less than 30 minutes.

• Output frequency range high enough for direct compressor drive

with no gearbox, eliminating costly lube oil systems in addition to the

gearbox, resulting in increased system efficiency.

• Up to 7.2 kV supply to the motor with no output transformer required

• Ability to operate drive banks in parallel for higher power levels up to

120 MVA

2

15/30 MVA

Power Module

Single Phase

Inverter using GCTs

15 MVA

8 MVA 20 MVA 30 MVA

Diode Rectifier,

36-pulse, one of

six modules.

Inverter modules,

two modules make

a five-level single

phase inverter

Induction or

Synchronous

Motor

Power supply,

three-phase

50/60 Hz

Externally mounted

input transformer

and zero impact on

building HVAC cost

Field windings

for Synchronous

Motor

for low harmonic

power system impact

Up to 64 kV

20 MVA VFD

Power Module

Single Phase

Inverter using IEGTs

8 MVA VFD

Power Module

Single Phase

Inverter using IGBTs

5.5 kA, 4.5 kV

6 kA, 6 kV

0.9 kA, 4.5 kV

XL Architecture using Diode Converter and

five-level Pulse Width Modulated Inverter

Three different inverter modules for

this architecture, three per VFD:

IGBT

IEGT

GCT

XLdrive Series Family Application Guide.indd 2 10/3/2011 3:15:44 PM

3

Variable

Frequency

Drive

Reactor

Reactor AC Machine

AC Machine

AC Machine

Variable

Frequency

Drives

Variable

Frequency

Drives

3

XLDriveFamilyPowerExpansion

Higher Power Levels. The XL VFDs can be run in

parallel to produce higher power levels than single

banks. Two, three, or four banks can be combined

to obtain the desired power. The example below

shows how an XL VFD can be expanded to four

banks for a power of 120 MVA (156,000 hp). The

table shows the maximum power levels available

from the VFD family.

The multi-bank VFDs provide drive and control

redundancy for improved reliability.

• Synchronous or Induction motor can control

rotating machinery directly for low and high

speed applications.

• A redundant control cabinet significantly

enhances reliability.

• Synchronous motor can control rotating

machinery directly for low and high speed

applications; paralleling reactor feeds the motor

• A redundant control cabinet significantly

enhances reliability.

• Synchronous motor can control rotating

machinery directly for low and high speed

applications ; paralleling reactor feeds the motor

• One bank can be redundant to other three banks

for increased reliability.

One-Bank TMdrive-XL – Power level up to 30 MVA

Two-Bank TMdrive-XL – Power level up to 60 MVA

Four-BankTMdrive-XL – Power level up to 120 MVA

XL Drive Power Levels, Single Bank Multiple Banks, Max

TMdrive-XL85 30 MVA (39,000 hp) 120 MVA (156,000 hp)

TMdrive-XL75 20 MVA (26,000 hp) 80 MVA (104,000 hp)

TMdrive-XL80 15 MVA (19,500 hp) 30 MVA (39,000 hp)

TMdrive-XL55 8 MVA (10,400 hp) 16 MVA (20,800 hp)

XLdrive Series Family Application Guide.indd 3 10/3/2011 3:15:55 PM

4

TMdrive-XL Series

Power Rating: 8 MVA, expandable to 16 MVA

Output Voltage: 6.6 kV

Output Frequency: Rated 50-60 Hz, 50 to 250 Hertz option

Dimensions: Width 6.5 m

Height: 2.5 m

Motor type: Synchronous

or Induction

Power Input/Output

Converter

• AC-fed 36-pulse diode rectifier using externally

mounted phase shifted transformer; no harmonic filter

required to meet IEEE 519 guidelines

• DC bus voltage: 3 x 5,000 Vdc

• Power factor greater than 95% in speed control range

Inverter

• Five-level inverter for motor friendly wave form

• Uses 8 IGBT devices for each of three phases

• 6 kV output to motor – no output transformer required

• Inverter power modules water cooled

• Conservative design for expected 20 year MTBF

Input Voltage

Any utility voltage using

separate transformer input

50/60 Hz ±2%

Output Voltage 6,600 Vac

Output Current 700 A rms

Output Frequency 50-60 Hz, for over 75 Hz,

consult TMEIC

Output Chopping 600 Hz (max)

Efficiency 98.6%

Cable Entry Bottom or top

Clean Motor Output Wave

As a result of the five-

level PWM control, the

output current waveform

is close to a sine wave.

Harmonic currents in

the motor windings are

minimized so the heat

loss is negligible and

there is very little shaft

torque ripple. Illustrated

waveform is from the

similar TMdrive XL85 test.

Line-to-Line Voltage at 100% Speed

U-phase Current at 100% Speed

Protective Functions Include:

• Inverter overcurrent

• Inverter overvoltage

• Low system voltage

• Motor ground fault

• Motor overload

• Cooling fan abnormal

• Over-temperature

• CPU error

• Water cooling alarm

• Exciter fault

• DC voltage drop

• Motor inverse rotation

• Stall detection

• Ground detection

Frequency Control

• Volt/Hertz Control – standard

• Sensorless vector control - optional

Output Voltage Modulation

The output switching modulation strategy is dynamically

adjusted based on three speed zones to minimize motor

torque pulsation.

Drive Inputs

• LAN Interface Options: Profibus-DP, DeviceNet,

Modbus RTU, TOSLINE

• Input/Output: 6 Analog I/O, 8 Digital I/O

Power Circuits

Motor Control

Insulated Gate Bipolar

Transistor (IGBT). Rated

4,500 Volts, 900 Amps.

TMdrive-XL55 – 8 MVA Frame

XLdrive Series Family Application Guide.indd 4 10/3/2011 3:15:56 PM

5

Power Rating: 20 MVA, expandable to 80 MVA

Output Voltage: 6 kV

Output Frequency: Rated 50-60 Hz, 50 to 250 Hertz

Power Input/Output

Converter

• AC-fed 36-pulse diode rectifier using externally

mounted phase shifted transformer; no harmonic filter

required to meet IEEE 519 guidelines

• DC bus voltage: 3 x 4,540 Vdc

• Power factor greater than 95% in speed control range

Inverter

• Five-level inverter for motor friendly wave form

• Uses 8 IEGT devices for each of three phases

• 6 kV output to motor – no output transformer required

• Inverter power modules water cooled

• Conservative design for expected 20 year MTBF

Input Voltage

Any utility voltage using

separate transformer input

50/60 Hz ±2%

Output Voltage 5,820 Vac

Output Current 1925 A rms

Output Frequency 50-60 Hz

Output Chopping 600 Hz (max)

Efficiency 98%

Cable Entry Top or bottom

Clean Motor Output Wave

As a result of the five-

level PWM control, the

output current waveform

is close to a sine wave.

Harmonic currents in

the motor windings are

minimized so the heat

loss is negligible and

there is very little torque

ripple on the output shaft.

Line-to-Line Voltage at 100% Speed

U-phase Current at 100% Speed

Protective Functions Include:

• Inverter overcurrent

• Inverter overvoltage

• Low system voltage

• Motor ground fault

• Motor overload

• Cooling fan abnormal

• Over-temperature

• CPU error

• Water cooling alarm

• Exciter fault

• DC voltage drop

• Motor inverse rotation

• Stall detection

• Ground detection

Frequency Control

• Volt/Hertz Control – standard

• Sensorless vector control – optional

• Power factor control for synchronous motors

Output Voltage Modulation

The output switching modulation strategy is dynamically

adjusted based on three speed zones to minimize motor

torque pulsation.

Drive Inputs

• LAN Interface Options: Profibus-DP, DeviceNet,

Modbus RTU, ISBus,TOSLINE

• Input/Output: 6 Analog I/O, 8 Digital I/O

Power Circuits

Motor Control

Injection Enhanced Insulated

Gate Transistor (IEGT). Rated

4,500 Volts, 2,100 Amps

TMdrive-XL75 – 20 MVA Frame

Dimensions: Width 9.4 m

Height: 2.7 m

Motor type: Synchronous or Induction

XLdrive Series Family Application Guide.indd 5 10/3/2011 3:16:06 PM

6

TMdrive-XL Series

Power Rating: 30 MVA, expandable to 120 MVA

Output Voltage: 7.2 kV

Output Frequency: Rated 50-60 Hz, 50 to 200 Hertz

Power Input/Output

Converter

• AC-fed 36-pulse diode rectifier using externally

mounted phase shifted transformer; no harmonic filter

required to meet IEEE 519 guidelines

• DC bus voltage: 3 x 5,450 Vdc

• Power factor greater than 95% in speed control range

Inverter

• Five-level inverter for motor friendly wave form

• Uses 8 GCT devices for each of three phases

• 7.2 kV output to motor – no output transformer

required

• Inverter power modules water cooled

• Conservative design for expected 20 year MTBF

Input Voltage

Any utility voltage using

separate transformer input

50/60 Hz ±10%

Output Voltage 7,200 Vac

Output Current 2400 A rms

Output Frequency 50-60 Hz

Output Chopping 600 Hz (max)

Efficiency 98%

Cable Entry Top or bottom

Clean Motor Output Wave

As a result of the five-

level PWM control, the

output current waveform

is close to a sine wave.

Harmonic currents in

the motor windings are

minimized so the heat

loss is negligible and

there is very little torque

ripple on the output shaft.

Line-to-Line Voltage at 100% Speed

U-phase Current at 100% Speed

Protective Functions Include:

• Inverter overcurrent

• Inverter overvoltage

• Low system voltage

• Motor ground fault

• Motor overload

• Cooling fan abnormal

• Over-temperature

• CPU error

• Water cooling alarm

• Exciter fault

• DC voltage drop

• Motor inverse rotation

• Stall detection

• Ground detection

Frequency Control

• Volt/Hertz Control – standard

• Sensorless vector control – optional

• Power factor control for synchronous motors

Output Voltage Modulation

The output switching modulation strategy is dynamically

adjusted based on three speed zones to minimize motor

torque pulsation.

Drive Inputs

• LAN Interface Options: Profibus-DP, DeviceNet,

Modbus RTU, TOSLINE

• Input/Output: 6 Analog I/O, 8 Digital I/O

Power Circuits

Motor Control

Gate Commutated Thyristor

(GCT) with driver board.

Rated 6,000 Volts, 6,000

Amps - the world’s largest

switching device

TMdrive-XL85 – 30 MVA Frame

Dimensions: Width 8.1 m

Height: 2.6 m

Motor type: Synchronous or Induction

d

r

i

v

e

-

X

L

8

5

–

3

0

M

V

A

F

r

a

m

e

XLdrive Series Family Application Guide.indd 6 10/3/2011 3:16:12 PM

7

Power Input/Output

Converter

• AC-fed 12- or 24-pulse diode rectifier using externally

mounted phase shifted transformer; no harmonic filter

required to meet IEEE 519 guidelines

• DC bus voltage: 3 x 5,700 Vdc

• Power factor greater than 95% in speed control range

Inverter

• Three-level inverter for motor friendly wave form

• Uses 4 GCT devices for each of three phases

• 3.8 kV output to motor – no output transformer

required

• Inverter power modules water cooled

• Conservative design for expected 20 year MTBF

Input Voltage

Any utility voltage using

separate transformer input

50/60 Hz ±10%

Output Voltage 3,800 Vac

Output Current 2400 A rms

Output Frequency 50-60 Hz

Output Chopping 600 Hz (max)

Drive Efficiency 98%

Cable Entry Top or bottom access

A Clean Output Wave

As a result of the three-level PWM control, the output

current waveform is close to a sine wave. Harmonic

currents in the motor are minimized so the heat loss is

negligible and there is very little torque ripple on the

output shaft.

Protective Functions Include

• Inverter overcurrent

• Inverter overvoltage

• Low system voltage

• Motor ground fault

• Motor overload

• Cooling fan abnormal

• Over-temperature

• CPU error

• Water cooling alarm

• Exciter fault

• DC voltage drop

• Motor inverse rotation

• Stall detection

• Ground detection

Frequency Control

• Volt/Hertz Control

• Vector control

• Power factor control for synchronous motors

Output Voltage Modulation

The output switching modulation strategy is dynamically

adjusted based on three speed zones to minimize motor

torque pulsation.

Drive Inputs

• LAN Interface Options: Profibus-DP, DeviceNet,

Modbus RTU,TOSLINE S-20

• Input/Output: 6 Analog I/O, 8 Digital I/O

Power Circuits

Motor Control

Gate Commutated Thyristor

(GCT) with driver board.

Rated 6,000 Volts, 6,000

Amps - the world’s largest

switching device.

TMdrive-XL80 – 15 MVA Frame

Power Rating: 15 MVA, expandable to 30 MVA

Output Voltage: 3.8 kV

Output Frequency: Rated 50-60 Hz, 50 to 200 Hertz

option with derate above 100 Hz

Dimensions: Width 4.8 m; Height: 2.7 m

Motor type: Synchronous or Induction

XLdrive Series Family Application Guide.indd 7 10/3/2011 3:16:15 PM

TMEIC Corporation

Office: 1325 Electric Road, Suite 200

Roanoke, VA, United States 24018

Mailing: 2060 Cook Drive

Salem, VA, United States 24153

Tel.: +1-540-283-2000; Fax: +1-540-283-2001

TMEIC Houston Branch

2901 Wilcrest Dr., Suite 110

Houston,Texas, 77042, USA

Tel: +1-713-784-2163; Fax: +1-712-784-2842

TOSHIBA MITSUBISHI-ELECTRIC INDUSTRIAL SYSTEMS

CORPORATION

Mita 43, MT Bldg.

13-16 Mita 3 chome, Minato-ku

Tokyo, Japan, 108-0073

Tel.: +81-3-5444-3828; Fax: +81-3-5444-3820

Web: www.tmeic.co.jp

TOSHIBA MITSUBISHI-ELECTRIC INDUSTRIAL

SYSTEMS

(Beijing) CORPORATION

21/F., Building B, In.do Mansion

48 Zhichunlu A, Haidian District

Beijing 100098, PRC

Tel.: +86 10 5873-2277; Fax: +86 10 5873-2208

TMEIC Europe Limited

6-9 The Square, Stockley Park

Uxbridge, United Kingdom, UB11 1FW

Tel.: +44 870 950 7220; Fax: +44 870 950 7221

TMEIC Industrial Systems India Private Limited

901/D, Filix, L.B.S. RoadOpp Asian Paints, Bhandup

West Mumbai, Maharashtra, India, 400 078

Tel.: +91-40-4434-0000; Fax: +91-40-4434-0034

Email: [email protected]

Web: www.tmeic.com/india

TMdrive is a registered trademark ofTOSHIBA MITSUBISHI-ELECTRIC INDUSTRIAL

SYSTEMS CORPORATION.

All other products mentioned are registered trademarks and/or trademarks of their

respective companies. All specifications in this document are subject to change

without notice.

All specifications in this document are subject to change without notice. The above

brochure is provided free of charge and without obligation to the reader or to

TMEIC.

TMEIC Corporation does not accept, nor imply, the acceptance of any liability

with regard to the use of the information provided.TMEIC Corporation provides

the information included herein as is and without warranty of any kind, express

or implied, including but not limited to any implied statutory warranty of

merchantability or fitness for particular purposes.The information is provided

solely as a general reference to the potential benefits that may be attributable to

the technology discussed. Individual results may vary. Independent analysis and

testing of each application is required to determine the results and benefits to be

achieved from the technology discussed. If you have any questions regarding your

project requirements, please contact TMEIC Corporation at 540-283-2301.

© 2011 TMEIC Corporation. All Rights Reserved. P- 114 5-A

Over 300 Service

Engineers world wide

Life Cycle Support from Commissioning to Post Sales Service

TMEIC offers comprehensive Customer Support, from pre-planning, through design,

commissioning and post sale service.

Over 70 Service Engineers

across North America

Customer Service Call Center

• Open 24x7x365

• Staffed by trained service engineers

• Supported by factory design engineers

Remote Drive and System Diagnostics

• Global Connectivity

• Quick Resolution

Motor and Generator Service

• EASA Service Centers supportTMEIC Motors

Commissioning and CustomerTraining

• Experienced commissioningTeam

• Comprehensive factory acceptance test

• Training of the entire team on the system at the

factory

• Customized training courses for allTMEIC

automation and control systems, drives , motors,

generators and otherTMEIC products

XLdrive Series Family Application Guide.indd 8 10/3/2011 3:16:19 PM

This manual suits for next models

4

Table of contents

Popular DC Drive manuals by other brands

GFA ELEKTROMATEN

GFA ELEKTROMATEN ST 16.24-40.00 installation instructions

Lenze

Lenze Tmd operating instructions

Omron

Omron SYSDRIVE 3G3JV quick start guide

Inovance

Inovance MD520 Series Safety function Guide

LiftEquip

LiftEquip MFC-16 Series Installation instruction

Danfoss

Danfoss VLT DriveMotor FCM 106 Design guide

Danfoss

Danfoss VLT 2800 manual

Siemens

Siemens Sinamics SM150 6SL3845-2NN41-8AD0 Operating and installation instructions

WEG

WEG CFW-11 Series user manual

SEW-Eurodrive

SEW-Eurodrive Movidrive MDX61B operating instructions

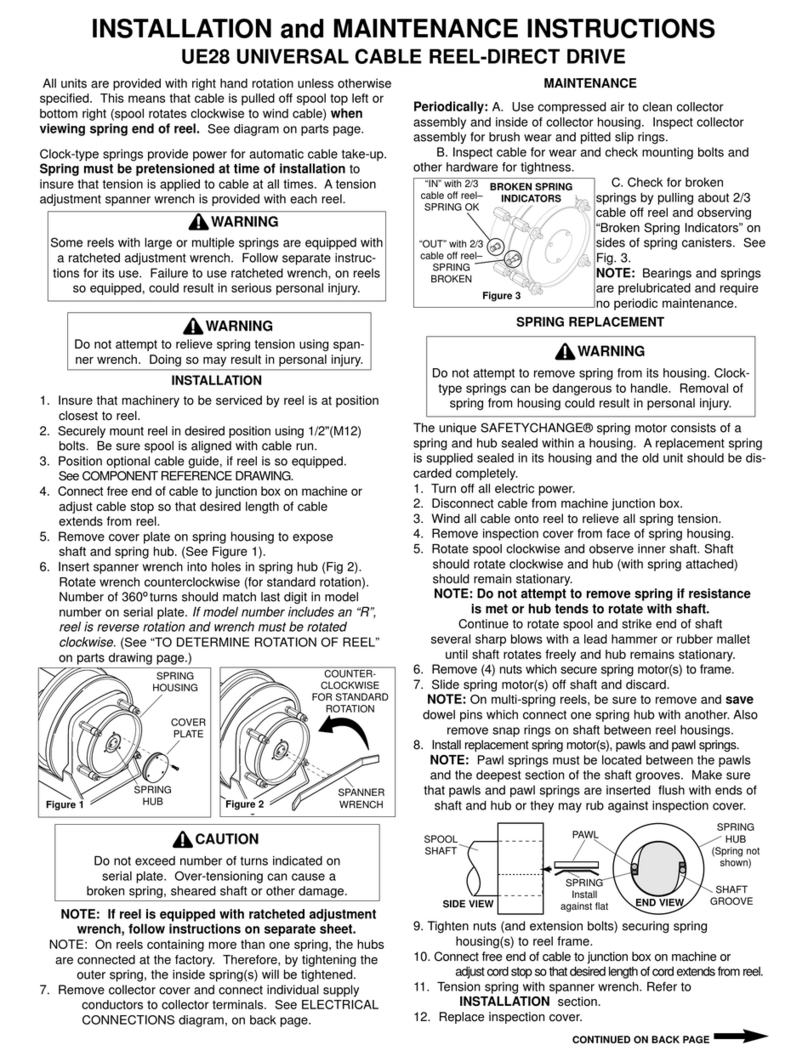

Hubbell

Hubbell Universal Cable Reel-Direct Drive UE28 Installation and maintenance instructions

Nidec

Nidec NE200 Series quick start guide