TMI Products 49-85 User manual

49-85/86/87

1

Rev.E

TESTING MACHINES, INC.

The Finest Test Equipment for all Industries

49-85/86/87 MICROMETERS

PLEASE READ BEFORE OPERATING UNIT

digital-micrometer-ld3581-49-86-m44.pdf 1digital-micrometer-ld3581-49-86-m44.pdf 1 15-6-2020 14:37:3215-6-2020 14:37:32

49-85/86/87

2

Rev.E

TESTING MACHINES, INC.

The Finest Test Equipment for all Industries

Worldwide Headquarters

Sales and Service

40 McCullough Drive

New Castle, DE 19720 USA

Phone: 302-613-5600

Toll Free: 800-678-3221

Fax: 302-613-5619

www.testingmachines.com

Dear Valued Customer:

You are now the proud new owner of quality physical testing equipment manufactured by Testing

Machines Inc., the industry’s leader for over 80 years. TMI has a long-standing commitment to

quality products and customer satisfaction.

To aid in setup, calibration, and operation of all Testing Machines Inc. equipment, we offer

telephone assistance by our Technical Support Department, available Monday through Friday

from 8:30 AM to 5:00 PM EST. TMI also offers on-site Preventative Maintenance and Calibration

service.

Please take the time to fill out the postage paid Warranty Card completely and return it to us.

Your comments make it possible for us to evaluate how well we are servicing your needs.

In the unlikely event that your equipment requires warranty repair service, or if you need to

arrange for non-warranty repair service, please follow the instructions on the repair policy page

located in this manual. Supplying the requested information on the repair policy page enables

our Technical Support Staff to service your needs faster.

Please contact us at (302) 613-5600 if additional information is required.

Sincerely,

Testing Machines, Inc.

digital-micrometer-ld3581-49-86-m44.pdf 2digital-micrometer-ld3581-49-86-m44.pdf 2 15-6-2020 14:37:5815-6-2020 14:37:58

49-85/86/87

3

Rev.E

IMPORTANT SAFETY INSTRUCTIONS

Read all of these instructions carefully before operating the instrument.

1. Save these instructions for future reference.

2. Follow all warnings and instructions that are marked on the instrument.

3. Unplug the instrument from the wall outlet before cleaning. Wipe the outside surfaces with a damp cloth

only.

4. Do not use this instrument near water.

5. Do not place the instrument on an unstable cart, stand, or table.

6. Only operate the instrument from the type of power source indicated on the label.

7. For safety, this product is equipped with a three-wire grounding type plug. This plug will only fit into a

grounding type power outlet. If you are unable to insert the plug into the outlet, contact your electrician to

replace the outlet with the proper type. Do not defeat the purpose of the grounding-type plug.

8. Do not allow anything to rest on the power cord. Do not locate this product where persons will walk on the

cord.

9. If an extension cord is used with this product, make sure that the total ampere ratings of the product(s)

plugged into the extension cord do not exceed the extension cord ampere rating. Extension cords must have a

minimum insulation rating of 600v.

10. Do not remove any panels from the tester. Never push objects of any kind into any openings in the

instrument’s covers. Failure to heed this warning could result in fire or electric shock. Never spill liquid of

any kind on the instrument.

11. Do not attempt to service this product yourself. Opening or removing

covers may expose you to dangerous high voltages.

12. At the end of its service life, dispose of the product according to the relevant statutory regulations.

13. Refer all servicing to Testing Machines’ Technical Support Staff:

Testing Machines Inc.

Customer Service Department

40 McCullough Drive

New Castle, DE 19720 USA

Phone: (800) 678-3221 or (302) 613-5600

Fax: (302) 613-5619

Email: responsecenter@testingmachines.com

Web: www.testingmachines.com

14. Unplug the unit from the wall outlet and refer servicing to qualified service personnel under the following

conditions:

i When the power cord or plug is damaged or frayed.

i If liquid has been spilled into the product.

i If the product has been exposed to rain or water.

15. Adjust only those controls that are covered by the operating instructions. Improper adjustments of other

controls may result in damage to the instrument and will often require extensive work by a technician to

restore the unit to normal operation.

digital-micrometer-ld3581-49-86-m44.pdf 3digital-micrometer-ld3581-49-86-m44.pdf 3 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

4

Rev.E

16. Back-up Battery:

Inside the Instrument tester a CR2032 type coin battery is used on the microcontroller

PCB to provide the necessary power to the timekeeping memory chip of the instrument during the power off

period. This to maintain the clock, calendar and setup information.

When the battery is worn out it may only be replaced by a trained service engineer!

When the battery is worn out dispose it under the ordinance of each local government or the law issued by

relating government.

The battery contains organic electrolyte.

In case of electrolyte leakage from the battery, and an eventual contact with this electrolyte to the operator

the actions described below are required.

In case of eye contact:

Flush the eyes with plenty of clean water for at least 15 minutes immediately, without rubbing. Take a

medical treatment. If appropriate procedures are not taken, this may cause an eye irritation.

In case of skin contact:

Wash the contact areas off immediately with plenty of water and soap. If appropriate procedures are not

taken, this may cause sores on the skin.

In case of inhalation:

Remove to fresh air immediately. Take a medical treatment

In case of electrolyte leakage, take it up with absorbent cloth.

This may only be done by a trained service engineer!

17. Instrument Labels:

The following labels can be found on the instrument.

Earth (Ground)

Electrical Shock Warning

Consult the Operator’s Manual

digital-micrometer-ld3581-49-86-m44.pdf 4digital-micrometer-ld3581-49-86-m44.pdf 4 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

5

Rev.E

Table of Contents

INTRODUCTION ........................................................................................................................................ 6

APPLICATION ............................................................................................................................................ 6

SPECIFICATIONS ...................................................................................................................................... 6

LIST OF EQUIPMENT ............................................................................................................................... 7

CALIBRATION GAUGE ............................................................................................................................ 7

FEATURES ................................................................................................................................................... 7

NAME AND FUNCTION OF PARTS ....................................................................................................... 8

SETUP ..........................................................................................................................................................12

OPERATION ...............................................................................................................................................12

INTRODUCTION .......................................................................................................................................16

PARALLELISM CHECK/ADJUSTMENT ..............................................................................................16

STATISTICS ………………………………………………………………………………………..……. 15

SERIAL DATA OUTPUT …………………………………….……………………...…………………. 15

MAINTENANCE ........................................................................................................................................18

digital-micrometer-ld3581-49-86-m44.pdf 5digital-micrometer-ld3581-49-86-m44.pdf 5 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

6

Rev.E

OPERATING INSTRUCTIONS

FOR

DIGITAL MICROMETERS

49-85,86,87 SERIES

INTRODUCTION

The TMI Digital Micrometer 49-8X Series measures the thickness of sheet material in the following

ranges:

Depending on the Model

49-85 and 49-86

0-0.050 in (Imperial Units)

0-1.27 mm (SI Units)

49-87

0-0.500 in (Imperial Units)

0-12.7 mm (SI Units)

The TMI Digital Micrometers – 49-8X Series combines a precision thickness measuring system with a

digital readout. The motor-driven instrument utilizes the dead weight micrometer principle. Each unit

has been designed and manufactured for use where the utmost precision is required, completely free of

operator influence.

The instrument consists of a heavy, solid frame which supports the unit and houses the thickness

measurement transducer and associated circuitry. A digital readout is provided to automatically

display the actual specimen thickness. The lower anvil as well as a movable pressure foot is made from

lapped, stainless steel.

APPLICATION

The TMI Micrometer is designed to measure the thickness or caliper of paper sheets, films and foils.

Almost any material including paper, natural or synthetic fabrics, leathers, metals, plastics and rubber

thickness can be measured with precision and accuracy. The 49-86 and 49-87 models also feature an

on board statistics package that stores up to 100 readings, calculates and displays the average, standard

deviation, maximum and minimum of the readings that are stored in the instrument’s temporary

memory.

SPECIFICATIONS

Dimensions: 7 in. (15cm) wide x 12 in. (30.5cm) high x 9.5 in. (24cm) deep

Approximate Weight: 22 lb. (10kg)

Power Requirements: 90-264VAC, 50/60 Hz

Ranges of Measurement: For Models 49-85 and 49-86:

Imperial Units; 0-0.050 in. x 0.0000254 in. resolution

SI Units; 0-1.270mm x 0.0005mm resolution

For Models 49-87:

Imperial Units; 0-0.50 in. x 0.0000254 in. resolution

SI Units; 0-12.70mm x 0.0005mm resolution

digital-micrometer-ld3581-49-86-m44.pdf 6digital-micrometer-ld3581-49-86-m44.pdf 6 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

7

Rev.E

Available Accessories: For Models 49-85 and 49-86:

TMI # 35-12-02 Gauge Blocks for accurate calibration

(.010 in./.254mm, .020 in./.508mm, .030 in./.762mm, .040 in./1.016mm

and .050 in./1.270mm in thickness)

For Models 49-87:

TMI # 35-12-03 Gauge Blocks for accurate calibration

(0.010 in./.254mm, .100 in./2.54mm, .200 in./5.08mm,

.300 in./7.62mm, .400 in./10.16mm and .500 in./12.70mm in thickness)

STANDARDS

TAPPI T 411, ISO 534, DIN 53105, ISO 3034, APPITA 1301.426, PAPTAC D.4, ISO 12625-3,

ISO 037, ASTM F2251, ISO 5084

NOTE: Only the 49-8X configured with the appropriate pressure foot and dead weight is capable

of meeting above standards

LIST OF EQUIPMENT

x 1 TMI Digital Micrometer

x 1 Instruction Manual

x 1 Box with Packing Material

NOTE: Carefully check all small wrappings, boxes, and envelopes to be sure all parts and supplies

are accounted for.

CALIBRATON GAUGE

To check the calibration properly, the user of the micrometer should have the necessary gauge

blocks on hand. The gauge blocks can be ordered separately from TMI. See Section 3 –

Specifications.

SAVE THE BOX

Remove the micrometer from the case with the greatest of care. Do not use

the pressure foot, the anvil or the spindle as a handle. Grasp the instrument

by the base only.

Please save all the original packing material from the micrometer. In the event the tester needs to

be returned, it must be packaged in the original shipping carton after receiving approval and a

Return Authorization Number (RA#) from TMI’s Customer Service Department.

FEATURES

x Digital readout and superior mechanical design

x Serial output for simple data collection

x Compact, for use throughout the laboratory and production floor

x Special anvil diameters and dead weight loads available on request

digital-micrometer-ld3581-49-86-m44.pdf 7digital-micrometer-ld3581-49-86-m44.pdf 7 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

8

Rev.E

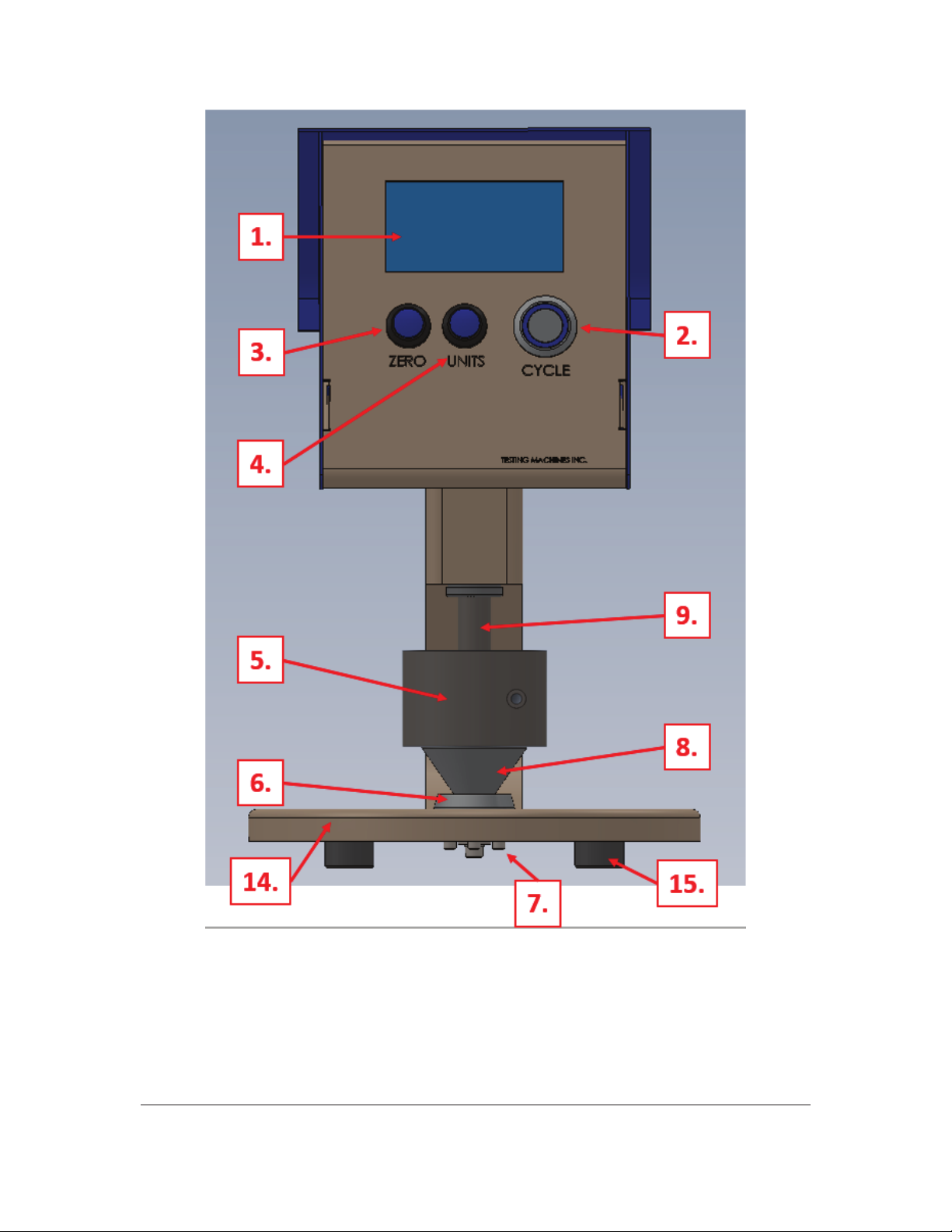

NAME AND FUNCTION OF PARTS

All the part names and their descriptions that are listed below can be found in Figure 1 and Figure 2...

for Model #’s 49-85, 49-86, and 49-87.

1. Display Window: The digital display window shows the thickness of the specimen measured.

2. Cycle Button: This Button is located on the front right side, a blue illuminated push button

switch. This button stops the anvil spindle and pressure foot from moving.

3. Zero Button: Pressing this will tell the machine to zero itself the next time that it comes to rest

on the lower platen or other static object. (In Menus this button will move the highlighted area

between different options.)

4. Units Button: This button is located on the middle of the front panel. In the 49-85 instrument,

this button will cycle the units through μm, mils, millimeters, and inches. (In Menus this button

will cycle through available options for the highlighted setting or accept the selected command

depending on the menu.) In the 49-86 and 49-87 instruments, the UNITS button is used to access

and navigate through the statistics pages as well as the Menus page.

5. Split Weight: TMI # 49-76-00-15 (Standard Model, 2 pieces of the afore mentioned part number

make this weight)

6. Lower Anvil: A testing surface that is optically flat. The specimen is placed on the anvil’s

surface and when the pressure foot comes down, a reading is obtained.

a. TMI # 49-01-07-016 (Standard Unit)

7. Set Screws: The three set screws are for the parallelism adjustment. (3) 10-32 x 5/8 set screws.

8. Pressure Foot: This part will move up and down once the machine is operating. The pressure

foot is the part that comes down on the specimen when the actual measuring is being performed.

TMI # 49-60-01-049 (Standard model)

9. Anvil Spindle: The spindle anvil will move up and down carrying the weight and pressure foot

with it.

10. On/Off Switch: The main power is switched on and off on this unit by a switch located on the

back on the unit built into the power entry module.

11. Serial Output: This unit has been fitted with RS-232 output via a Mini USB connector.

a. Serial Communication Parameters

A Null Modem is not required

i. Baud: 9600 bps

ii. Data Bits: 8

iii. Parity: None

iv. Stop Bits: 1

v. Flow Control: None

12. AC Line Cord Connection: The style of the line cord that is supplied with the unit is decided by

the country that the unit is being used.

digital-micrometer-ld3581-49-86-m44.pdf 8digital-micrometer-ld3581-49-86-m44.pdf 8 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

9

Rev.E

13. Fuse: 0.25 Amps. TMI # 680-075

a. Fuse Drawer: TMI # 680-062

b. (The Fuse is located inside the Fuse Drawer. you must depress two tabs, one on either

side, on the fuse drawer to remove it.)

Note:

In case of a blown fuse it needs to be replaced by one that has the identical

shape and the same current rating. In this case always disconnect the

power cord from the AC power inlet of the instrument before opening the

fuse holder.

Do not use fuses with a higher current rating then the original as this can cause damage to the instrument!

The use of repaired fuses, and/or short circuiting the fuse holder is prohibited!

14. Base Plate: The solid plate that the machine stands on.

15. Rubber Foot: To make sure the machine stands flat and secure on the ground; the machine has

four rubber spacing feet. TMI # 240-001

digital-micrometer-ld3581-49-86-m44.pdf 9digital-micrometer-ld3581-49-86-m44.pdf 9 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

10

Rev.E

Figure 1.

digital-micrometer-ld3581-49-86-m44.pdf 10digital-micrometer-ld3581-49-86-m44.pdf 10 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

11

Rev.E

Figure 2.

11.

10.

13.

12.

digital-micrometer-ld3581-49-86-m44.pdf 11digital-micrometer-ld3581-49-86-m44.pdf 11 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

12

Rev.E

SETUP

1. Take the micrometer out of the box and place it on a rigid, level bench top, free from large

temperature variations, excessive air currents and vibration. Ensure there is appropriate clearance

from the rear of the instrument to easily operate the power shutoff device.

2. MAKE SURE TO REMOVE THE SHIPPING COLLAR FROM THE ANVIL SPINDLE.

(The Shipping collar is typically a plastic tube secured by a large cable tie).

3. If included, mount the Split Weight to the micrometer spindle using the included 9/64” Allen

Wrench. (Split Weights are removed for shipping)

Note:

Please handle the split weights with great care to avoid damage. The edges of the split weights can

have sharp edges. Please be aware of the possible danger of cutting yourself!

4. Remove the rubber pad that is located in between the anvils during shipment.

(If the machine has a range of 0.000”-0.050” you will have to gently lift upper anvil enough

to slide the pad out).

5. Connect the power cord from the power entry module (located on the back of the unit) to a

suitable AC outlet, free from electrical noise and large voltage variations.

Warning:

If the supplied power plug needs to be adapted to the local power requirements this must be done by a

qualified electrical engineer. The plug must be equipped with a safety earth terminal.

Please Note:

Power cord wire colors:

Brown or Black = Line

Blue or White = Neutral

Yel/Grn or Green = Earth/Ground

OPERATION

1. Ensure that the shipping collar has been removed from the unit. Serious damage can occur if

the shipping collar has not been removed.

2. Turn the power switch to the “On” position. At this time, the display and start/stop button will

become illuminated. The first screen will only show until the end user confirms that they have

removed the restraints. TMI is not liable for damage cause by disregarding this warning.

3. The second screen will now appear. The machine will need to run 2 to 3 cycle to find the limits of

its travel. This is done by pressing the Units button. While cycling, the blue LED button should

pulse.

4. The third screen will remind you to clean the anvils for optimal performance. Draw a piece of

soft-body paper through the pressure foot and anvil; this will remove any foreign matter. Also

visually inspect the anvil surfaces for any debris, it might be necessary to use a small amount of

rubbing alcohol to clean them.

digital-micrometer-ld3581-49-86-m44.pdf 12digital-micrometer-ld3581-49-86-m44.pdf 12 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

13

Rev.E

5. The fourth screen to appear will be the main testing screen. It displays the measured gap, the

units, and the time. For best results, allow the micrometer to warm up for approximately 30

minutes minimum before performing any tests. It is highly recommended to always zero the

instrument before running samples.

6. Zero the Micrometer: To zero the micrometer, press the Zero button on the front panel.

Pressing this will tell the machine to zero itself the next time that it comes to rest on the lower

platen or other static object.

7. If you wish, you can perform a quick check of your micrometer. This is done with the TMI Gauge

Blocks:

For Model 49-85 and 49-86:

TMI # 35-12-02

For Model 49-87:

TMI # 35-12-03

Slip one of the gauge blocks between the pressure foot and the anvil. Ensure that the gauge block

is located at the visual center of the anvils. The digital display reading should be the same as the

thickness of the gauge block. (See the instrument’s calibration record for tolerance.) If the

micrometer does not give the correct reading of the gauge block, calibrate the micrometer. (See

Section 9 – Calibration of the micrometer.)

8. All samples that are to be tested should be prepared and conditioned according to TAPPI T400 or

applicable standards. Each sample should be cut and prepared as described in TAPPI T411 or any

other applicable standard. Any samples that are kinked, bent or creased should not be used since

this may affect the reading of the sample.

9. Measure the thickness by placing the specimen between the automatically cycling pressure foot

and the anvil when they are apart. Ensure that the specimen fully covers the area of contact

between the pressure foot and the anvil. During the time when the pressure foot rests on the

specimen, the specimen's thickness is measured and displayed on the digital readout. At the end

of the cycle time, the pressure foot again moves upward and a new measurement can be made. Be

sure to only take one reading at one point on the specimen.

Special Notes on Operation:

- Readings that appear to be slightly out of tolerance have a high likelihood of being caused by

trace amounts of debris left on the surfaces of the anvils.

USER OPTIONS MENU (49-86 and 49-87 only)

You may enter the User Options Menu from the main screen by pressing and holding the Units

Button and pressing the Zero Button. This menu contains the following options:

Password Protection (optional)

The instrument’s Options Menu can be protected by a “manager” password if the user chooses to

do so. The default setting for the instrument is 0-0-0-0, which disables the password prompt. To

enable a password, select the option and input a 4-digit code other than 0-0-0-0.

Note: If you would like to reset the password, use the calibration password. This will reset the

password to the factory default (disabled).

digital-micrometer-ld3581-49-86-m44.pdf 13digital-micrometer-ld3581-49-86-m44.pdf 13 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

14

Rev.E

Lowering Speed (in mm/s)

Your standard may specify a specific lowering speed. The options are 1, 2, and 5mm/s (10 mm/s

49-87 only)

Dwell Time (in seconds)

Your standard may specify a specific time to wait after the spindle motion stops on the sample

before it returns a result. The “0 seconds” option will report a result as soon as the machine

registers a stop. Dwell Times over 1 second will pause the motor in order to wait for the reading.

The options are 0,1,2,3,4,5, and 6 seconds.

Starting Units

This is the units that the machine will default to when powering on. The options are “μm” for

micrometers, “mils” for mils, “mm” for millimeters, and inches.

Record Stats:

The options for this setting are ON or OFF. Statistics can still be viewed if set to OFF, but no

new readings will be recorded.

Stat Threshold:

The options for this setting are OFF, 2 μm, 4 μm, and 6 μm. These are in metric because the

machine is internally a metric machine. Statistics will not be recorded if the reading is within the

tolerance band (+/-) around zero.

Zero Threshold:

This sets a small range around a reading of 0.00 to be reported as 0.00. For example: if the

machine is set to a Zero Threshold of 2 μm then any reading from -2 to 2 μm will return a reading

of 0 μm. The options for this setting are OFF, 2 μm, 4 μm, and 6 μm. These are in metric because

the machine is internally a metric machine.

Time:

This line contains several options

o 24Hr or A.M./P.M. – changes between 24 and 12 hour time

o Hours – adds one hour

o Minutes – adds one minute

o Seconds – resets the seconds to zero

Live Readings:

This option changes how the main screen displays the current gap. Turning Live Readings ON

will show a constant feed of the updated gap. Turning Live Readings OFF will cause the screen to

only update when it has a valid reading. These options will not change how the machine

communicates its readings with GraphMaster.

LED Pulse:

This will toggle the Cycle Button’s LED functions between constantly on and pulsing when a test

is being conducted. This has no effect on the machine’s function.

digital-micrometer-ld3581-49-86-m44.pdf 14digital-micrometer-ld3581-49-86-m44.pdf 14 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

15

Rev.E

Return:

This saves the options and returns you to the main screen.

STATISTICS

The 49-86 and 49-87 models have a statistics feature that allows the user to display the average,

standard deviation, maximum, and minimum values of the readings stored in the instrument’s

temporary memory (this memory is erased when the power to the instrument is turned off).

1. To access the main statistics screen from the main (measurement) screen, press the UNITS button.

2. The main statistics screen will display the current reading, the average of the stored readings, the

standards deviation of the stored readings and the maximum and minimum of the stored readings.

3. Press the UNITS button again to list the readings

a. Navigate this screen by pressing the ZERO key to highlight ↑ , ↓ , DELETE, or RETURN

b. Press the UNITS key to act on the highlighted option

i. Pressing UNITS when the ↑ is highlighted will scroll the active reading selection

box up once.

ii. Pressing UNITS when the ↓ is highlighted will scroll the active reading selection

box down once.

iii. Pressing UNITS when the DELETE is highlighted will delete the active reading

in the selection box.

iv. Pressing UNITS when the RETURN is highlighted will return to the main

statistics screen.

c. Press and hold the UNITS key, then press the ZERO key to delete all readings. User

confirmation is required for this.

4. Press and hold the UNITS key, then the ZERO key to return to the Main (measurement) screen.

SERIAL DATA OUTPUT

These Testing Machine Inc. Micrometers (Thickness Gauges) output a string through a mini-USB

connector on the back panel of the instrument.

The USB host (PC) will need to be looking for serial data on one of its COM ports. The number of the

COM port will vary from host to host.

These are the settings needed to capture the serial data -

Baud rate: 9600

Data: 8 bits

Parity: None

Stop Bit(s): 1

Flow Control: None

Here are some serial string examples-

x Initial string - "CC5.1.1.13;"

o This is an identifier string used by our GraphMaster product. You can ignore it if you are

not using GraphMaster. It will only show up after powering on.

x After each cessation of downward motion, like the spindle coming to rest on a sample, the

machine will output a serial data string in the following format.

TM V00.01.02 49-87-00-000112345-67 00000000053+000004.370

o "TM V00.01.02 " - A software version number

digital-micrometer-ld3581-49-86-m44.pdf 15digital-micrometer-ld3581-49-86-m44.pdf 15 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

16

Rev.E

o "49-87-00-0001" - The machine's complete model number

o "12345-67" - The machine's serial number. Yours will probably look like 8xxxx-01

o "0000000005" - An identifier for this reading. This resets to zero on powering on and

rolls over to 0 after its maximum is reached.

o "3" - The unit of the reading. '3' is mils (thousandths of an inch) and '0' is microns

(micrometers)

o "+000004.370" - The reading itself in the units just specified. The '+' is there because the

machine can show negative values if zeroed while resting on something besides the

platen.

CALIBRATION

INTRODUCTION

This machine has been adjusted and calibrated at the factory. The 49-8X series micrometer has a

large portion of its calibration done via a PC. For that reason and the highly technical nature of

the calibration we recommend that it only be performed by factory trained personnel. When

adjustments and calibration are necessary, refer to the following procedures:

1. Use a set of TMI gauge blocks when calibrating or making adjustments. The set consists of

five steel gauge blocks of different sizes. (See Section 3 – Specifications.) These gauge

blocks are checked against standards that are traceable to the NIST. The part number for the

TMI gauge blocks is as follows:

For Model 49-85 and 49-86:

TMI # 35-12-02

For Model 49-87:

TMI # 35-12-03

2. Turn the micrometer on. Allow the micrometer to warm-up for approximately one half hour

before attempting to calibrate.

3. The pressure foot and the lower anvils must be clean and free of dirt. The gauge blocks must

be cleaned thoroughly with alcohol before use. Do not touch the working surface with

fingers before making any measurements.

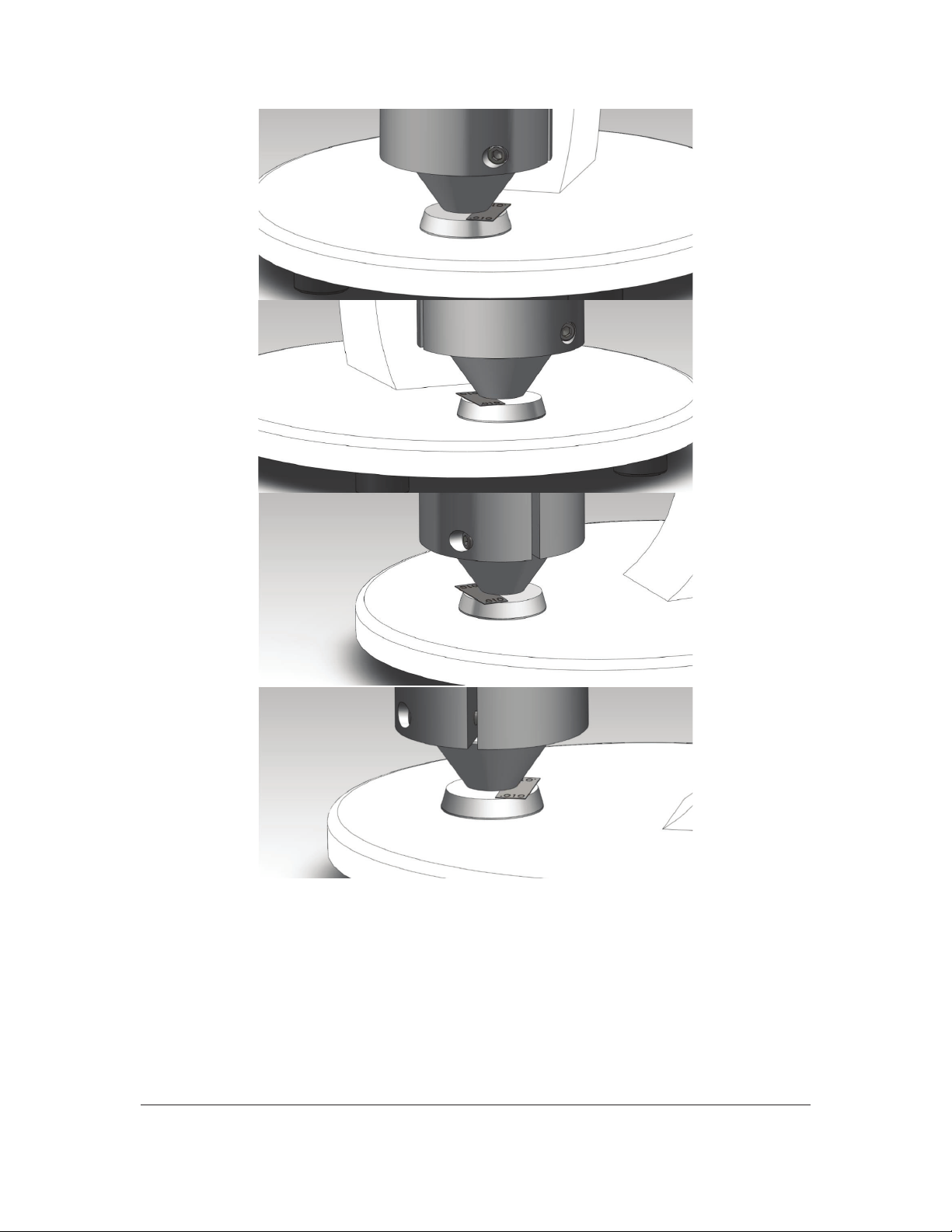

PARALLELISM CHECK/ADJUSTMENT (pictures on following page)

Adjustment of parallelism should only be made by a trained professional

1. Always check the anvil parallelism first. Insert one half of the width of the .010 in. gauge

block between the anvils on the right side of the unit and take a reading.

2. Insert the same one half of the width of the gauge block between the anvils on the left side of

the unit. See Figure 1.

3. Repeat the above procedure for the front, back and center of the anvils.

digital-micrometer-ld3581-49-86-m44.pdf 16digital-micrometer-ld3581-49-86-m44.pdf 16 15-6-2020 14:37:5915-6-2020 14:37:59

49-85/86/87

17

Rev.E

Figure 1

digital-micrometer-ld3581-49-86-m44.pdf 17digital-micrometer-ld3581-49-86-m44.pdf 17 15-6-2020 14:38:0015-6-2020 14:38:00

49-85/86/87

18

Rev.E

4. For Model 49-85 and 49-86:*

The readings must be within 0.00004 in. of each other for the anvil and the pressure foot to

be considered parallel and no adjustment needs to be done.

For Model 49-87:*

The readings must be within 0.0002 in. of each other for the anvil and the pressure foot to be

considered parallel and no adjustment needs to be done.

5. If the parallelism measurements, as described in Section 9.2 – Steps 1 and 2, do not fall

within the tolerance range, the anvil needs to be adjusted. Underneath the base plate, there

are three leveling screws that attach the anvil to the base plate. Use an Allen key to adjust

the leveling screws while securing the nut with a 3/8 in. wrench.

For Model 49-85 and 49-86:*

Adjust the leveling screws until all readings are within .00004 in. (.001 mm) across the

anvil’s surfaces.

For Model 49-87:*

Adjust the leveling screws until all readings are within .0002 in. (.005 mm) across the

anvil’s surfaces.

When the adjustments are completed, recheck the parallelism.

* For instruments 49-86-00-0003 and 49-87-00-0003 perform three sets of readings, adjusting the

screws each iteration in order to establish a baseline parallelism. Only perform this parallelism

adjustment if measurements with gauge blocks placed in the visual center of the anvil are outside

the tolerances of the instrument’s calibration record.

MAINTENANCE

The TMI Digital Micrometers – 49-8X Series do not require oiling or special maintenance. A rise in

operating temperature is expected. The temperature will rise until it reaches operating temperature.

Keep the instrument clean and in an environment that is free of dirt and dust. For consistent test

readings, it is very important that the anvil and pressure foot are kept clean.

If the instrument is not in use for an extended period of time, a plastic cover should be used to protect

it from dirt and other foreign matter. The pressure foot and the anvil should not be in contact for

extended periods of time. Place a piece of paper, film, etc. between the pressure foot and anvil.

digital-micrometer-ld3581-49-86-m44.pdf 18digital-micrometer-ld3581-49-86-m44.pdf 18 15-6-2020 14:38:0015-6-2020 14:38:00

49-85/86/87

19

Rev.E

TERMS AND CONDITIONS OF SALE

All purchases from TMI are subject to TMI’s Standard Terms and Conditions linked below. The TMI Terms

and Conditions are an integral part of each business transaction, as indicated in TMI’s price bulletins,

quotations or order acknowledgements provided.

All materials delivered, services provided, and work performed by TMI are subject to the Terms and

Conditions listed on the linked document.

To view and/or download the complete Terms and Conditions of Sale

document in PDF format, please visit:

http://www.testingmachines.com/terms-and-conditions-of-sale

digital-micrometer-ld3581-49-86-m44.pdf 19digital-micrometer-ld3581-49-86-m44.pdf 19 15-6-2020 14:38:0015-6-2020 14:38:00

digital-micrometer-ld3581-49-86-m44.pdf 20digital-micrometer-ld3581-49-86-m44.pdf 20 15-6-2020 14:38:0015-6-2020 14:38:00

This manual suits for next models

2

Table of contents

Popular Measuring Instrument manuals by other brands

KAEL Muhendislik Elektronik

KAEL Muhendislik Elektronik ENERGY 11-DIN instruction manual

GeoMax

GeoMax Zipp20 series installation guide

Tektronix

Tektronix 7853A instruction manual

National Instruments

National Instruments 9235 Getting started guide

Endress+Hauser

Endress+Hauser Tankvision Multi Scan NXA83 operating instructions

Toya

Toya VOREL 81775 Original instructions