TONG YANG MAGIC DWA-2033 User manual

BEFORE SERVICING THE APPLIANCE,

READ THIS A/S MANUAL

CONTENTS

1. APPLIANCE SPECIFICATIONS - 2

2. FUNCTIONS OF THE BUTTON - 3

3. NAME OF PARTS - 4

4. ELECTRIC PART SPECIFICATION - 5~8

5. CIRCUIT DIAGRAM - 9

- 10~15

7. TROUBLE SHOOTING GUIDE - 16~27

8. TECHNICAL GUIDE - 28

9. DISASSEMBLING & ASSEMBLING - 29~35

10. WATER SOFTENER - 36

- 37~46

October-2006

6. SELF TEST PROGRAM AND ERROR

CHECK LIST

DISH WASHER

A/S MANUAL

DWA-2033

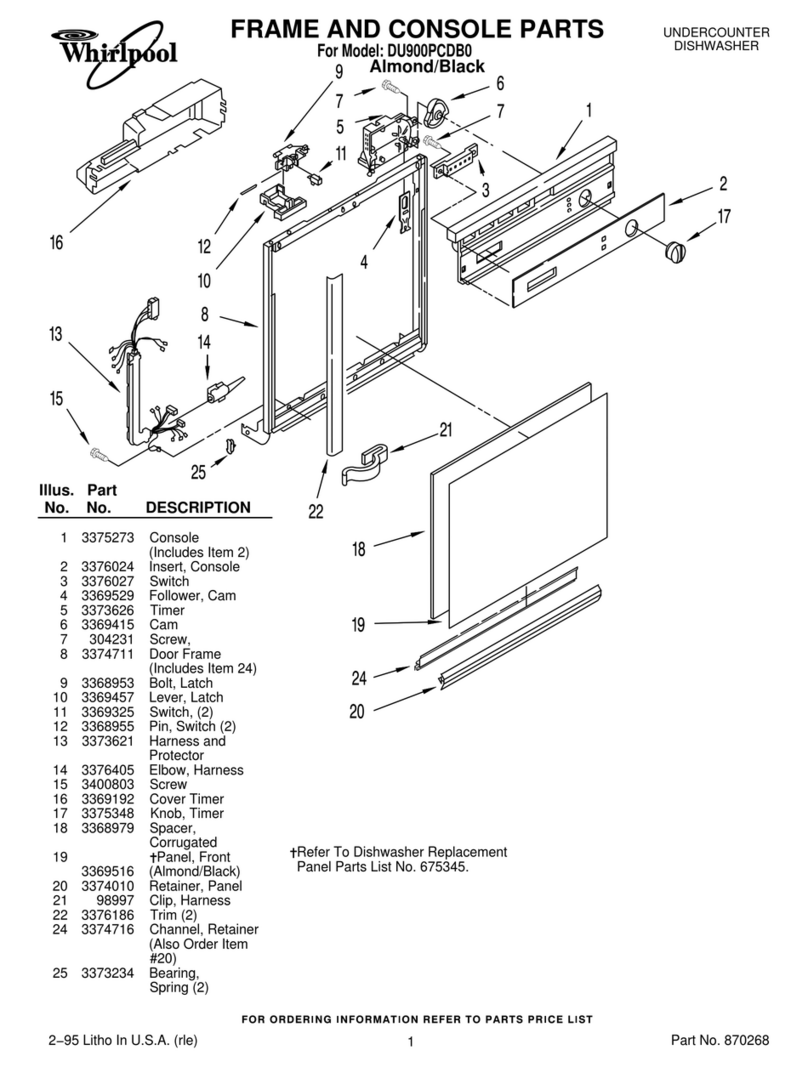

11. EXPLODED VIEW & PART LIST

Remark

Eco. Course

Eco. Course

(with regeneration)

Eco. Course

KOR-3301H

FLOW METER

Temperature perception method

Washing method

2200W

2000W

150W

Installation method

Overall Dimension(mm)

Weight

The 1 course consumption

of power

Inlet water temperature

Total

Heater

Circulation pump

Drain pump

Power

Consumption

Item

Type

Model

Capacity

1.APPLIANCE SPECIFICATIONS

Condensing force air ventilation dry type

Float s/w

Room temperature 2 times/

60℃ Heating 1 time

Thermistor(40,45,50,60,65,70,75,80℃)

0.86kWh

Contents

Power sourse

0 ~ 70℃

Fully Automatic Dishwasher

598(W)*596(D)*840(H)

10g

Quadruple filter

30W

FREE STANDING

0.2 ~ 8 ㎏f/㎠(bar)

12 place setting

47kg

AC 230V, 50Hz

Detergent amount

Filter

Safety

Rotary jet type

Over flow

Over heating

Drying method

Rinsing method

Thermistor, Thermo fuse, HPS

Fan motor 12W

Required water pressure

Water consumption

Water perception method

The 1 course consumption

of water 15ℓ

3.4 ±0.4ℓ

2.FUNCTIONS OF THE BUTTON

3.NAME OF PARTS

■ Power consumption : 2000W

■ Rated voltage: AC 220V/230V, 60Hz/50Hz

In case of the Fan Motor's trouble :

- At the drying cycle, the noise occurred.

After the dishwasher was chilled enough,

measuring the coil resistance in normal temp.

■ Coil resistance: 24.7Ω~28Ω

4-3. Heater

■ Coil resistance: 163Ω±9Ω

■ Power consumption: 30W

■ Rated voltage/frequency: AC 220V-240V, 50Hz.

4. ELECTRIC PART SPECIFICATION

4-1. Water Circulation Pump

■ Model: CS-0290LY

■ Rated voltage/frequency: AC 230V, 50Hz.

■ Power consumption: 144 ± 15% W

■ Coil resistance:

black-red(SUB) :104.2Ω±5%

■ Rated voltage/frequency : AC 230V, 50Hz

■ Model: B20-6

4-4. Dry Fan ASS'Y

■ Power consumption : 12W

black-violet(MAIN):74.5Ω±5%

■ Model: 1TYM00402

☞ A method of confirming trouble

- The impeller was not rotated.

Therefore the wet vapor does not exhaust,

and dishes cannot be drying.

4-2. Drain Pump

M~

4㎌

450VAC

black

violet

red A

red B

4-5. THERMISTOR

# DATA TABLE OF COIL RESISTANCE

temp coil

resistance

Voltage

division

Value[V]

5 124.2 4.3065

20 60.96 3.7648

30 39.31 3.3139

40 26 2.8261

50 17.6 2.3404

60 12.16 1.8905

70 8.552 1.4976

80 6.112 1.1703

: AC 220V/230V, 60Hz/50Hz

■ Type: N61 TYPE

4-7. INLET VALVE ASS'Y

■ Manufacturer: SAMJU FUSE

■ Rated voltage : 250V 3A

4-6. FUSE

☞A method of confirming trouble : After the dishwasher

was chilled enough, measuring the coil resistance of

thermistor on normal temp.

■ Rated voltage/frequency

■ Water pressure: 0.2 ~8 ㎏/㎠(0.2 ~8 bar)

■ Rated voltage : 230V 16A

☞ A method of confirming trouble

:SEE THE TROUBLE SHOOTING GUIDE

☞ A method of confirming trouble

:SEE THE TROUBLE SHOOTING GUIDE

4-11. DISPENSER

■ Model:549

■ Power consumption:10W

■ Rinse capacity:140mℓ

■ Operating time: 1min / Return time: 5min

4-9. DISPLAY PCB ASS'Y

4-8.LATCH ASS'Y

■ A point of contact : NORMAL CLOSE

■ Detegent capacity:40g(15g+25g)

4-10. MAIN PCB ASS'Y

Inlet v/v relay

~

220V ~

Inlet v/v

■ RPM : 5 (50Hz) / 6 (60Hz)

■ Model: M2LB49Z-S32

■ input voltage : AC 230V/50Hz

■ output voltage : AC 14.5V/0.4A

■ Direction : CCW

■ Model: BNP-45M040G2

■ Rated voltage: AC 450V 4㎌

4-14. TRANSFORMER

4-12. SYNCHRONOUS MOTOR

■ Rated voltage: AC 220V /240V

4-13. CAPACITOR

■ Power consumption: 3 / 2.5 W

4-15. WATER SOFTENER

■ Rated voltage: 220-240V / 50Hz-60Hz

5. CIRCUIT DIAGRAM

- NOTES - T.A : THERMOACTUATOR WS : WATER SOFENER

TH : THERMISTER DR : DOOR S/W F/M : FAN MOTOR

FL : FLOAT S/W D/M : DISTRIBUTER MOTOR DS : DISPENSOR

D/S : DISTRIBUTER S/W MAIN RELAY C/P : CIRCULATION PUMP

HEATER RELAY WV : INLET VALVE FM : FLOW METER

HPS : HIGH PRESSURE S/W D/P : DRAIN PUMP SA : SALT S/WW

6-1.SELF TEST PROGRAM AND ERROR CHECK LIST

No.

1 DISPLAY

SWITCH

SELF TEST PROGRAM

[Start/Pause+Power] 2. Self test program FLOW

: Display confirmation

: Tact switch confirmation

: Switch & sensor confirmation

: Relay confirmation

: A/D data confirmation

FUNCTION EXPLANATION NOTE

1. If you press the Start/Pause+Power button, the self test program is

started.

LED check

START

KEY check

SENSOR check

LOAD check

A/D data check

END

Selec Half

Fuzzy

Dry

Delay

Start

Start

/Pause Power

Rinse

plus

Pre

Rinse

DISPLAY

No.

2 LED check program 1) LED check flow

2) Progress to NO 3 if is completed all by upside procedure.

No.

3 KEY check program 1) [PU] is displayed and waits key input to Remain indicator.

- Progress by 2) if all key are pressed down more than 1.

KEY NO KEY NO

Select 1 Pre Rinse 5

Half 2 Delay Start 6

Fuzzy Dry 3 Start/Pause 7

Rinse plus 4 Power 8

No.

4 Sensor check program 1) [dr] is displayed and wait state change of door switch.

- You can progress next operation by Input key.

(Skip function is all possible from 1)~6).)

2) [nu] is displayed and waits state change of Float Switch.

4) [rn] is displayed and waits state change of rinse switch

5) [st] is displayed and waits state change of salt switch

FUNCTION EXPLANATION NOTE

- If press Start + Power , LED check program is gone.

FUNCTION EXPLANATION NOTE

- Whenever you press key, you can hear the sounds from buzzer.

FUNCTION EXPLANATION NOTE

- If there is state change, buzzer rings 1 times and progresses by 2).

- If there is state change, buzzer rings 1 times and progresses by 3).

3) [bS] is displayed and waits state change of Bottom Level Switch.

- If there is state change, buzzer rings 1 times and progresses by 5).

- If there is state change, buzzer rings 1 times and progresses by 5).

6) [FL] is displayed and waits state change of flow meter.

- If there is state change, buzzer rings 1 times and progresses by 6).

- LED lights up gradually to about 0.3 seconds .

- Lighting procedure

88Segment1 [a → b → c → d → e → f → g] → [Time] → [M]

→ [Hr]→ [Upper]→ [-]→ [Lower]→ [1/2]→ [Normal]→

[Perfect]→ [Eco.]→ [crystal]→ [Rinse Dry]→ [Short]→

[Pwr.]→ [Fuz.]→ [Pre Rinse]→ [Prewash]→ [Wash]→

[Rinse]→ [Dry]→ [Keep Dry]→ 88Segment2

[a→b→c→d→e→f→g]→[℃]→[Rinse plus1]→[Rinse

plus2]→[Child Lock]→[Rinse Refill]→[Salt]→[Rinse plus]

No.

5

Load check program

2) Progress to NO 6 if is completed all by upside procedure.

FUNCTION EXPLANATION NOTE

1) Progress by below order and relevant load acts for about 1 second.

Main relay is operating

continuously.

[Co] DISPLAY, Normal LED

Water supply valve operation

[Cp] DISPLAY, Intensive LED

c/pump operation

[dP] DISPLAY, Eco. LED

d/pumpr operation

[ds] DISPLAY,Short. LED

dispensor operation

[Fn] DISPLAY, Dry LED

Dry fan operation

[UU] DISPLAY, Dry LED

synchronous motor operation

[Ht] DISPLAY, Rapid LED

heater operation

[st] DISPLAY, Dry LED

water softener v/v operation

No.

6 A/D data check

program

5 124.2 4.3065

10 97.23 4.1470

15 76.71 3.9660

20 60.96 3.7648

25 48.79 3.5463

30 39.31 3.3139

35 31.87 3.0721

40 26.00 2.8261

45 21.34 2.5810

50 17.60 2.3404

55 14.59 2.1090

60 12.16 1.8905

65 10.18 1.6865

70 8.552 1.4976

75 7.216 1.3257

80 6.112 1.1703

85 5.195 1.0310

90 4.431 0.9068

- A standard of resistance value is the specification

of the thermistor.

FUNCTION EXPLANATION NOTE

4) Main temperature A/D conversion price and thermistor resistance price .

- Voltage value is calculated by reference resistance value of 20KΩ.

- Tolerence of the resistance value &voltage value is about 10%.

Temp [℃] Thermistor

resistance[㏀]

Voltage

division

value[V]

1) A/D conversion price that correspond in temperature at water temp

sensor is displayed.

2) Check the display whether the resistance value is right with comparing

display to resistance value.

3) If the display is right, you can press the POWER BUTTON to complete

self-test prgram.

6-2. ERROR CHECK LIST

No. FUNCTION EXPLANATION NOTE

1 Types & notification 1. Types of errors

of errors - E1, E2, E3, E4 : Out of order or user correctable

- F1 ~ F8 : Out of order (user incorrectable)

4. Method to resolving an error

stop the action. (Power button will not function in F1 ~ F8)

(1) Door error 1. Occurs when the door is open for more than 10 minutes

[E1] 2. Error Display

- [E1] will be displayed in time display portion

(2) Water supply error

than 100 within 60sec after water supplying starts.

(HPS operation : When c/pump is working after water suppy,

HPS s/w check open or close

[E2] 2. Occurs when Flow meter rpm is less than input data with in 240sec.

3. Occurs when HPS is open for 10 sec consecutive after flow meter

operation nomally.

- [E2] will be displayed in time display portion

(3) Water disposal error

water disposal stroke 3times

[E3] 2. Error Display

[E3] will be displayed in time display portion

3. When water disposal error occurs, water diposal will not occur.

(4) Hot water supply

error

[E4] 2. Error display

- [E4] will be displayed in time display portion

(5) F/W (Flow Meter)

error

[F1] 2. Error display

- [F1] will be displayed in time display portion

3. If there is an error, a buzzer of 1sec of ON/0.5sec of OFF will be

heard 5 times.

2. If there is an error, error type will be displayed in time display indigater.

- F1 ~ F8

POWER button will not be inputted. Power plug must be unplugged

- Don't dispose water in case of water disposal error .

- Turning off the power when water disposal is in progress will

1. Occurs when water disposal stoke cannot be complete even after

performing

4. Error Display

1. Occurs when HPS is open for 5sec & Flow meter rpm is less

to resolve the error.

- For every other errors pressing the POWER button and turn off power.

: E1, E2, E3, E4

5. If error occurs, progress the water disposal stroke and dispose the

water in the washer tank.

1. Occurs when HPS is close for 5sec & Flow meter rpm is less than

100 within 60sec after water supplying starts.

1. Occurs when water temp is above 85 degrees celsius during

supply stroke

예

No. FUNCTION EXPLANATION NOTE

(7) Leak error

[F3] 2. Error display

- [F3] is displayed in time display portion

[F4] 2. Error display

- [F4] will be displayed in time display portion

error reach desired temperature within 40min.

[F5] 2. Error display

- [F5] will be displayed in time display portion

[F6] 2. Error display

- [F6] will be displayed in time display portion

1. Occurs when positioning function of sychronous motor is not working

2. A fuse blew because of a short circuit.

[F8] 3. Error display

- [F8] will be displayed in time display portion

Door open 1. Before operation or when paused

2 [dr]

- All buttons except POWER button do not function.

2. When door is open during operation

- All load (motor, heater, pump, etc.) will be turned OFF.

MAIN RELAY will be ON.

- All buttons except POWER button will not function.

- The above mode will continue until door close or power OFF.

3. When the door is OPEN and 10 minutes pass, error occurs

and buzzer will sound 5 times. (E1 error)

3

[tS] 2. Display when resistance value is 0

[t0] - [tS]displayed

- Buzzer will sound 5 times and water disposal

3. Display when resistance value is ∞

- [tO] displayed

- Buzzer will sound 5 times

(10) Water supply valve

1. Occurs when the rotation number of Flow Meter are more than 250.

(in case of water supply in not working)

1. Occurs when the Float Switch (located in the bottom of washer) is closed.

1. Occurs when water temp is above 90 degrees celsius during

heating & sprinkling stroke

(8) High temperature

error

(9) Low temperature

Thermistor

detect function

- When door is opened, [dr] will be displayed with LED.

- Closing the door will be back to before Door open

- When door closes, [dr] is deleted in 88 segment and stroke will

continue after display of remaining time

of current washing.

- [dr] is displayed in the 88 segment and the display shows the

mode that was in progress.

1. Occurs In a heating and sprinkling stroke, when the temperature does not

(11) Sychronous Motor

error

5. After solving the cause, all may be resolved by reconnecting the

power plug.

1. When thermistor's resistance value is 0 (short) or ∞ (disconnection),

it will be detected and will be displayed with the buzzer.

4. Detection of disconnection or short of thermistor will function

when power plug is plugged and when error occurs at this time,

water disposal will not occur.

예

7.TROUBLE SHOOTING GUIDE

● Check and caution before service.

- Grasp consumer's service request contents in detail.

- Execute self-test program and grasp correctly trouble after visit.

- Remove power that is running to product, and close supply valve.

- According to trouble solve method, execute service.

- Check whether dish-washing machine is operated normally.

- Arrange used parts and surrounding cleanly after service.

- Know well correctly solution method accordingly and

prepare connected tool and parts when trouble is

DOOR ERROR [E1]

Connect the connector of CN4&6

Replace the LATCH ASS'Y

예

예

Replace MICRO SWITCH.

NO

YES

NO

NO

YES

Replace the PCB ASS'Y MAIN.

Start

End

Is the connector connected to CN4

& 6 in PCB ASS'Y MAIN conntected

correctly?

Please check After Electrical connection.

Be carefull to be running AC230V on PCB.

Check wire connector of CN9 or

reconnect.

NO

NO

YES

YES

YES

Does the product works normally?

Is the wire connected to door switch

connected to PCB ASS'Y MAIN

correctly?

If you close the door, does the

LATCH LEVER press the buttom of

micro switch?

when the door is close,

is a point of contact of the micro switch

close? (EC7 - OPEN:5V, CLOSE:0V)

* PREPARE PARTS

- MAIN PCB ASS'Y

- LATCH ASS'Y

- MICRO SWITCH

WATER SUPPLY ERROR [E2]

Start

Replace the PCB ASS'Y MAIN

NO

YES

Check Lead wire or replace.

when water supply, Is DC2~3V

running on flow meter terminal?

YES

YES

NO

Replace the PCB ASS'Y MAIN

End

YES

NO

Does supply error happen ?(E2)

Does the water supply end normally?

Please check After Electrical connection.

Be carefull to be running AC230V on PCB.

Check Lead wire or replace.

Replace the PCB ASS'Y MAIN

NO

NO

NO

NO

YES

YES

YES

Is electric wire that is connected to

Main pcb's CN6 & CN11 connected

exactly with HPS, Flow Meter?

Dose AC230V contact at both

ends of water supply valve?

when water supply,

is a point of contact of RY7 close?

Is DC12V running on D12 when

water supply?(D10)

Is the connector connected to CN8 in

PCB ASS'Y MAIN conntected

correctly?

Replace the Flow meter ass'y.

NO

Check Lead wire or replace. Check Lead wire or replace.

Is operation sound of supply valve? Replace supply valve.

Is there supply operated normally?

Check flow meter or replace

NO

YES

YES

YES

YES

NO

Please Check the door whether the door is open.

* PREPARE PARTS

- MAIN PCB ASS'Y

- INLET V/V ASS'Y 1SET

- HPS(HIGH PRESSURE

SWITCH)

WATER DISPOSAL ERROR [E3]

Start

YES

YES

Replace the PCB ASS'Y MAIN

YES

Check the drain hole or the drain

YES

YES

NO

NO

NO

NO

YES

Check Lead wire or replace.

NO

Replace drain pump

Is the drain hole close?

while the drain pump works, Is DC12V

running on D13 in PCB ASS'Y MAIN?

Is there operation sound of drain pump ?

Is the water disposed normally?

While the drain pump works, is

AC230V running on the drain

pump?

Does the water drain end normally?

NO

End

YES

NO Check HPS or replace

Replace the PCB ASS'Y MAIN.

YES

Does disposal error happen after 180

seconds passage after disposal

beginning?(E3)

Please check After Electrical connection.

Be carefull to be running AC230V on PCB.

Check Lead wire or replace

NO

Replace the PCB ASS'Y MAIN

NO

YES

While the drain pump works,

is a point of contact of RY8 close?

Is electric wire that is connected to Main

pcb's CN6 connected exactly with HPS ?

* PREPARE PARTS

- MAIN PCB ASS'Y

- LEAD WIRE MAIN

- HPS(HIGH PRESSURE

SWITCH)

HIGH TEMPERATURE WATER SUPPLY ERROR [E4]

Start

YES

Replace thermister.

YES

the water temperature is high

use cold water only.

NO

NO

Does the water temperature exceed 85℃?

Compare to table, is the resistance

value of the thermistor right?

Please check After Electrical connection.

Be carefull to be running AC230V on PCB.

Replace the PCB ASS'Y MAIN

NO

YES

End

YES

Does the product works normally?

* PREPARE PARTS

- MAIN PCB ASS'Y

- Thermistor

FLOW METER (F/M) ERROR [F1]

Start

Is the connector connected to CN8, CN11

in PCB ass'y main connected correctly?

Replace the PCB ASS'Y MAIN

NO

YES

NO

YES

* PREPARE PARTS

- PCB ASS'Y MAIN

- HPS

- LEAD WIRE MAIN

- FLOW METER

Check Lead wire or replace.

NO

YES

Check Lead wire or replace.

when water supply,

is a point of contact of RY7 close?

Is AC230V running on the inlet valve?

Please check After Electrical connection.

Be carefull to be running AC230V on PCB.

YES

YES

YES

NO

NO

Replace inlet valve

Is there operation sound of inlet

valve ?

Are DC 2~3V of voltage running

flowmeter while water supply?

Replace the PCB ASS'Y MAIN.

NO

Check flowmeter or replace.

Does the water supply end normally?

End

Table of contents