Toro Greensmaster 04251 User manual

Other Toro Lawn Mower manuals

Toro

Toro GrandStand HDX User manual

Toro

Toro 3200 User manual

Toro

Toro TimeCutter HD MyRide 75211 User manual

Toro

Toro 21848T User manual

Toro

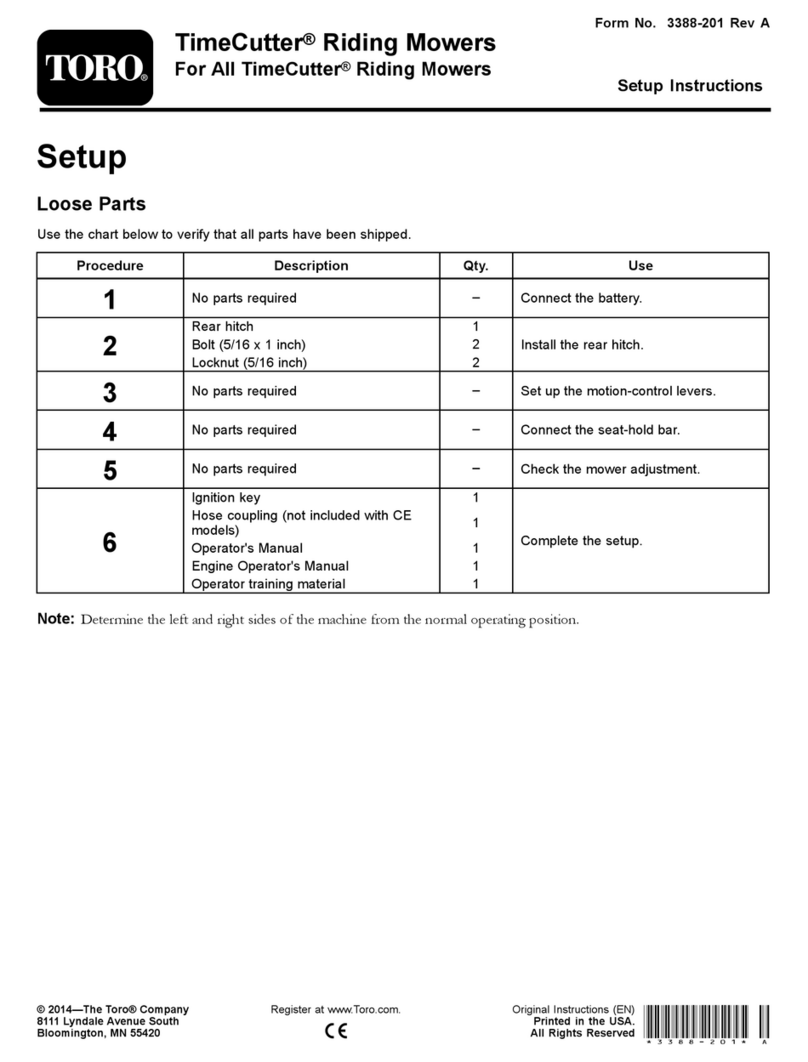

Toro TimeCutter 77301 User manual

Toro

Toro TimeCutter MX 4200 Manual

Toro

Toro 20014 User manual

Toro

Toro Recyler 20353 User manual

Toro

Toro TimeCutter SS 4235 User manual

Toro

Toro 72116 User manual

Toro

Toro GrandStand 18840TE User manual

Toro

Toro 74950 User manual

Toro

Toro Groundsmaster 4100-D User manual

Toro

Toro 74642 User manual

Toro

Toro Recycler 20376 User manual

Toro

Toro Z Master Z587L User manual

Toro

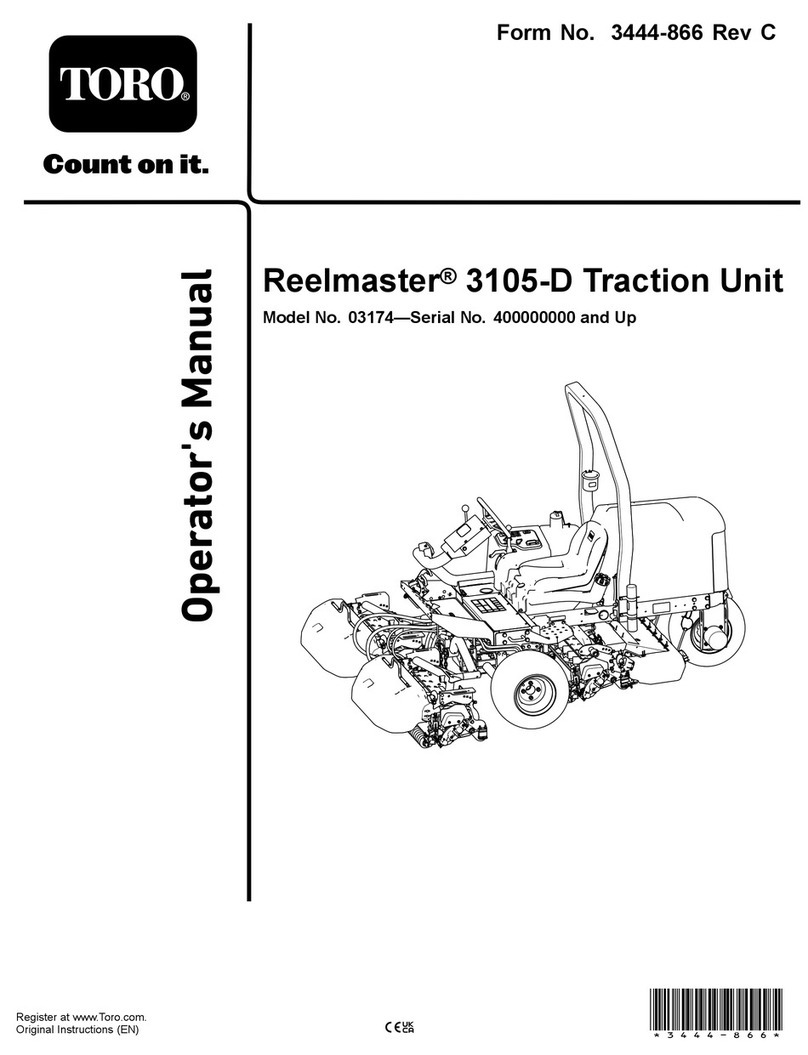

Toro 03200 Reelmaster 3100-D User manual

Toro

Toro Groundsmaster 4500-D User manual

Toro

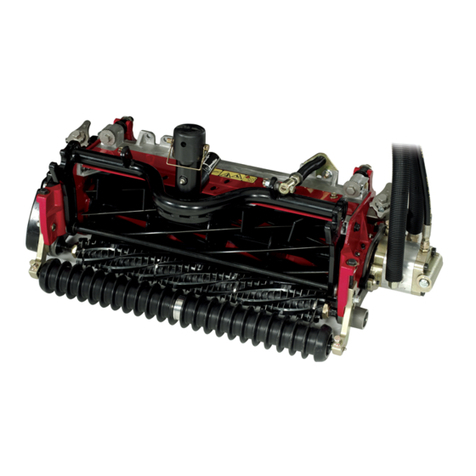

Toro 30553 User manual

Toro

Toro 20052 User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

MTD

MTD 795, 792, 791, 790 Operator's manual