Table of Contents >>

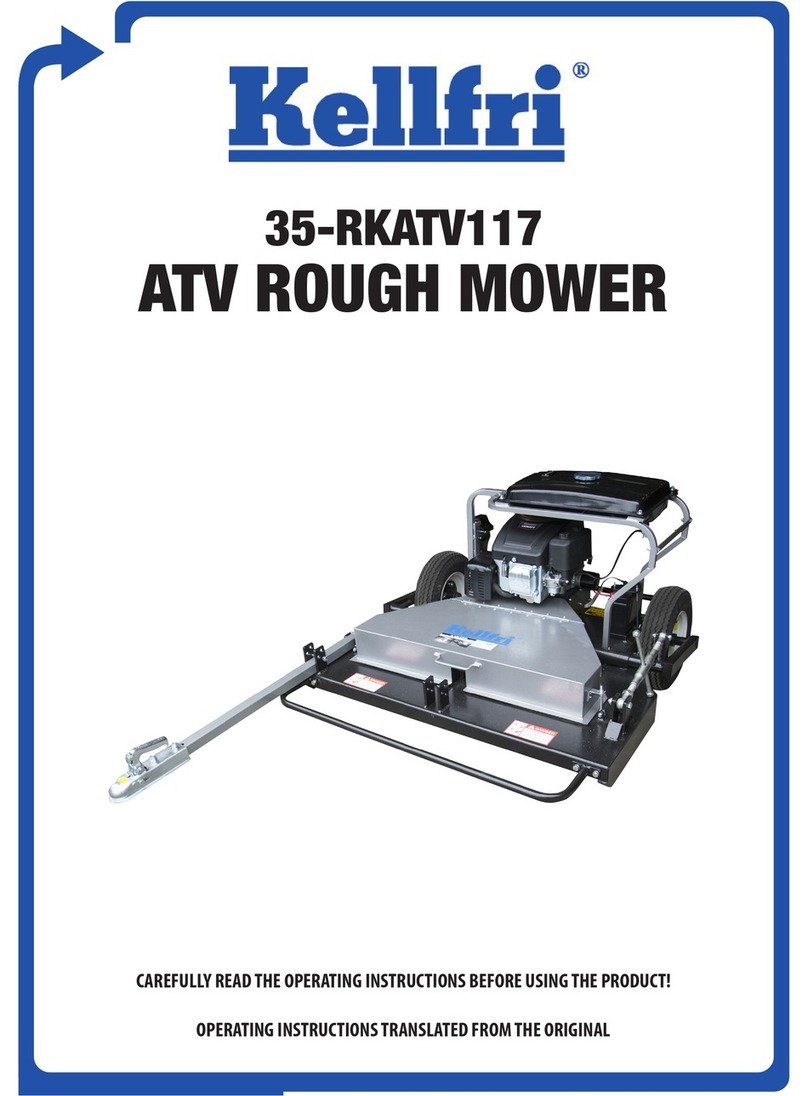

INTRODUCTION

Thank you for choosing a product from Kellfri AB. Compliance with the general safety instructions,

operating instructions and common sense will guarantee many years of enjoyment using the

product. Kellfri’s equipment and products are aimed at self-employed farmers who have stringent

performance demands.

PRODUCT INFORMATION

The WKM195H ail mower has a working width of 1.95 m, making it practical for ailing, topping or

cutting medium-sized or large grasslands and grassed areas.

The ail mower has a ne-toothed welded counter bar in the chassis to break up the grass more

eectively.

The cutting height is adjusted by the support roller and skids. The adjustable support roller

guarantees a correct cutting height on uneven ground.The cutting height can be adjusted between

0-55 mm, enabling you to cut the grass close to the ground and thus achieve a more level result.

The grass is evened out and the remnants moulder away faster. The support roller has a scraping

iron to keep the roller free from cut material.

The front of the ail mower is tted with chain guards that adapt to the substrate and protect both

the tractor and the surroundings from stone chipping and grass spray.

The ail mower is tted as standard with hammer ails.

This ail mower is equipped as standard with hydraulic side shift adjustment, which enables you

to shift the machine to the left or right. The side shift adjustment means that you can cut at the side

of your tractor and thereby reach areas that would otherwise be dicult to reach. The hydraulic side

shift adjustment enables you to drive with just one pair of wheels in the uncut area and cut closer to

ditches, fences, etc. The maximum side shift adjustment of the machine is 294 cm to the right and

78 cm to the left from the mid-point of the tractor.

The mower has an openable ap. You open the ap when you know you are cutting or topping

ground that generates a higher ow of material. This enables you to drive freely under the same

conditions as with a closed ap and a normal ow of material. You save on fuel and reduce wear on

the belts, and you can also operate at a higher speed, as the grass does not become twisted around

the roller. The grass is also spread more evenly.

TECHNICAL DATA 35-WKH195

Length x width x height 2085 x 945 x 950 mm

Working width 1950 mm

Operating height 0 - 55 mm

Weight 398 kg

Number of ails (hammer) 28 (Adapted for Y-ails, which can be purchased additionally - not included.)

Power requirement 50 - 60 hp

Operating speed 6-12 km/h

Gearbox oil 0.7 L [Transmission oil 80W-90]

Side shift adjustment Hydraulic

RPM/ha 540

PTO drive shaft Standard

3-point linkage Cat 1 & 2