Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

tractionunit

Operator's Man ual

.Alwayspayattentionto

thesafetyalertsymbol,whichmeans

Caution

,

W ar ning

,

or

Danger

—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonalinjury

ordeath.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementpartsand

accessoriesmadebyothermanufacturerscouldbedangerous,

andsuchusecouldvoidtheproductwarranty.

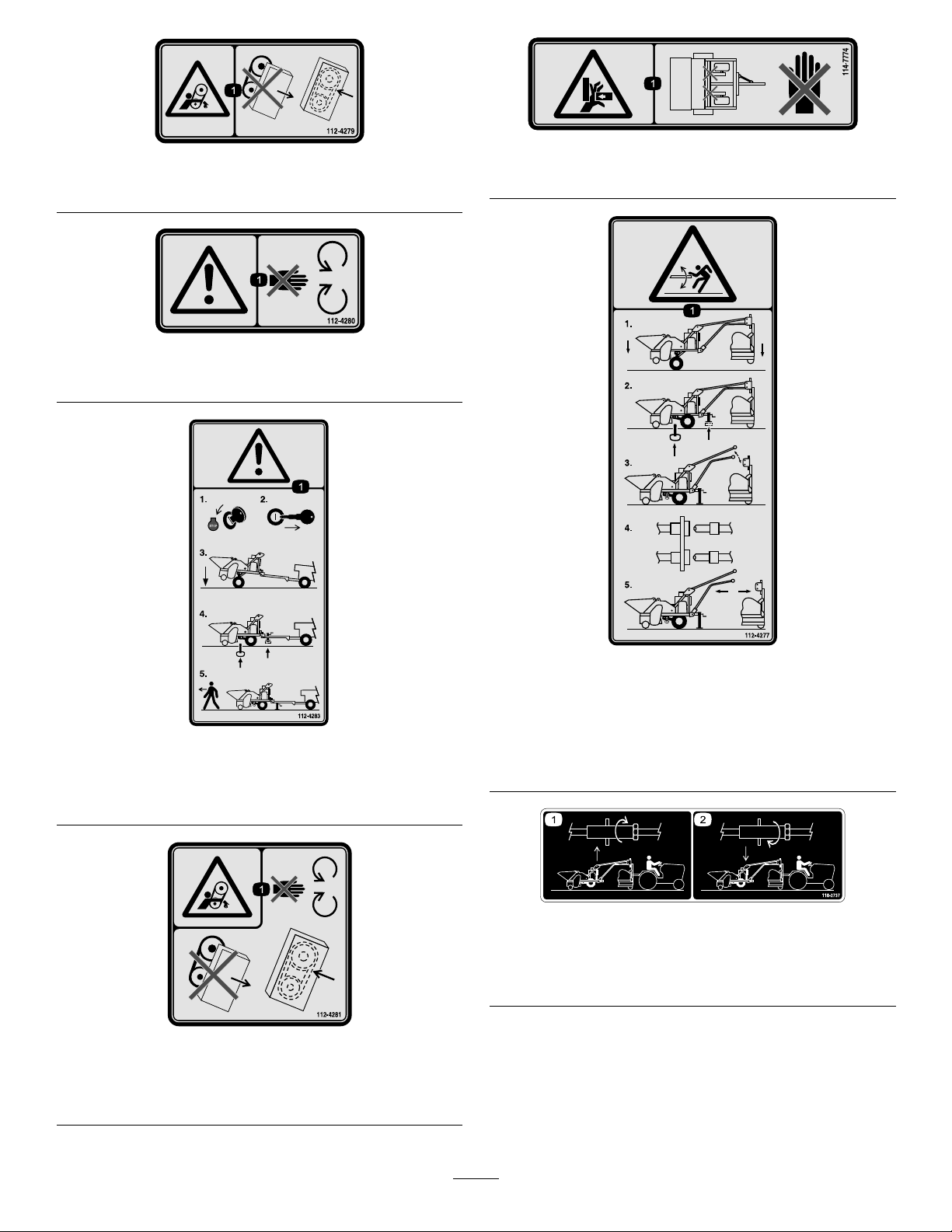

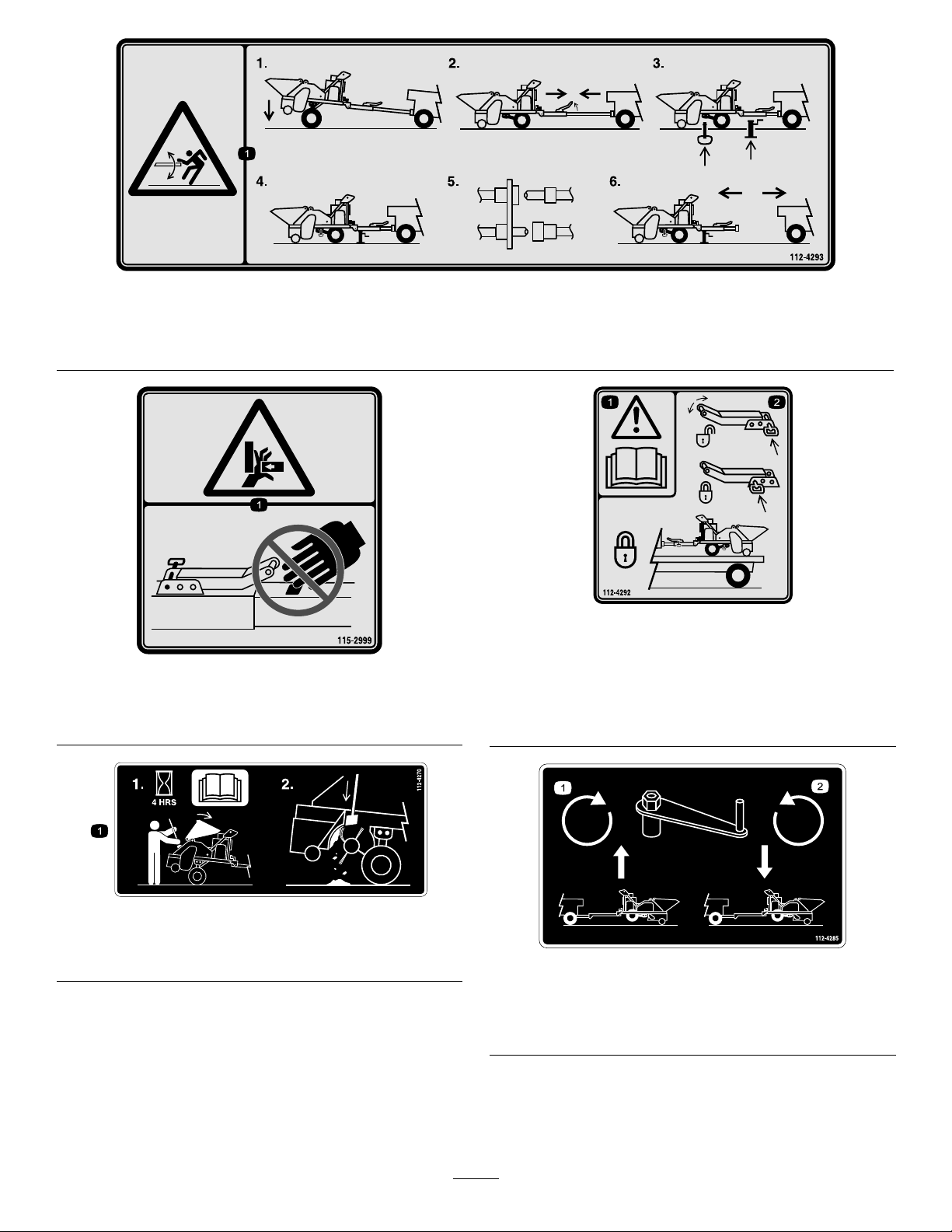

Training

•ReadtheOperator’sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

properuseofequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemachine.Local

regulationsmayrestricttheageoftheoperator.

•Knowhowtostoptheenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.Ifa

shield,safetydevice,ordecalbecomesdamaged,illegible,

orismalfunctioning,repairorreplaceitbeforeoperation

iscommenced.Also,tightenloosenutsandboltsto

ensurethatthemachineisinsafeoperatingcondition.

•Whileoperatingthemachine,alwayswearsubstantial,

slip-resistantfootwear,longtrousers,hardhat,safety

glasses,andearprotection.Longhair,looseclothing,or

jewelrymaygettangledinmovingparts.Donotoperate

theequipmentwhenbarefootorwearingopensandals.

•Wearsafetyglasses,safetyshoes,longpants,andahelmet.

Itisrequiredbysomelocalordinancesandinsurance

regulations.

•Donotalterthisequipmentinanymannerwhichmay

causehazardousconditions.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,useextreme

carewhenhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Onlyuseanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacethefuelcapandtighten

securely.

WhileOperating

•Rotatingpartscancauseseriouspersonalinjury.Keep

hands,feet,hair,andclothingawayfromallmovingparts

topreventinjury.Neveroperatethemachinewithcovers,

shrouds,orguardsremoved.

•Neveroperatethemachinewhileundertheinuenceof

drugsoralcohol.

•Stopthecoreprocessorwhenapersonorpetcomesinto

operatingarea.Carelessoperation,combinedwithterrain

angles,ricochets,ormissingordamagedguards,canlead

tothrownobjectinjuries.Donotresumeoperationuntil

areaiscleared.

•Nevercarrypassengers.

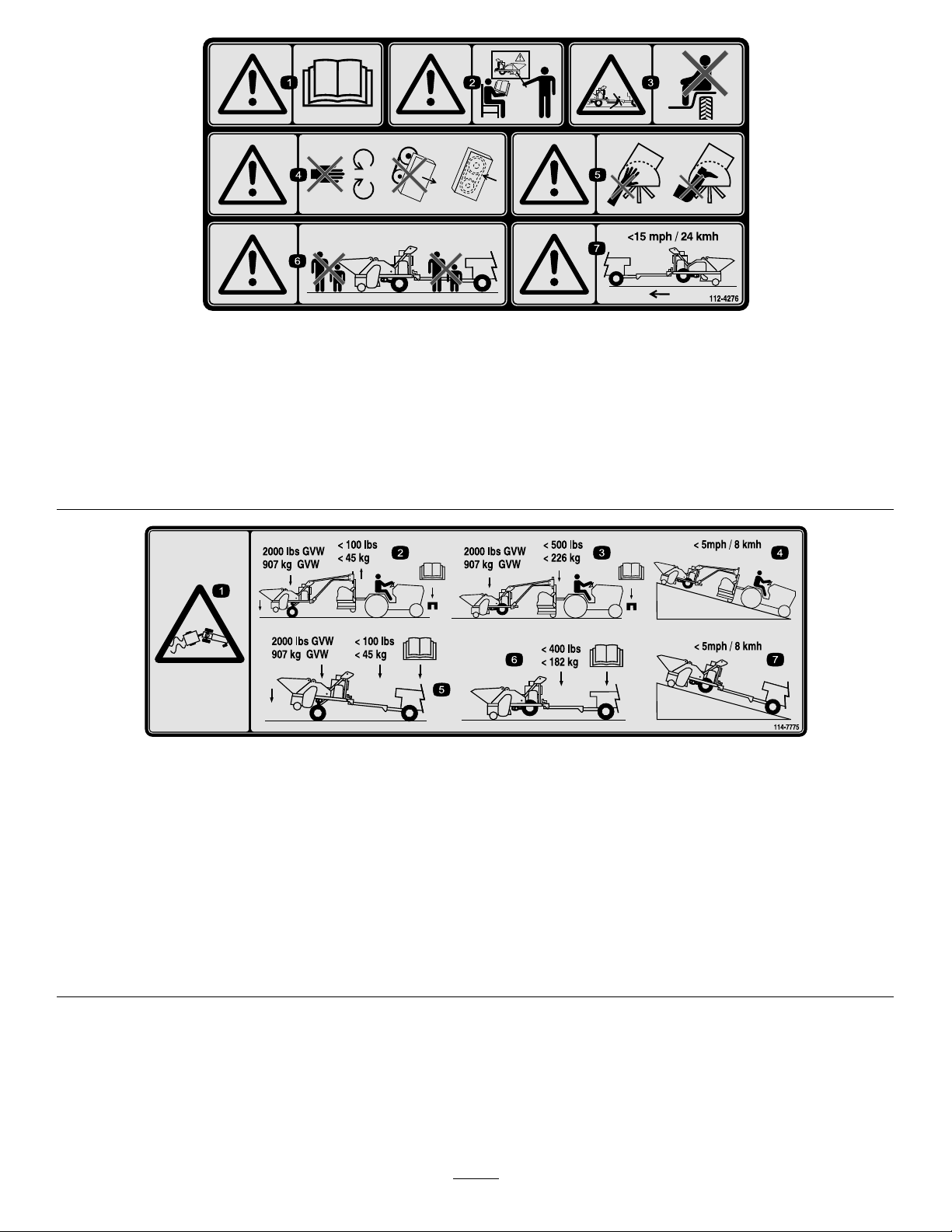

•Ifthetowvehicleenginestallsorthemachineloses

headwayandcannotmakeittothetopofaslope,donot

turnmachinearound.Alwaysbackslowlystraightdown

theslope

•Topreventlossofcontrol,dothefollowing:

–Operateonlyindaylightorwhenthereisgood

articiallight.

–Driveslowly.

–Watchforholesintheterrainorotherhazards.

–Usecarewhenbackingmachine.

–Donotdriveclosetoasandtrap,ditch,creek,drop

off,orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Avoidturningthecoreprocessoronahillsideor

embankment.

–Donotgofromreversetoforwardnorforwardto

reversewithoutcomingtoacompletestoprst.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

•Donotoperatethismachineunlessyouareskilledinand

trainedonhowtodriveonhillsides.Failuretousecaution

4