Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................6

SoundPowerLevel...............................................7

SoundPressureLevel...........................................7

VibrationLevel....................................................7

EngineEmissionCertication..............................7

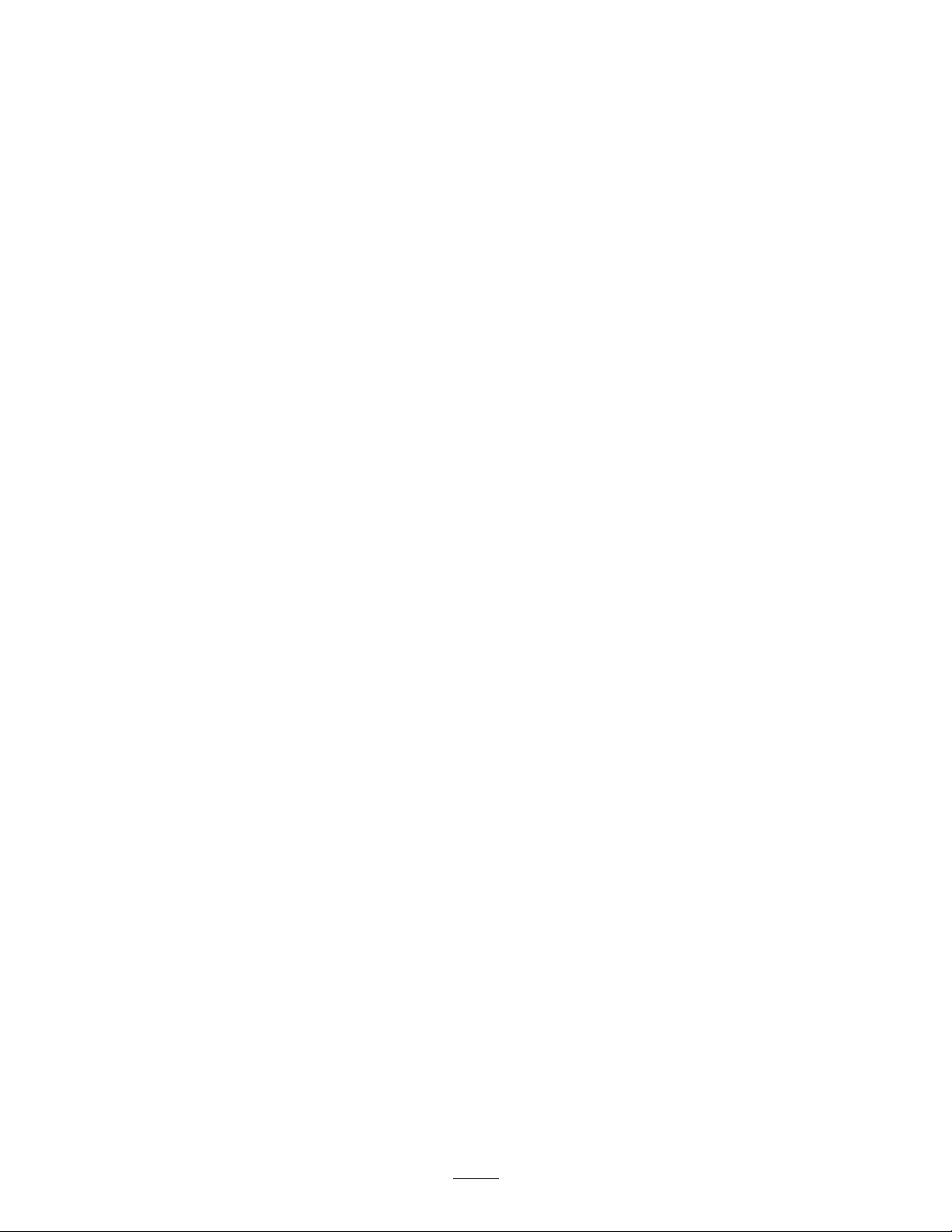

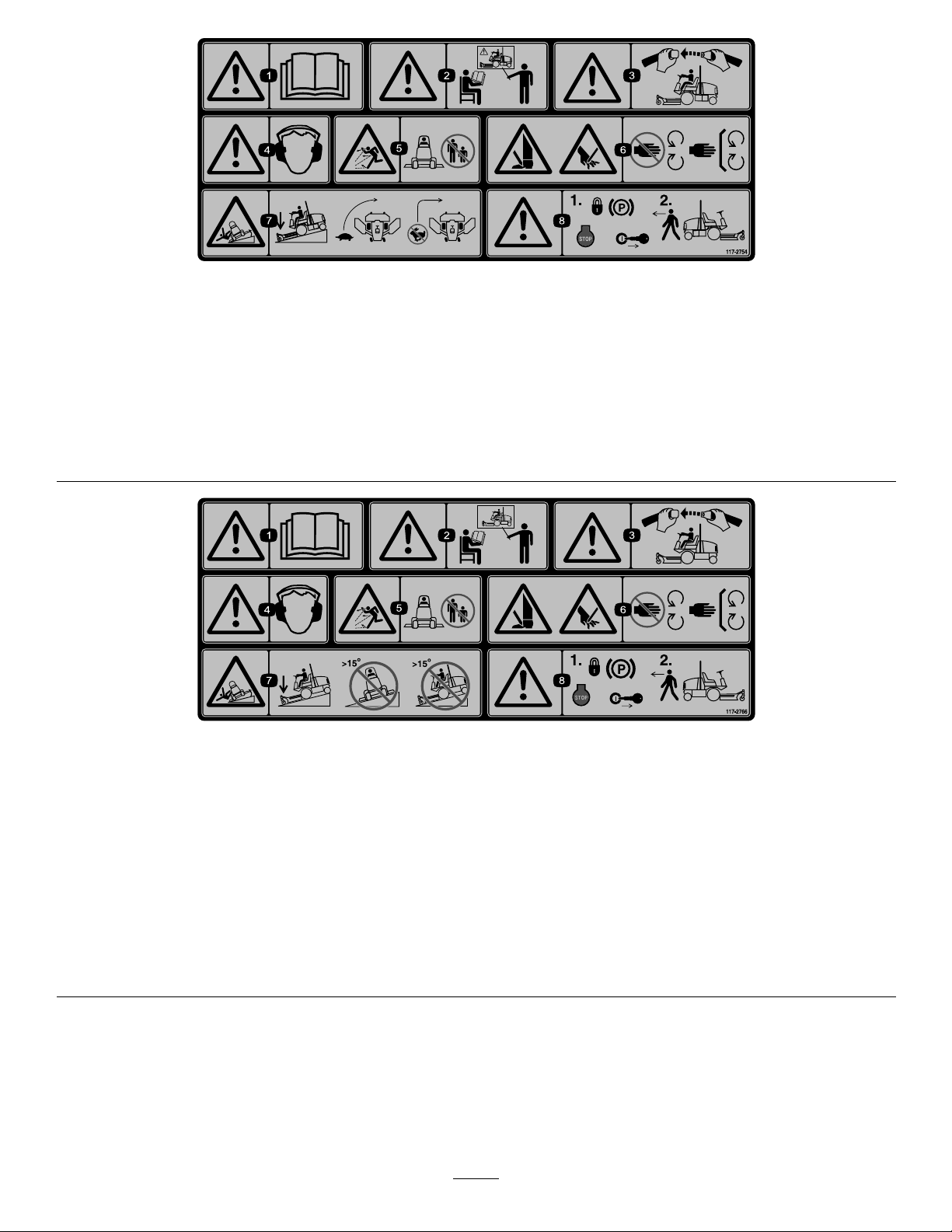

SafetyandInstructionalDecals.............................8

Setup.........................................................................14

1GreasingtheMachine......................................14

2ReplacingtheWarningDecal............................14

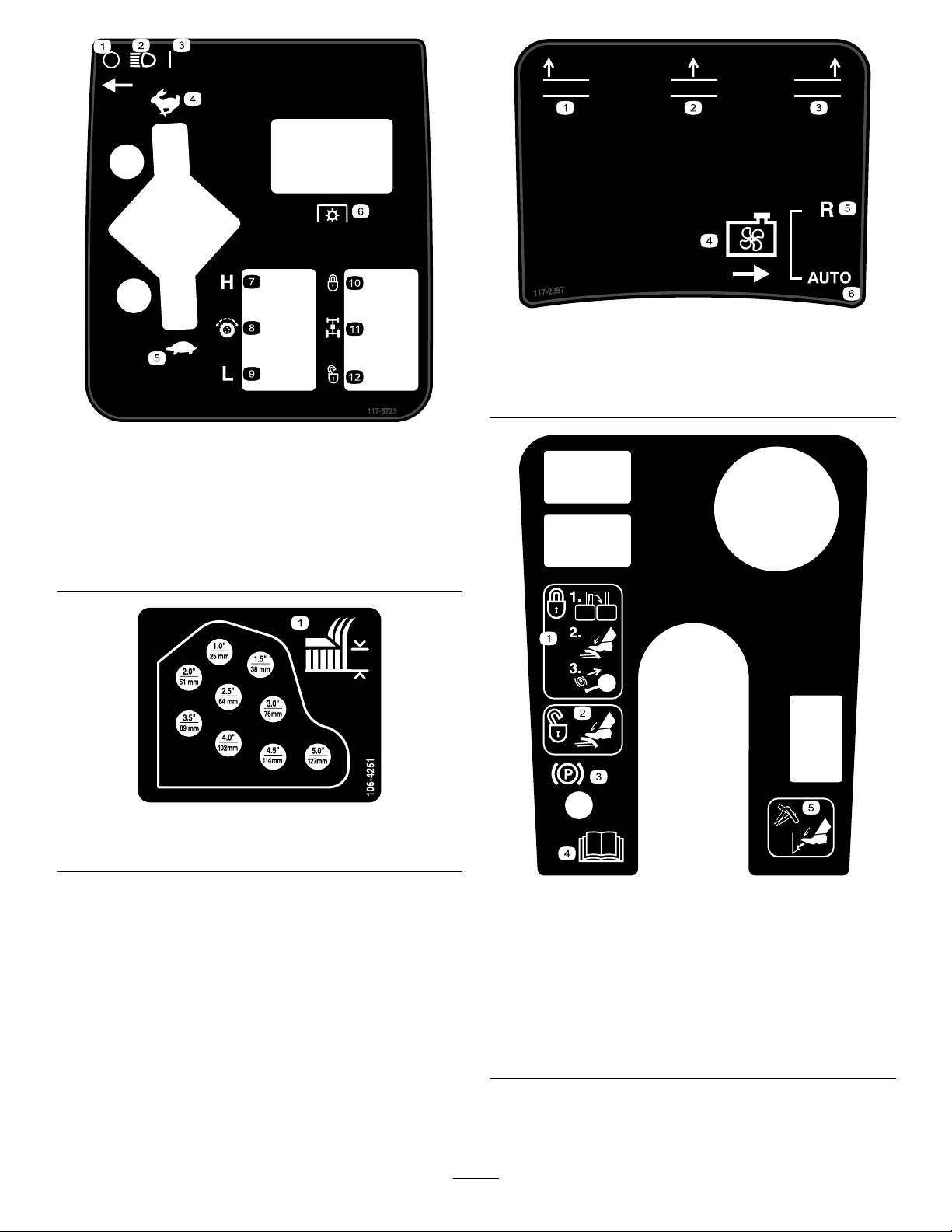

ProductOverview......................................................15

Controls.............................................................15

Specications.....................................................18

Attachments/Accessories...................................18

Operation...................................................................19

BeforeOperating................................................19

AdjustingtheMirrors.........................................27

AimingtheHeadlights........................................28

StartingandStoppingtheEngine........................28

EngineCoolingFanOperation...........................28

CheckingtheInterlockSwitches.........................28

PushingorTowingtheMachine..........................29

JackingPoints.....................................................30

TieDowns.........................................................30

OperatingCharacteristics...................................30

OperatingTips...................................................31

Maintenance...............................................................33

RecommendedMaintenanceSchedule(s)................33

ServiceIntervalChart.........................................34

Lubrication.............................................................34

GreasingtheBearingsandBushings....................34

EngineMaintenance...............................................38

AirCleanerMaintenance....................................38

ServicingtheEngineOilandFilter......................39

FuelSystemMaintenance.......................................39

ServicingtheFuelSystem...................................39

BleedingAirfromtheInjectors...........................40

ElectricalSystemMaintenance................................41

BatteryCare.......................................................41

Fuses..................................................................42

DriveSystemMaintenance.....................................43

ChangingthePlanetaryGearDrive

Oil..................................................................43

ChangingtheRearAxleLubricant.......................44

CheckingtheRearWheelToe-In.........................45

ChangingtheFrontTires....................................45

CoolingSystemMaintenance..................................45

ServicingtheEngineCoolingSystem..................45

BrakeMaintenance.................................................46

AdjustingtheServiceBrakes...............................46

BeltMaintenance....................................................47

ServicingtheAlternatorBelt...............................47

Re-tensioningtheBladeDriveBelts....................47

ReplacingtheBladeDriveBelt............................47

ControlsSystemMaintenance.................................48

AdjustingtheThrottleCable...............................48

AdjustingtheTractionPedalLinkage..................48

HydraulicSystemMaintenance...............................49

ChangingtheHydraulicFluid.............................49

ReplacingtheHydraulicFilters...........................50

CheckingtheHydraulicLinesandHoses.............50

AdjustingtheCounterbalancePressure...............50

MowerMaintenance...............................................51

Pivoting(Tilting)theFrontCuttingUnit

Upright..........................................................51

PivotingtheFrontCuttingUnitDown................52

AdjustingtheCuttingUnitPitch.........................52

ServicingtheCastorArmBushings.....................53

ServicingtheCastorWheelsandBearings............53

ReplacingtheCuttingUnitHingeCovers............54

BladeMaintenance.................................................54

CheckingforaBentBlade...................................54

RemovingandInstallingtheCutter

Blade(s)..........................................................54

InspectingandSharpeningtheCutter

Blade(s)..........................................................55

CorrectingCuttingUnitMismatch......................56

SparkArrestorMaintenance...................................57

ServicingtheSparkArrestorMufer...................57

CabMaintenance....................................................58

CleaningtheCabAirFilters................................58

Storage.......................................................................59

PreparingforSeasonalStorage............................59

Schematics.................................................................60

3