Contents

Safety...........................................................................4

GeneralSafety.........................................................4

VibrationLevel.......................................................4

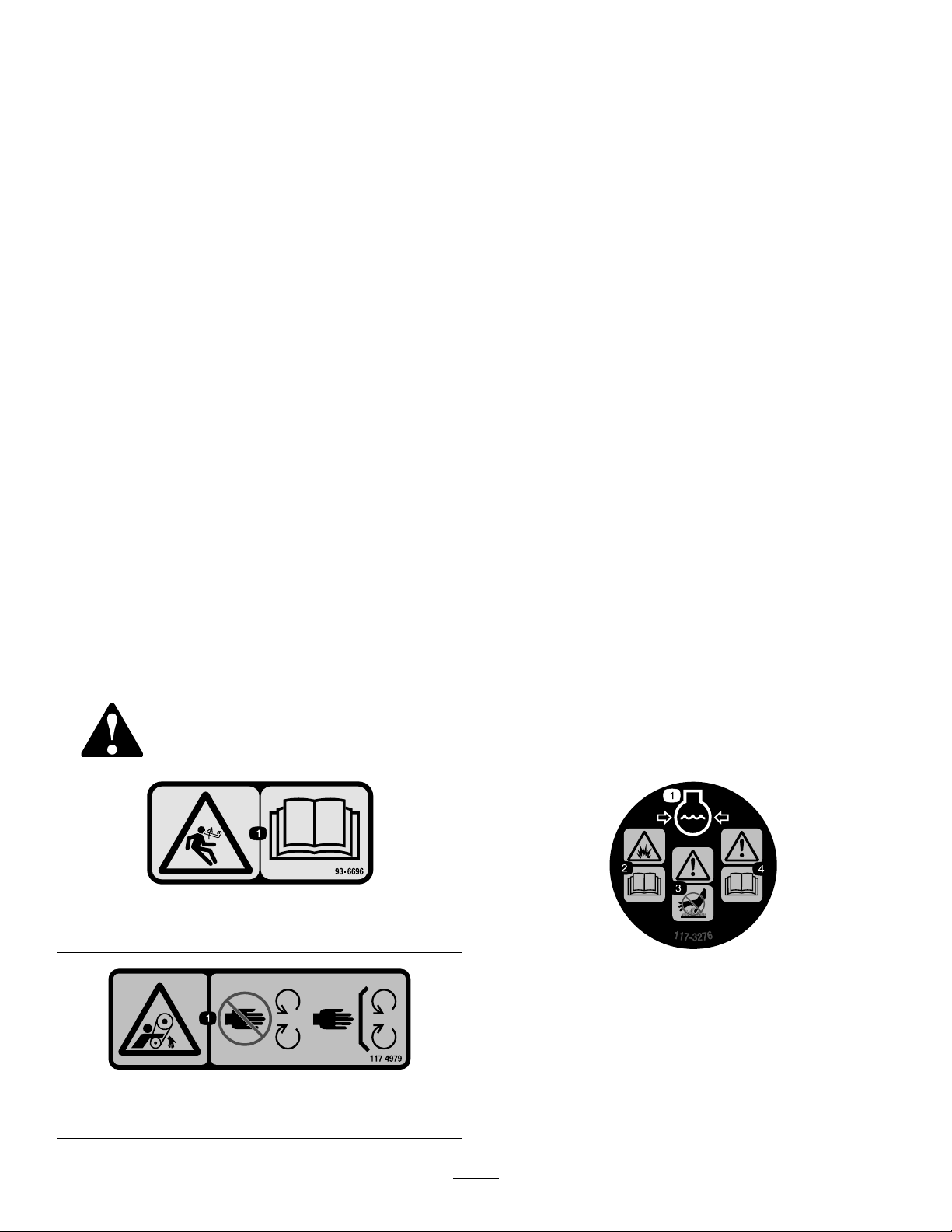

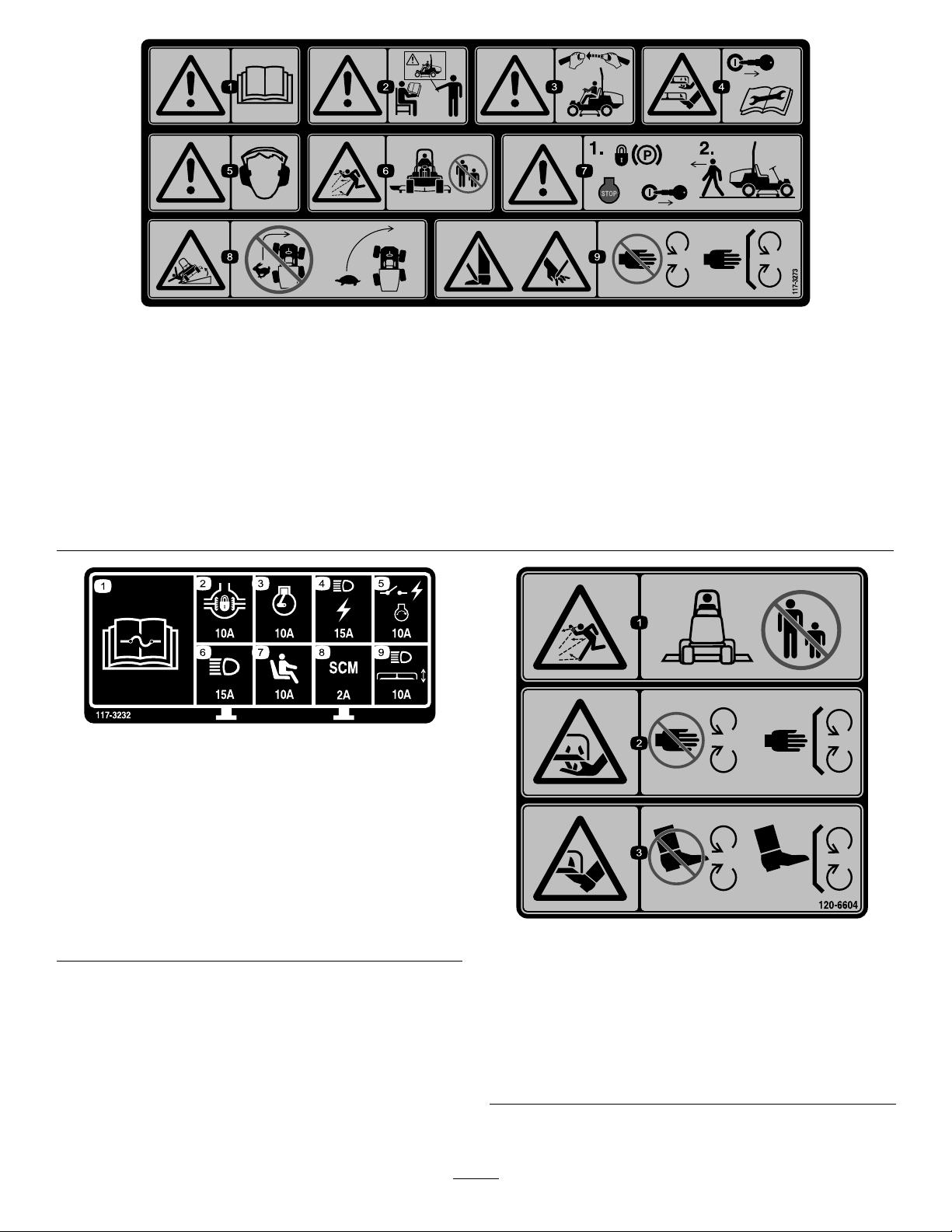

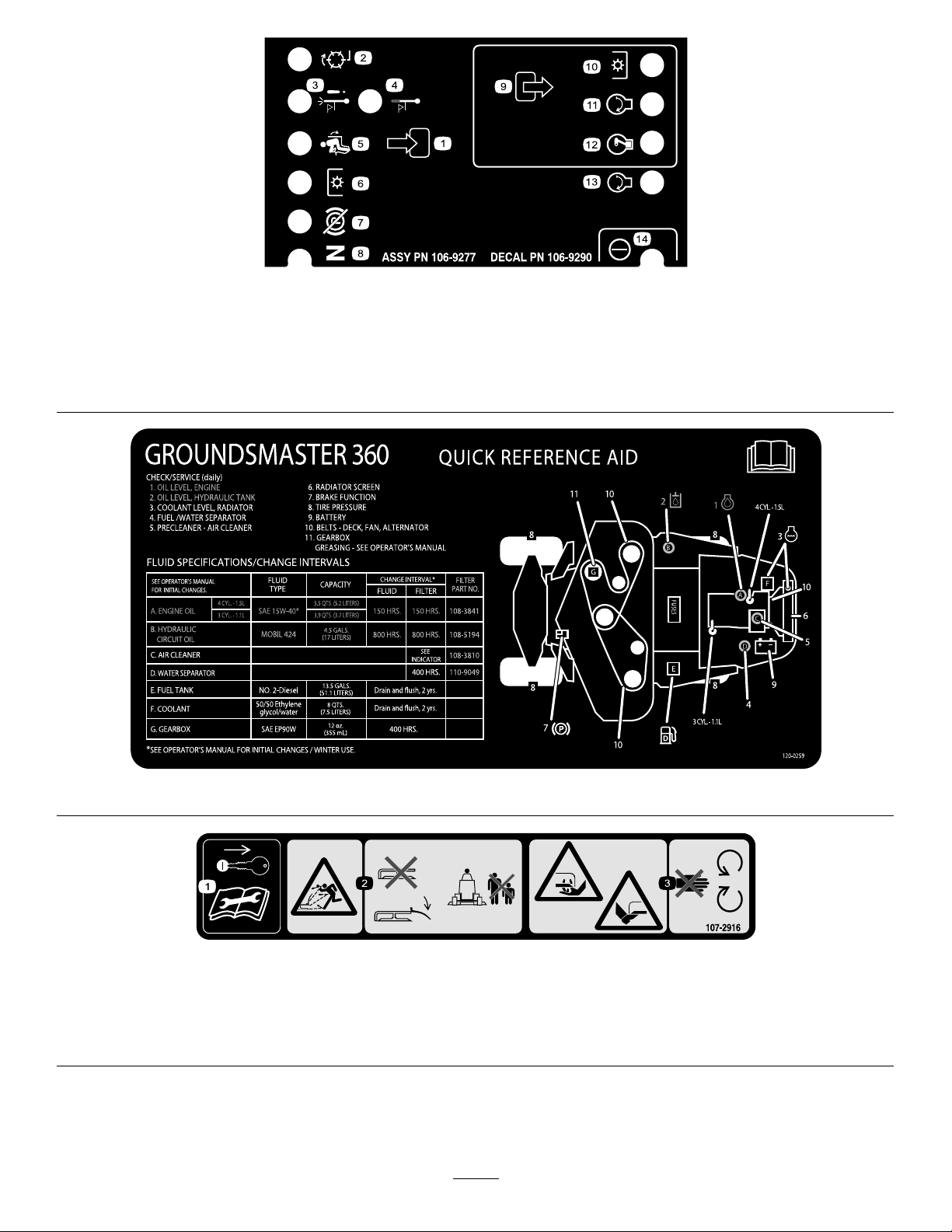

SafetyandInstructionalDecals.................................4

Setup............................................................................9

1AdjustingtheROPS..............................................9

2CheckingtheTirePressure.....................................9

3CheckingtheFluidLevels.....................................10

ProductOverview.........................................................10

Controls...............................................................10

Specications........................................................12

Attachments/Accessories........................................12

BeforeOperation......................................................12

BeforeOperationSafety..........................................12

FillingtheFuelTank...............................................13

PositioningtheStandardSeat...................................14

PositioningtheDeluxeSeat......................................15

RaisingandLoweringtheSeat..................................16

DuringOperation.....................................................16

DuringOperationSafety.........................................16

ThinkSafetyFirst...................................................17

UsingtheRollover-ProtectionSystem(ROPS)............17

StartingandShuttingofftheEngine..........................18

DrivingtheMachine...............................................19

StoppingtheMachine.............................................19

TheSafety-InterlockSystem....................................19

UnderstandingtheDiagnosticLight..........................20

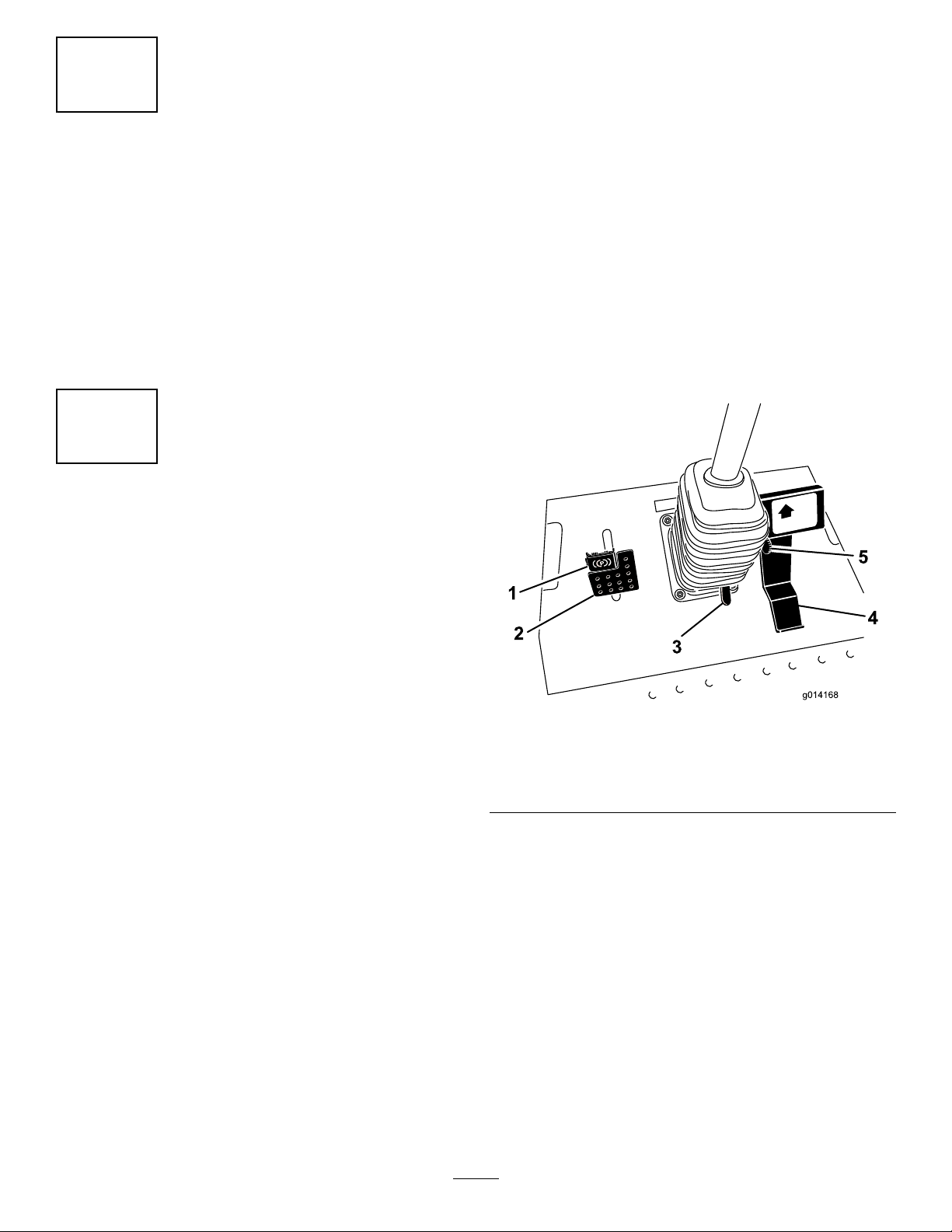

DiagnosticAceDisplay...........................................20

CheckingtheInterlockSwitches...............................21

OperatingtheMower..............................................22

OperatingTips......................................................23

AfterOperation........................................................23

AfterOperationSafety............................................23

PushingtheMachinebyHand..................................23

HaulingtheMachine...............................................24

Maintenance.................................................................25

RecommendedMaintenanceSchedule(s)......................25

DailyMaintenanceChecklist....................................26

PremaintenanceProcedures........................................27

Pre-MaintenanceSafety...........................................27

PreparingtheMachineforMaintenance.....................27

UsingtheHood-PropRod.......................................28

Lubrication...............................................................28

GreasingtheBearingsandBushings..........................28

EngineMaintenance..................................................30

EngineSafety.........................................................30

ServicingtheAirCleaner.........................................30

CheckingtheEngine-OilLevel.................................30

ChangingtheEngineOilandFilter...........................31

AdjustingtheThrottle.............................................32

FuelSystemMaintenance...........................................32

ServicingtheWaterSeparator..................................32

BleedingtheFuelSystem.........................................33

BleedingAirfromtheFuelInjectors..........................33

CleaningtheFuelTank............................................33

CheckingtheFuelLinesandConnections..................34

ElectricalSystemMaintenance....................................34

ElectricalSystemSafety...........................................34

CheckingtheFuses.................................................34

ServicingtheBattery...............................................35

StoringtheBattery..................................................35

DriveSystemMaintenance.........................................36

CheckingtheTirePressure......................................36

CoolingSystemMaintenance......................................36

CoolingSystemSafety.............................................36

CheckingtheCoolingSystem..................................36

BrakeMaintenance....................................................37

AdjustingtheServiceBrakes....................................37

AdjustingtheParkingBrake....................................37

BeltMaintenance......................................................38

CheckingtheAlternatorBelt...................................38

ControlsSystemMaintenance.....................................39

AdjustingtheTractionDriveforNeutral....................39

AdjustingtheMaximumGroundSpeed.....................39

HydraulicSystemMaintenance....................................40

HydraulicSystemSafety..........................................40

CheckingtheHydraulicSystem................................40

ChangingtheHydraulicFluidandFilter.....................41

Storage........................................................................42

ServicingtheEngine...............................................42

ServicingtheMachine.............................................42

3