2

All Rights Reserved

Printed in the USA

W2005 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects, and other reproductive harm.

Warning

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Toro Riding Mower Safety 5. . . . . . . . . . . . . . . . . .

Sound Pressure Level 6. . . . . . . . . . . . . . . . . . . . . .

Sound Power Level 6. . . . . . . . . . . . . . . . . . . . . . .

Vibration Level 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

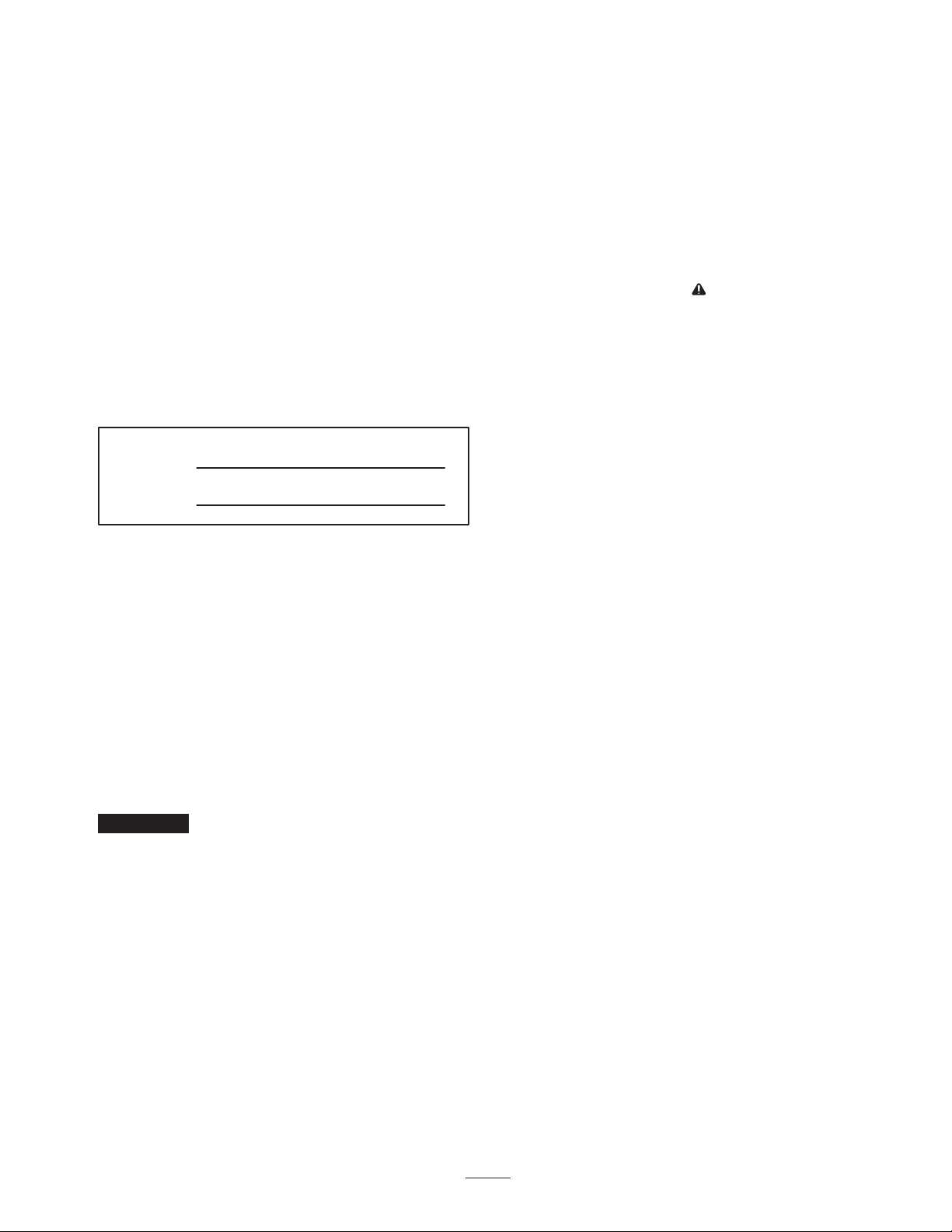

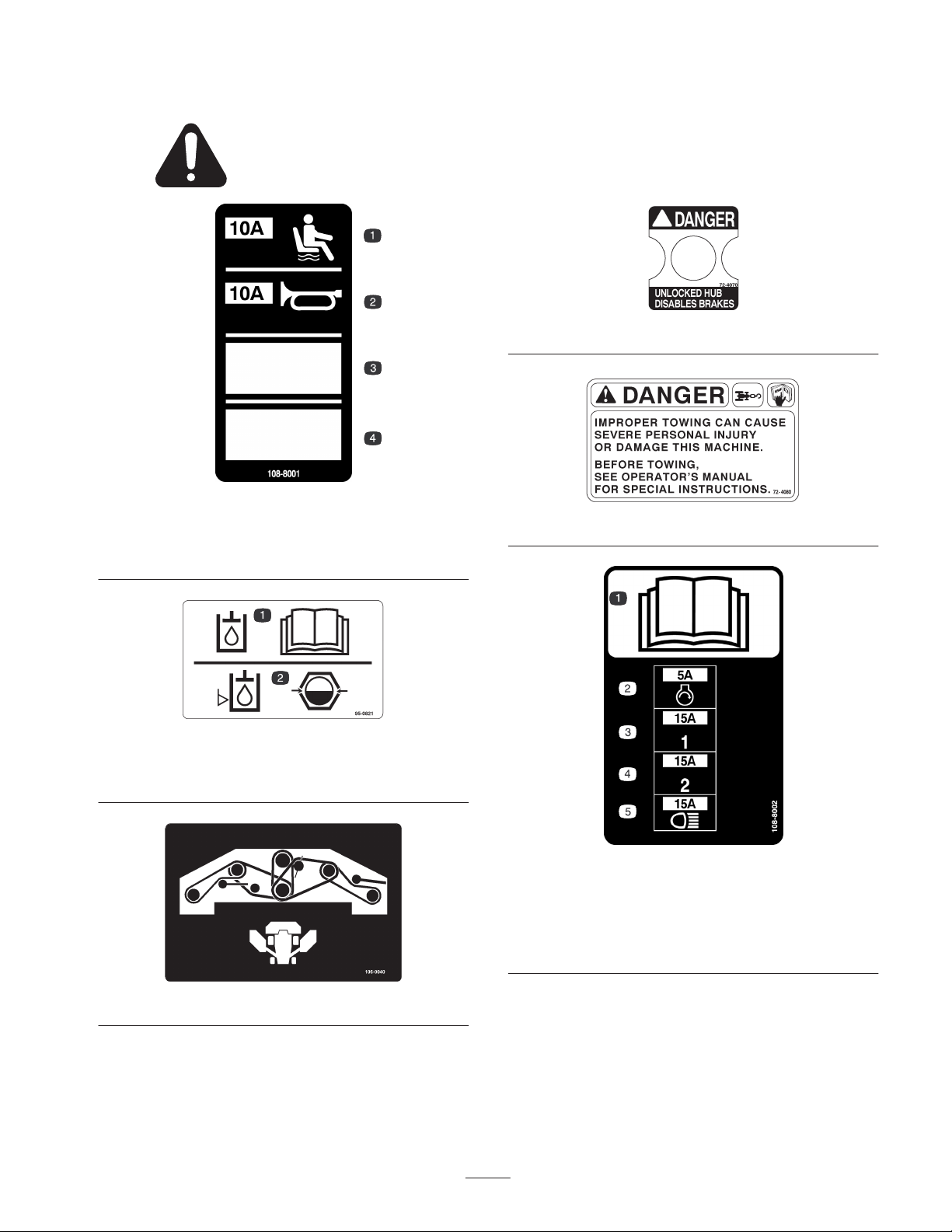

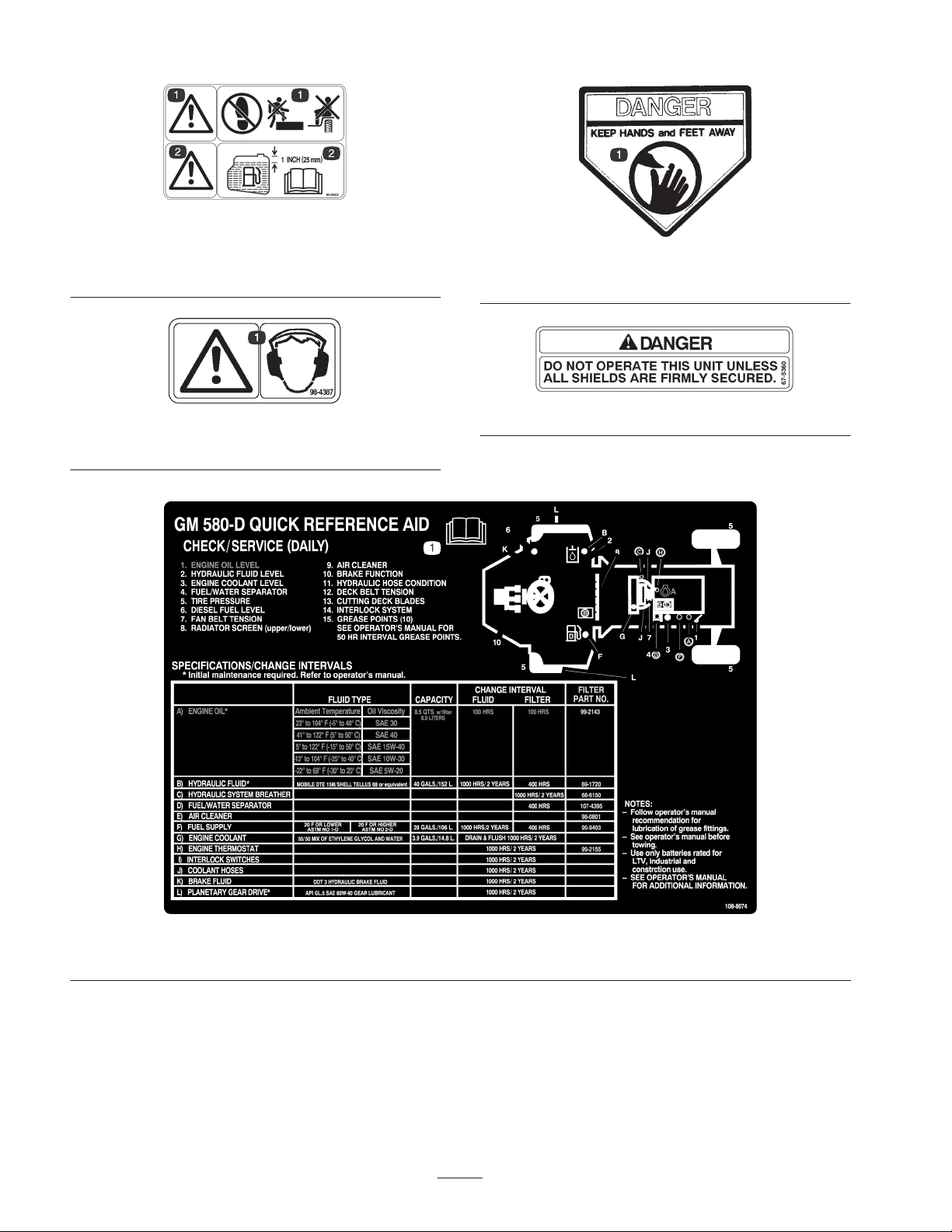

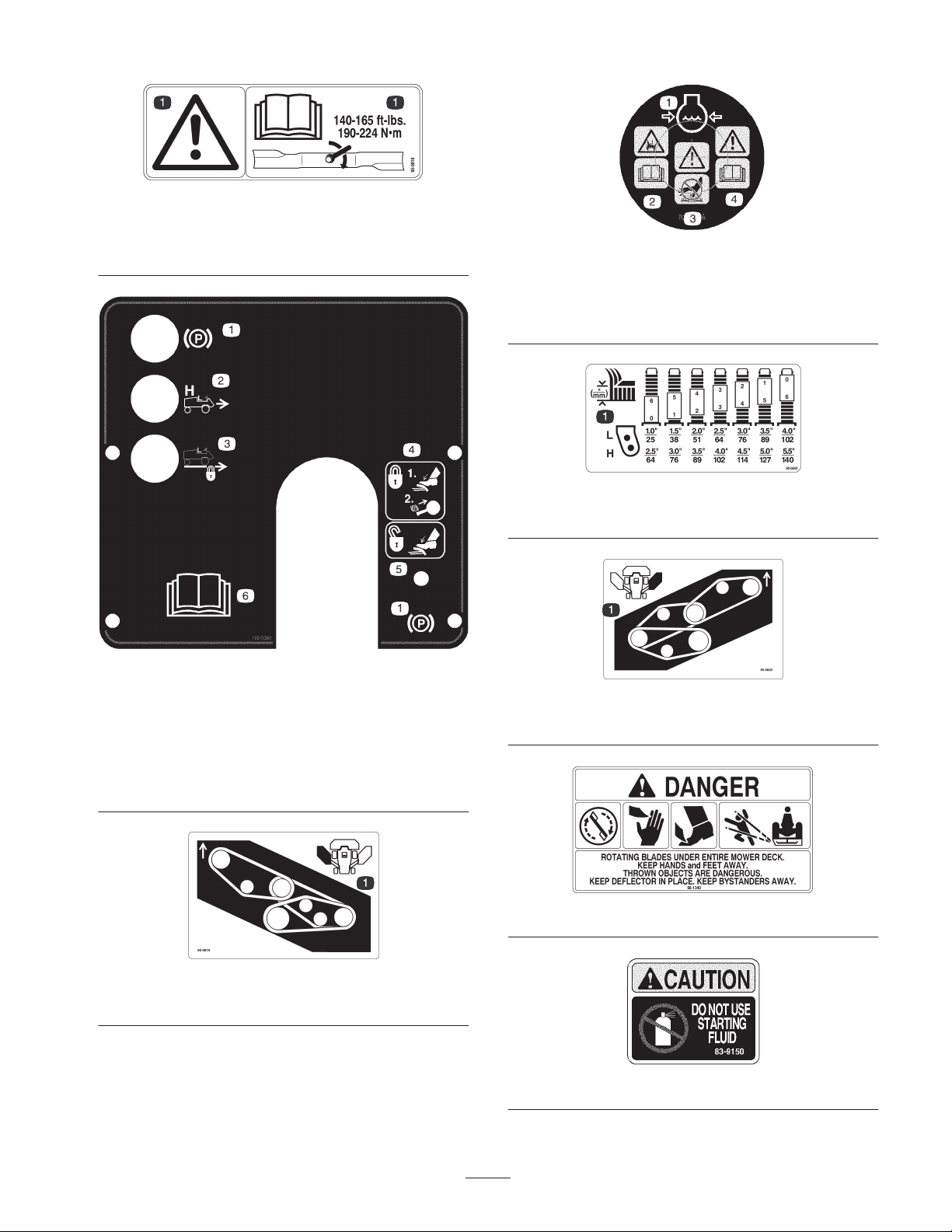

Safety and Instruction Decals 7. . . . . . . . . . . . . . . .

Specifications 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Unit 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

All Cutting Units 14. . . . . . . . . . . . . . . . . . . . . . . . .

Triflex Cutting Unit (Front) 14. . . . . . . . . . . . . . . . .

Outboard Cutting Units 15. . . . . . . . . . . . . . . . . . . .

Dimensions 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Equipment 15. . . . . . . . . . . . . . . . . . . . . . .

Setup 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Batteries 16. . . . . . . . . . . . . . . . . . . . .

Before Operating 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Engine Oil 18. . . . . . . . . . . . . . . . . . .

Checking the Cooling System 19. . . . . . . . . . . . . . .

Checking the Hydraulic System Fluid 19. . . . . . . . .

Filling the Fuel Tank 20. . . . . . . . . . . . . . . . . . . . . .

Checking the Tire Pressure 20. . . . . . . . . . . . . . . . . .

Checking Systems Operation 20. . . . . . . . . . . . . . . .

Checking Cutting Unit Mismatch 20. . . . . . . . . . . . .

Adjusting the Height of Cut 21. . . . . . . . . . . . . . . . .

Adjusting the Skids 22. . . . . . . . . . . . . . . . . . . . . . .

Operation 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping the Engine 27. . . . . . . . . . . . .

Bleeding the Fuel System 28. . . . . . . . . . . . . . . . . . .

Diagnostic Light 28. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic ACE Display 29. . . . . . . . . . . . . . . . . . .

Checking the Interlock Switches 29. . . . . . . . . . . . .

Checking the Warning Indicator Lights 32. . . . . . . .

Pushing or Towing the Machine 32. . . . . . . . . . . . . .

Operating Characteristics 32. . . . . . . . . . . . . . . . . . .

Four Wheel Drive Operation 33. . . . . . . . . . . . . . . .

Maintenance 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 35. . . . . . . . .

Daily Maintenance Checklist 36. . . . . . . . . . . . . . . .

Service Interval Chart 37. . . . . . . . . . . . . . . . . . . . . .

Lubrication 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil and Filter 40. . . . . . . . . . . . . . . . . . . . . .

Engine Fuel System 41. . . . . . . . . . . . . . . . . . . . . . .

Engine Cooling System 42. . . . . . . . . . . . . . . . . . . .

General Air Cleaner Maintenance 43. . . . . . . . . . . .

Servicing the Air Cleaner 43. . . . . . . . . . . . . . . . . . .

Servicing the Hydraulic System 44. . . . . . . . . . . . . .

Servicing the Planetary Gear Drive 46. . . . . . . . . . .

Servicing the Battery 47. . . . . . . . . . . . . . . . . . . . . .

Fuses and Circuit Breaker 48. . . . . . . . . . . . . . . . . .

Servicing the Brake System 48. . . . . . . . . . . . . . . . .

Wheels and Tires 49. . . . . . . . . . . . . . . . . . . . . . . . .

Cutting Unit Lubrication 49. . . . . . . . . . . . . . . . . . .

Blade Maintenance 49. . . . . . . . . . . . . . . . . . . . . . . .

Blade Bolt Torque 50. . . . . . . . . . . . . . . . . . . . . . . . .

Checking for a Bent Blade 51. . . . . . . . . . . . . . . . . .

Removing the Cutting Unit Blade 51. . . . . . . . . . . .

Inspecting and Sharpening the Blade 51. . . . . . . . . .

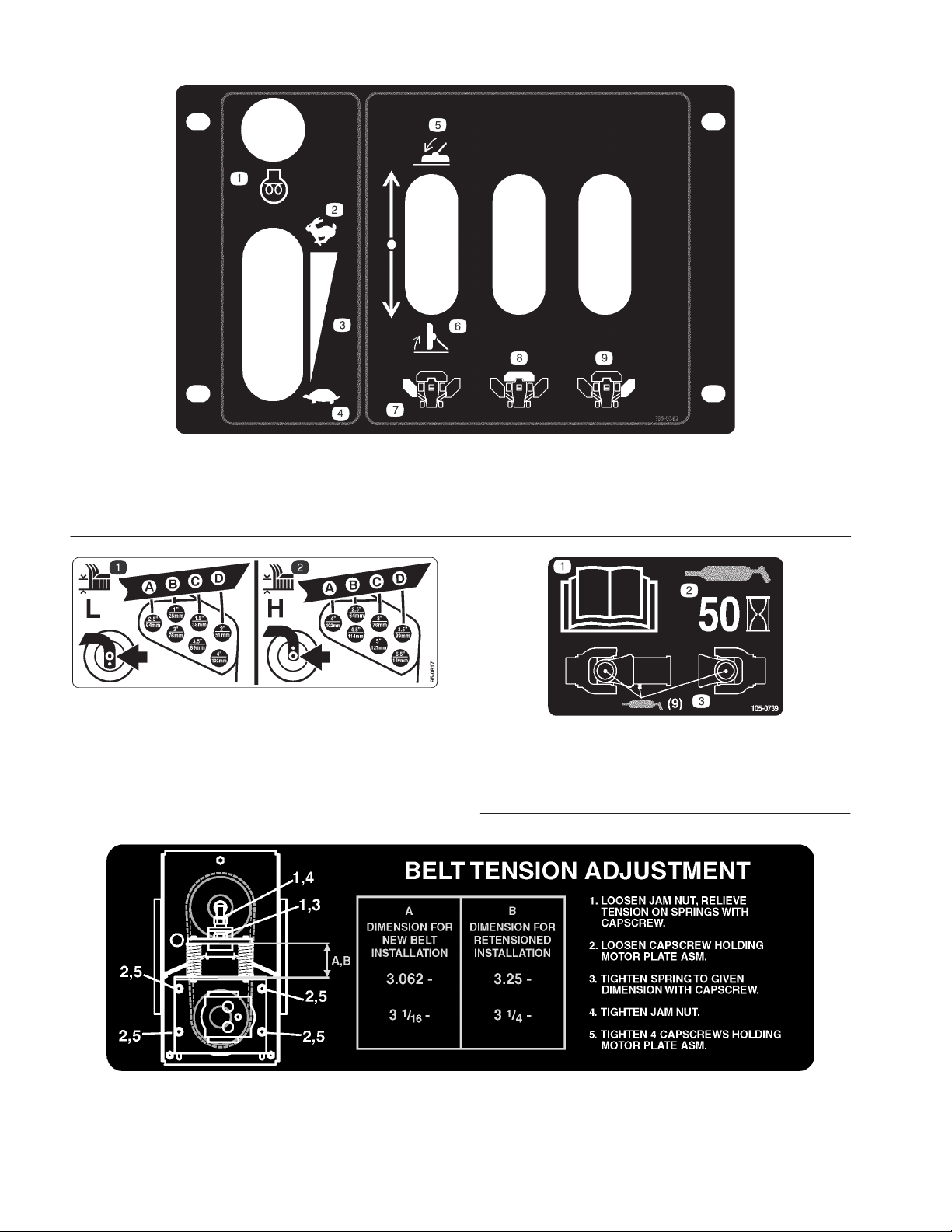

Inspecting and Adjusting the Cutting Unit

Belt Tension 52. . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Blade Drive Belts 53. . . . . . . . . . . . .

Separating the Cutting Units from the

Traction Unit 55. . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking and Correcting Cutting Blade Mismatch 55

Adjusting the Winglet Stabilizers 56. . . . . . . . . . . . .

Adjusting the Traction Control Rod 57. . . . . . . . . . .

Cylinder Head Bolts 57. . . . . . . . . . . . . . . . . . . . . . .

Engine Valve Clearance 57. . . . . . . . . . . . . . . . . . . .

Inspect and Adjust Fuel Injection Nozzles 57. . . . . .

Electrical Schematic – Model 30582 58. . . . . . . . . .

Electrical Schematic – Model 30583 59. . . . . . . . . .

Hydraulic Schematic – Model 30582 60. . . . . . . . . .

Hydraulic Schematic – Model 30583 61. . . . . . . . . .

The Toro General Commercial Products Warranty 64. .