9

CheckingtheSideDischarge

Chute

NoPartsRequired

Procedure

Ifthereareplastictiesholdingthesidedischargechute

up,removethemandlowerthechuteintoplace.

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectsinthe

operator’sorbystander’sdirectionandresultin

seriousinjuryordeath.Also,contactwiththe

bladecouldoccur.

Neveroperatethelawnmowerwiththegrass

deectorremovedunlessyouinstallacover

plate,amulchplate,oragrasschuteand

catcher.

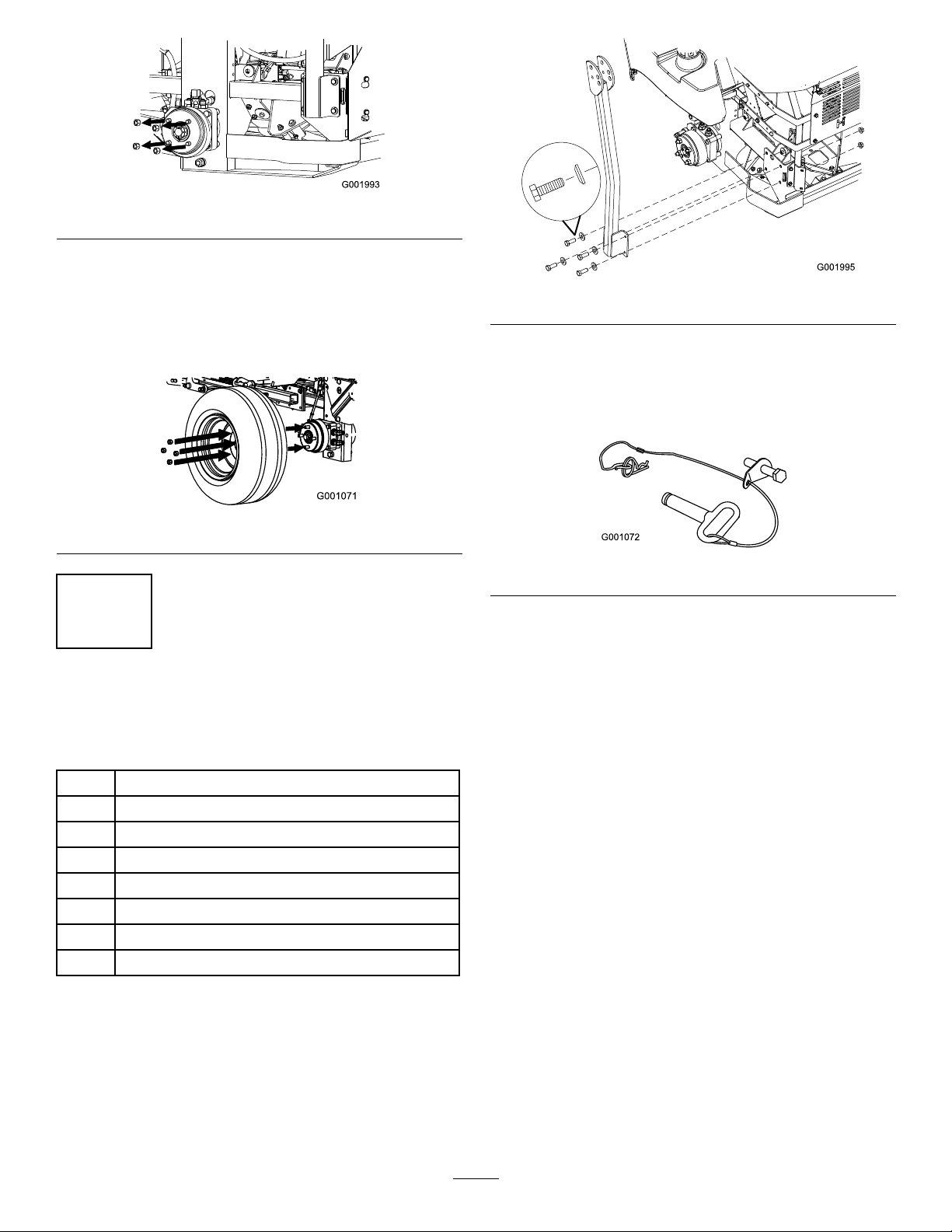

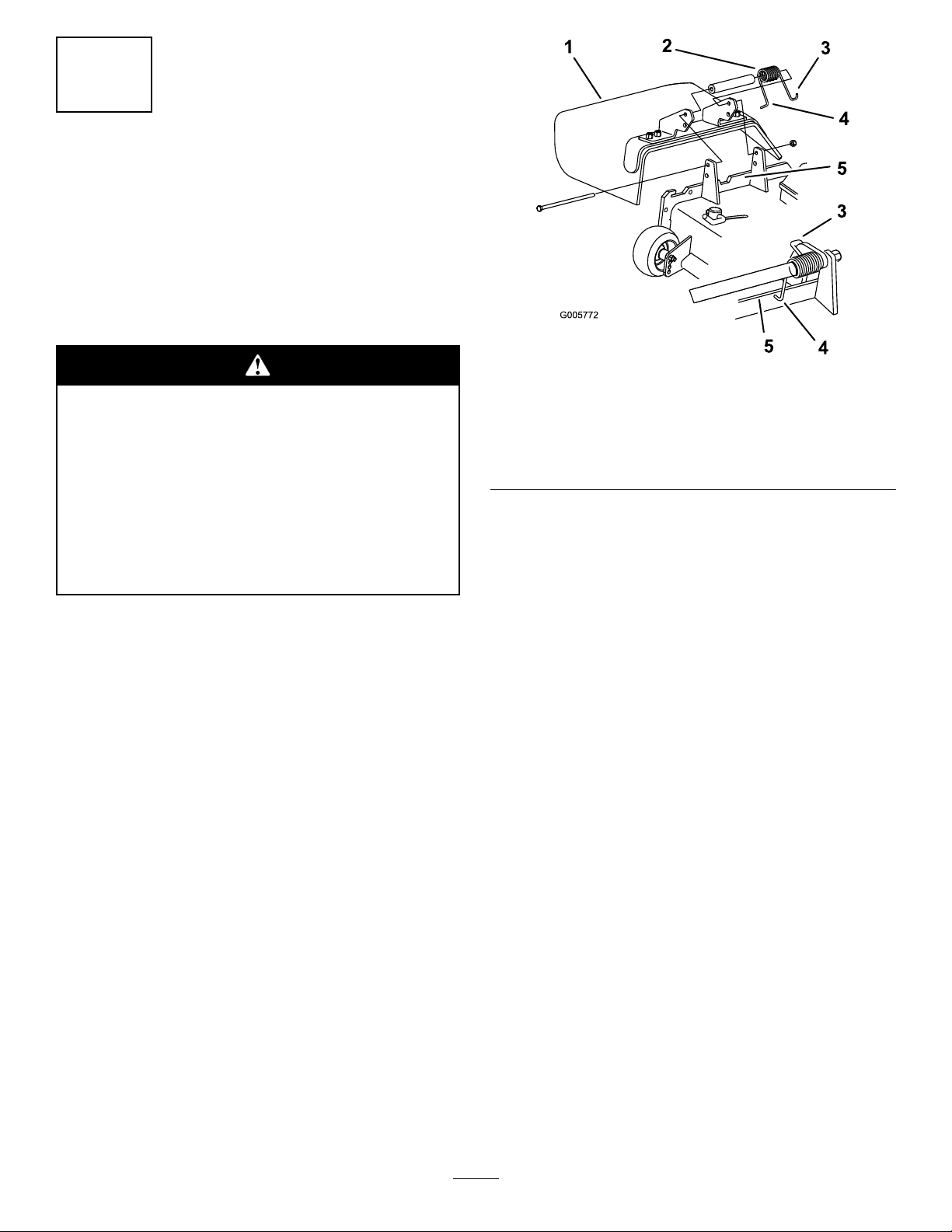

1.MakesuretheLendofspringisinstalledbehind

thedeckedgebeforeinstallingtheboltasshownin

Figure16.

2.PlacetheJhookendofspringaroundgrassdeector

(Figure16).

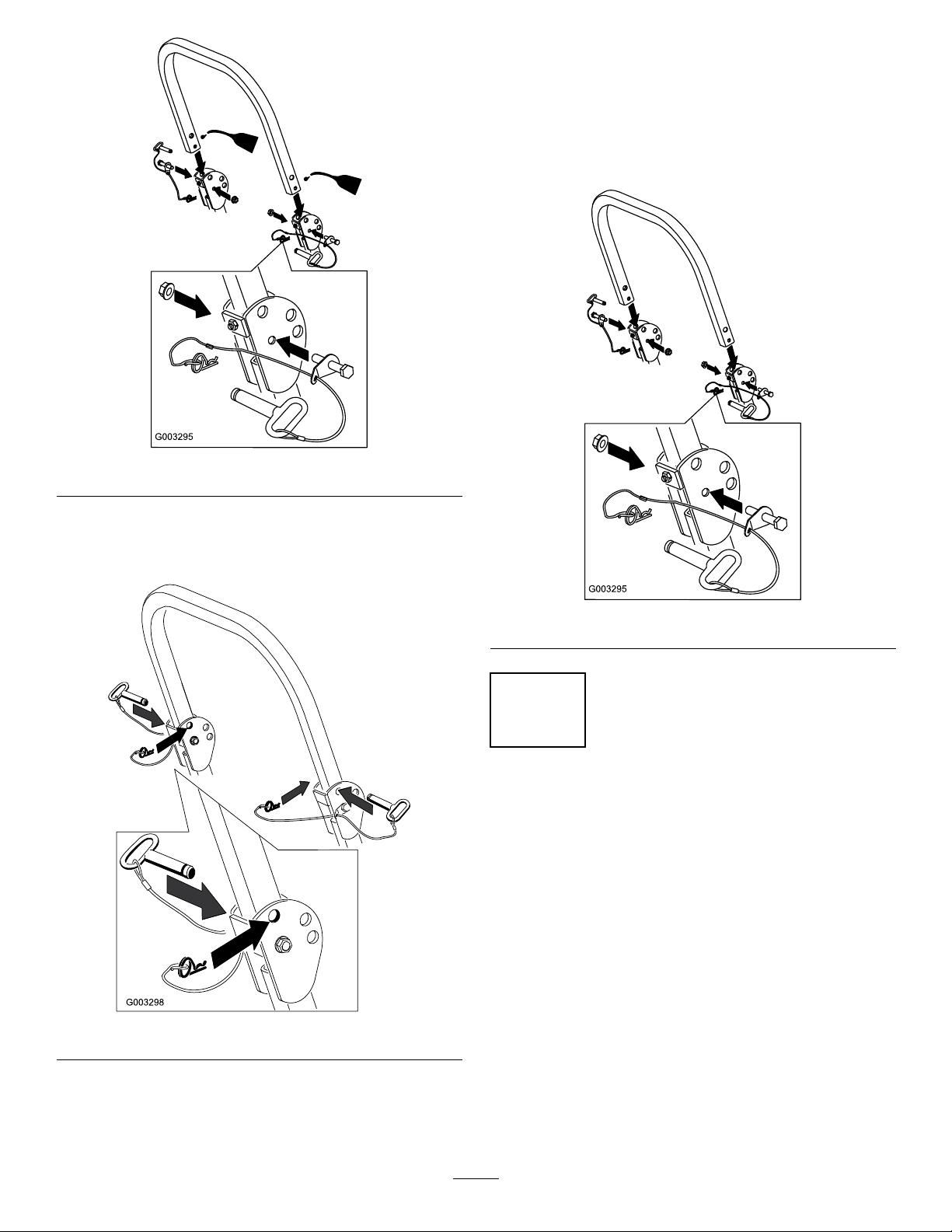

Important:Thegrassdeectormustbefreeto

rotatewithdownwardtension.Liftthedeector

uptothefullopenpositionandensurethatit

rotatesfreely,withoutbindingintothefulldown

position.

Figure16

1.GrassDeector4.Lendofspring,place

behinddeckedgebefore

installingbolt

2.Spring5.Deckedge

3.Jhookendofspring

7