8

Fault Finding

Before starting work on the pump, make sure that the electricity supply has been switched off

and that it cannot be accidentally switched on.

One of the most common causes of pump problems is air in the system. To purge air from the

system, with the pump not running allow maximum flow by removing the shower handset and

allowing the hose to hang into the shower tray or bath. Operate maximum hot and cold flow for

at least 5 minutes each. For fixed head showers remove the shower rose and connect a length

of hose, hanging into the shower tray or bath.

Fault Possible Cause and Remedy

Check that the electricity supply to the pump is switched on.

Check the fuses and any replace blown fuses. If the new ones blow too, the

electric installation should be checked.

The pump motor has built-in thermal protection to switch off the motor and

prevent overheating, which resets automatically within 1 to 2 hours.

Check that any isolating valves on pump inlets and outlets are fully open.

Check that the pump strainers are not blocked. Close the service isolating

valves, clean the strainers and re-open the service isolating valves.

Ensure that the pump is installed with vertical discharge ports (flow switches).

The pump fails

to start.

Ensure that the water flow with the pump switch off is at least 0.5 l/min.

Check that the pump strainers are not blocked. Close the service isolating

valves, clean the strainers and re-open the service isolating valves.

The flow from

the shower

drops. Purge any air in the system. With the pump not running allow maximum flow

by removing the shower handset and allowing the hose to hang into the

shower tray or bath. Operate maximum hot and cold flow for at least 2 minutes

each.

Ensure there are no leaks in the system and that all taps and outlets are off.

Purge any air in the system. With the pump not running allow maximum flow

by removing the shower handset and allowing the hose to hang into the

shower tray or bath. Operate maximum hot and cold flow for at least 5 minutes

each. For fixed head showers remove the shower rose and connect a length

of hose, hanging into the shower tray or bath.

Flow switch or reed switch faulty or incorrectly set. Contact the helpline for

adjustment or replacement details.

The pump

runs

continuously.

Ensure that the float in the outlet port is not stuck in the up (on) position.

Ensure that there is no debris in pump housing or outlet port.

The pump

pulses. Ensure that taps or other outlets are not causing water hammer, which can

cause the pump to start momentarily. A low pressure non-return valve can be

fitted on the outlet pipework from the pump. Contact your installer.

Ensure that air can not enter the pump, most commonly from the hot-water

cylinder. Fit a Surrey or Essex flange and ensure that there are no high points

in the pipework layout where air can collect.

Ensure that the hot-water temperature at the pump is not above 60ºC (140ºF).

Unstable

water

temperature /

noisy pump. Ensure that there is no debris caught in the pump impeller casing.

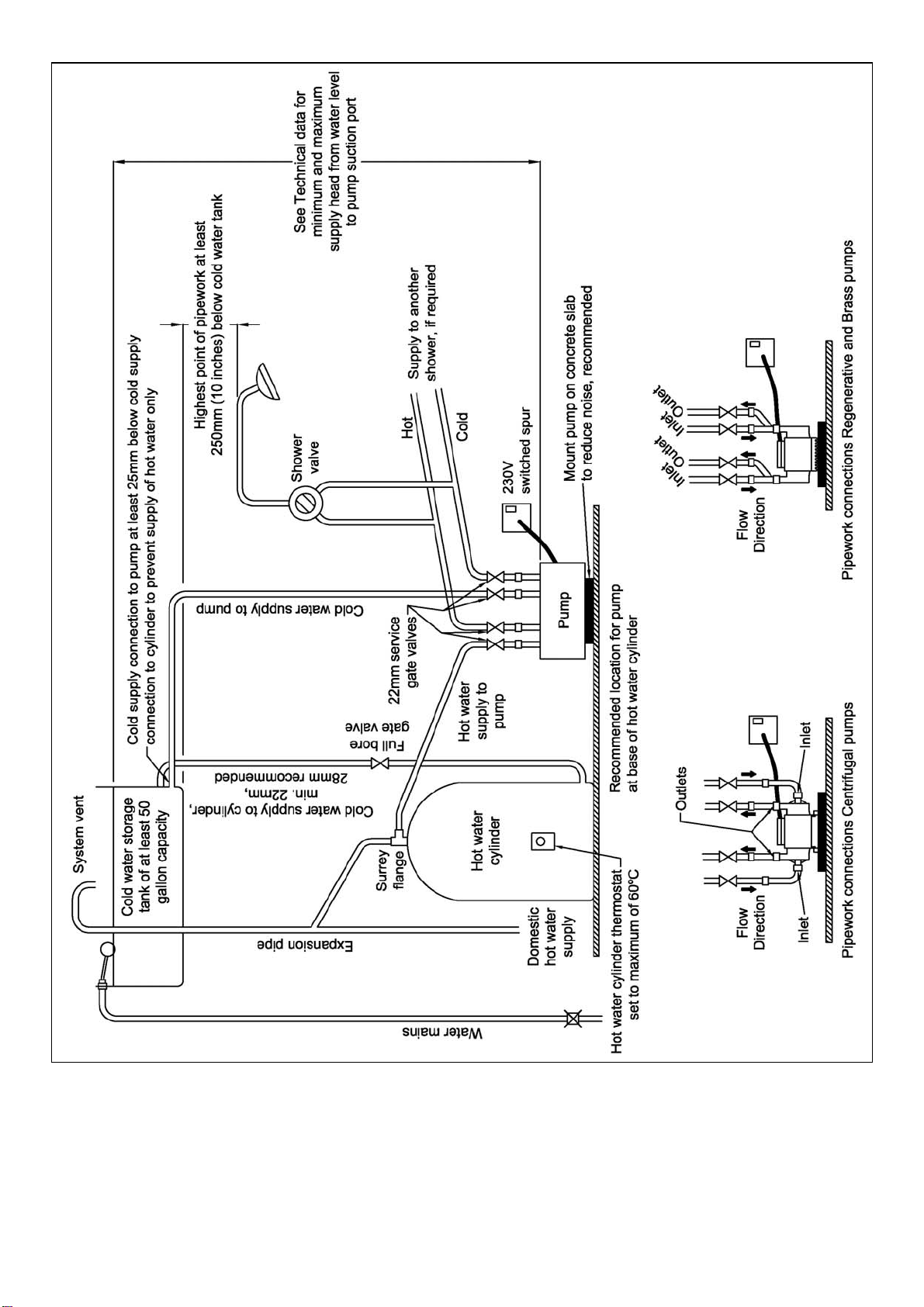

Noisy pump. Noise caused by vibration through the pump mounting surface can be reduced

by mounting the pump on a concrete slab.

Hose

connection

leaking.

For screw connection hoses, ensure that the hose washers and strainer

washers are fitted and that the plastic nuts on the hoses are tight.

For push fit connection hoses, ensure that the hose connection is fully inserted

to a minimum depth of 33mm.

ML10053 03

12