Toshiba RAS-18YKH-E User manual

Other Toshiba Air Conditioner manuals

Toshiba

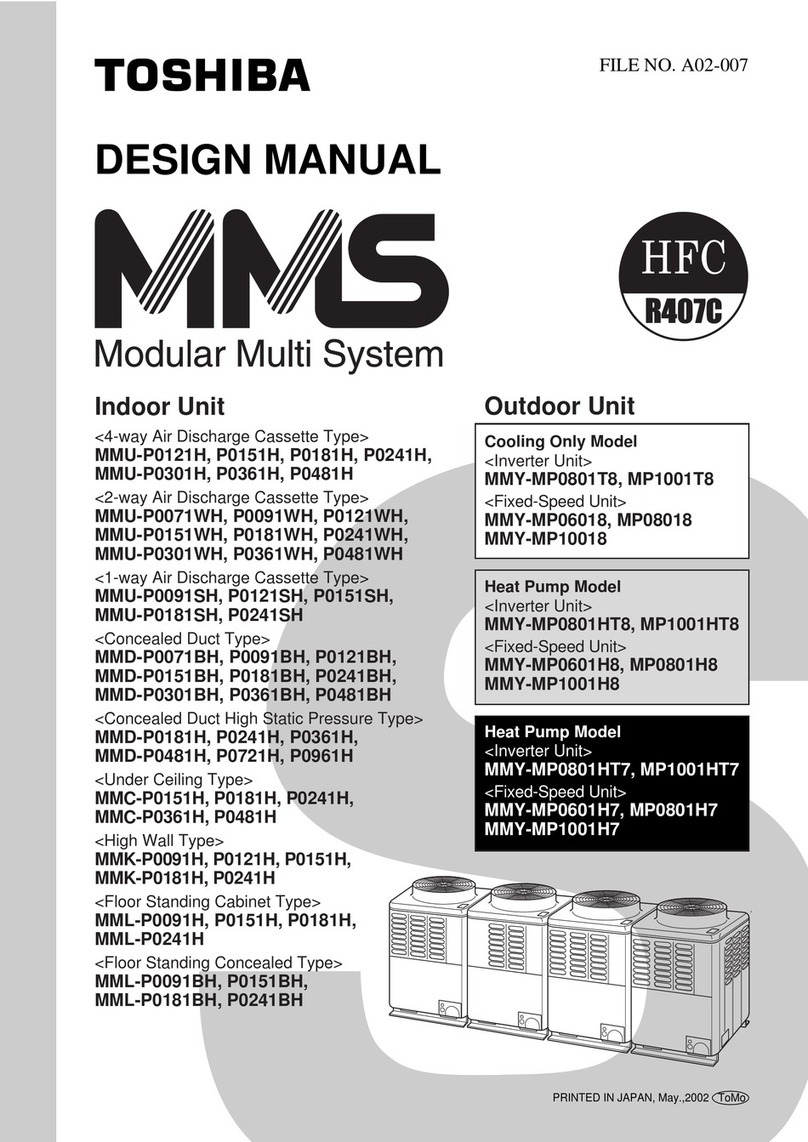

Toshiba MMS Series Guide

Toshiba

Toshiba RAS-10G2KVP Series User manual

Toshiba

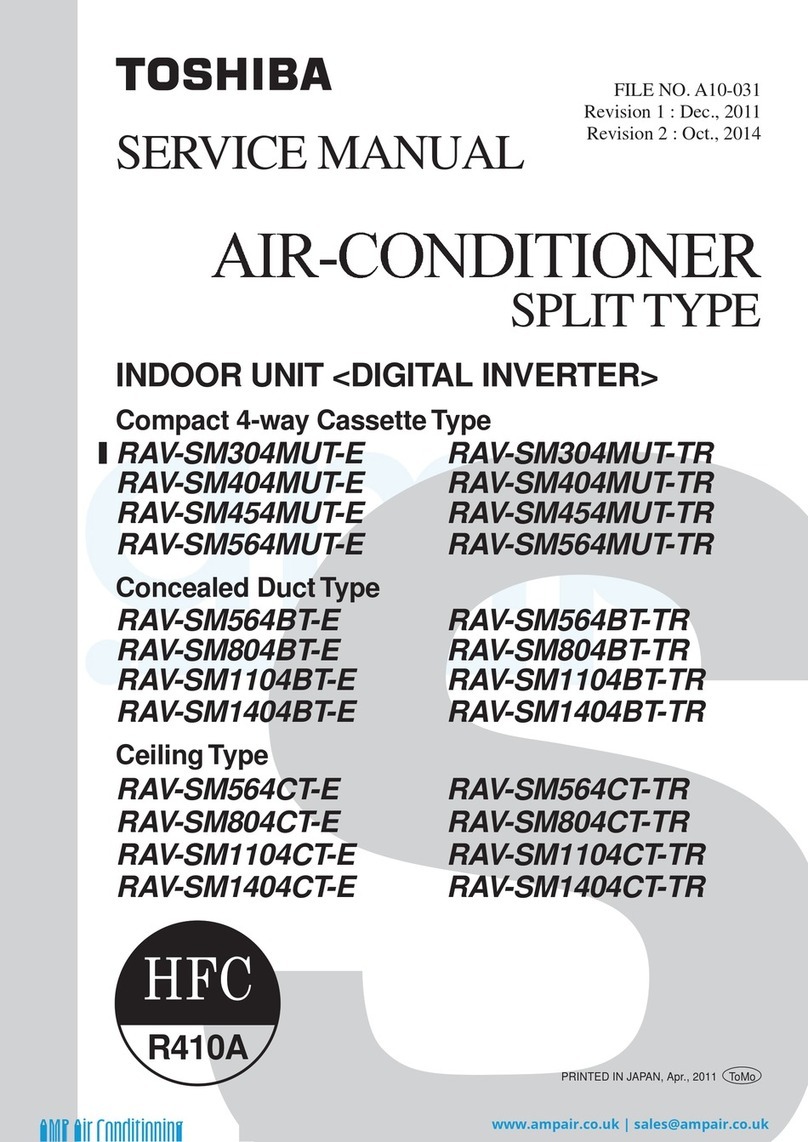

Toshiba RAV-SM304MUT-E User manual

Toshiba

Toshiba MMU-UP0091HP-E User manual

Toshiba

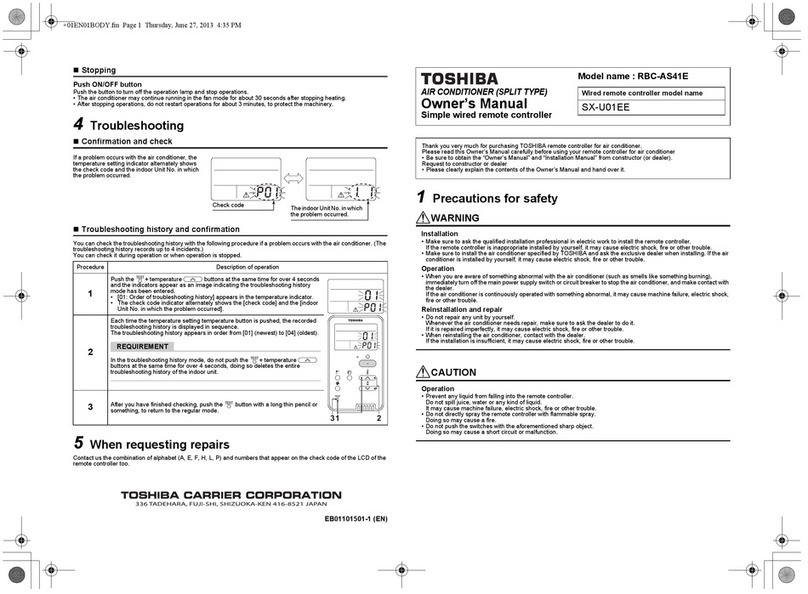

Toshiba RBC-AS41E User manual

Toshiba

Toshiba RAV-5M561UTP-E User manual

Toshiba

Toshiba RAV-SM560AT-E User manual

Toshiba

Toshiba RAV-SP804ATP-E User manual

Toshiba

Toshiba RAS-107SKV Series User manual

Toshiba

Toshiba RBC-DTWP101E User manual

Toshiba

Toshiba Carrier MMU-AP0074HPUL Product guide

Toshiba

Toshiba RAV-GM901KRTP-E User manual

Toshiba

Toshiba RAV-SM182UTP-UL User manual

Toshiba

Toshiba HWS-455H-E User manual

Toshiba

Toshiba RAS-10S3AV-E User manual

Toshiba

Toshiba RAS-10 series User manual

Toshiba

Toshiba RAS-25L User manual

Toshiba

Toshiba RAV-GM561ATP-E User manual

Toshiba

Toshiba MML-UP0071NHP-E User manual

Toshiba

Toshiba MCY-MHP0404HS8-E User manual