Total Control Greyline 2000 Series User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Greyline 2000 Series

Operator Workstation

Hardware Manual

LD2

F1 F2 F3

LD6

LD7

LD8

LD5

LD3

LD4

F6F4 F5 F7 F8

2

0

1

CLR

45

3

SEL

ENT ESC

6

PREV

LD1

87 9

NEXT

Greyline 2000 Series

Operator Workstation Hardware Manual

2024-701

Revision D

December, 1997

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual was produced by Total Control Products, Inc., Melrose Park, Illinois.

Copyright 1995, Total Control Products, Inc. All rights reserved.

Manual design and implementation by Glenn Rodgers.

Information in this document is subject to change without notice and does not represent a commitment on the part of

Total Control Products, Inc. The software described in this document is provided under a license agreement. The

software may be used or copied only under the terms of the agreement. Only one copy of the software may be made for a

backup.

Total Control Products, Inc. makes no warranty, either expressed or implied, including but not limited to any implied

warranties of merchantability or fitness for a particular purpose, regarding these materials and makes such materials

available solely on an "as-is" basis.

In no event shall Total Control Products, Inc. be liable to anyone for special, collateral, incidental, or consequential

damages in connection with or arising out of purchase or use of these materials. The sole and exclusive liability to Total

Control Products, Inc., regardless of the form of action, shall not exceed the purchase price of the materials described

herein.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying, recording, or information storage and retrieval systems, for any purpose other than the

purchaser's personal use, without the express written permission of Total Control Products, Inc.

The following logo is registered to Total Control Products, Inc.

Total Control Products, Inc.

2001 N. Janice Ave., Melrose Park, IL 60160 USA

Phone (708) 345-5500 FAX (708) 345-5670

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Contents •

••

•i

Contents

Chapter 1 - Welcome 1

Welcome!...................................................................................................................................1

What Manual Should I Use...? ...................................................................................................1

...to Install and Connect the Greyline Workstation ......................................................1

...to Program and Operate the Greyline Workstation...................................................1

Chapter 2 - Receiving Inspection 3

Packing List................................................................................................................................3

What to Do if Something is Missing or in Error ........................................................................3

Chapter 3 - Introduction: Main Features 5

Introduction to the Greyline Operator Workstation....................................................................5

Options.........................................................................................................................5

10-30 VDC Powered Unit (10VDC)............................................................................5

230 VAC Powered Unit (230VAC).............................................................................5

Clock/Calendar Chip....................................................................................................6

Main Features .............................................................................................................................6

Front Panel Features .....................................................................................................6

Alphanumeric Display .................................................................................................6

Numeric Keypad..........................................................................................................7

Numeric Function Keys ...............................................................................................7

Function Keys..............................................................................................................8

LEDs............................................................................................................................8

Replaceable Legends ...................................................................................................8

Installing the Replaceable Legends..............................................................................9

Rear Panel Features....................................................................................................10

Power Connection......................................................................................................10

Port B.........................................................................................................................10

Port X.........................................................................................................................11

Dip Switch .................................................................................................................11

Status Codes...............................................................................................................11

Program/Run/Bypass Switch......................................................................................11

LCD Adjust................................................................................................................12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ii •

••

•Contents Greyline 2000 Series Operator Workstation Hardware Manual

Chapter 4 - Switch Settings 13

Dip Switch............................................................................................................................... 13

Baud Rate.................................................................................................................. 13

Multiple Function Keys.............................................................................................. 14

Display Placeholder ................................................................................................... 14

Auto Repeat............................................................................................................... 14

Repeat All.................................................................................................................. 14

Program/Run/Bypass Switch.................................................................................................... 15

LCD Contrast Adjust................................................................................................................ 16

Chapter 5 - Electrical Connections 17

Power Connections................................................................................................................... 17

Chassis Ground ......................................................................................................... 17

Logic Ground............................................................................................................ 17

115 VAC................................................................................................................... 19

230 VAC................................................................................................................... 19

10-30 VDC................................................................................................................ 19

Chapter 6 - Greyline Communication Ports 21

SERIES TWO Devices on a Port ................................................................................................. 21

PLCs on a Port......................................................................................................................... 21

Port B....................................................................................................................................... 22

Pinout - Port B .......................................................................................................... 22

PLC Cables ............................................................................................................... 23

Port X ...................................................................................................................................... 23

Pinout - Port X .......................................................................................................... 23

Programming Cable .................................................................................................. 23

Chapter 7 - Power On and Self Test 25

Power On................................................................................................................................. 25

Self Test................................................................................................................................... 25

Local Self Test......................................................................................................................... 25

Testing Switch Settings............................................................................................. 26

Testing Keys ............................................................................................................. 26

Chapter 8 - Dimensions 27

Chapter 9 - Specifications 29

2000 Series .............................................................................................................................. 29

2100 Series .............................................................................................................................. 30

Index 31

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Chapter 1 - Welcome •

••

•1

Chapter 1 - Welcome

Welcome!

Total Control Products, Inc. is proud to present its newest family of products, the Greyline 2000 Series

Operator Workstations.

What Manual Should I Use...?

...to Install and Connect the Greyline Workstation

For information on installing and connecting the Greyline Workstation, refer to this manual, the "Greyline

Operator Workstation Hardware Manual." This manual provides installation information, dimensions,

connections and specifications. In addition, this manual introduces the user to the hardware features of the

Greyline.

...to Program and Operate the Greyline Workstation

For information on programming and operating the Greyline Workstation, refer to the "Greyline Universal

Software Manual" in combination with the applicable protocol reference guide.

CAUTION Please read this documentation before attempting to install the unit.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Chapter 2 - Receiving Inspection •

••

•3

Chapter 2 - Receiving Inspection

Packing List

After receiving your Greyline Operator Workstation, you should immediately check to confirm that you

have received the following items:

•Greyline Operator Workstation

•Greyline Operator Workstation Hardware and Software Manuals

•Set of Replaceable Legend Sheets

•Protocol Reference Guides

•Ten 10-16 x 3/8" Hi-Lo Thread Forming Fasteners with Blunt Point (8 required; 2 spares)

•Ten Lockwashers (8 required; 2 spares)

What to Do if Something is Missing or in Error

If you find that there has been a packing error, contact Customer Service at:

(708) 345-5500 Customer Service

(708) 345-5670 FAX

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Chapter 3 - Introduction: Main Features •

••

•5

Chapter 3 - Introduction: Main Features

Introduction to the Greyline Operator Workstation

The 2000/2100 Series Greyline Operator Workstations feature 2 or 4 line alphanumeric LCD displays,

encased in lightweight molded plastic. The following sections describe the hardware features of the

Greyline Operator Workstation. There are two models, the 2000 Series which feature a Backlit

Supertwist LCD display, and the 2100 Series, which feature a Vacuum Fluorescent display.

Options

The following options may be specified for the Greyline Operator Workstation:

1. 10-30 VDC powered unit

2. 230 VAC powered unit

3. Clock/Calendar Chip

10-30 VDC Powered Unit (10VDC)

If you specified the 10-30 VDC powered unit as an option, refer to the section addressing connections for

the 10-30 VDC.

230 VAC Powered Unit (230VAC)

If you specified the 230 VAC powered unit as an option, refer to the section addressing connections for

the 230 VAC.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6 •

••

•Chapter 3 - Introduction: Main Features Greyline 2000 Series Operator Workstation Hardware Manual

Clock/Calendar Chip

This option keeps track of the time and date. Refer to the Greyline Universal Software Manual for further

information.

Main Features

The following sections describe the main features of the Greyline Operator Workstation.

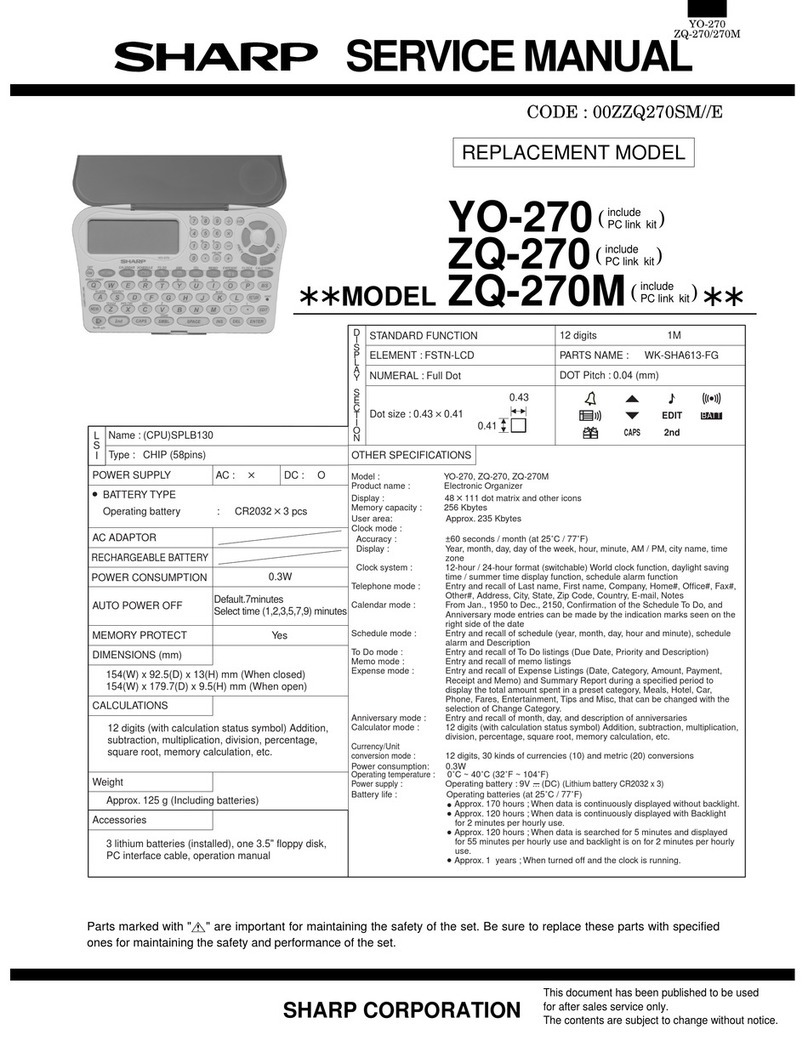

Front Panel Features

The following sections describe the front panel features of the Greyline Operator Workstation. Below is

an illustration of the front panel.

LD2

F1 F2 F3

LD6

LD7

LD8

LD5

LD3

LD4

F6F4 F5 F7 F8

2

0

1

CLR

45

3

SEL

ENT ESC

6

PREV

LD1

87 9

NEXT

Alphanumeric Display

The Greyline Operator Workstation features a 2 or 4 line alphanumeric display. This 5mm Backlit Super

Twist LCD display (2000 Series) is capable of displaying up to 20 characters per line. Models 2024 and

2124 feature the 2 line display. Model 2025 and 2125 feature the 4 line display. Model 20xx is LCD and

Model 21xx is VF.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Chapter 3 - Introduction: Main Features •

••

•7

Numeric Keypad

The numeric keypad features digits 0-9, Clear and Enter keys, and 4 additional function keys. The Clear

key cancels the keypad data entry in progress. The Enter key completes the keypad data entry.

2

0

1

CLR

45

3

ENT

6

87 9

Refer to the following section for a description of the numeric function keys.

Note: The Greyline Operator Workstation features a "beep" which provides audible

feedback to the user. One beep signals a positive acknowledgement and two

beeps signal a negative acknowledgement.

Numeric Function Keys

There are four numeric function keys to the right of the numeric keypad. These numeric function keys are

user definable and are independent of the numeric keypad. Refer to your Greyline Universal Software

Manual for further information.

SEL

ESC

PREV

NEXT

Note: The Greyline Operator Workstation features a "beep" which provides audible

feedback to the user. One beep signals a positive acknowledgement and two

beeps signal a negative acknowledgement.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

8 •

••

•Chapter 3 - Introduction: Main Features Greyline 2000 Series Operator Workstation Hardware Manual

Function Keys

Function keys F1 through F8 are located below the numeric keypad. These function keys are user

definable. Refer to your Greyline Universal Software Manual for further information.

F1 F2 F3 F6F4 F5 F7 F8

Note: The Greyline Operator Workstation features a "beep" which provides audible

feedback to the user. One beep signals a positive acknowledgement and two

beeps signal a negative acknowledgement.

LEDs

LEDs, located on the left side of the front panel, are user definable and typically reflect the status of a bit

in the PLC. The LEDs are independent of the function keys. Refer to the Greyline Universal Software

Manual for further information.

LD2

LD6

LD7

LD8

LD5

LD3

LD4

LD1

Replaceable Legends

Replaceable legends (blank slip-in legend sheets) are provided for function keys, LEDs, and the numeric

function keys. These legend sheets are made of durable plastic and are comprised of two separate strips --

one for the LEDs, function keys F1 through F7, and another for the numeric function keys and function

key F8. The removable legends are located beneath the surface of the Greyline front panel. The following

section describes how to remove and replace the legend strips.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Chapter 3 - Introduction: Main Features •

••

•9

Installing the Replaceable Legends

The illustration below shows where the legend sheets are located. To remove the legend sheets, tilt the

Greyline and pull firmly on the ends of the legend sheets protruding from the unit. To replace the legend

sheets, insert the replacement set into the openings where the original legend sheets were removed. If you

have problems inserting the new legends, try trimming the edges so that the new legends are the same size

or slightly smaller than the originals.

2024ES4

STATUS CODES

45 78

1

PO BRT PORT X

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

10 •

••

•Chapter 3 - Introduction: Main Features Greyline 2000 Series Operator Workstation Hardware Manual

Rear Panel Features

The following sections describe the rear panel features of the Greyline Operator Workstation. Below is an

illustration of the rear panel (2000 Series).

(NOT LISTED -NO CONNECT)

PORT X

115 VAC

EARTH

NEUTRAL

HOT

20.RS-232 DTRB

PORT B

REPEAT ALL (ON)

DISP PLACE (ON)

M ULTIFU NC (OFF)

AUTO REPEAT (ON)

BD4(ON)

BD2(ON)

BD1(OFF)

SPARE (O FF)

STATUS CODES

1 2345678

BYPASS

PROGRAM

LCD

CONTRAST

ADJUST

RUN

24.RS-422 TXDB +

23.RS-422 TXDB -

22.RS-422 CTSB +

21.RS-422 CTSB -

7.SIGNALGROUND

11.ICTSB -

12.ICTSB +

18.IRXDB -

19.IRXDB +

15.RS-422 RTSB +

14.RS-422 RTSB -

16.RS-422 RXDB -

17.RS-422 RXDB +

6.RS-232 DSRB

5.RS-232 CTSB

4.RS-232 RTSB

3.RS-232 RXDB

1.SHEILD

2.RS-232 TXDB

PORT B

21.RS-422 CTSX -

RXDB

TXDB

RXDX

TXDX

22.RS-422 CTSX +

23.RS-422 TXDX -

24.RS-422 TXDX +

3.RS-232 RXDX

4.RS-232 RTSX

5.RS-232 CTSX

6.RS-232 DSRX

7.SIGNALGROUND

14.RS-422 RTSX -

15.RS-422 RTSX +

20.RS-232 DTRX

10.RESERVED

9.RESERVED

17.RS-422 RXDX +

16.RS-422 RXDX -

1.SHEILD

2.RS-232 TXDX

PORT X

operator workstation

UL

®UL

C ®

LISTED

6M04

INDUSTRIAL CONTROL EQUIPMENT

MODEL :

ITEM :

LOT :

Power Connection

The power connection for the Greyline is located on the lower right portion of the rear panel. The

illustration below shows the power connections for 115 VAC, 230 VAC, and 10-30 VDC.

Port B

Port B is located to the left of Port X on the lower portion of the Greyline rear panel. Serial

communication using RS-232, RS-422, RS-485 or current loop may be used for connecting Port B to the

PLC. Communication connections are made through 25 pin "D" type connectors.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Chapter 3 - Introduction: Main Features •

••

•11

Port X

Port X, a serial expansion port, is located to the right of Port B on the lower portion of the Greyline rear

panel. This Auxiliary port provides flexibility for the Greyline user. Although used primarily for

programming the workstations, Port X may also be configured to interface with a SERIES TWO network, a

serial printer, a host computer, or a different model PLC. Serial communication using RS-232, RS-422,

and RS-485 may be used. Communication connections are made through 25 pin "D" type connectors.

Dip Switch

The Dip Switch is located on the underside (interior) of the rear panel, beneath Port B and to the far left of

the Program/Run/Bypass Switch. The switches are marked 1 through 8. Refer to Chapter 4 for

information on the Dip Switch settings. The following illustration depicts the underside of the rear panel.

2024ES4

45 78

1

STATUS CO DES

PO BRT PO R T X

Status Codes

The Status Codes are located to the left, above Port B on the rear panel of the Greyline Operator

Workstation. When lit, these status codes display coded numbers which indicate possible errors or status

information. Refer to the tables in the Greyline Universal Software Manual for a complete listing of the

Status Codes.

Program/Run/Bypass Switch

The Greyline features a Program/Run/Bypass Switch located on the underside (interior) of the rear panel,

beneath Port X and to the right of the Dip Switch. This switch allows the user to program the workstation,

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

12 •

••

•Chapter 3 - Introduction: Main Features Greyline 2000 Series Operator Workstation Hardware Manual

run the program following completion of programming, and/or bypass directly to the PLC for

programming purposes. Refer to the Greyline Universal Software Manual for further information.

Note: Before Bypass mode can be selected, the user must first download a TSP or

Greyline Universal Software configuration matching the communication

parameters of Port B and the PLC model.

LCD Adjust

The LCD Contrast Adjust is located at the center of the underside (interior) of the rear panel. A blue-

colored knob, this LCD Adjust is used to change the contrast of the display of the Greyline Operator

Workstation. Refer to paragraph 4.3 for instructions. This adjustment is only available on Backlit

Supertwist LCD models (20xx Series).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Chapter 4 - Switch Settings •

••

•13

Chapter 4 - Switch Settings

Dip Switch

Default settings for dip switches 1 through 8 are shown below.

Switch No. Function Position

1Baud Rate 1 OFF

2Baud Rate 2 ON

3Baud Rate 4 ON

4Spare OFF

5Multiple Function Keys OFF

6Displacement Placeholder ON

7Auto Repeat ON

8Repeat All ON

Baud Rate

The baud rate for the Greyline Operator Workstation is switch selectable if in Program mode, and software

selectable if in Run and Bypass mode. Refer to the Greyline Universal Software Manual for a more

complete explanation for baud rates that are software selectable (Run and Bypass mode).

In Program mode, the baud rate is switch selectable, meaning that the baud rate is determined by the

position of the Dip Switch. Although the baud rate choices are 300, 600, 1200, 2400, 4800, 9600, and

19200, at this time, the software only supports 9600. Therefore, after switches 1, 2, and 3 are initially set

for 9600 baud, there is no need to make future adjustments.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

14 •

••

•Chapter 4 - Switch Settings Greyline 2000 Series Operator Workstation Hardware Manual

Baud Rate 1, Baud Rate 2, and Baud Rate 4 constitute Dip Switch switches 1, 2, and 3 respectively. If in

Program mode, adjust the switches as indicated by the gray area shown below, to select the appropriate

baud rate:

BD RT 1 BD RT 2 BD RT 4 Baud Rate

0 0 0 Test Mode

1 0 0 300 baud

0 1 0 600 baud

1 1 0 1200 baud

0 0 1 2400 baud

1 0 1 4800 baud

0 1 1 9600 baud

1 1 1 19200 baud

A "0" in the above chart represents a switch which is off

or open. A "1" in the chart represents a switch

which is on or closed.

4578

1

OFF

ON

Note: Set switches then cycle power. Switches are only read during power up.

Multiple Function Keys

Switch 5 on the Dip Switch. When this switch is activated, the Greyline is capable of recognizing multiple

function keys.

Display Placeholder

Switch 6 on the Dip Switch. When this switch is activated, variable data placeholders appear as

underscore characters on the Greyline display. When not activated, variable data placeholders appear as

space characters on the Greyline display. Refer to your Greyline Universal Software Manual for further

information.

Auto Repeat

Switch 7 on the Dip Switch. When this switch is activated, the function keys will automatically repeat

when pressed and held down.

Repeat All

Switch 8 on the Dip Switch. When this switch is activated, both the function keys and numeric function

keys will automatically repeat when pressed and held down.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Greyline 2000 Series Operator Workstation Hardware Manual Chapter 4 - Switch Settings •

••

•15

Program/Run/Bypass Switch

The illustration below shows the position of the toggle switch for all three modes.

PROGRAM RUN BYPASS

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

1

Table of contents