Totech Superdry XSDC 601-01 User manual

XSDC 601-01

Operation manual XSDC 601-01

XSDC 601-01

1. Safety Information 4

1.1 Adherence to information provided in the Operation Manual 4

1.2 Operator Obligations 4

1.3 Personnel Obligations 4

1.4 Organizational Measures 4

1.5 Information related safety precautions 4

1.6 Intended use 5

1.7 Hazards related to cabinet handling 5

1.8 Protective devices 5

1.9 Electrical hazards 5

1.10 Hazards arising from hot surfaces 5

1.11 Maintenance, Service and troubleshooting 6

1.12 Dehumidifier modification 6

1.13 Cabinet cleaning and disposal 6

2. Technical Specifications 7

2.1 Description 7

2.2 Operating conditions 7

2.3 Function 7

2.4 Main Components 8

3. Ordinary Maintenance 9

3.1 Preliminary inspection operations 9

3.2 Internal and external cleaning of the refrigerator cabinet 9

3.3 Cleaning the condenser unit 9

4. Extraordinary Maintenance 9

5. Installation 10

5.1 Transport 10

5.2 Environmental specifications. 10

5.3 Positioning 10

5.4 Space needed for maintenance 11

6. Operation 11

6.1 Preliminary inspection operations 11

6.2 Start up 11

6.3 Shut-down 11

6.4 Defrosting 12

6.5 Front panel description 12

7. Programming 13

7.1 Programming of the setpoint 13

7.2 Programming the parameters 13

7.2.1 Keyboard lock function 13

7.2.2 Manual defrosting 13

XSDC 601-01

8. Troubleshooting 14

9. Waste disposal and dismantling 15

10. Warranty and RMA Procedure 16

10.1 Warranty and liability 16

10.2 Full Warranty 16

10.3 Exchange warranty 16

10.4 Third year warranty 17

10.5 Guidelines for the RMA procedure of Totech Europe B.V. 17

11. Serial numbers 18

11.1 Cabinet serial numbers 18

12. CE Declaration 18

XSDC 601-01

1. Safety Information

1.1 Adherence to information provided in the Operation Manual

Being familiar with the basic safety information and regulations is essential for safe handling and

failure-free operation of this device.

✓This Operation Manual contains the most important information required in order to safely

operate the device.

✓Please ensure, all personnel operating the device adheres to this Operation Manual and in

particular to the safety information provided herein.

✓Additionally, any rules and regulations with respect to accident prevention, applicable at the

your respective location, are to be complied with.

1.2 Operator Obligations

The operator undertakes to exclusively authorize individuals to work at the cooling cabinet, who:

✓are familiar with relevant regulations on occupational safety and accident prevention, and

have been trained in the device’s handling;

✓are in possession of and/or have proven to possess the required expertise and know-how;

✓have read and understood the safety information and precautions provided in this Operation

Manual.

✓Furthermore, the operator undertakes to regularly check its personnel's for a safety-conscious

mode of practice.

1.3 Personnel Obligations

All personnel assigned to operate the device, undertake to:

✓comply with the relevant occupational safety and accident prevention regulations and follow

the safety information and precautions provided herein, before operating the device.

1.4 Organizational Measures

✓Required personal protective equipment (PPE) is to be provided by the operator.

✓All existent safety installations are to be inspected regularly.

1.5 Information related safety precautions

✓Ensure the Operation Manual's general availability at the device’s application site.

✓In addition to the Operation Manual, also provide for and ensure to comply with general as

well as local regulations on accident prevention and environmental protection.

✓Ensure to keep all safety information and precautions applied to the device in legible

condition.

XSDC 601-01

1.6 Intended use

The device is exclusively intended to cool atmospheric air. Any deviating or exceeding deployment is

considered unintended use. Totech EU will not assume any liabilities for damage resulting therefrom.

The device must not be mounted in and/or exposed to the intake of liquids (e.g. filled

tanks or sumps, flooded areas etc.).

Operation in and/or with potentially explosive ambiance is not permissible.

Intended use also includes compliance with all information provided in the Operation Manual as well

as adherence to the remarks made on.

1.7 Hazards related to cabinet handling

The device was built in accordance with state-of-the-art technology and generally accepted technical

safety requirements. Ensure to exclusively use it:

✓for its intended use;

✓in good order and condition with respect to safety.

✓Ensure to immediately remedy any malfunction, which might impede the device’s safety.

1.8 Protective devices

✓Generally ensure all protective devices to be properly installed and functional before operating

the device.

✓Protective devices may only be removed:

a) After shutdown

b) As safeguarding against unintended restart.

✓For delivery of subcomponents, the operator shall ensure the standard installation of

protective devices.

1.9 Electrical hazards

✓Works performed at the electrical power supply are to be executed by qualified electricians

only.

✓Ensure to always keep the control area locked. Access is to be granted to authorized and

adequately equipped personnel only.

✓In the event works are to be performed at live parts, ensure to provide for a second person

who can switch off electricity, if necessary.

1.10 Hazards arising from hot surfaces

✓Defrosting cycles process may cause the cooling module surface to heat up to approx. 40°C.

✓Ensure not to touch the operating cooling module without wearing adequate protective

equipment.

✓Ensure to keep a minimum distance of 5 cm at the unit's back side.

XSDC 601-01

1.11 Maintenance, Service and troubleshooting

✓The device is maintenance-free.

✓Ensure to inform operators prior to the commencement of maintenance activities.

✓For repair works, switch device to neutral and secure main switch against unexpected

restart.

✓Apply restart warning sign.

✓Check unscrewed fastenings for secure tightness.

✓After completion of the repair works, check safety devices for functionality.

1.12 Dehumidifier modification

✓Any modification, extension, and/or conversions to the device are subject to Totech EU's

written consent.

✓Exclusively use original spare parts to ensure the device’s proper and safe function and

operation.

1.13 Cabinet cleaning and disposal

Ensure proper handling and disposal of deployed substance and materials. This particularly applies to

cleaning activities including the use of solvents.

XSDC 601-01

2. Technical Specifications

2.1 Description

✓This equipment is designed and deployed for cooling functions in process engineering,

air-conditioning technology, and cooling in production and storage spaces, inside which

products and installations require low temperatures. Any other use is improper.

✓The equipment is not suitable for installation outdoors and/or in areas subject to weather. the

manufacturers denies any responsibility for unintended uses of the equipment.

2.2 Operating conditions

In general, cooling cabinets made by Totech are designed for initial conditions of 20-40°C at

0-60%RH. Higher ambient temperature conditions will adversely affect cooling performance.

✓Ensure to exclusively operate the device in ambient temperatures (control-side) ranging

between 10°C and 40°C!

✓Ensure the intake air does not contain any free water (water drops)

✓Ensure devices are not mounted in and/or exposed to the intake of liquids (e.g. filled tanks or

sumps, flooded areas etc.).

✓Any operation in and/or with potentially explosive ambience is not permissible.

2.3 Function

The device has been equipped with an easy to control logic display, mounted in the front panel of the

cabinet. The respective module serves to control the device's temperature and functions monitoring.

In order to ensure ideal cooling, the cooling unit requires adequate defrosting. Therefore the device

has an automatic defrosting cycle. This means that the device will start defrosting every 6 hours. Each

individual defrosting cycle will take about 30 minutes. During defrosting processes, active cooling is

not feasible.

It provides an external display, indicating several reports such as malfunction, alarms, actual and

pre-set values. The air temperature can be controlled by means of the logic module, integrated in the

display. The function is operated via the central display.

XSDC 601-01

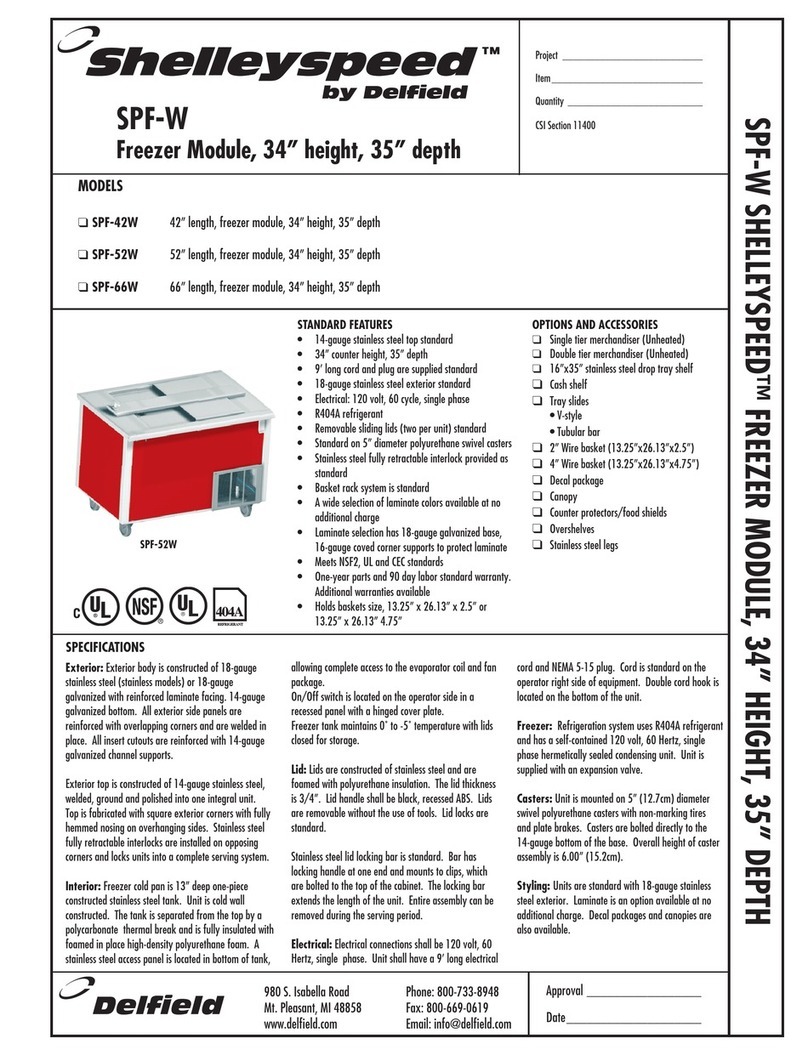

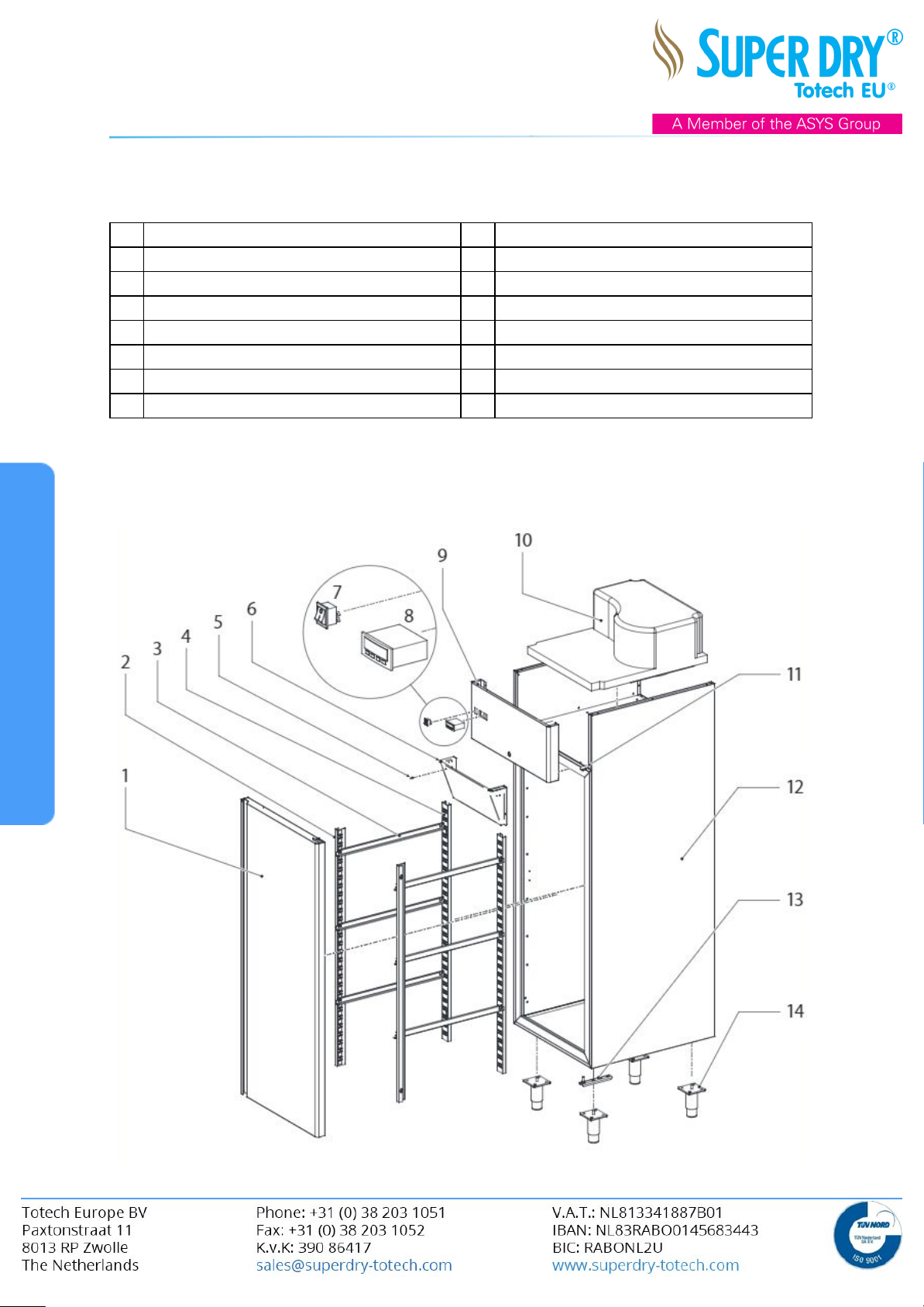

2.4 Main Components

The equipment is made up of the following (see table and figure)

Pos.

Part

Pos.

Part

1

DOOR

8

THERMOSTAT

2

FRONT RACK

9

INSTRUMENT PANEL

3

DOOR TRAY GUIDE

10

REFRIGERATOR UNIT

4

REAR RACK

11

UPPER HINGE

5

DIAGNOSTIC LED

(ONLY DEBATTER)

12

CASING

6

CONVEYOR

13

LOWER HINGE

7

SWITCH

14

FOOT

The shelves found inside the refrigerator cabinet have the following dimensions: 530 x 500 mm.

The areas that come in contact with the product are made out of AISI 304 Stainless Steel or coated in

non-toxic plastic material. The refrigerator units use refrigerant fluids permitted by current legislation.

XSDC 601-01

3. Ordinary Maintenance

3.1 Preliminary inspection operations

Before any maintenance, replacement, repair, cleaning, lubricating or other

operation, the equipment must be isolated from electrical power!

✓Wear the appropriate safety gloves when performing maintenance operations.

3.2 Internal and external cleaning of the refrigerator cabinet

✓Do not use jets of water to wash the internal parts of the refrigerator cabinet: there are

electrical and electronic parts that could be damaged.

✓Do not use hard metal tools to remove ice.

✓To clean the internal parts of the refrigerator cabinet use a non-aggressive detergent diluted

in warm water. Dry damp parts with a soft cloth.

✓Weekly cleaning is recommended.

✓Avoid using products with chlorine, caustic soda, abrasive detergents, muriatic acid, vinegar,

bleach or other products that should scratch or abrade.

Also clean the exterior of the equipment with non aggressive detergent to prevent it from getting dirty

3.3 Cleaning the condenser unit

All cleaning operations of the refrigerator monoblox or the incorporated condenser

unit must be performed by qualified and authorized technicians.

✓In order to be able to count on the proper operation of the condenser unit, it must be cleaned

periodically with a jet of air from inside towards the outside of the unit or with a long-bristle

brush along the outside of the condenser.

Do not damage the refrigerant circuit.

4. Extraordinary Maintenance

✓Extraordinary maintenance requires a qualified and authorized technician.

Before any maintenance, replacement, repair, cleaning, lubricating or other

operation, the equipment must be isolated from electrical power.

XSDC 601-01

5. Installation

Personal safety devices must be

used during this operation.

5.1 Transport

The refrigerator cabinet is shipped on a pallet and

protected by its packaging.

The refrigerator cabinet should always and only be

transported in a vertical position

(indicated Up-Down on the packaging) (see figure).

Installation and start-up must be

performed by qualified and

authorized personnel only.

5.2 Environmental specifications.

When positioning the equipment, keep in mind that its operation is guaranteed only in environmental

conditions with a temperature of +18°C to +43°C.

5.3 Positioning

Check the suitability of the electrical plug installed (SHUKO) according to current national

laws. Replace the plug if not in compliance; the replacement must be done by qualifed

personnel. Check that the mains voltage corresponds with that of the REFRIGERATOR

CABINET as reported on the label. Before positioning the equipment, put on safety clothing

and gloves for moving it since the metal parts could be sharp. Position the product in a

clean, dry and well-ventilated area. The refrigerator is set for operation in environments

where the temperature is between +18°C and +43°C (Tropicalized Compressor) -Climate

Class T -. The equipment should be located far from heat sources and in places with

sufficient ventilation. Do not install the equipment in places where there are explosive

and/or corrosive gases/powders. Make sure the equipment is level and on flooring that is

capable of supporting its weight and in a suitable area based on its dimensions and use.

Make sure the product is not near any heat sources.

Once the refrigerator cabinet is positioned in the intended area,

make sure it is level using the adjustable feet.

Do not locate the REFRIGERATOR CABINET near

heat sources or in areas with elevated temperatures

since this could lower performance and increase

equipment wear. Leave at least 50cm between the

equipment and any upper surface (FIG. 3)

.

Make sure the power cable is not under the

equipment.

XSDC 601-01

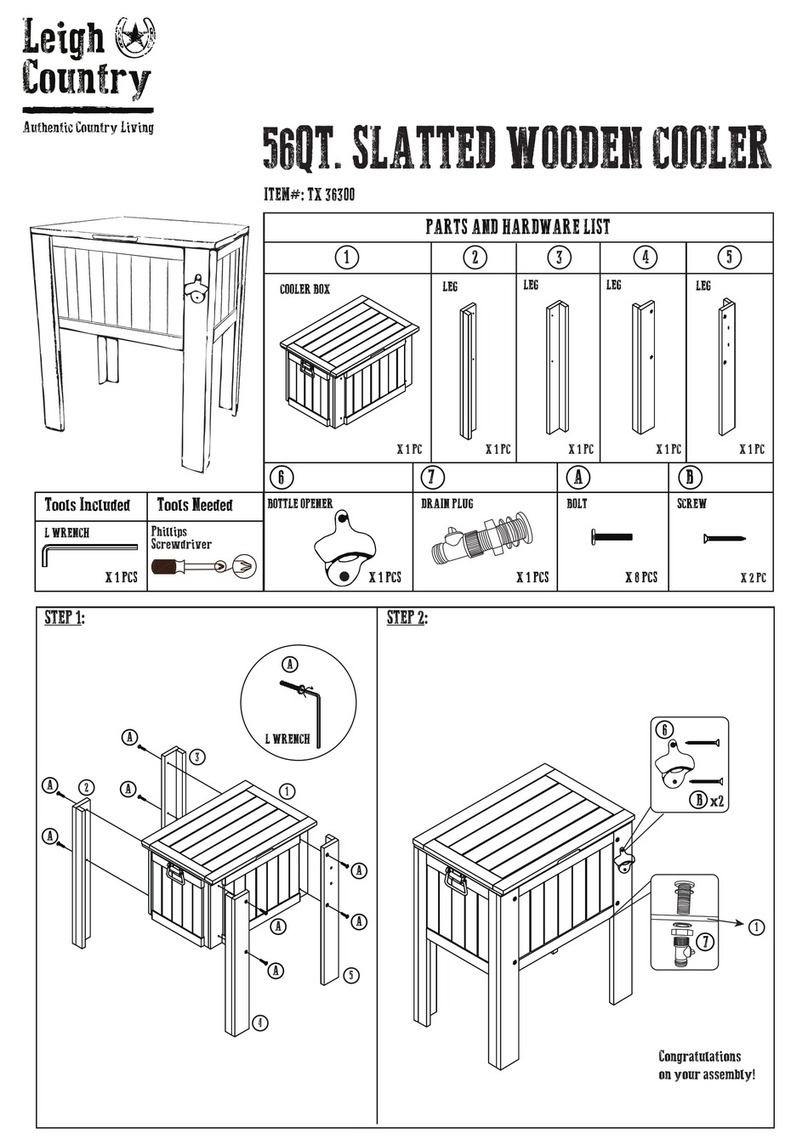

5.4 Space needed for maintenance

When installing the refrigerator cabinet,

enough space must be left around it for

maintenance operations (FIG. 4).

6. Operation

6.1 Preliminary inspection

operations

Wait the necessary time for the

equipment to reach the set temperature

before storing food inside of it. Do not

put hot foods or beverages inside the

refrigerator.

Store the products inside the perimeter

defined by the grills in order to prevent

blocking the flow of air. Do not obstruct

the fan intake area.

Do not obstruct the upper part of the

refrigerator or the air intakes when the

refrigerator cabinet is in operation or

under electrical power.

6.2 Start up

At the first startup, make sure the

refrigerator cabinet was transported only in a vertical position: otherwise wait 8 hours from the

time it was positioned before proceeding with start-up. Turn on the equipment by pressing the

general switch to “I” (FIG. 5, POS. 6).

6.3 Shut-down

To shut down the refrigerated cabinet, just press the main switch to the “0” position (FIG. 5, POS. 6);

the light on the switch will shut off.

To isolate the refrigerator from electrical power, remove the plug from the outlet.

XSDC 601-01

6.4 Defrosting

In order to ensure ideal cooling, the cooling unit requires adequate defrosting. Therefore the device

has an automatic defrosting cycle. This means that the device will automatically start defrosting every

6 hours. Each individual defrosting cycle will take about 30 minutes.

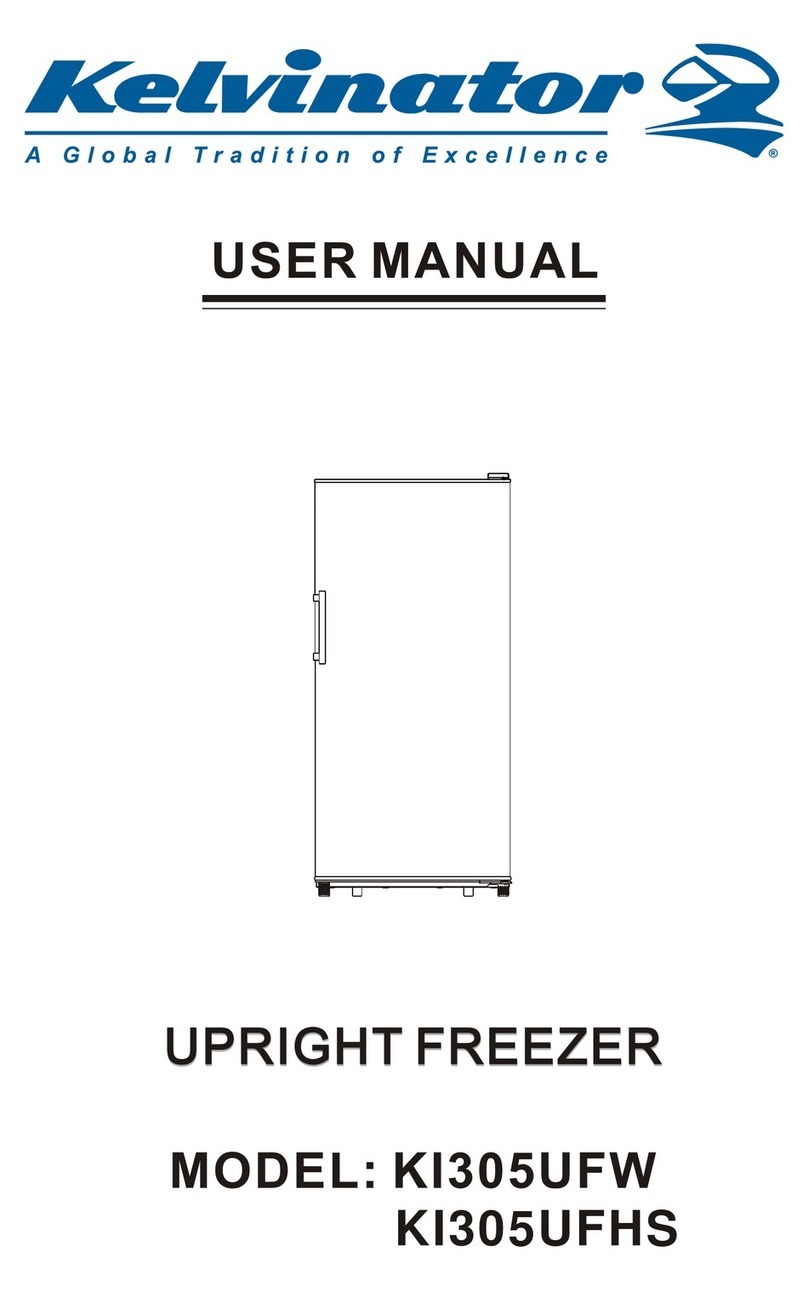

6.5 Front panel description

1 - Key P: Used for setting the setpoint and for

programming the function parameters.

2 - Key DOWN: Used for decreasing the values to be

set and for selecting the parameters.

3 - Key UP: Used for increasing the value to be set,

for selecting parameters and for activating manual

defrosting.

4 - Key U: Used for visualising the temperatures

taken by the cell and evaporator probes (Pr1 and

Pr2).

5 - Led OUT: Indicates the compressor output status on (on), off (off) or inhibited (flashing).

6 - Led DEF: Indicates defrosting in progress (on) or dripping (flashing).

7 - Led FAN: Indicates that the fan is on (on), off (off) or delayed (flashing) after the defrost cycle.

8 - Led SET: Indicates the input in programming mode and the programming level of the parameters.

9 - Stand-By: indicate the Stand-By status.

XSDC 601-01

7. Programming

7.1 Programming of the setpoint

Pressing the key P will show SP alternating with the set value on the display. To change the setpoint,

press the UP key to increase the value or DOWN to decrease it.

These keys increase or decrease the value one digit at the time, but if the button is pressed for more

than one second the value increase or decreases rapidly, and after two seconds pressed, the speed

increases even more to all the desired values to be reached rapidly.

Exiting the setpoint mode is achieved by pressing the Pkey. The display also returns to the normal

function mode when no button is pressed for 15 seconds.

7.2 Programming the parameters

To access the instrument’s function

parameters, press the key Pand keep it

pressed for about 5 seconds, after which the

SET led will light up, the display will visualise

the code that identifies the first group of

parameters (“-SP“) and the group of

parameters that are to be edited are selected

by pressing the UP and DOWN keys. Once the

group of parameters has been selected, press

the P and the code that identifies the first

parameter in the selected group will be

visualised. Again using the UP and DOWN

keys, the desired parameter can be selected and pressing the P key, the display will alternately show

the parameter code and its setting that can be changed with the UP and DOWN keys. Once the

desired value has been set, press the key Pagain: the new value will be memorised and the display

will show only the abbreviation of the selected parameter.Pressing the UP and DOWN keys, it is

possible to select another parameter (if present) and change it as described. To return to select

another group of parameters, keep the UP or the DOWN key pressed for about 1 second, after which

the display will return to showing the code of the parameter group. Release the pressed key and using

the UP and DOWN keys it will be possible to select another group (if present). To exit the

programming mode, do not press any key for about 20 seconds, or keep the Ukey pressed until it

exits the programming mode.

7.2.1 Keyboard lock function

It is also possible to lock the keyboard completely on the display. This function is particularly useful

when the regulator is reachable by the users and it is desired to avoid any modification. To activate

the keyboard lock it’s enough program the par. “Lo” to a different value than oF. The value program

to this parameter is the time (0 to 30 minutes) of inactivity of the keys after which the keyboard will

be locked. Insofar not pressing any key for the time "Lo" the instrument automatically disable the

normal functions of the keys. When the keyboard is locked, if any of the key is pushed, on the display

will appear “Ln” to indicate the active lock. To unlock the keyboard it’s enough to contemporarily

push key P and UP and keep them pushed for 5 sec., afterwhich the label “LF” will appear on the

display and all the keys functions will be available again.

7.2.2 Manual defrosting

To start up a manual defrosting cycle, press the key UP/DEFROST when it is not in programming

mode and keep it pressed for about 5 seconds after which, if the conditions are correct, the led DEF

will light up and the instrument will carry out a defrosting cycle. The defrosting cycle takes 30

minutes.

XSDC 601-01

8. Troubleshooting

Problem

Causes

Solutions

The refrigerator does not

turn on.

The plug is not connected to

the outlet.

Connect the plug to a suitable

outlet.

Malfunction of the general

switch.

Turn off and back on using the

general switch.

The outlet does not supply

power or the voltage is

insufficient.

Adapt the outlet to the refrigerator’s

needs.

The blue indicator light

on the switch is on but

the display is still off.

Malfunction of the display or

transformer.

Contact us at our service portal:

http://service.superdry-totech.com/

Both the blue indicator

light on the switch and

the display show an error

rather than the

temperature.

Malfunction of the room or

evaporator sensor.

Contact us at our service portal:

http://service.superdry-totech.com/

The display is on but the

compressor does not

start.

The refrigerator is already at

the set temperature.

Set a lower temperature.

Motor unit failure.

Contact us at our service portal:

http://service.superdry-totech.com/

The compressor starts

but the refrigerator

doesn’t cool and doesn’t

reach the set

temperature.

Possible lack of refrigerant

gas.

Contact us at our service portal:

http://service.superdry-totech.com/

The set temperature is too

low.*

Set the thermostat to a higher

temperature.

The evaporator is clogged

with ice.

Turn the refrigerator off and wait

for the ice to melt.

The condenser is clogged

with dust or foreign objects.

Thoroughly clean the condenser or

remove the objects.

The room temperature is too

high. **

Move the refrigerator or lower the

room temperature.

* Remember that the maximum/minimum temperatures that can be set by the refrigerator is -2 to

+8°C

** The maximum temperature in the area where the refrigerator is installed must not exceed +43°C.

Above this temperature, proper operation is not guaranteed (not possible to reach the set

temperature).

XSDC 601-01

9. Waste disposal and dismantling

ATTENTION!

Demolition and disposal should be performed by personnel qualified in performing

these operations since they have the proper information and tools for this purpose.

At the end of the product's life cycle, do not dispose of in the environment. The doors must be

removed before disposing of the equipment. Temporary storage of special waste is permitted with the

intention of disposal through final storage and/or treatment. The current laws regarding

environmental protection in the country where used must be followed.

SAFETY FOR THE DISPOSAL OF WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE

DIRECTIVE 2002/96).

Do not dispose of pollutants in the environment. dispose them according to current laws.

XSDC 601-01

10. Warranty and RMA Procedure

10.1 Warranty and liability

Principally, we apply our "General Terms & Conditions", which the operator has been provided with

upon contract conclusion at the latest. Warranty and liability claims in relation to personal injury and

property damage shall be excluded if the same arise from one or more of the causes below:

✓the cabinet’s unintended use;

✓the cabinet’s improper and inappropriate installation, commissioning, operation, and/or

maintenance;

✓operation with defect safety devices or non-functional safety and protective devices;

✓unauthorized modification or unauthorized alteration of the technical design;

✓repair works performed in an inappropriate manner;

✓disaster situations, impact by foreign objects, and events of force majeure.

After purchase we provide warranty on all our new products, unless agreed differently.

10.2 Full Warranty

Valid during the first year after purchase of the new product

All drying cabinets, cooling cabinets, vacuum machines & spare parts (including dry-units).

Full warranty:

The end user will receive the defective part replaced at no costs. The transport costs are to be paid by

the receiving party. The defective part has to be returned after it is replaced with the new one.

Actual replacement is done by the end user with support from Totech technical support if needed.

10.3 Exchange warranty

Valid during the second year after purchase of the new product

Only U-5000 series & U-7000 series.

Exchange warranty:

The end user will receive the defective part at a lower price. The old part will be returned by the end

user to Totech EU as soon as the defective part is replaced with the new one.

Actual replacement is done by the end user with support from Totech technical support if needed.

XSDC 601-01

10.4 Third year warranty

Valid during the third year after purchase of a new product

Only U-5000 series & U-7000 series.

Third year warranty:

Each case will be evaluated by the technical support department, and the Part(s) will be provided

under leniency circumstances. The end user will receive the defective part at an especially quoted

price by Totech EU sales department. The old part will be returned by the end user to Totech EU as

soon as the defective part is replaced with the new one.

Actual replacement is done by the end user with support from Totech technical support if needed.

Please note: all the parts needs to be shipped back to Totech Europe B.V. within 30 days of

receiving the warranty parts. If not, you will be invoiced for the normal price.

10.5 Guidelines for the RMA procedure of Totech Europe B.V.

The RMA form:

Requirement: Microsoft Excel, Email.

You can download the RMA from: http://www.superdry-totech.com/

The purpose of this new RMA form is to make one standard form for all Totech dealers & customers.

Please provide us as much as possible details by filling in the yellow lines to speed up the process.

✓Do not change, rename and/or delete any of the worksheets.

✓Please fill in the, Company name, Address, Zip code, City, Country, Tel. nr., Fax. nr., Contact

person, and Email.

✓Fill in ALL the yellow lines of the Complaint form starting with the first one.

✓When the complaint form is filled in correctly the overview sheet will be filled in automatically.

✓Use the “Save as” function in Excel to rename the form. Send the completely filled in

complaint form to our service portal at http://service.superdry-totech.com/

✓Totech Europe B.V. will only accept the Complaint form send in electronically at this stage.

✓We will provide you the warranty and/or repair parts as soon as possible.

Shipping the parts to Totech Europe B.V.

✓Each part must have its own complaint form attached.

✓All parts must be shipped back in original packaging as much as possible, and ESD safe.

✓Those parts that are returned to Totech EU without any proper packaging will not be accepted

for warranty or repair.

✓Broken or damaged parts due to shipping, or bad packaging, will not be accepted for

warranty.

Send all parts to:

Totech Europe B.V.

To: Technical support department

De linge 28

8253 PJ Dronten

The Netherlands Europe

Totech Europe B.V. will not provide warranty on returned parts when the Complaint form is not filled

in correctly.

XSDC 601-01

11. Serial numbers

11.1 Cabinet serial numbers

Explanation how the serial number of the cabinet is identified:

12. CE Declaration

With this writing, we:

Totech Europe BV

De Linge 28

8253 PJ Dronten

confirm that the cooling cabinet described corresponds with the fundamental

safety and health demands of the following EC instructions:

EN55011: 1998+A1:1999+A2:2002

EN61000-6-2:2001

2006/95/EG

2004/108/EG

Totech Europe B.V.

Gerhard Kurpiela

Table of contents