Totem 10 User manual

TOTEM ENERGY srl

via Ivrea, 70

10098 Rivoli (To) - Italia

+39 0119579211

User’s Guide

TOTEM 10A -TOTEM 20A MICROCOGENERATORS

User’s Guide | TOTEM 10 - TOTEM 20

2 of 30

1.

Declaration of Conformit .................................................................. 3

2.

General Safet Instructions ................................................................ 4

A.

S mbols Used in the Guide .................................................................. 4

B.

Glossar of Terms and Definitions ........................................................ 4

C.

Safet Instructions .............................................................................. 5

D.

Potential Safet Risks .......................................................................... 7

3.

Product Description ........................................................................... 9

A.

General Information ............................................................................ 9

B.

Product ID........................................................................................ 10

C.

Module Main Components .................................................................. 10

D.

TOTEM - La out of Components ......................................................... 14

E.

Safet Instructions ............................................................................ 15

F.

Size and Overall Dimensions .............................................................. 17

G.

Control Switchboard .......................................................................... 18

H.

Connection Panel .............................................................................. 19

I.

Noise Emissions and Vibrations .......................................................... 20

4.

Use of the Micro Cogenerator .......................................................... 20

A.

Preparing the Unit for Use ................................................................. 20

B.

Operator Panel ................................................................................. 21

C.

Starting and Working Principle ........................................................... 23

D.

Operating Conditions ......................................................................... 24

E.

Fuel Characteristics ........................................................................... 24

F.

User S stem’s Water Characteristics ................................................... 25

G.

Emergenc Stop and Shutdown .......................................................... 26

H.

Calendar .......................................................................................... 26

I.

Diagnostics ....................................................................................... 26

5.

Remote Control ............................................................................... 27

A.

Local Area Network Connection .......................................................... 27

B.

Remote Connection ........................................................................... 28

6.

Maintenance ................................................................................... 29

User’s Guide | TOTEM 10 - TOTEM 20

3 of 30

1.

Declaration of Conformit

2.

General Safet

A.

S mbols

B.

Glossar of Terms and Definitions

Machine Operator

specific skills

the operator’s control devices, checking on its proper functioning and reporting an

p

ossible anomal to the Technical Support Service

Qualified

possessing specialist technical expertise in the fields of heating s stems, hot water

production s stems, electrical and electrical energ generating s stems, combustible

gas-

fired plants and ap

engines as well as components thereof. Such professionals must be licensed as

required b the applicable laws in force in the place where the TOTEM® is installed.

Maintenance staff

possessing formall recognized professional skills, trained and authorized b Totem

Energ to carr out maintenance operations on the

Personal

Protective

shall mean the following safet wear and equipment:

PPE must be

starting and maintenance

User’s Guide | TOTEM 10

General Safet

Instructions

S mbols

Used in the Guide

Glossar of Terms and Definitions

Machine Operator

: “Machine Operator” shall mean

an member of

specific skills

who can onl perform simple tasks, namel :

operating the unit b using

the operator’s control devices, checking on its proper functioning and reporting an

ossible anomal to the Technical Support Service

;

Technician: “Qualified Technician”

shall mean a trained professional

possessing specialist technical expertise in the fields of heating s stems, hot water

production s stems, electrical and electrical energ generating s stems, combustible

fired plants and ap

pliances equipped with Otto or Miller

engines as well as components thereof. Such professionals must be licensed as

required b the applicable laws in force in the place where the TOTEM® is installed.

Maintenance staff

: “Maintenance staff”

shall mean a Qualified Technician

possessing formall recognized professional skills, trained and authorized b Totem

Energ to carr out maintenance operations on the

TOTEM®

units

Protective

Equipment PPE): “

personal protective equipment

shall mean the following safet wear and equipment:

hearing protections

(earmuffs or earplugs) for the hearing protection of

workers operating on the TOTEM® unit in operation with the sound

insulation panels removed (which

can be done solel for

troubleshooting or maintenance purposes).

protective gloves and goggles when working with batter acid, gl col

and engine lubricant oil;

safet shoes;

dielectric face shield and gloves when carr ing out operations on

energized electrical parts.

PPE must be

worn b Maintenance staff at all times when

performing

starting and maintenance

activities on the TOTEM®.

[Information]

This s mbol indicates important information related to

the use of the equipment.

[Warning]

This s mbol indicates operating procedures whose

incorrect

performance can seriousl damage the equipment.

[Danger]

This s mbol indicates operating procedures whose incorrect

performance can cause injur or even death.

User’s Guide | TOTEM 10

- TOTEM 20

4 of 30

an member of

staff with no

operating the unit b using

the operator’s control devices, checking on its proper functioning and reporting an

shall mean a trained professional

possessing specialist technical expertise in the fields of heating s stems, hot water

production s stems, electrical and electrical energ generating s stems, combustible

pliances equipped with Otto or Miller

-c cle endothermic

engines as well as components thereof. Such professionals must be licensed as

required b the applicable laws in force in the place where the TOTEM® is installed.

shall mean a Qualified Technician

possessing formall recognized professional skills, trained and authorized b Totem

units

.

personal protective equipment

” (PPE)

(earmuffs or earplugs) for the hearing protection of

workers operating on the TOTEM® unit in operation with the sound

can be done solel for

protective gloves and goggles when working with batter acid, gl col

dielectric face shield and gloves when carr ing out operations on

performing

installation,

This s mbol indicates important information related to

This s mbol indicates operating procedures whose

performance can seriousl damage the equipment.

This s mbol indicates operating procedures whose incorrect

C.

Safet Instructions

If ou smell gas odor:

If ou smell products of combustion:

If ou

Unit:

Installation, calibration and modification of the gas feed

performed b a Qualified Technician abiding b all applicable national and local

standards as well as b the instructions provided in this Guide.

Installation, calibration or

performed b a Qualified Technician abiding b all applicable national and local

standards as well as b the instructions provided in this Guide.

Installation, calibration or

b a Qualified Technician abiding b all applicable national and local standards

as well as b the instructions provided in this Guide.

It is mandator to connect the exhaust gas evacuation line of the appliance to

an exhaust gas

requirements in force in the place where the TOTEM® unit is installed. Failure

to compl with said rule poses a serious risk to human and animal safet .

According to the provisions for use,

installed unit in good condition and to ensure the safe and reliable functioning

User’s Guide | TOTEM 10

Safet Instructions

If ou smell gas odor:

turn our gas suppl valve off;

ventilate the room;

do not operate an electrical device or appliance, including cell phones;

leave the premises and call a Qualified T

echnician or the gas utilit

compan immediatel from a different location. If the are unavailable

or in case of an emergenc , call the loc

al Fire Brigade;

if the room is equipped with a gas leak detection s stem, please report

an possible malfunctioning of said active safet equipment.

If ou smell products of combustion:

turn the appliance off;

ventilate the room;

call a Qualified Technician;

if the room is equipped with a smoke/carbon monoxide detection

s stem, please report an possible malfunctioning of said active safet

equipment.

see water, gl col, oil, or other

fluids’ spills on the floor or near

turn the unit off;

call a Qualified Technician;

shut off the User s stem’s circuits, if

an , e.g. water or gas suppl

Installation, calibration and modification of the gas feed

performed b a Qualified Technician abiding b all applicable national and local

standards as well as b the instructions provided in this Guide.

Installation, calibration or

modification of the electrical s stem must be

performed b a Qualified Technician abiding b all applicable national and local

standards as well as b the instructions provided in this Guide.

Installation, calibration or

modification of the water s st

em must be performed

b a Qualified Technician abiding b all applicable national and local standards

as well as b the instructions provided in this Guide.

It is mandator to connect the exhaust gas evacuation line of the appliance to

an exhaust gas

evacuation duct built in compliance with all applicable legal

requirements in force in the place where the TOTEM® unit is installed. Failure

to compl with said rule poses a serious risk to human and animal safet .

According to the provisions for use,

the user has an obligation to keep the

installed unit in good condition and to ensure the safe and reliable functioning

User’s Guide | TOTEM 10

- TOTEM 20

5 of 30

do not operate an electrical device or appliance, including cell phones;

echnician or the gas utilit

compan immediatel from a different location. If the are unavailable

al Fire Brigade;

if the room is equipped with a gas leak detection s stem, please report

an possible malfunctioning of said active safet equipment.

if the room is equipped with a smoke/carbon monoxide detection

s stem, please report an possible malfunctioning of said active safet

fluids’ spills on the floor or near

the Totem

an , e.g. water or gas suppl

Installation, calibration and modification of the gas feed

s stem must be

performed b a Qualified Technician abiding b all applicable national and local

standards as well as b the instructions provided in this Guide.

modification of the electrical s stem must be

performed b a Qualified Technician abiding b all applicable national and local

standards as well as b the instructions provided in this Guide.

em must be performed

b a Qualified Technician abiding b all applicable national and local standards

It is mandator to connect the exhaust gas evacuation line of the appliance to

evacuation duct built in compliance with all applicable legal

requirements in force in the place where the TOTEM® unit is installed. Failure

to compl with said rule poses a serious risk to human and animal safet .

the user has an obligation to keep the

installed unit in good condition and to ensure the safe and reliable functioning

of the micro cogenerator and o

relevant activities performed b Qualified Technicians.

The

user has an obligation to have the appliance maintained b a Qualified

Technician in accordance with the provisions of this Guide and ensuring

compliance with all applicable domestic and International standards.

TOTEM ENERGY

animals that ma arise from incorrect installation or bad maintenance.

Before switching the unit on, alwa s ensure that all protective panels and

guards have been properl mounted to avoid risks to the safet of personne

Do not obstruct,

Do not use or store an

flam

mable materials in the same room

installed.

When

installed.

The micro cogenerator, an

for its

detectors, pane

room etc.) must not be tampered with, modi

reason

ma

damage, including

This booklet is an integral and fundamental part of the micro cogenerator and

it must be carefull kept b the user for future reference. In the event of a

change of ownership of the micro cogenerator or of the premises where it is

in

stalled, please ensure that this booklet is handed over to the new user.

This booklet contains up

issued, without prejudice to possible amendments or technical updates.

Since our products are const

pictures, process descriptions and technical data.

If ou wish to request the most updated version of this document, to suggest

improvements or report an discrepanc , please contact the compan .

This mi

designed for, namel , the combined production of:

User’s Guide | TOTEM 10

of the micro cogenerator and o

f all s stems connected thereto, having the

relevant activities performed b Qualified Technicians.

user has an obligation to have the appliance maintained b a Qualified

Technician in accordance with the provisions of this Guide and ensuring

compliance with all applicable domestic and International standards.

TOTEM ENERGY

shall not be held liable for

an damage to people, things or

animals that ma arise from incorrect installation or bad maintenance.

Before switching the unit on, alwa s ensure that all protective panels and

guards have been properl mounted to avoid risks to the safet of personne

Do not obstruct,

not

even partiall , the suction duct and exhaust pipe ends.

Do not use or store an

hazardous materials, such as

explosive, combustible or

mable materials in the same room

where the micro cogenerator is

installed.

When

the unit

is in operation, do not sta in the room

installed.

The micro cogenerator, an

auxiliar components

thereof, the s stems

for its

functioning (GAS, water, power, shut-

off devices, firefighting

detectors, pane

ls, switchboards, components of the Totem Unit’s

room etc.) must not be tampered with, modi

fied or otherwise

reason

whatsoever. Failure to compl with this provision

ma cause injuries or

damage, including

severel , people, animals or things.

This booklet is an integral and fundamental part of the micro cogenerator and

it must be carefull kept b the user for future reference. In the event of a

change of ownership of the micro cogenerator or of the premises where it is

stalled, please ensure that this booklet is handed over to the new user.

This booklet contains up

-to-

date information referring to the date it has been

issued, without prejudice to possible amendments or technical updates.

Since our products are const

antl updated, slight differences ma be found in

pictures, process descriptions and technical data.

If ou wish to request the most updated version of this document, to suggest

improvements or report an discrepanc , please contact the compan .

This mi

cro cogenerator must be used solel for the purpose it was expressl

designed for, namel , the combined production of:

hot water in domestic and/or industrial closed-

circuit water s stems;

low voltage (400 V

olts) power for net metering, feed

self consumption.

User’s Guide | TOTEM 10

- TOTEM 20

6 of 30

f all s stems connected thereto, having the

user has an obligation to have the appliance maintained b a Qualified

Technician in accordance with the provisions of this Guide and ensuring

compliance with all applicable domestic and International standards.

an damage to people, things or

animals that ma arise from incorrect installation or bad maintenance.

Before switching the unit on, alwa s ensure that all protective panels and

guards have been properl mounted to avoid risks to the safet of personne

l.

even partiall , the suction duct and exhaust pipe ends.

explosive, combustible or

where the micro cogenerator is

is in operation, do not sta in the room

where the unit is

thereof, the s stems

needed

off devices, firefighting

equipment,

ls, switchboards, components of the Totem Unit’s

equipment

fied or otherwise

altered for an

ma cause injuries or

This booklet is an integral and fundamental part of the micro cogenerator and

it must be carefull kept b the user for future reference. In the event of a

change of ownership of the micro cogenerator or of the premises where it is

stalled, please ensure that this booklet is handed over to the new user.

date information referring to the date it has been

issued, without prejudice to possible amendments or technical updates.

antl updated, slight differences ma be found in

If ou wish to request the most updated version of this document, to suggest

improvements or report an discrepanc , please contact the compan .

cro cogenerator must be used solel for the purpose it was expressl

circuit water s stems;

olts) power for net metering, feed

-in to the grid or

TOTEM ENERGY

for an damages arising from the incorrect installation or use of the unit and, in

an case

instructions or with all applicable national and local laws.

D.

Potential

Risk

related to Mechanical

Injuries from mechanical

guards protecting the micro cogenerator’s moving parts

Said activities must,

specificall for said purpose and wearing the appropri

Risk related to Electrical Hazards

Electrical injuries can occur when safet devices are removed from the s stem,

the

control

Moreover, modifications of the existing

hazards if

performed b unauthorized

Said activities must,

specificall for said purpose and wearing the appropriate PPE.

Risk related to Thermal Hazards

During regular functi

high temperatures.

with frame panels properl mounted, thus preventing access to hot components.

Onl

authorized

Risk related to Noise Hazards

In regular op

the frame’s heat

emissions.

Risk

related to Vibration Hazards

The TOTEM® unit is fitted with suitabl sized anti

vibration transmission to the structures and installations connected thereto.

The removal

exhaust fumes line and the heating

Risk related to Electromagnetic Radiation/Waves Hazards

The TOTEM

to

electromagnetic

as nchronous generator can cause disturbances temporaril affecting the functioning

of electro-

medical

in close proximit to it.

Risk related to Contact with Hazardous Materials and Substances

On the inside, the TOTEM® module contains chemicals that are essential

proper functioning.

User’s Guide | TOTEM 10

TOTEM ENERGY

shall bear no liabilit -

either contractual or extra

for an damages arising from the incorrect installation or use of the unit and, in

an case

whatsoever

, from failure to compl with the manufacturer’s

instructions or with all applicable national and local laws.

Potential

Safet Risks

related to Mechanical

Hazards

Injuries from mechanical

hazards

can occur when the safet devices

guards protecting the micro cogenerator’s moving parts

-

are removed

Said activities must,

therefore, be performed sole

l b the Maintenance

specificall for said purpose and wearing the appropri

ate PPE.

Risk related to Electrical Hazards

Electrical injuries can occur when safet devices are removed from the s stem,

control

switchboard, or from the ignition s stem.

Moreover, modifications of the existing

power suppl s stem

performed b unauthorized

personnel.

Said activities must,

therefore, be performed solel b

Maintenance staff

specificall for said purpose and wearing the appropriate PPE.

Risk related to Thermal Hazards

During regular functi

oning, some of the TOTEM®’s inner components

high temperatures.

The entire appliance must, therefore, work under safe conditions

with frame panels properl mounted, thus preventing access to hot components.

authorized

Maintenance staff are authorized to remove the

unit’s panels.

Risk related to Noise Hazards

In regular op

eration, the whole TOTEM® unit

must work under safe conditions with

the frame’s heat

-insulation panels properl mount

ed, which lowers the Unit’s noise

related to Vibration Hazards

The TOTEM® unit is fitted with suitabl sized anti

-

vibration mounts to reduce

vibration transmission to the structures and installations connected thereto.

The removal

of anti-vibration fittings from connec

tions with the gas

exhaust fumes line and the heating

s stem is strictl forbidden.

Risk related to Electromagnetic Radiation/Waves Hazards

The TOTEM

unit complies with Directive

2004/108/EC

electromagnetic

compatibilit . However, the electroma

gnetic fields from the

as nchronous generator can cause disturbances temporaril affecting the functioning

medical

devices such as, for example,

pacemakers or hearing aids located

in close proximit to it.

Risk related to Contact with Hazardous Materials and Substances

On the inside, the TOTEM® module contains chemicals that are essential

proper functioning.

User’s Guide | TOTEM 10

- TOTEM 20

7 of 30

either contractual or extra

-contractual –

for an damages arising from the incorrect installation or use of the unit and, in

, from failure to compl with the manufacturer’s

can occur when the safet devices

- panels or

are removed

.

l b the Maintenance

staff trained

Electrical injuries can occur when safet devices are removed from the s stem,

from

ma cause serious

Maintenance staff

trained

oning, some of the TOTEM®’s inner components

ma reach

The entire appliance must, therefore, work under safe conditions

with frame panels properl mounted, thus preventing access to hot components.

unit’s panels.

must work under safe conditions with

ed, which lowers the Unit’s noise

vibration mounts to reduce

vibration transmission to the structures and installations connected thereto.

tions with the gas

suppl grid, the

2004/108/EC

relating

gnetic fields from the

as nchronous generator can cause disturbances temporaril affecting the functioning

pacemakers or hearing aids located

Risk related to Contact with Hazardous Materials and Substances

On the inside, the TOTEM® module contains chemicals that are essential

to its

User’s Guide | TOTEM 10 - TOTEM 20

8 of 30

Namel , it contains substances such as batter acid, fresh/spent lube oil and gl col-

water mixtures.

In the presence of spills outside the TOTEM® unit, an direct contact of these

substances with skin and e es must be avoided at all times.

In the event that ou come into contact with these chemicals, ou must thoroughl

wash the affected bod parts and seek medical advice if necessar , bringing the

relevant Product Safet Data Sheet with ou. Said substances ma even be hot and

cause skin burns.

When in operation, the TOTEM module also produces a constant flow of exhaust

fumes.

In the event of exhaust fumes build-up or leaks from the exhaust gas evacuation

s stem, leave the area immediatel and switch off the module if possible.

Based on the standards in force in the TOTEM®’s place of installation, ou ma also

be required to install a CO/CH

4

gas detector in the module’s room.

The TOTEM alread has an incorporated CH

4

leak detector. Please contact our

Technical Support Service for the detector’s periodic calibration.

Risk related to Slip, Trip and Fall Hazards

Following breakdown or malfunctioning, lubricant oil, water-gl col fluids or batter

acid leaks ma occur, making the floor slipper thus creating a risk for falls.

Said spills must be readil contained and whenever possible disposed of according to

the relevant laws in force.

Risk related to Emergenc stop/Emergenc shutdown

The TOTEM® module is designed to stop immediatel following the activation of one

or more external safet devices connected to it.

Risk related to Power Suppl Interruption

The TOTEM® is designed to enable an immediate safe stop function in the event of

an interruption of the mains power suppl . A suitable interface protection device –

not supplied b TOTEM ENERGY - approved based on the applicable standards in the

module’s place of installation can implement the module’s disconnection from power

suppl whenever the standards of applicable regulations are not met.

Risk related to Control Switchboard malfunction/failure

The TOTEM® module is designed to enable an immediate safe stop in case of

control switchboard malfunction or failure.

Risk from Breakdown during Regular Operation

If kept intact, used for the purpose it was designed for ensuring compliance with the

technical parameters set b TOTEM ENERGY as well as properl maintained, the

TOTEM® is designed to work under conditions that are full safe for machine

operators and s stems connected to it.

Hazards from Use in Environments at Risk of Fire/Explosion - EX

The TOTEM® is not intended for use in environments at risk of fire or explosion (Ex).

Do not keep or store materials that ma increase the risk of explosion or fire in the

room where the TOTEM® is installed.

User’s Guide | TOTEM 10 - TOTEM 20

9 of 30

3.

Product Description

A.

General Information

This User’s Guide is intended to provide the necessar information for the use of

TOTEM units. TOTEM micro cogeneration units are appliances that allow for the

combined production of electricit and heat at the user’s site, thus optimizing the use

of the fuel’s primar energ and reducing grid distribution and separate generation

losses.

CHP units, indeed, can be easil integrated into an technological environment,

enabling fulfillment of the heating requirements of different users in a variet of

sectors:

hospitalit ;

wellbeing;

catering;

health-care;

housing;

public;

agri-food;

distribution chains.

Using a micro cogeneration unit allows to achieve significant economic savings and

environmental benefits.

The unit consists of an endothermic engine originall devised for the automotive

industr , coupled to an as nchronous generator.

The heat produced in the endothermic engine’s combustion process is almost full

recovered b means of a high-efficienc heat exchangers s stem and made available

to users as hot water.

Thanks to its modern propellers manufactured b FCA, speciall engineered to run on

gas and optimized to work under stead -state, the unit allows for optimized

performance and longer maintenance intervals. Moreover, its modern Euro 6

technolog enables a significant reduction of nitrogen oxides - NO

x

- and carbon

monoxide - CO - emissions as compared to conventional condensing boilers.

TOTEM® units’ compact size and versatilit allows installation in tight equipment

rooms and their use on existing premises, including with environmental or

architectural constraints.

Its control s stems allow to monitor and log data for power and heating load profiles,

including remotel . Moreover, it enables service staff to monitor an alarm signal

detected thus enabling emergenc service in case of breakdown or malfunctioning.

User’s Guide | TOTEM 10 - TOTEM 20

10 of 30

B.

Product ID

Each TOTEM® micro cogeneration unit is fitted with a special plate providing all

details for its identification.

C.

Module Main Components

Ever TOTEM® module is the result of painstaking engineering research and

selected technological solutions combining high qualit materials from specialist

suppliers. A detailed description of the module’s main components is provided in the

following sections.

-Endothermic Engine

FCA Fire 1.4 51 kW Bifuel Euro 6, four stroke, Otto c cle endothermic engine, fuel

feeding s stem fitted with a Venturi and throttle for fuel injection adjustment; fuel

injection is governed b a stepper motor.

Engine speed for the TOTEM® module 10 is set at 1,500 revs/minute.

Engine speed for the TOTEM® module 20 is set at 3,000 revs/minute.

Displacement cm

3

1368

Maximum shaft power kW 51

Maximum Output Torque 104 Nm@3250 RPM

Arrangement / Number of C linders L-NA / 4

Vlaves per c linder 2

User’s Guide | TOTEM 10 - TOTEM 20

11 of 30

Compression ratio 11 : 1

Oil Pressure at 1,500 revs bar > 1.8

Oil Pressure at 3,000 revs bar > 3.5

Crankcase Cast Iron

C linder head Steel

Engine weight kg 88

-Asynchronous Generator

TOTEM 10 ASYNCHRONOUS GENERATOR - TECHNICAL FEATURES

Rated power kW 12

Electric power output kW 10

Pole number 4 - 1500 RPM

Rotor Squirrel cage

Cooling s stem Liquid

T pe of cooling fluid water + gl col (max 30%)

Cooling circuit max pressure bar 3

Coolant max flow rate l/h 4000

Max pressure drop with max flow rate bar 0.5

Coolant temp. range °C 30 - 75

H draulic In/Out threading/coupling size inch 1"

Installation environment temp. range °C -20°C +60

Mechanical Design B3/B5 (foot and flange mounting)

Direction of axis horizontal

Terminal box position

On top, with cable exit holes on

the back

Effiienc 92.7 (Efficienc class: IE3)

Power suppl - Voltage - Frequenc Three-phase - 400V - 50 Hz

Insulation/Dut class H/S1 – continuous dut

Rated power factor >0.81

Winding connection Delta/W e 400/690 V

Height of axis mm 160

Shaft diameter mm 42

Length mm 620 (shaft excluded)

Shaft length mm 110

TOTEM 20 ASYNCHRONOUS GENERATOR - TECHNICAL FEATURES

Rated power kW 22

Electric power output kW 20

Pole number 2 - 3000 RPM

Rotor Squirrel cage

Brushless

Cooling s stem Liquid

T pe of cooling fluid water + gl col (max 30%)

Cooling circuit max pressure bar 3

User’s Guide | TOTEM 10 - TOTEM 20

12 of 30

Coolant max flow rate l/h 4000

Max pressure drop with max flow rate bar 0.5

Coolant temp. range °C 30 - 75

H draulic In/Out threading/coupling size Inch 1"

Installation environment temp. range °C -20°C +60

Mechanical Design B3/B5 (foot and flange mounting)

Direction of axis horizontal

Terminal box position

On top, with cable exit holes on

the back

Effiienc 92.7 (Efficienc class: IE3)

Power suppl - Voltage - Frequenc Three-phase- 400V - 50 Hz

Insulation/Dut class H/S1 – continuous dut

Rated power factor >0.81

Winding connection Delta/W e 400/690 V

Height of axis mm 160

Shaft diameter mm 42

Length mm 620 (shaft excluded)

Shaft length mm 110

Compliance with standards:

2006/42/EC Machiner Directive;

2006/95/EC Low Voltage Directive;

2004/108/EC EMC Directive;

IEC EN 60034;

1997/23/EC Directive.

-Heat Recovery System

The TOTEM® unit is equipped with a high performance in-built heat exchange

s stem that can recover heat energ from the gen set, the engine water and oil

circuits, and exhaust fumes. The s stem does not include an heat dissipator device,

therefore, it is onl activated following heat demand.

Heat is recovered b means of the following equipment:

As nchronous generator: the heat recover s stem is incorporated in

the gen set canop . Please see the generator features section.

Engine Oil: AISI 316L stainless steel water/oil brazed plate heat

exchanger

Engine water: AISI 304 stainless steel brazed plate heat exchanger

Exhaust gases: AISI 304 stainless steel water/fumes tube bundle heat

exchanger.

The engine water circuit is governed b a high-efficienc circulator pump having the

following technical features:

Power suppl V 230

Frequenc Hz 50

Max. current A < 2

User’s Guide | TOTEM 10 - TOTEM 20

13 of 30

Minimum inlet pressure 0.1 bar with fluid at 95°C

Fluid temperature °C -10 to + 95

Protection grade

IP X2D

Insulation class H

Equipment class I

The TOTEM’s internal circuit size, flow rates, temperature deltas and circuit pressure

values have been carefull calculated and set upon design.

-Exhaust Treatment and Discharge Line

Exhaust gases from the endothermic engine are conve ed along the treatment and

cooling line before being expelled. The exhaust discharge line comprises a 4-1

manifold, a coaxial exchanger, a three-wa catal st, a tube bundle exchanger for

heat recover and an in-built silencer.

The 4-1 manifold conve s exhaust gases from the 4 engine c linders into the

exhaust duct. It is equipped with a lambda sensor for injected mass control as well

as with a sensor checking gas temperature right at the engine outlet.

The manifold is efficientl insulated so as to minimize heat dispersion along this

section. Gases then go through the coaxial heat exchanger where a first cooling

stage takes place, after which the are sent to the three-wa catal st where

emissions are lowered. The ceramic substrate catal st simultaneousl reduces CO,

NO

x

and HC emissions. It is fitted with a sensor at the inlet to check the right

operating temperature for the catal st, plus a lambda sensor downstream for a

second level titration control. The catal st is thermall insulated, too. The gases

leaving the catal st reach the tube bundle exchanger where the are cooled down

until condensation occurs (T<70°C).

Before being discharged, gases go through an exhaust gas silencer, specificall

devised to lower the noise emissions from the micro-cogenerator for the given rev

number.

-Electrical and Control Switchboard

The Electrical Switchboard complies with current applicable standards and it contains

all the electrical safet devices as well as all control devices governing the unit’s

functioning.

The TOTEM is governed b 3 control units:

ECU (Engine Control Unit): manufactured b Magneti Marelli, it governs

control of the endothermic engine. The control unit is set to work under

stead state conditions and it interfaces through CANbus s stem with

the MCU. It is located inside the unit’s enclosure;

MCU (Machine Control Unit) “Ar a”: developed to fit specific TOTEM

ENERGY requirements, it governs the control and operation of the

TOTEM® unit through an interface with the ECU via CANbus and with

the Gatewa via Modbus protocol. Also, it is connected to a multi-

function multimeter that conforms to a 0.5s accurac class in

compliance with IEC 62053-22 standards. It is located inside the unit’s

enclosure.

User’s Guide | TOTEM 10 - TOTEM 20

14 of 30

Gatewa : unit for data communication to external networks. It governs

control of the HMI (Human-Machine Interface), data transmission to

the Operator Panel consisting of a 7’’ LCD touchscreen monitor, the in

Cloud remote control platform and to external SCADAs, if an . It

communicates via LAN, Wi-Fi and GSM according to modBus TCP

standards. It is found inside the Electrical Switchboard.

-Frame and Panels

Frame with self-supporting base, made of press-bent steel panels. Panels are

powder-coated with pol ester-based coating.

D.

TOTEM - La out of Components

1. Enclosure air vent

2. ARYA control unit

3. Water cooled s nchronous generator

4. Engine water circulator pump

5. Spent oil tank

6. Thermostatic valve

7. Water to water plate heat exchanger

8. Condensate collector tra

9. FIAT FIRE endothermic engine

10. Zero governor valve

11. Water tra

12. Methane gas safet detector

1

2

5

3

4

11

12

6

9

10

8

7

User’s Guide | TOTEM 10 - TOTEM 20

15 of 30

13. Engine air filter

14. Safet frame structure temperature sensor

15. Exhaust silencer

16. Exhaust manifold

17. Oil filter

18. Fumes to water tube bundle heat exchanger

19. Water to oil plate heat exchanger

20. Marelli three-wa catal st

21. Water to fumes coaxial heat exchanger

22. Fresh oil tank

23. Marelli ECU

24. Engine air suction snorkel

E.

Safet Instructions

The TOTEM is equipped with EN ISO 13849 compliant safet s stems so as to

protect machine operators and maintenance staff against hazards linked to the

micro-cogenerator operation.

Risk anal sis has identified the following hazards:

Exhaust gas emissions

Lack of water flow

Spark advanced with temperature increase

Methane gas leak

The s stem is composed of a chain of safet sensors: an electromechanical

thermostat, a methane gas sensor, and an emergenc pushbutton.

Methane gas leakage hazard

The TOTEM is fitted with a catal thic methane gas sensor for gas leaks. The sensor

features a two-threshold calibration that trigger safet s stem activation when gas

leaks are detected inside the unit’s enclosure. The first threshold value is set to 20%

of LEL. Values exceeding threshold are sent to the ARYA PLC that will command the

13

14

17

15

16

23

24

18

21

22

20

19

User’s Guide | TOTEM 10 - TOTEM 20

16 of 30

unit to turn off thus restoring safet conditions. The second threshold value is set to

50% of LEL, exceeding of this values is reported directl to the safet rela that is

actuated even in the event of PLC malfunctioning, closing the gas suppl valve and

turning the unit off.The electrical switchboard terminal block includes a contact for

connection to the natural gas solenoid of the central heating s stem. In the event of

a gas leak, the rela opens this circuit, too, b commanding valve closure.

Exhaust Gas Emission Hazard, Lack of Water Flow Hazard, Timing variation

Hazard

The above mentioned occurrences can pose a danger b causing an increase in

temperature which ma cause some of the unit’s parts to become hot thus putting

the operator at risk of burns, or b causing a discharge of exhaust gases that

upstream of the catal st feature a high carbon monoxide content.

These anomalies can be detected b a safet thermostat fitted inside the unit’s

enclosure and calibrated to actuate the emergenc rela upon reaching 75°C, which

willl switch the unit off. This is a certified s stem guaranteeing high reliabilit even in

the event of a failure of all other control s stems fitted onto the TOTEM.

Emergency Pushbutton

The Operator Panel features an emergenc pushbutton that can be pressed in the

event of an risk situation. The emergenc pushbutton actuates the emergenc rela

that will switch the micro cogenerator off thus restoring safet .

In order to ensure proper functioning of the safet devices and, consequentl ,

Totem’s operation under full safe conditions, the following requirements must

mandatoril be met upon installation:

-The central heating s stem solenoid must be connected to the speciall

devised terminal block located on the TOTEM electrical switchboard;

-Proper room ventilation – at least 600 m

3

/h must be ensured or,

alternativel , enough windows must be provided in the room so as to

ensure an equivalent ventilation rate according to volumes, or a CO sensor

must be installed in the central heating s stem.

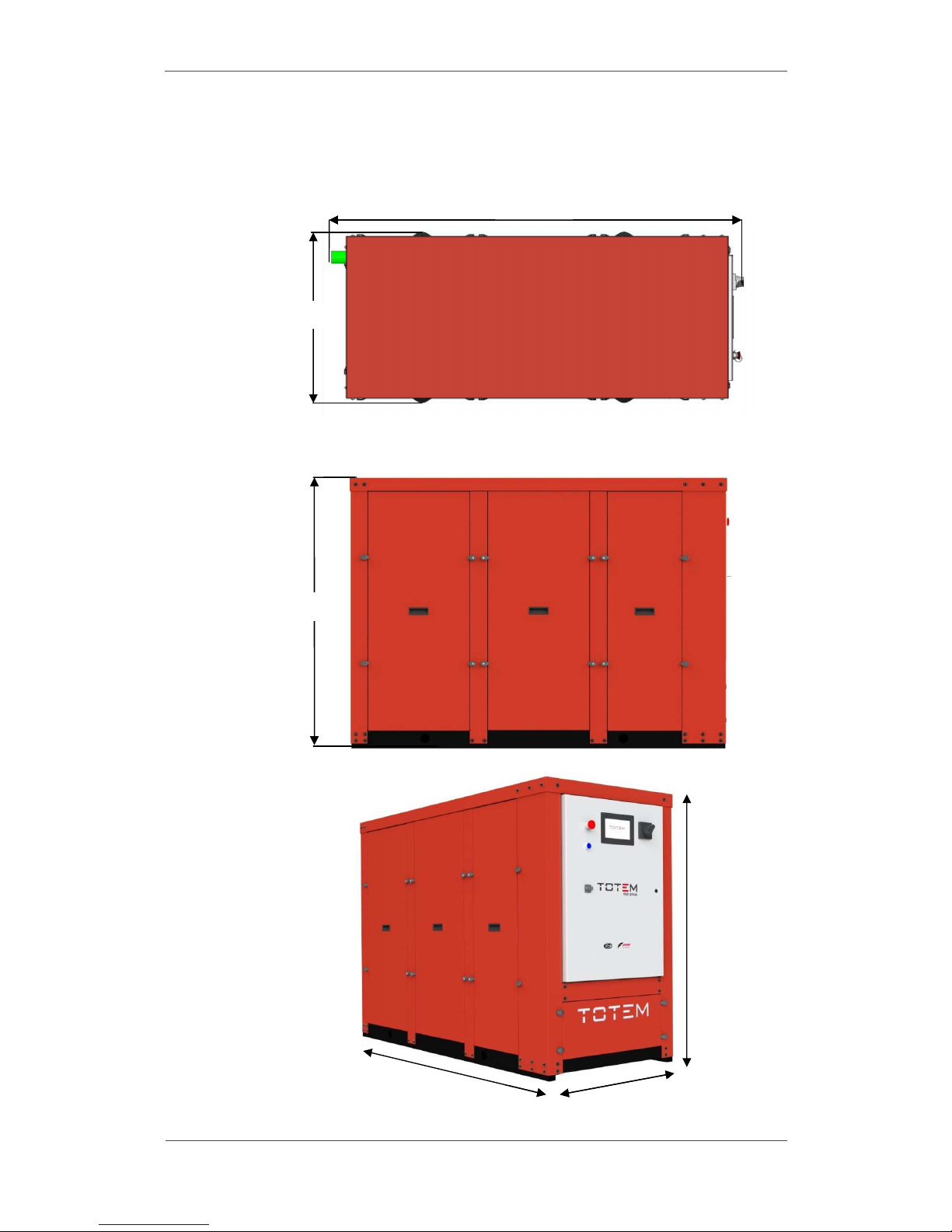

F.

Size and

770 mm

1.280 mm

User’s Guide | TOTEM 10

Size and

Overall Dimensions

1,810 mm

1,810 mm

770 mm

User’s Guide | TOTEM 10

- TOTEM 20

17 of 30

1.

280

mm

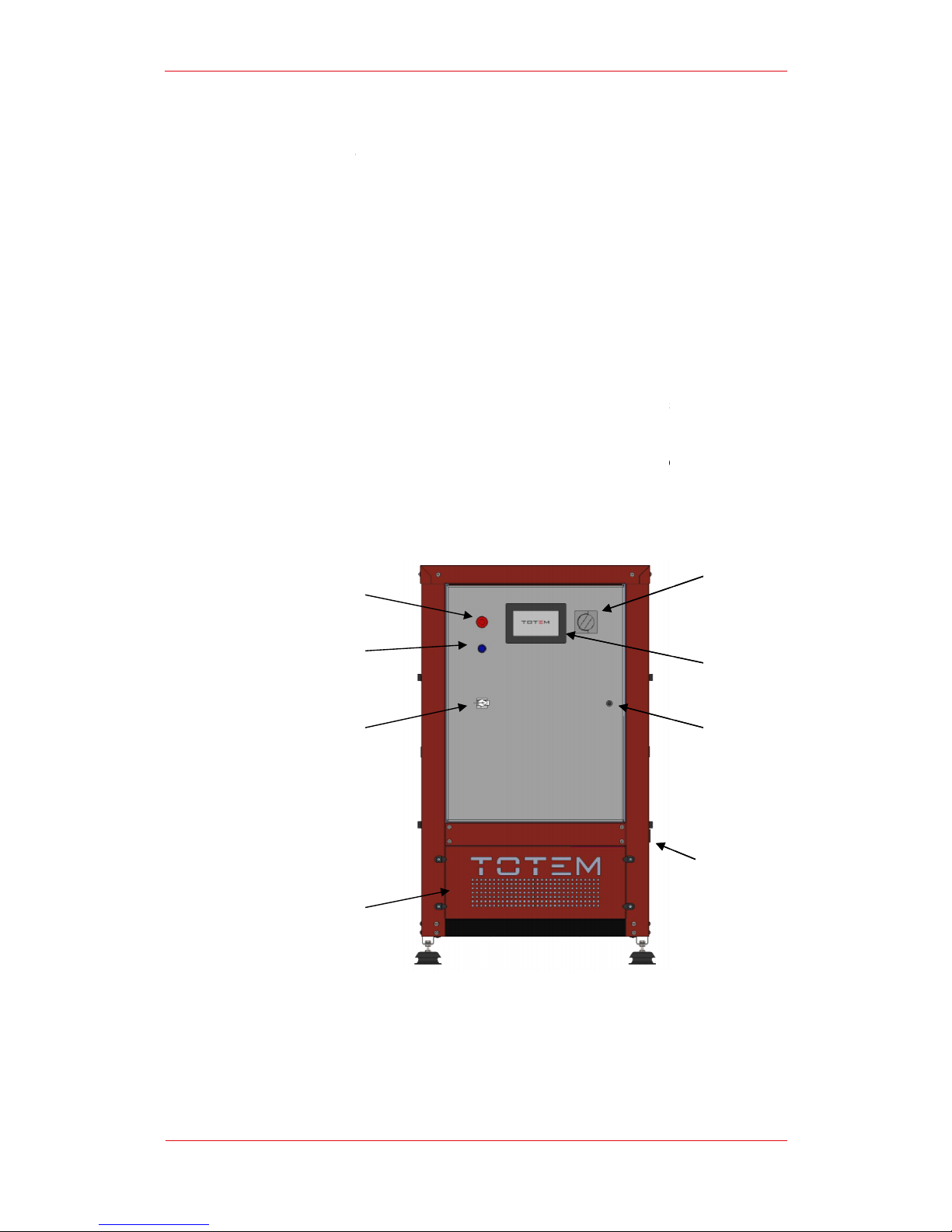

G.

Control Switchb

Machine Operators can operate the machine solel b using the controls available on

the control

remains strictl forbidden due to the presence of energized and hot parts.

The Control switchb

G

E

C

B

User’s Guide | TOTEM 10

Control Switchb

oard

Machine Operators can operate the machine solel b using the controls available on

the control

switchboard; acces

s to the inside of the Control switch

remains strictl forbidden due to the presence of energized and hot parts.

The Control switchb

oard features the following control devices:

Main Switch (A): b operating the Main Switch

, an so

suppl is interrupted and the unit i

s disconnected from the power grid

Emergenc pushbutton (B):

in the event of an emergenc , the unit can

be switched off b pressing the emergenc pushbutton;

Emergenc rela manual reset pushbutton (C):

if the unit is switched

off b means of the emergenc pushbutton or following activation of

one of the alarms along the safet chain (high temperature or methane

leak) , the emergenc rela must be manuall reset b pressing the

reset button before restarting the unit;

Operator Panel (D): it consists of a LCD

7” touchscreen

displa s all the unit’s operating info and enabling operators to enter all

relevant commands;

LAN connection (E): the LAN port enables con

nection to other devices

providing access the operator panel.

A: Main Switch

B: Emergenc Pushbutton

C: Emergenc Rela Manual Reset Button

D: Operator Panel

E: LAN connection

User’s Guide | TOTEM 10

- TOTEM 20

18 of 30

Machine Operators can operate the machine solel b using the controls available on

s to the inside of the Control switch

oard cabinet

remains strictl forbidden due to the presence of energized and hot parts.

, an so

urce of power

s disconnected from the power grid

;

in the event of an emergenc , the unit can

be switched off b pressing the emergenc pushbutton;

if the unit is switched

off b means of the emergenc pushbutton or following activation of

one of the alarms along the safet chain (high temperature or methane

leak) , the emergenc rela must be manuall reset b pressing the

7” touchscreen

monitor that

displa s all the unit’s operating info and enabling operators to enter all

nection to other devices

H

F

D

A

The Electrical Board and Air intake compartment can be opened with a special ke

solel b authorized personnel.

H.

Connection

All process connec

side,

opposite to the Control Switchb

The c

onnection

In

a standard configuration, process connections must fulfill the following

requirements:

A

: Fumes discharge

B:

Fuel gas suppl (natural gas

C:

User water outlet

D: User water inlet

E: Condensate drain

A

B

C

D

E

User’s Guide | TOTEM 10

F: Control switchboard lock

G: Air intake compartment

H: Power cable entr

The Electrical Board and Air intake compartment can be opened with a special ke

solel b authorized personnel.

Connection

Panel

All process connec

tions are located on one of the vertical members of the unit’s back

opposite to the Control Switchb

oard.

onnection

s’ position is shown in figure.

a standard configuration, process connections must fulfill the following

requirements:

Fumes discharge :2” GTAS female

Natural gas connection: ¾” GAS female

User Water outlet: 1” ¼ GAS female

User Water inlet : 1” ¼ GAS female

Condensate Drain: ¾” GAS female

: Fumes discharge

Fuel gas suppl (natural gas

)

User water outlet

D: User water inlet

E: Condensate drain

A

B

C

D

E

User’s Guide | TOTEM 10

- TOTEM 20

19 of 30

The Electrical Board and Air intake compartment can be opened with a special ke

tions are located on one of the vertical members of the unit’s back

a standard configuration, process connections must fulfill the following

User’s Guide | TOTEM 10 - TOTEM 20

20 of 30

I.

Noise Emissions and Vibrations

Thanks to its high-qualit technical solutions and its high-performing sound insulation

materials, the TOTEM® units feature low noise emissions.

The data shown in the technical datasheet are measured at 1 m distance, free-field,

as per standards.

Despite its carefull selected sound-insulating, vibration-damping materials, when in

operation the TOTEM® unit can generate small vibrations that ma in some cases be

transferred to surrounding structures.

For extremel sound sensitive applications, additional solutions ma be necessar to

further reduce noise and vibrations.

4.

Use of the Micro Cogenerator

A.

Preparing the Unit for Use

Before starting the unit, ensure that all connections described in the Installation

Guide have been performed correctl .

All installation procedures must be performed solel b Qualified Technicians.

A description of said procedures is provided in the Installation Guide.

In all cases, commissioning must be performed solel b authorized Totem Energ

personnel b calling the Technical Support Service. Carr ing out commissioning

without the supervision of Totem Energ authorized personnel will nullif the

warrant .

In the event that the unit has to be restarted after prolonged inactivit , we

recommend calling the Technical Support Service.

Once all connections to the User s stems have been checked, it is possible to

operate the Main Switch thus powering the Electrical Board and switching the

Touchscreen Operator Panel on. the Panel’s displa will become operational after a

few minutes.

TOTEM units use air for combustion. The proper amount of air for recirculation in the

room - 600 m

3

/hour - must also be provided through suitabl sized openings in the

building envelope. Such airflow inlets must not interfere with pre-existing openings, if

an , created for other devices or heat generators.

To ensure the unit’s proper functioning, the ambient operating temperature must

range between 1°C and 40°C.

For applications with ambient temperatures that ma , even occasionall , be equal to

or lower than 0°C, it is mandator to treat the user s stem’s water properl and add

an anti-freeze solution in suitable concentration.

For applications in areas with ambient temperatures that ma , even occasionall , get

lower than -15°C, it is mandator to properl treat the micro cogenerator’s internal

circuit coolant, too. Please contact TOTEM ENERGY’s Technical Support Service.

This manual suits for next models

1

Table of contents

Popular Inverter manuals by other brands

LG

LG LGXXXN1T-V5 installation manual

Status

Status SEM1600T User instructions

Cherokee

Cherokee TS-300 user manual

Sinexcel

Sinexcel PWS2-30K-NA user manual

Generac Power Systems

Generac Power Systems 004090-2, 004091-2, 004092-2, 004093-2, 004094-2, 004095-2, 004096-2, 004097-2, 004474-0, 004124-1, 004125-1, 004126-1... owner's manual

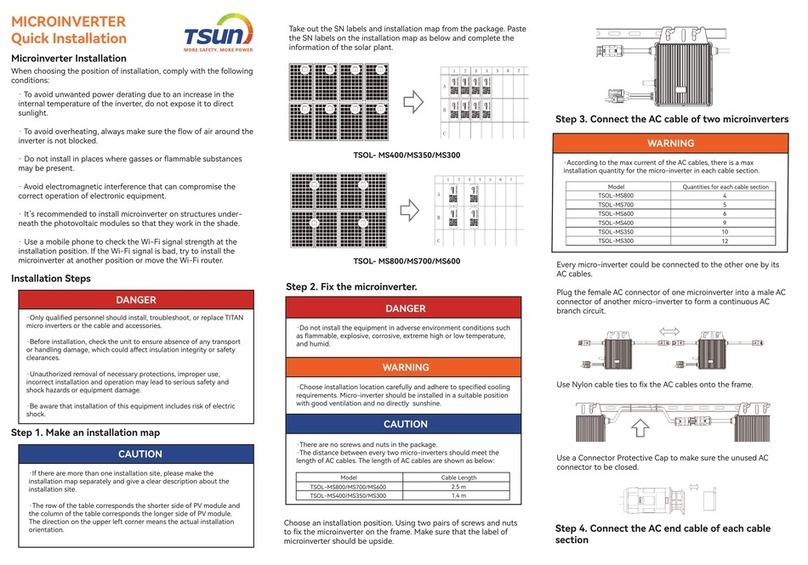

Tsun

Tsun TSOL-MS400 Quick installation

AIMS Power

AIMS Power PWRINV150W instruction manual

Winco

Winco WC6000HE/F Installation and operator's manual

Solectria Renewables

Solectria Renewables SGI 225 Installation and operation manual

BRIGHT

BRIGHT Home 800 user manual

Njoy

Njoy Astris 3K/1P1T1 installation manual

Velleman

Velleman SOL30UC12V user manual