tousek TX 310 User manual

Connection and installation manual

Radio transmission system TX 310

- 2 - tousek / E_TX-310_03 / 21. 03. 2019

GENERAL WARNING AND SAFETY NOTES for installation

• These installation and operating instructions form an integral part of the product TX310 and they have been

specically written for professional installers trained and skilled in the trade and should be carefully read in

their full length before carrying out the installation. This is for Radio transmission system TX 310, and not

for the complete installaion of automatic gate. After the installation this manual has to be handed over to the

user.

• Installation, connection, adjustments, putting into operation, and servicing may only be carried out by trained

professionals in full accordance with these installation- and operating instructions.

• Before carrying out works at the gate-system, the power supply has to be turned o.

• The arrangement of the components is dependent on the structural conditions and the gate design.

• The switching device may only be used to hedge dangers at crushing and shearing points on automatic sliding

gates (specications regular use). Any other use is prohibited.

• When using non-original components (including safety edges) any warranty or liability expires.

• The national and international regulations for gate safety must be observed. The safety function of the applica-

tion must always be considered as a whole and never referred only to the individual plant part.

• Connections must be observed and complied with in accordance with the applicable EC or national standards

in their current version.

• The current in the specic case OVE / VDE regulations and standards must be observed.

• The EU Machine Directive, laws and rules concerning the prevention of accidents, and laws and standards which are in

force in the EU and in the individual countries have to be strictly followed.

• The packaging materials (cardboard, plastic, EPS foam parts and lling material etc.) have to be properly disposed of

in accordance with the applying recycling- and environmental procection laws. They may be hazardous to children and

therefore have to be stored out of children´s reach.

• The product is not suitable for installation in explosion-hazardous areas.

• The product may only be used in accordance with its original purpose, for which it has been exclusively designed, and

which is described in these installation and operating instructions. The TOUSEK Ges.m.b.H. rejects any liability if the

product is used in any way not fully conforming to its original purpose as stated herein.

• Children have to be instructed, that the gate facility as well as the belonging parts may not be used improperly, e.g. for

playing. Furthermore handheld transmitters have to be kept in safe places and other impulse emitters as buttons and

switches have to be installed out of children‘s reach.

• The TOUSEK Ges.m.b.H. rejects any liability for claims resulting from usage of the product in combination with compo-

nents or devices which do not fully conform to the applying safety laws and rulesvorschriften entsprechen.

• Only original spare- and replacement parts may be used for repair of the product.

Declaration of Conformity:

The company TOUSEK Ges.mbH, Zetschegasse 1, 1230 Vienna, declares that the radio transmission system TX 310

following directives:

- Machinery Directive 2006/42 / EC, the R & TTE Directive 1999/5 / EC

It was here applied the following standards: EN ISO 13849-1, EN 12978

October 2013

Important

The radio transmission system TX 310 is only suitable for use with tousek products!

This manual is the sole property of the TOUSEK Ges.m.b.H. and may not be made available to competitors. All rights reserved. No part of it may be reproduced without our prior

written permission. We will not accept liability for any claims resulting from misprints or errors. This edition of the manual replaces all earlier publications of the same.

tousek / E_TX-310_03 / 21. 03. 2019 - 3 -

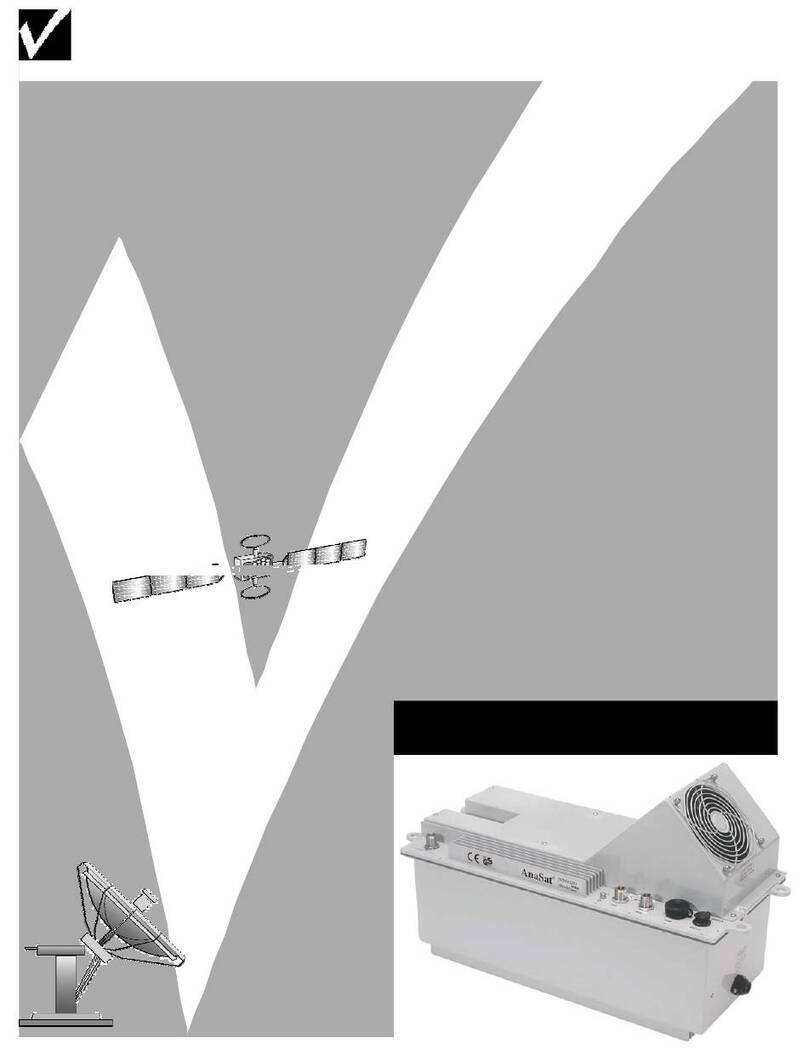

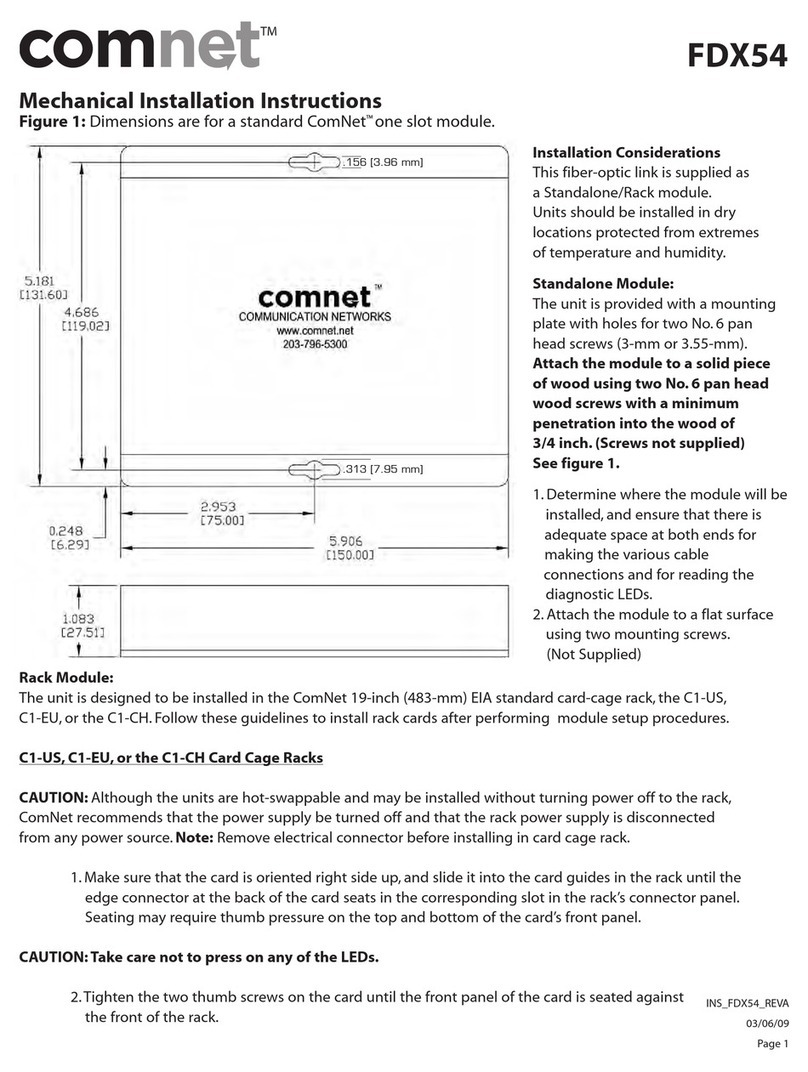

1. General features Radio transmission system TX 310

Connection example of TX310 System:

Features

• Bidirectional radio transmission system 868,95MHz and

869,85MHz

• Receiver with 1 output (so that the door can be secured

either CLOSED or OPEN direction)

• 10 transmitters can be learned into receiver (1-channel)

• Automatic frequency adjustment or manual frequency set-

tings provides high noise immunity

• 1 input selectable for 8,2kΩ resistance contact strip or

potential free contact e.g. pedestrian contact or wicket door.

• 1 output 8,2kΩ or N.C. (normally closed contact)

• Battery use of transmitter with 2 Lithium-Batteries 3V

(Type CR2032)

• Accoustic signal (inside receiver) when battery low

• Power supply for receiver: 12–24V a.c./d.c.

•

General

The TX 310 is a wireless signal transmission system (radio) in combination with safety edges to avoid dangers at crushing

and shearing at gate systems. There is a connection between a receiver that is connected to the controller of the engine, and

a transmitter that is attached to the gate and performs the evaluation of 8.2 kOhm resistor strips or potential free contacts.

Up to 10 stations can be stored in the receiver.

Technical Data

Radio transmission system TX 310 (transmitter- receiver kit 1-channel)

Frequency bands 868.95 MHz & 869.85 Mhz Software class A

Range 10 m

in optimal conditions Operating temperature -20°C bis +55°C

degree of pollution 2 article code. TX 310-Kit 13660380

Ball pressure test

(IEC 695-10-2)

PCB: 125°; Gehäuse: 75° article code. 1battery

for transmitter

(Lithium Type CR2032)

13140040

Transmitter Receiver

supply voltage 3 V d.c

(2 x Lithiumbattrie CR2032) supply voltage 12 / 24 V a.c./d.c.

power consumption on sending: 17 mA, in stand-by: 16 μA

station memory 10

Output Relay, 24 V, 0,5 A;

micro shutdown 1B

Resistances of the

safety edges 8,2kΩ

power consumption 0,4 W bei 12 V

1,2 W bei 24 V

Rated impulse withstand voltage

(gem. EN 60730-1) 300 V

Input test signal 12 / 24 V a.c./d.c.

Protection class IP 55 Protection class IP 54

Dimensions (WxHxD) 190 x 51 x 36 mm Dimensions (WxHxD) 137 x 45 x 95

transmitter receiver motor

safety edge

S

E

•

The receiver (E) is mounted near the operator - with operators with integrated control unit inside or on the operator.

• The mounting of the transmitter (S) has to be made on the gate (Cable exit down).

IMPORTANT: When screwing the housing cover of the transmitter necessarily

follow the max. torque of 45 Ncm, otherwise there is a risk of leakage due to

bending of the cover!

max.

45Ncm

- 4 - tousek / E_TX-310_03 / 21. 03. 2019

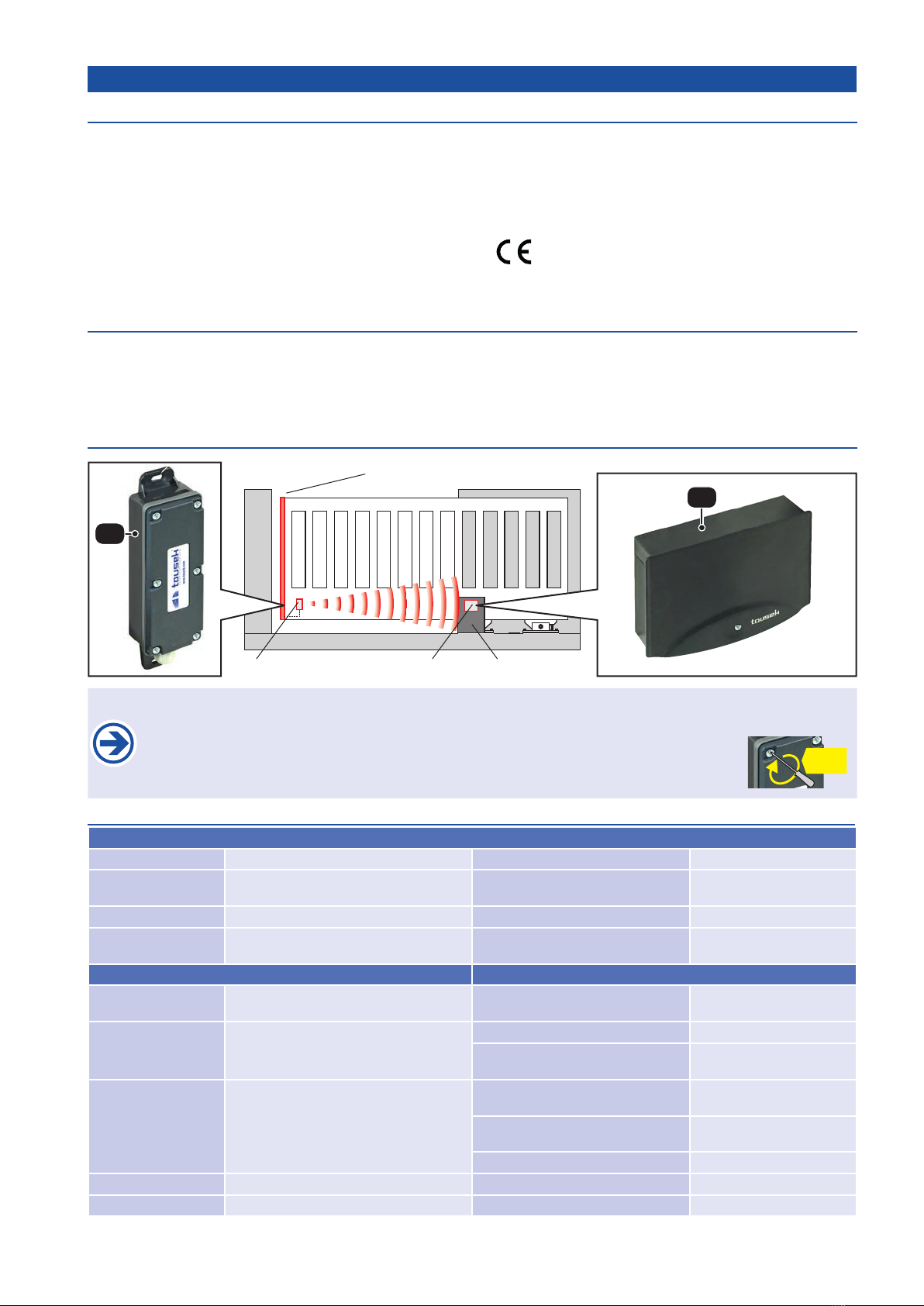

2. Connection / Adjustments Radio transmission system TX 310

(KL) connection clamps

(BAT1) battery 1 CR2032

(BAT2) battery 2 CR2032

(LED) LED (actuation)

(DIP) DIP-switches

(TS) programming

button of transmitter

(A) antenna

DIP-switches

DIP 1

ON ( )

for connection of a

8,2kΩ safety edge DIP

ON

1 2

factory preset

()

OFF for connection of a

NO contact

DIP 2

ON Frequency 1: 869,85 MHz

OFF ( )Frequency2: 868,95 MHz

Input (term. 1/2) : selectable for 8,2kΩ safety edge or pot.free contact

ON

1 2

→

8k2

For the safetey operation mode with a 8,2kΩ safety edge (terminals 1/2) set DIP 1 = ON

!

ON

1 2

→

N.C.

N.O.

For connecting a potential free contact (terminals 1/2), e.g. pedestrian contact, set DIP 1 = OFF !

Switching the potential free input from N.C. (= factory setting ) to N.O.:

• After insert the 1. battery (BAT1) the current input

status is going to be indicated by LED:

N.C.: 2x flash, N.O.: 5x flash

• If you would like to switch over the input, push

the button (TS) within 10s until the LED flashes.

Now insert the 2. battery (BAT2) - switching over

is finished.

STATUS

2x: N.C.

5x: N.O.

TS

~2s

max. 10s

BAT1

BAT2

Batteries

• Take print from the housing place 2 batteries

(Type CR2032) in the correct order BAT1, BAT2 as

shown in picture (Plus-Pole above) .

• If the order is not complied with, is not guaranteed

to function properly!

• We kindly recommend to replace the batteries during the

annual maintenance!

Important

• Transmitter and receiver should not be mounted on the same surface due to spark/radio technical reasons.

• The distance between transmitter and receiver and between transmitters themselves with each other must be

at least 1m.

• For safety reasons, the memory mode is exited 10 seconds after the last button activity automatically..

• TIP: For longer distances between transmitter and receiver, we recommend that you save the transmitter

before mounting on the receiver. The transmitter can (max 10 stations. Learnable) are stored with or without

attached circuit bar or NO contact (eg wicket door).

1 2 3

DIP

LEDTSA

++

KL

BAT1BAT2 pot.free contact

N.C. or N.O.

selectable

safety edge

8,2kΩ

OR

= N.C.

IMPORTANT: When screwing the housing cover of the transmitter necessa-

rily follow the max. torque of 45 Ncm, otherwise there is a risk of leakage

due to bending of the cover! max.

45 Ncm

2.1 Transmitter Connection / Adjustments

tousek / E_TX-310_03 / 21. 03. 2019 - 5 -

Important

• DIP Switch 2 does not normally need to be changed. To

avoid interference with the operation of two systems

that are operated close to each other, the frequency of

a system (transmitter and receiver) should be changed.

• DIP Switch 4: In heavily disturbed environments (eg if

there are cranes in the vicinity) this function helps to

improve the disturbance response. However, this really

should be used only when it is really needed, because

the system is thus slightly slowed.

• The lengths of the antennas in the transmitter and re-

ceiver are tuned to the operating frequency and must

not be changed!

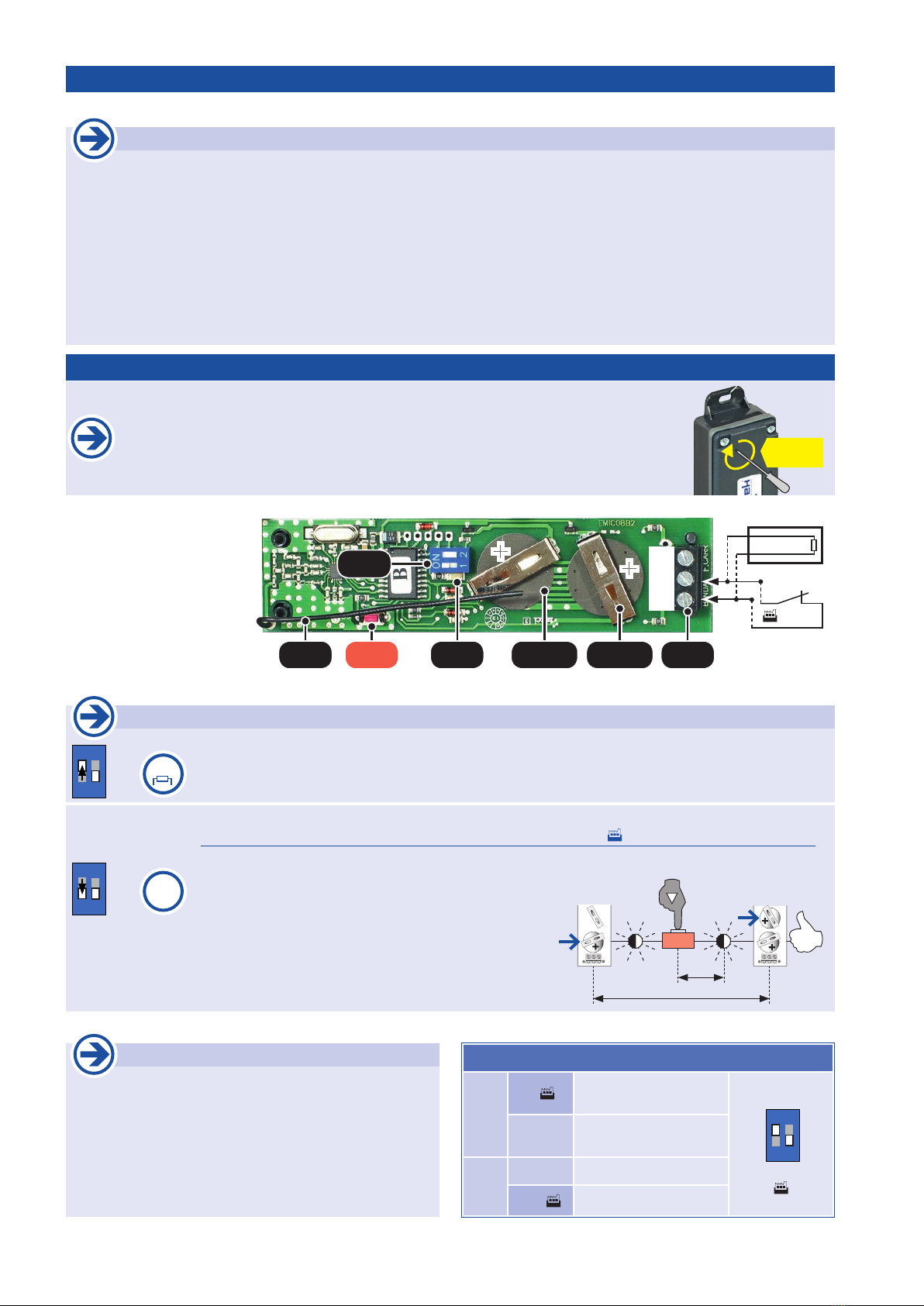

E

(KL) connection clamps

1/3 power supply

12/24V a.c./d.c

2 Test input

4/5 output

(LED1) LED 1 (system standby)

(LED2) LED 2 (Program mode)

(DIP) DIP- switches

(PROG) programming button

of receiver

(S) buzzer

(A) antenna

DIP-switches

DIP 1 ON ( )Standard setting

DIP 1 always on Position ON!

OFF no safety operation

DIP 2 ON Frequency 1: 869,85 MHz

OFF ( )Frequency 2: 868,95 MHz

DIP 3 ON ( )Test input NC

DIP 3 always on Position ON!

OFF Test input NO

DIP 4 ON frequency adjustment on

OFF ( )frequency adjustment o

DIP-switches

factory setting ( )

ON

1 2 3 4

The receiver (E) is mounted near the operator - so for opera-

tors with integrated control boards on (in) the operator (eg. in

PULL T5, -T8, -T10 operator: mounting of TX 310 receivers

with Velcro strap - see picture)

The receiver can not be mounted in the operators

PULL T15, PULL T24 and PULL T24speed!

2.2 Connecting the receiver for controls with 8,2kΩ input Connection / Adjustments

+ –

~ ~

KL

DIP

S LED2A

12/24V

a.c./d.c.

LED1

OUTPUT

(for controls with

8,2kΩ input)

Test

PROG

Connection

• Connect the terminals of the TX 310 with the termi-

nals of the used tousek control (acc. to table on next

page):

- Terminals 1/3 supply 12/24V a.c./d.c.

- Terminals 2 Test input

- Terminals 4/5 OUTPUT

- 6 - tousek / E_TX-310_03 / 21. 03. 2019

Connection examples Connection / Adjustments

• The TX 310 transmitter (S) inform the receiver (E) with a triggering of the mobile contact strip, then the

receiver forwards this via an output to the connected controller (ST) ..

• The receiver output (terminals 4/5) has the desired function, safety in the CLOSED or OPEN direction,

are connected to the control terminals concerned (stationary contact strips with the same function to

be connected in series). .

• A TX 310 receiver can manage via multiple transmitters several mobile safety contact edges with the same

function. For different functions you will need two transmitters and two receivers.

S

mZ

operator

sA sZ

2 x 0,752

2 x 0,752

2 x 0,752

E ST

CLOSE OPEN

S

mZ

operator

sAsZ

2 x 0,752

2 x 0,752

2 x 0,752

EST

OPEN CLOSE

Connection to the tousek control boards

Connection / Adjustments

• IMPORTANT: The TX 310 System has to be activated in the control board menu!

• In case the TX 310 is going to be used with Master/Slave automation system (=system with two sliding

gates running in opposite direction) you need to connect it to the master control unit and to the slave

control unit.

• For more information on the control system used see the appropriate manual.

* The receiver is not suitable for PULL T15, -T24, -T24speed housings!

tousek-control board:

Terminals receiver TX 310

INPUTS Power supply/Test OUTPUT

Terminal 1 Terminal 2 Terminal 3 Terminal 4 Terminal 5

+ / ~ Test – / ~ Common

safety edge

safety in

CLOSE-

direction

safety in

OPEN-

direction

sliding gate

operator controls

PULL T24*, T24speed*17 41 16 50 52 51

PULL T5, T8, T10, T15*

40 41 43 50 52 51

DYNAMIC Series, TPS 60 PRO

Series TPS-20, -35, -40, -6speed

44 41 43 50 51 56

in Master-Slave operation

For sliding gates running in opposite direction are two separate TX 310 systems (one for Master

and one for Slave) required. The terminals above need to be connected to the Master- and Slave

control unit.

Swing gate operator controls

ST 51, ST 61 44 41 43 50

safety

left leaf

or inside

safety

right leaf

or outside

52 53

Connect the two TX 310

systems separate.

Once to the Master con-

trol unit and afterwards

to the Slave control unit!

Connection shown on

this picture

Components of the MASTERS

ST Master control,

ETX 310 receiver

S1 TX 310 transmitter 1, S2 TX 310 transmitter 2

safety in CLOSE-direction:

mZ mobile safetey contact edge (nal edge)

sZ stationary safety edge (passage edge)

safety in OPEN-direction:

sA stationary safety edge (nal edge)

Connection example TX 310 to PULL -T8, -T10, -T15 Master/Slave

Components of the SLAVE

ST Slave control,

ETX 310 receiver

S1 TX 310 transmitter 1, S2 TX 310 transmitter 2

safety in CLOSE-direction:

mZ mobile safetey contact edge (nal edge)

sZ stationary safety edge (passage edge)

safety in OPEN-direction:

sA stationary safety edge (nal edge)

tousek / E_TX-310_03 / 21. 03. 2019 - 7 -

safety in CLOSE-direction:

mZ mobile safety edge (nal edge)

sZ stationary safety edge (passage edge)

safety in OPEN-direction:

mA mobile safety edge (nal edge)

sA stationary safety edge (passage edge)

Connection example 2: Mobile contact edges on gate for safety in OPEN-/CLOSE-direction and

stationary contact edges on pillar for safety in OPEN-/CLOSE-direction

CLOSE OPEN

S1

operator

sA sZ

TX 310-transmitter

S1

1 2 3

8,2kΩ

mZ

TX 310-transmitter

S2

1 2 3

8,2kΩ

mA

2 x 0,752

2 x 0,752

E1

E2

2 x 0,752

2 x 0,752

mZ mA

S2

ST

TX 310

receiver E1

(signal of S1 )

40

41

43

50

51

52

control board

ST

TX 310

receiver E2

(signal of S2 )

sZ sA

Application Example 1: Mobile contact strip at the gate for safety in the CLOSE-direction and

stationary contact strips on the column for safety in the OPEN-/CLOSE-direction

TX 310 - transmitter

S

1 2 3

S

mZ

operator

TX 310 - receiver E

40

41

43

50

51

52

control board ST

sA sZ

2 x 0,752

2 x 0,752

2 x 0,752

E ST

8,2kΩ

8,2kΩ

mZ

sZ sA

CLOSE OPEN

safety in CLOSE-direction:

mZ mobile safetey contact edge (nal edge)

sZ stationary safety edge (passage edge)

safety in OPEN-direction:

sA stationary contact edge (nal edge)

Connection example TX 310 to PULL T5, -T8, -T10, -T15

- 8 - tousek / E_TX-310_03 / 21. 03. 2019

safety in CLOSE-direction:

mZ mobile safety edge (nal edge)

sZ stationary safety edge (passage edge)

safety in OPEN-direction:

mA mobile safety edge (nal edge)

sA stationary safety edge (passage edge)

Connection example 2: Mobile contact edges on gate for safety in OPEN-/CLOSE-direction and

stationary contact edges on pillar for safety in OPEN-/CLOSE-direction

CLOSE OPEN

S1

e.g. operator PULL T24

sA sZ

TX 310 - transmitter

S1

1 2 3

8,2kΩ

mZ

TX 310 - transmitter

S2

1 2 3

8,2kΩ

mA

2 x 0,752

2 x 0,752

E1

E2

2 x 0,752

2 x 0,752

mZ mA

S2

ST

TX 310

receiver E1

(signal of S1 )

16

17

41

50

51

52

control board

PULL T24 ST

TX 310

receiver E2

(signal of S2 )

sZ sA

– +

Connection example TX 310 to PULL T24, -24speed

Application Example 1: Mobile contact strip at the gate for safety in the CLOSE-direction and

stationary contact strips on the column for safety in the OPEN-/CLOSE-direction

S

mZ

eg.

operator

PULL T24

TX 310 - receiver E

sA sZ

2 x 0,752

2 x 0,752

2 x 0,752

E ST

8,2kΩ

TX 310 -

transmitter

S

1 2 3

8,2kΩ

mZ

sZ sA

CLOSE OPEN

– +

control board

PULL T24 ST

16

17

41

50

51

52

safety in CLOSE-direction:

mZ mobile safetey contact edge (nal edge)

sZ stationary safety edge (passage edge)

safety in OPEN-direction:

sA stationary contact edge (nal edge)

tousek / E_TX-310_03 / 21. 03. 2019 - 9 -

KL

DIP

S LED2A

LED1

Test

Test

S

B

C

0V

12/24V

PROG (KL) Anschlussklemmen

(LED1) LED 1 (Systembereitschaft)

(LED2) LED 2 (Programmiermode)

(DIP) DIP-Schalter

(PROG) Programmiertaster

des Empfängers

(S) Summer

(A) Antenne

2.3 Connecting the receiver if using a N.C. contact Connection / Adjustments

e.g. Connecting TX 310/NC with garage door operator GTZ-Digital TX 310-Kit

Garage door operator GTZ-Digital

3

2

1

N.C.

contact

DIP-switches

DIP 1 = ON !

DIP 2 = OFF !

DIP 3 = OFF !

DIP 4 = OFF !

ON

1 2 3 4

TX 310/NC

receiver

TX 310/NC

transmitter

3 1 2 4 70 71

Test

Test

S

B

C

0V

12/24V

Important

• Do not connect anything to this

terminal block.

• Everything hasto beconnected

to the terminal block KL!

DIP-switches

DIP 1 = OFF !

DIP 2 = OFF !

ON

1 2

Important

Be sure that the potential free

input connection (KL. 1/2) is set

to N.C.(factory setting)!

page 4

- 10 - tousek / E_TX-310_03 / 21. 03. 2019

e.g. Connecting TX 310/NC with garage door operator TT60/TT120 TX 310-Kit

Lighting

230V a.c.,

max. 100W

+ –

primary line 2

primary line 1

230V a.c.

limit switch OPEN

limit switch CLOSED

common

motor

secondary line 1

secondary line 2

red

blue

grey

green

red

stop button

photocell / transmitter

photocell / receiver

impulse button

warning light

24V d.c. / 20W max.

24V d.c.

GND

contact 1

contact 2

KL1

KL2

KL3

KL4

24V ac.

Garage door operator TT60/TT120

DIP-switches

DIP 1 = ON !

DIP 2 = OFF !

DIP 3 = OFF !

DIP 4 = OFF !

ON

1 2 3 4

TX 310/NC

receiver

DIP-switches

DIP 1 = OFF !

DIP 2 = OFF !

ON

1 2

3

2

1

N.C.

Kontakt

TX 310/NC

transmitter

Test

Test

S

B

C

0V

12/24V

Important

Be sure that the potential

free input connection (KL.

1/2) is set to N.C. (factory

setting)!

page 4

transformer transformer

tousek / E_TX-310_03 / 21. 03. 2019 - 11 -

5. Error diagnosis Radio transmission system TX 310

Event viewer explanation solution

to save on

transmitter:

Signal will sound 10

seconds

Full preset memory.

The maximum number

of 10 channels per output

has been exceeded

delete transmitter

No signal after

transmitter-Touch

No wireless connection.

Frequency of transmitter

and receiver must match

set DIP-Switch correctly:

Frequency 1 (869.85 MHz)

or

ON

1 2 3 4

ON

1 2

S E

Frequency 2 (868.95 MHz)

(factory setting)

ON

1 2 3 4

ON

1 2

S E

during

operation:

malfunction

(e,g. near a construction

site/crane)

Very high levels of inter-

ference of radio link

automatic Switching

frequency adjustment

ON

1 2 3 4

E

during each

command: signal sounds 2-4 times batteries almost empty change batteries

• Set the system under tension.

• Push all safety edges one after the other and check desired function of receiver hence of control

board.

4. Function test Radio transmission system TX 310

3. Programming Radio transmission system TX 310

Storing a transmitter Programming

• Access the memory function: Press the button of the

receiver (PROG) until you hear a beep.

The LED 2 lights red for a maximum of 10 seconds (dis-

play memory Standby Output 1).

• Within these 10 seconds, the transmitter must be enabled:

Press transmitter button (TS), until you hear a sound

on the receiver. Additional transmitters can now also be

stored by pressing the button (TS).

• Exit storing: wait 10 seconds until two beeps can be heard.

Reset: delete receiver memory Programming

• Access the memory function: Press the receiver button

(PROG) until you hear a beep. Press the button (PROG)

again, until you hear short beeps.

• The receiver memory is deleted now. After 10 seconds, you

will hear two signals and the memory mode is automatically

released.

max. 10s

PROGPROG

LED-2

TS TS

OK

~10s

PROGPROG

> 1,5s

PROG

> 3s

PROG

OK

2x

your service partner:

Tousek Ges.m.b.H. Austria

A-1230 Vienna

Zetschegasse 1

Tel. +43/ 1/ 667 36 01

Fax +43/ 1/ 667 89 23

Tousek GmbH Germany

D-83395 Freilassing

Traunsteiner Straße 12

Tel. +49/ 8654/ 77 66-0

Fax +49/ 8654/ 57 196

Tousek Benelux NV

BE-3930 Hamont - Achel

Buitenheide 2A/ 1

Tel. +32/ 11/ 91 61 60

Fax +32/ 11/ 96 87 05

Tousek Sp. z o.o. Poland

PL 43-190 Mikołów (k/Katowic)

Gliwicka 67

Tel. +48/ 32/ 738 53 65

Fax +48/ 32/ 738 53 66

Tousek s.r.o. Czech Republic

CZ-252 61 Jeneč u Prahy

Průmyslová 499

Tel. +420 / 777 751 730

We reserve the right to change dimensions and/or technical specications with-

out prior notice. Claims resulting from misprints or errors cannot be accepted.

tousek PRODUCTS

• sliding gate operators

• cantilever systems

• swing gate operators

• garage door operators

• folding door operators

• trac barriers

• electronic controls

• radio remote controls

• key operated switches

• access control

• safety devices

• accessories

tousek

E_TX-310_03

21. 03. 2019

Table of contents