TOYODenki VFDB2009 Series User manual

VFDB2009

Operation Manual

1

Forword

Thank you for choosing Toyo VFDB2009 series dynamic brake unit.

This instruction manual contains information regarding the VFDB2009 series dinamic brake unit. For

correct use, please carefully read this instruction manual prior to using the VFDB2009 series dynamic brake

unit.

In order to accommodate the many special functions to a wide variety of applications in addition to the

inverter functions, please thoroughly read the VF66B inverter manual as well as any other applicable

specialized instruction manuals.

2

Please read before use

For safety

Before installing, operating, maintaining and inspecting VFDB2009 series dynamic brake unit, please read

this manual and all other appendices thoroughly in order to get familiarize with the feature of this option,

safely information and correct handling. In this instruction manual, the safety instructions are classified in to

two levels: DANGER and CAUTION. These signs have important instructions. Please follow the instructions

without fail.

DANGER

Indicates a hazardous situation which may result in death or serious injury if it

is handled improperly.

CAUTION

Indicates a hazardous situation which may result in moderate or minor injury or

only in property damage if it is handled improperly. However, such a situation

may lead to serious consequences depending on circumstances.

CAUTION [Installation]

Mount on the noninflammable material as metal, etc.

Doing so may cause a fire.

Do not place any flammable materials near the DB unit.

Doing so may cause a fire.

DB unit is an open structure, it is put into panel and it is carried out as a turning-on-electricity part.

Failure to do so may cause an electric shock.

Do not carry with the option cover.

Doing so may lead to personal injury by dropping.

Install the DB unit at endurable place ageinst weight.

Doing so may lead to personal injury by dropping.

Do not install or operate the DB unit if it is damaged or has any of its parts missing.

Doing so may lead to personal injury.

DANGER [Wiring]

Before wiring, make sure the power is OFF.

Failure to do so may cause an electric shock or fire.

Make sure that the unit is correctly earthed.

Failure to do so may cause an electric shock or fire.

Wiring must be done by skilled technicians.

Failure to do so may cause an electric shock or fire.

Wire the unit after it is installed.

Failure to do so may lead to personal injury or cause a fire.

CAUTION [Wiring]

Please check that the voltage setting change of DB unit is in agreement with inverter power supply voltage.

5.2.1 Change of a power supply voltageand5.4.3 F20Power supply voltage selection ・Master /

slave selection ・Station number set-up mode are reffer to.

Failure to do so may cause an electric shock or fire.

3

DANGER [Operation]

Turn the power ON after close the panel door. Do not open the panel door while the power is ON.

Doing so may cause an electric shock.

Do not operate any switch with wet hands.

Doing so may cause an electric shock.

Do not touch the DB unit while the power is ON, even if the DB unit is in the idle state.

Doing so may cause an electric shock.

CAUTION [Operation]

The DB unit radiating fin, the radiating resistors and Dynamic brake resistors are hot. Do not touch them.

Failure to follow this warning may cause burns.

DANGER [Maintenance, inspection and parts replacement]

Always turn the power OFF before inspecting the DB unit and passing of 10 minutes or more from

confirmation of stop of motor. Also check DC voltage between P to N and confirm that it is less than 30V.

Failure to do so may cause an electric shock, personal injury or fire.

Unauthorized persons shall not perform maintenance, inspection or parts replacement.

Use insulated tools for maintenance and inspection.

Failure to do so may cause electric shock or personal injury.

DANGER [Other]

Never modify the unit.

Doing so may cause electric shock or personal injury.

CAUTION [General precautions]

Some illustrations given in this manual show the in DB unit from which the option cover or safety shields have

been removed to illustrate the details. Before operating, reinstall these covers and shields to their original

positions and the DB unit according to this manual.

These safety precautions and specifications stated in this manual are subject to change without notice.

4

Table of contents

PLEASE READ BEFORE USE ...................................................................................................................................................2

FOR SAFETY......................................................................................................................................................................................... 2

CHAPTER 1 FUNCTIONAL OUTLINE ...............................................................................................................................6

1.1 OPERATION PRINCIPLE .............................................................................................................................................................. 6

CHAPTER 2 BASIC SPECIFICATION..................................................................................................................................8

2.1 COMMON SPECIFICATION ...................................................................................................................................................... 8

2.2 UNIT SPECIFICATION............................................................................................................................................................... 8

CHAPTER 3 INSTALLATION AND WIRING...................................................................................................................9

3.1 INSTALLATION.......................................................................................................................................................................... 9

3.2 CONNECTION......................................................................................................................................................................... 10

3.3 TERMINAL SPECIFICATIONS........................................................................................................................................................ 13

CHAPTER 4 OUTLINE DIMENSION................................................................................................................................ 14

CHAPTER 5 OPERATION.................................................................................................................................................. 15

5.1 EXPLANATION OF OPERATION .................................................................................................................................................. 15

5.1.1 VFDB2009-Z printed circuit board .......................................................................................................................... 15

5.1.2 Display............................................................................................................................................................................. 17

5.1.3 Operation method of a display for indication...................................................................................................... 17

5.2 SET-UP BEFORE OPERATION...................................................................................................................................................... 19

5.2.2 Set-up of single operation or Master/Slave system paralle operation.......................................................... 21

5.3 DYNAMIC BRAKE OPERATION................................................................................................................................................... 22

5.4 SET-UP ITEMS ........................................................................................................................................................................... 23

5.4.1 List of set-up items...................................................................................................................................................... 23

5.4.2 F10Setting mode of DB operation voltage.................................................................................................... 23

5.4.3 F20Power supply voltage selection ・Master / Slave selection ・Station number set-up mode24

5.4.4 F30The display gain / offset automatic adjustment mode of D.C. voltage........................................ 26

5.4.5 F40The display gain / offset hand adjustment mode of D.C. voltage................................................. 27

CHAPTER 6 SELECTION OF PERIPHERAL DEVICE.................................................................................................... 29

6.1 RESTRICTION IN DB OPERATION .............................................................................................................................................. 29

6.1.1 DB operating time and a quiescent period........................................................................................................... 29

6.1.2 Current value which the transistor built in DBunit permits.............................................................................. 29

6.2 SELECTION OF BRAKING RESISTOR ............................................................................................................................................ 30

6.3 SELECTION OF THERMAL RELAY................................................................................................................................................ 33

6.4 EXAMPLE OF PERIPHERAL EQUIPMENT SELECTION...................................................................................................................... 33

CHAPTER 7 OPTION ....................................................................................................................................................... 34

5

7.1 COMMUNICATION OPTION BOARD [DBIF2009-Z PC BOARD]......................................................................................... 34

7.1.1 Extension of the function by appling of a communication option PC board ............................................. 34

7.1.2 Communication option DBIF2009-Z PC board.................................................................................................... 35

7.1.3 Attachment of a communication option board, connection of a connector .............................................. 36

7.1.4 Connection of a telecommunication cable and a setup of a terminator switch........................................ 38

7.1.5 Station number set-up................................................................................................................................................ 43

7.1.6 Main circuit wiring at the time of communication option PC board attachment...................................... 43

7.1.7 Set-up of the inverter at the time of communication option PC board use................................................ 45

7.2 OPTION COVER........................................................................................................................................................................ 45

CHAPTER 8 REPLACEMENT WITH THE OLD MODEL DB UNIT ........................................................................................... 46

8.1 REPLACEMENT WITH VFDB2002 SERIES.................................................................................................................................46

8.2 REPLACEMENT WITH VFDB5022,VFDB5044,VFDB91-200............................................................................................. 46

8.3 PARALLEL OPERATON METHOD WITH VFDB SERIES.................................................................................................................. 47

8.3.1 Setup of VFDB2009 series......................................................................................................................................... 47

8.3.2 Connection..................................................................................................................................................................... 47

CHAPTER 9 TROUBLE SHOOTING .............................................................................................................................. 49

9.1 PROTECT DISPLAY.................................................................................................................................................................... 49

9.2 TROUBLE SHOOTING................................................................................................................................................................ 49

9.3 RESET ...................................................................................................................................................................................... 50

9.4 PROTECTION OAT THE TIME OF COMMUNICATION OPTION USE................................................................................................ 51

CHAPTER 10 MAINTENANCE ....................................................................................................................................... 52

10.1 REGULAR CHECK ................................................................................................................................................................... 52

10.2 DISPOSAL.............................................................................................................................................................................. 52

6

Chapter 1 Functional outline

VFDB2009 series dynamic brake system is equipment (DB unit) which controls the regeneration energy for

acquiring brake power. In order to acquire brake power other than DB unit, the braking resistor (DBR) which

consumes regeneration energy as heat, and the protection thermal relay (OCRY) which carries out electrical

overload detection are required.

The brake power gained due to the loss (a total of about 10 to 15%) by inside the inverter and inside the

motor because the inverter unit doesn’t have the ability to process the suppresion energy. When making the

continuous regeneration energy under operation, or the big regeneration energy in a sudden slowdown

consume by resistance and acquiring brake power, VFDB2009 series dynamic brake system is used.

VFDB2009 series dinamic brake system has compatibility in VFDB2002 series dynamic brake system,

attachment, and an operating method. The VFDB2002 series dynamic brake system applied to the present

system is exchanged for a VFDB2009 series dynamic brake system, and a simple substance and operation to

mix are possible.

VFDB2009 dinamic brake system is designed so that the content of a lead, mercury, cadmium, sexavalent

chrome, PBB, and PBDE may be based on the RoHS instructions which EU defines in consideration of the

influence on environment.

1.1 Operation principle

The suppression energy returns to the inverter unit when motor becomes the regeneration mode. The DC voltage of

inverter rises, because the inverter doesn't provide the regenerative function to the power supply. The DB unit detects this

DC voltage, operates the switching element (IGBT) in the unit, and consumes the regenarative energy to resistor (DBR)

for power generation. If the regenerative mode became finish,DC voltage returns to a normal value, switching element

(IGBT) becomes an immovable work.

* Regenerative mode *

The case where the torque has been put out the motor to the machine`s called powering mode in the place where the

machine is driven with inverter. The motor rotation frequency rises more than the output frequency of the inverter, it enters

the state to have returned the torque from the machine to the motor under such a condition when the sudden

deceleration or a big load of GD2is naturally decelerated from this state for instance, this is called the regentive mode.

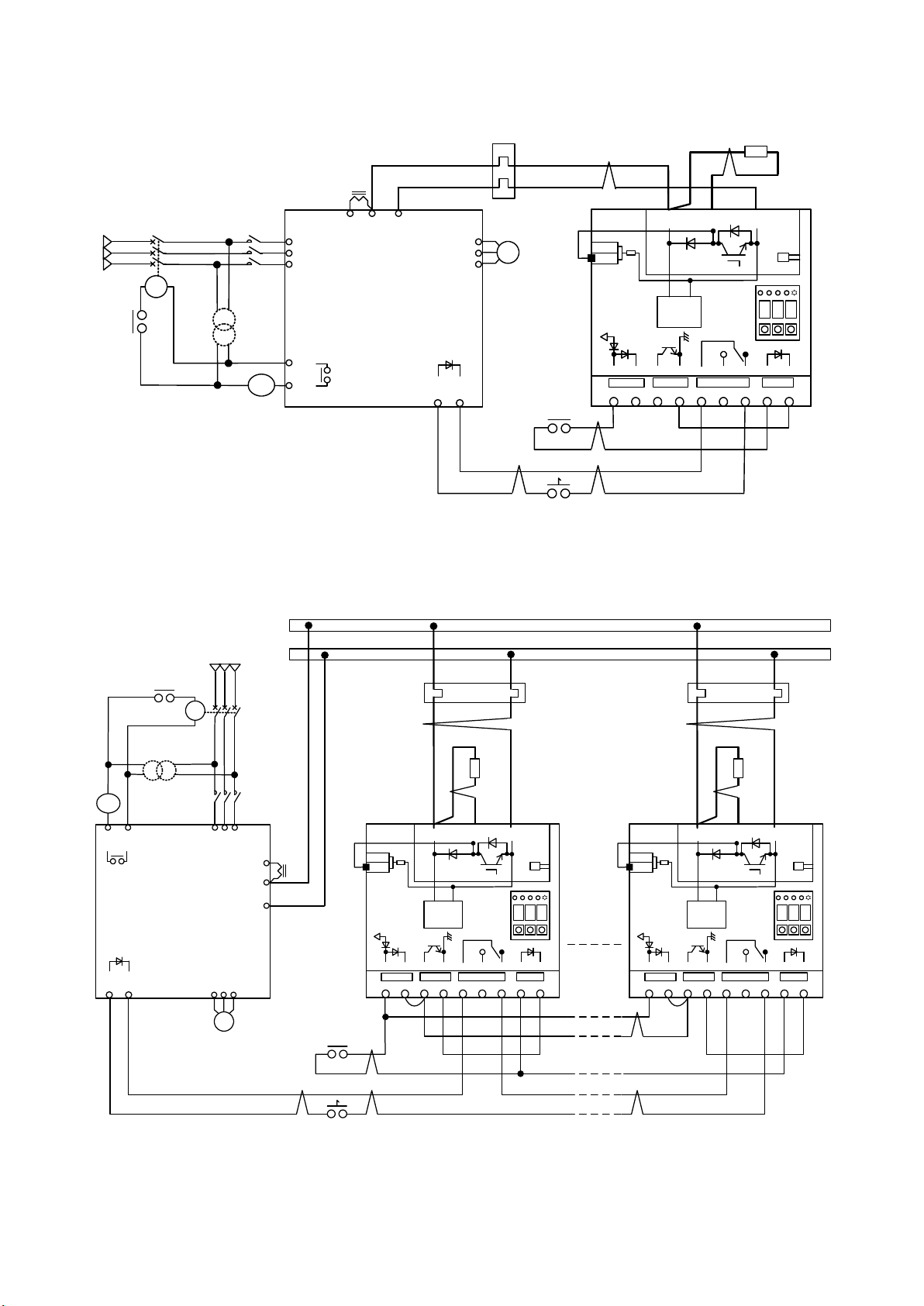

DB UNIT

Figure 1-1 basic circuit

INVERTER

UNIT

DBR

OCRY

DC/DC

IGBT

7

VDC

Input Output

Motor

VDC

Input Output

Motor

Fig1-2 Power flow of powering mode Fig 1-3 Power flow of regenerative mode

CAUTION [Safety precautions]

Carefully read the instruction manual before use, and use the inverter correctly.

Our VFDB2009 series dynamic brake system are not designed or manufactured for the purpose of use in

life-support machines or systems.

If you intend to use the product stated in this document for special purposes, such as passenger cars, medical

devices, aerospace devices, nuclear energy controls and submarine relaying machines or systems, consult our

sales department.

This product is manufactured under strict quality control. However, if it is used in critical equipment in which

VFDB2009 series dynamic brake system failure may result in death or serious damage, provide safeguard to

avoid serious accidents.

To use this product, electrical work is necessary. The electrical work must be done by qualified expert.

8

Chapter 2 Basic Specification

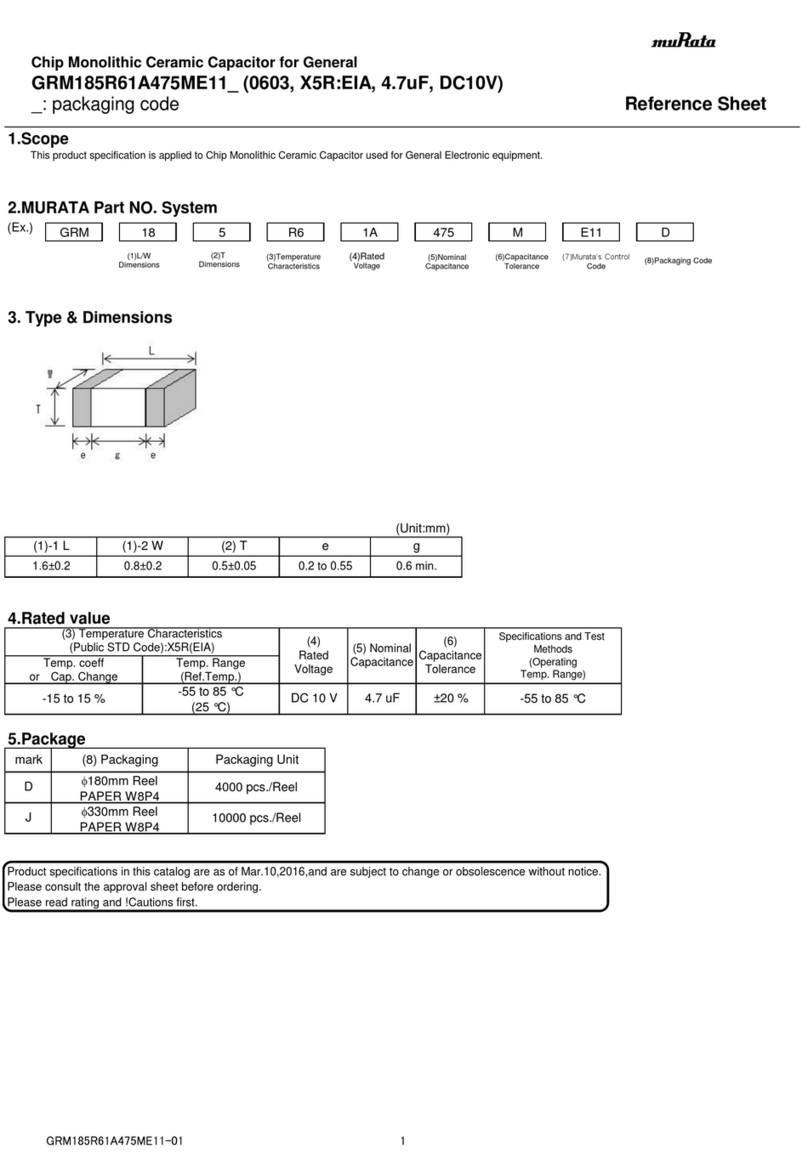

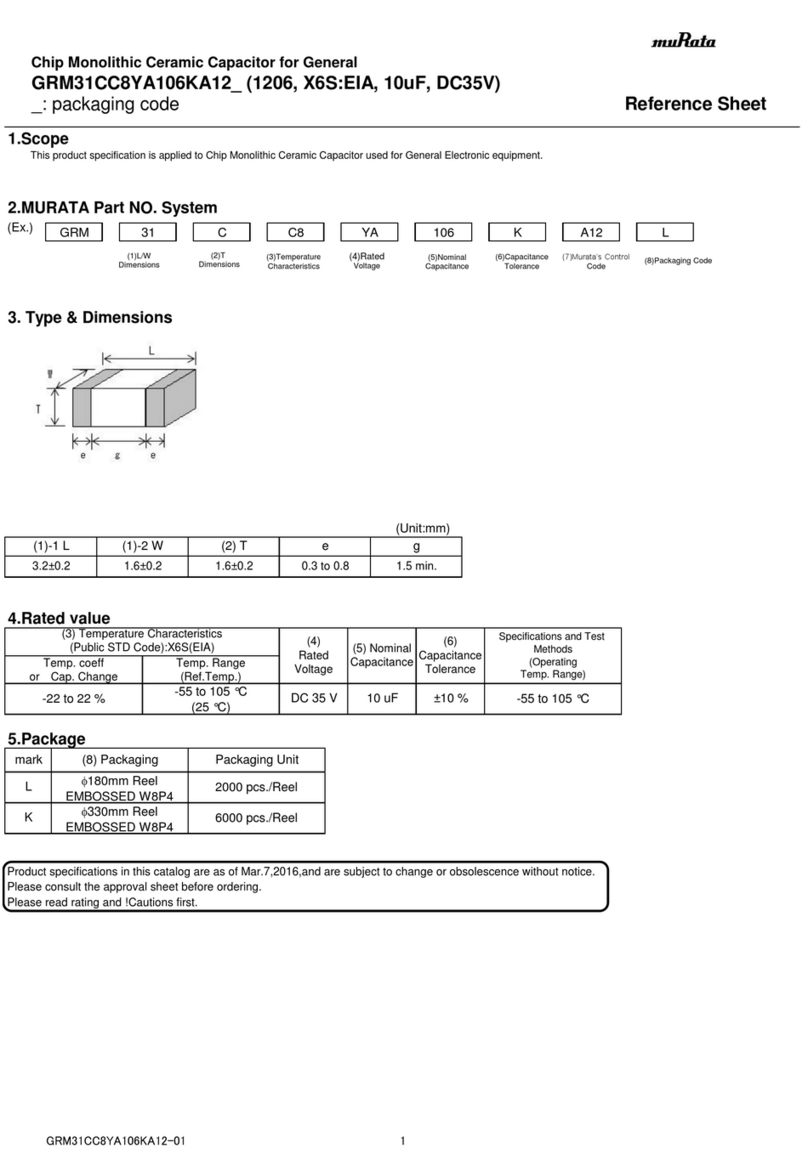

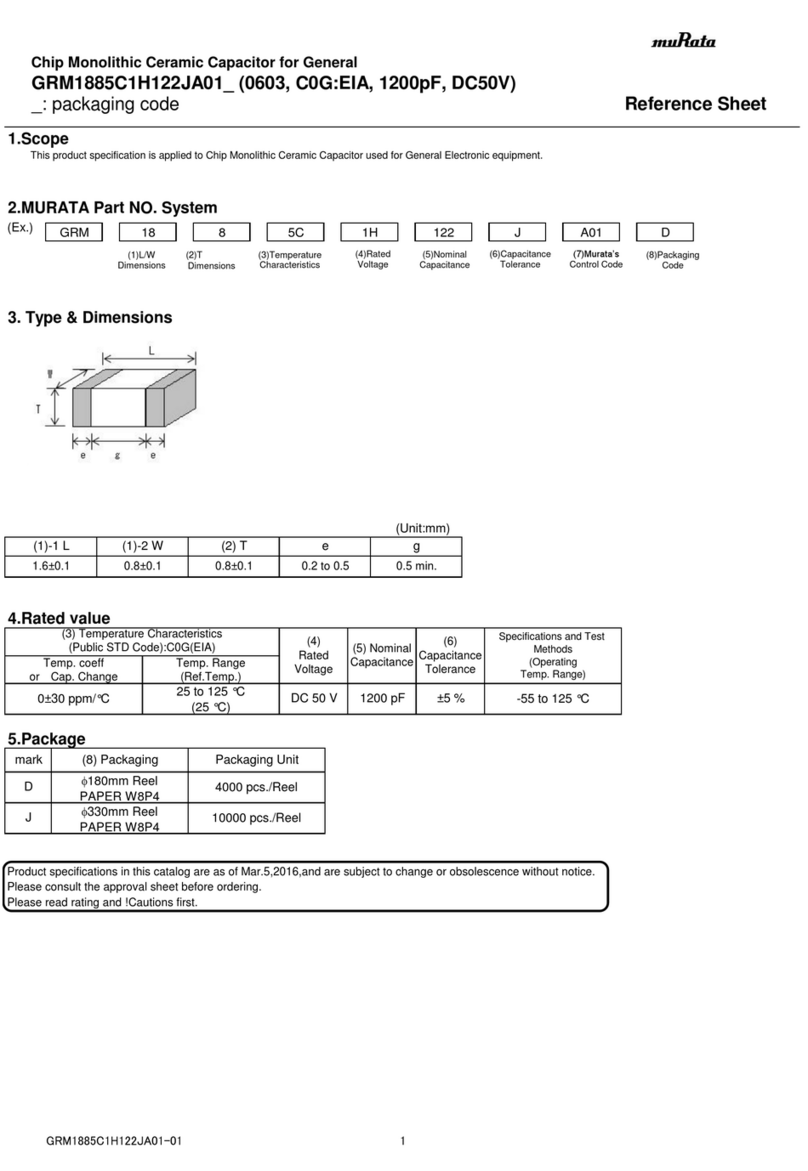

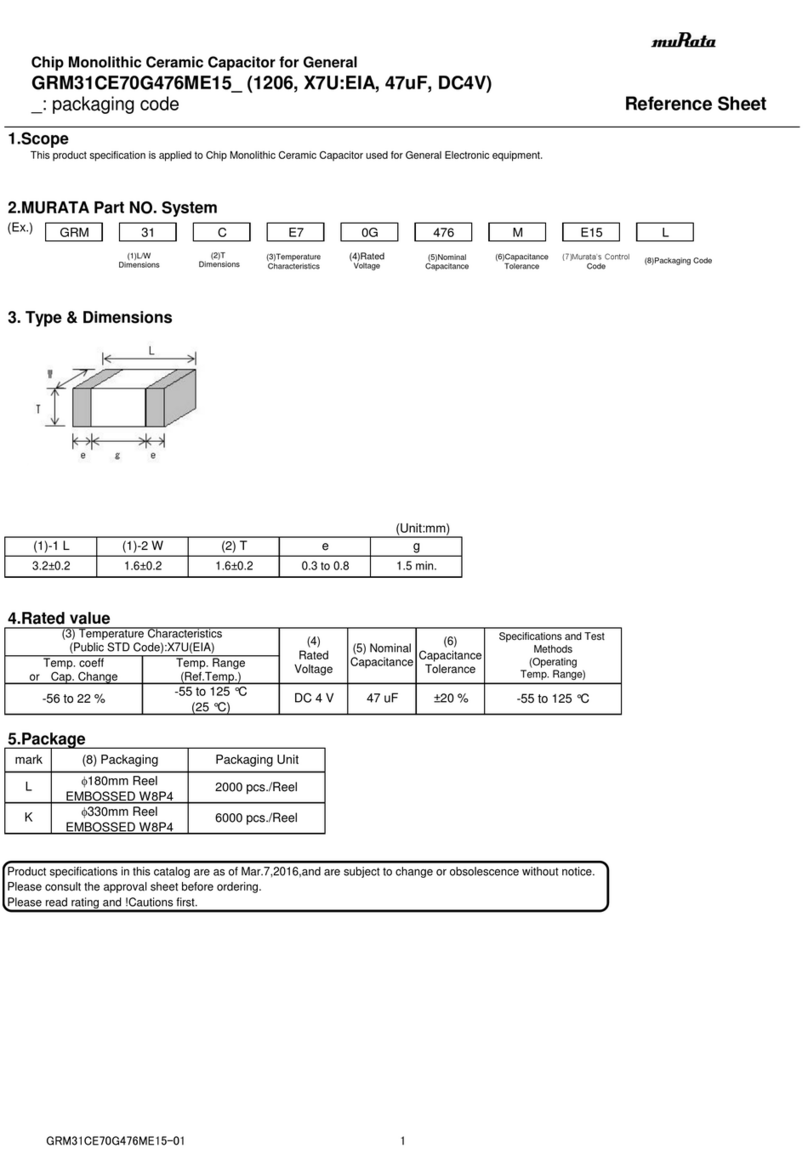

2.1 Common specification

The common specification of VFDB2009 series dinamic brake system (VFDB2009 series DB unit) are shown

in the following table.

Table 2.1 Common specification

DB operation

voltage

(Adustment)

[200V series]DC300V~400V±3%

[400V series]DC600V~800V±3%

Parallel operation

MasterSlave sysytem

Maximum

parallel number

Six sets

Protection

function

Abnormalities of a main circuitFin overhaetAbnormalities of a preset value

200V series over voltage

Correspondence

standard

RoHS instruction conformity

Environmental condition

Temperature

of operation

0~50℃

Preservation

temperature

-20~60℃

Humidity

20~90%Not condensation

Altitude

1000m or less

Atmosphere

No poisonous gas, metal powder, and oil and fat etc.

Protection

structure

IP00JIS C 0920EN/IEC60529

Structure of an open type where the protection to a human body, the protection to

invasion of a solid object, and the protection to invasion of water are not taken into

consideration in particular.

2.2 Unit specification

The specification of each VFDB2009 series DB unit is shown in the following table.

Table 2.2 DB unit specification

Type

VFDB2009-50

VFDB2009-200N

VFDB2009-200F

Rated

current

Peak

current

※1

50[A]1[min]

200A[] 1[min]

200[A] 1[min]

Continuous

current

12[A]

58[A]

120[A]

Cooling sysytem

Air cooling without blower

Air cooling without blower

Air cooling

※1:DB usage rate =10[%]

9

Chapter 3 Installation and Wiring

3.1 Installation

○

1Installation location of unit

The conditions in the installation location affect the life and the reliability of the inverter. Avoid using it in the

following places.

(1) If the DB unit is installed in a highly humid or dusty place, or in a place exposed to water or oil, the

circuit insulation will be deteriorated, and the life of the parts will be shortened.

(2) If the working ambient temperature is too high, the life of the capacitor and cooling fan motor will be

shortened.

(3) In a place with corrosive gas, connector contact failure, breaking of electric wires and damage of parts

may be caused.

(4) In a place with heavy vibration, connector contact failure, breaking of electric wires and damage of parts

may be caused.

(5) If the DB unit is used at an ambient temperature of 0℃or less, use a heater to increase the temperature

to more than 0℃at the start of the DB unit. After the DB unit starts, it generates heat by itself to

more than 0℃and will operate normally.

Installing the unit

To use dynamic brake unit installed in a control panel, install as follows.

DANGER [Mounting]

Improper installation may cause an electric shock or a fire.

(1) Installation direction

VFDB2009 DB unit turns a main circuit terminal down and attaches it perpendicularly. If installed

horizontally, it will not be ventilated sufficiently and will be overheated. Enogh consideration must be

taken to the routes of suction and exhaust of air.

Moreover, the cooling fan of DB unit (VFDB2009-200F) with a cooling fan inhales from the bottom, and

exhausts air to the top. Keep sufficient space above the unit so that ventilation is not prevented by

wiring dusts, etc.

When installing VFDB2009 DB unit, keep cooling spaces as shown in the following figure3.1.

When VFDB2009 DB unit is installed in a control panel, ventilate the panel to keep the temperature in

the panel within 50℃.If the ambient temperature is high, the reliability of the inverter will be

degraded.

(2) Cautions

Surely exhaust the heat generated by the DB unit to the outside of the panel. Prevent the exhaust from

the DB unit to circulate in the panel.

Install the resistor on the outside of the panel as much as possible.

Avoid using the DB unit in a considerably coarse environment.

10

Min100

[mm]

Min100

[mm]

Figure 3.1 DB unit cooling space

3.2 Connection

A maximum of six sets of parallel runs are possible for VFDB2009 series dynamic brake system. Please

keep in mind that control wiring differs in single operation and parallel operation. Moreover, it is necessary

to change a setup of DB unit in accordance with wiring. refer to "5.2.2 Set-up of single operation or

Master/Slave system paralle operation" for change of a setup. In addition, a parallel operation with

VFDB2002 series is also possible for this VFDB2009 series. Refer to "8.3.2 connection method" for the wiring

at the time of a parallel run with VFDB2002 series.

The parallel operation of DB unit of our company has adopted “Master & Slave system.” “Master & Slave

system” sets to Master DB unit which each DB unit performed DB operation detection and carried out DB

operation detection previously, and takes out instructions of ON/OFF of switching device (IGBT) to other

parallel units. Figure 3.3 shows the connection method and the wiring between each DB unit becomes the

same.

DB unit set up by Master unit performs DB operation detection, and "Master & Slave system" of VFDB2002

series takes out instructions of ON-OFF of switching device (IGBT) of a slave unit. Even when VFDB2009

series DBunit is applied, "Master & Slave system" of VFDB2002 series is possible. Refer to Figure 8.1 for the

connection method in that case.

In accordance with the power supply voltage system of an inverter, a DB unit setup is required before use.

When DB unit is used by mistaken setup, there is fear of breakage and unusual operation. Refer to "5.2.1.

Change of a power supply voltage" and "5.4.3 F20 (Power supply voltage selection and Master/Slave

selection and Station number set-up mode) for a setup of a power supply voltage system.

11

1 2 3 4 5 6 8 97

P PR N

OCRY

DBR

CN2

CN3

400V

200V

TH

52MAX

8 8 8

SHT

OCRY

52MAX

M

TB2

DB

_IN DB_ON 86A 52MA

MCCB MC

R

S

T

12

U

V

W

DCL

RUNNING SIGNAL

INVERTER UNIT

Inverter Operation

Contact (52MA)

400V Line

at

400V/200V

Transfomer

DB Unit

DB Voltage

DC/DC

Converter

Slave Master Protection DB Operation

Inverter Operation command

Figure 3.2 Example of connection of single operation

52MAX

M

U VW

SHT

OCRY

MCCB

MC

R S T

52MAX

1

2

1 2 3 4 5 6 8 97

P PR N

OCRY

DBR

CN2

CN3

400V

200V

TH

8 8 8

TB2

DB

_IN DB_ON 86A 52MA

1 2 3 4 5 6 8 97

P PR N

OCRY

DBR

CN2

CN3

400V

200V

TH

8 8 8

TB2

DB

_IN DB_ON 86A 52MA

DC

L

400V Line

at

400V/200V

Transfomer

Inverter Operation

Contact (52MA)

INVERTER UNIT

RUNNING SIGNAL

Inverter Operation command

D.C. Busbar

DB Unit

DB Voltage

DC/DC

Converter

Slave Master Protection DB Operation

DB Unit

DB Voltage

DC/DC

Converter

Slave Master Protection DB Operation

6parallels

or less

Figure 3.2 Example of connection of parallel operation

12

○Notes at the time of wiring

Lay the main circuit wires and the control signal wires apart from each other.

Wiring of an inverter should follow the instructions manual of inverter each model.

Inside of a figure 3 of a part of the connection example wires for the twist. Please lay out the

equipment to shorten as much as possible and wire for wiring. If the twist line is not used, the surge

voltage is by the twice or more. there is a possibility of damaging the unit.

Please connect input power source (P,N) of DB unit from the middle D.C. power (+2,-) of the Inverter

unit by twist cable. Refer to Table 3-1 for the size of the use cable and number of time to twist .

Change the connector on DB unit according to the voltage system of an inverter. Refer to "5.2.1

Change of power supply voltage" for details.

Wire the DB unit for the interlock relay use doing that operates by the INV RUN signal contact

(52MAX) of the inverter so that the DB unit should not work while the inverter is stopping and wire

use twist cable. The interlock relay must use the lopower relay.

Select braking resistor (DBR) so that required regeneration power is obtained, and take protection

coordination in thermal relay (OCRY). It becomes a cause of a fire when cooperation cannot be taken.

About selection of braking resistor (DBR) and thermal relay (OCRY), refer to "6.2 Selection of braking

resistor" and "6.3 Selection of thermal relay." Thermal relay (OCRY) should use what operates with

direct-current current.

Please shorten wiring to braking resistor (DBR) and thermal relay (OCRY) as much as possible, and

twist it, and the wiring near braking resistor (DBR) should perform heat-resistant processing.

Since braking resistor (DBR) generates heat (200 degrees or more), it is installed in a place with

sufficient ventilation, and does not put combustibles on the surroundings.

By operation of thermal relay (OCRY), the trip of circuit braker (MCCB) or electromagnetic contactor

(MC) by on the inverter input is carried out.

Protection contact(86A) of the DB unit operates by protection of DBunit. Please connect the

protection contact (86A) of the DB unit to the circuit of inverter operation instructions in series as an

interlock of inverter operation.

Main circuit wiring of an inverter and DB unit should set to a maximum of 10m, and please wire as

short as possible.

Please be sure to connect the ground of a DB unit.

When you use DB unit by a parallel operation, please be sure to connect master instructions signal

(DB-IN) and a slave input signal (DB-ON).

13

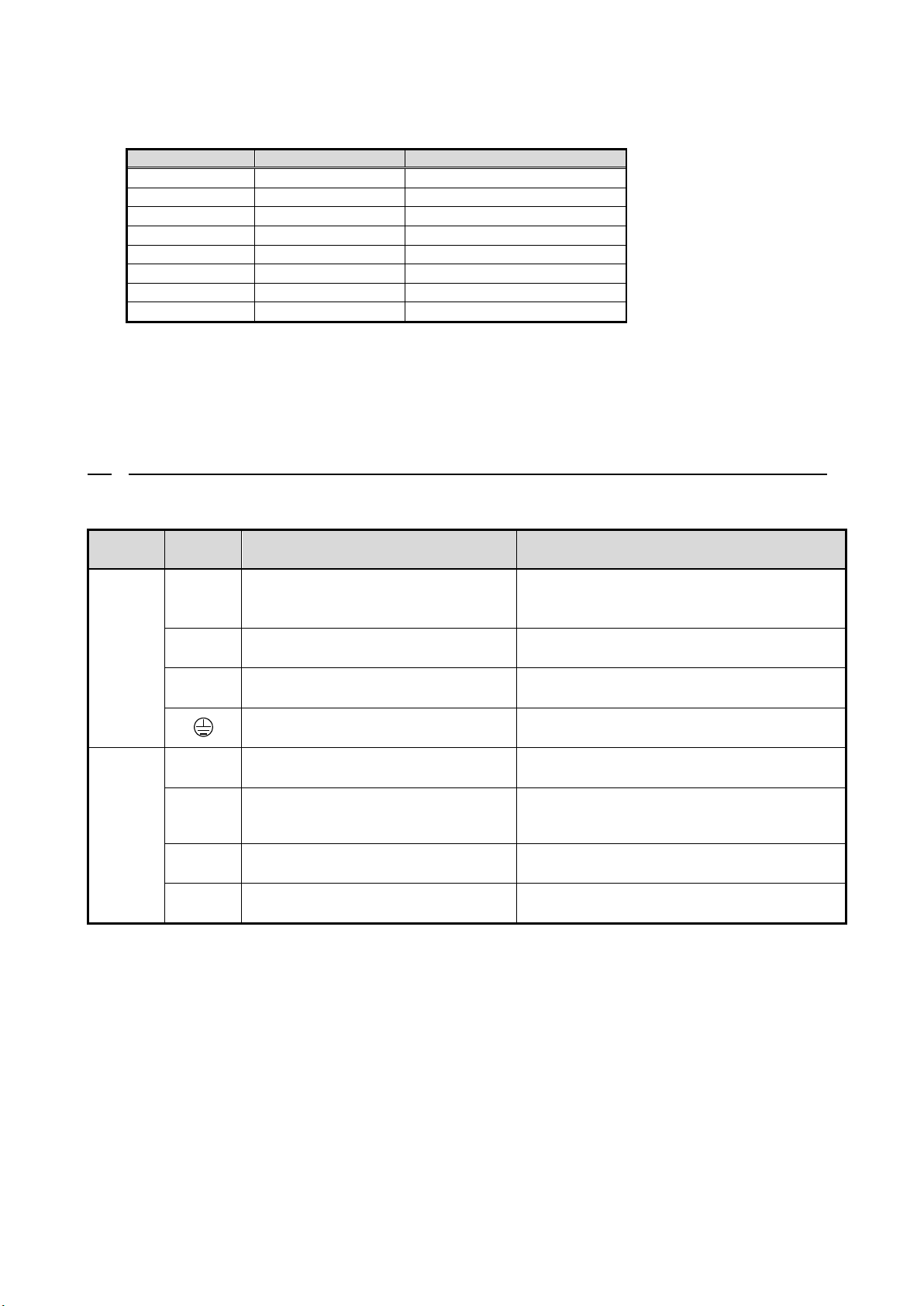

Table 3.1 Main circuit used cable (DB usage rate 10%ED

Main current[A]

Wiring size[mm2]

Number of times to twist[turn/m]

200

38

5

160

22

7

110

14

8

80

8

10

50

8

10

40

5.5

10

30

3.5

10

18

2

10

※Table 3.1 is the wire size at the time of adopting the fire-resistant poly flex time electric wire.

( Example:MLFC[Hitachi Cable])

※Twist a wire equally so that the length of each wire becomes the same.

3.3 Terminal specifications

Table 3.2 List of terminal specification

Device

Terminal

number

Use

Description

Main

circuit

P

DC voltage input (+ side)

For DBR connection

For thermal relay (OCRY) connection

Connect the inverter-middle D.C. voltage(○

2)

Connect a braking resistor

Connect the thermal relay(OCRY)

PR

For DBR connection

Connect a braking resistor

N

DC voltage input (- side)

For thermal relay (OCRY) connection

Connect the inverter-middle D.C. voltage(○

)

Connect the thermal relay(OCRY)

Earth

Connect the ground

VFDB

2009-Z

terminal

block

TB2

DB-IN

Slave input

DB operation will be started if a signal is

inputted during DB operation permission.

DB-ON

master instructions

A signal is outputted when the

inverter-middle D.C. voltage exceeds DB

operation starting potential (F10).

86A

Protection contact

DB unit turns on during the protection mode.

(86A:AC230V 0.5A)

52MA

Operation contact

It will be in the state in which DB operation is

possible by ON.

14

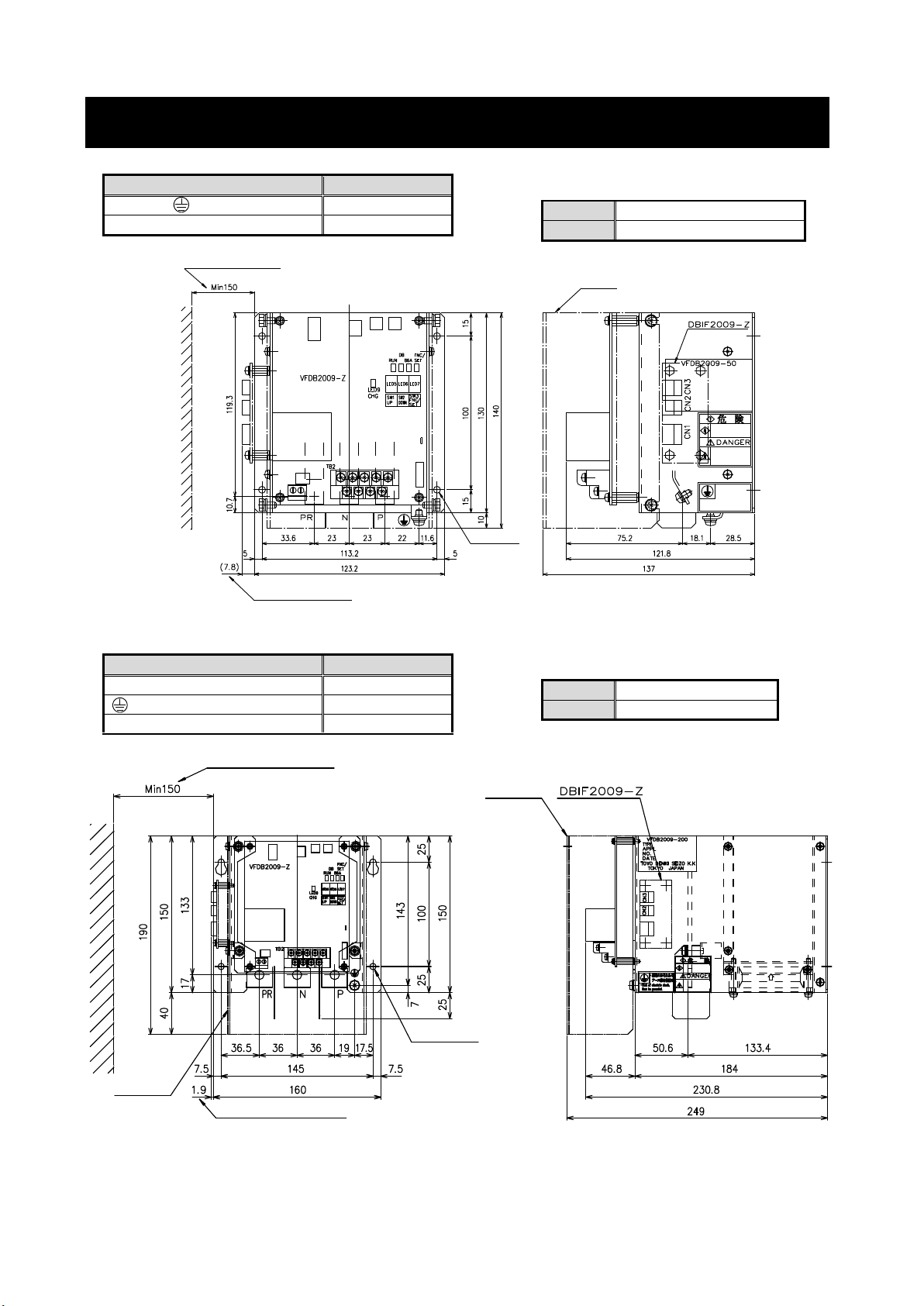

Chapter 4 Outline dimension

○VFDB2009-50

Color

Mansel 5Y7/1

Weight

1.2kg

○VFDB2009-200N

VFDB2009-200F

Color

Mansel 5Y7/1

Weight

4kg

DBIF2009-Z(Option) used

DBIF2009-Z(Option) used

Cover

(Option)

4-M5

Mouting Hole

Cover

(Option) (Option)

Space

Treminal marking

Terminal screws

PR,N,P,

M4

VFDB2009-Z TB2

M3

Treminal marking

Terminal screws

PR,N,P

M8

M5

VFDB2009-Z TB2

M3

DBIF2009-Z(Option) used

Space

DBIF2009-Z(Option) used

Cover

(Option)

4-M4

Mouting Hole

(Option)

15

Chapter 5 Operation

VFDB2009 series Dynamic brake unit operates in the power supply of the middle D.C. voltage of the

inverter. The DB unit becomes a waiting state if the inverter run signal(52MA) is input after the

inverter-middle D.C. voltage rises, and LED “RUN" (Light Emitting Diode) lights. Main switching device(IGBT)

operates when the middle D.C. voltage rises by the regeneration of the inverter, and it rises up to the voltage

set to the DB operating point,and LED “DB" lights. At this time, brake resistor connected to DB unit consumes

regeneration energy, and if inverter-middle D.C. voltage turns into below the voltage that stops DB operation,

a switching device is turned off.

5.1 Explanation of operation

5.1.1 VFDB2009-Z printed circuit board

Figure 5.1 VFDB2009-Z printed circuit board

TB2

DB-IN

DB-ON

86A

52MA

CN1

CN

CN

CN4

CN5

[200V]

[400V]

DB 電圧

CN6

LED1

LED2

LED3

RUN

LED8

LED9

CHG

LED4

DB

86A

FNC/SET

VFDB2009-Z

TB1

LED5

LED6

LED7

SW1

SW2

SW3

UP

DOWN

FNC/SET

DANGER

Hazardous Voltage

RY1

16

Table 5.1 List of parts use and functions on the VFDB2009-Z printed cuicuit board

Name※5

Parts use and functions

CN2

The connector for a change of a power supply voltage system

CN3

CN6

The connector for connection with communication option DBIF2009-Z PC board(※1)

LED8

LED for a normal operation check of CPU (※2)

LED9

CHG lamp (※3)

TB2

The terminal block for DB unit control (※4)

※1: Refer to "7.1 communication option DBIF2009-Z PC board" for a communication option board.

※2: LED8 blinks in a cycle of about 2 seconds, while the VFDB2009-Z board is operating normally. While not

blinking, failure of the loose connection of CN1 or a VFDB2009-Z board can be considered.

※3: The middle D.C. voltage of an inverter turns on LED9 by 30V or more. When the light is not switched on,

failure of the loose connection of CN1 or a VFDB2009-Z board can be considered.

※4: Refer to "3.3 Terminal specifications" for the function of TB2.

※5: Refer to "5.1.2 Display" for LED 1-7 and SW 1-3.

DANGER [VFDB2009-Z PC board]

DB unit cannot be recklessly touched during CHG LED lighting.

Failure to do so may cause electric shock.

Wiring of TB1,CN1,CN4,CN5 are not changed.

Failure to do so may cause electric shock or personal injury and part breakage

17

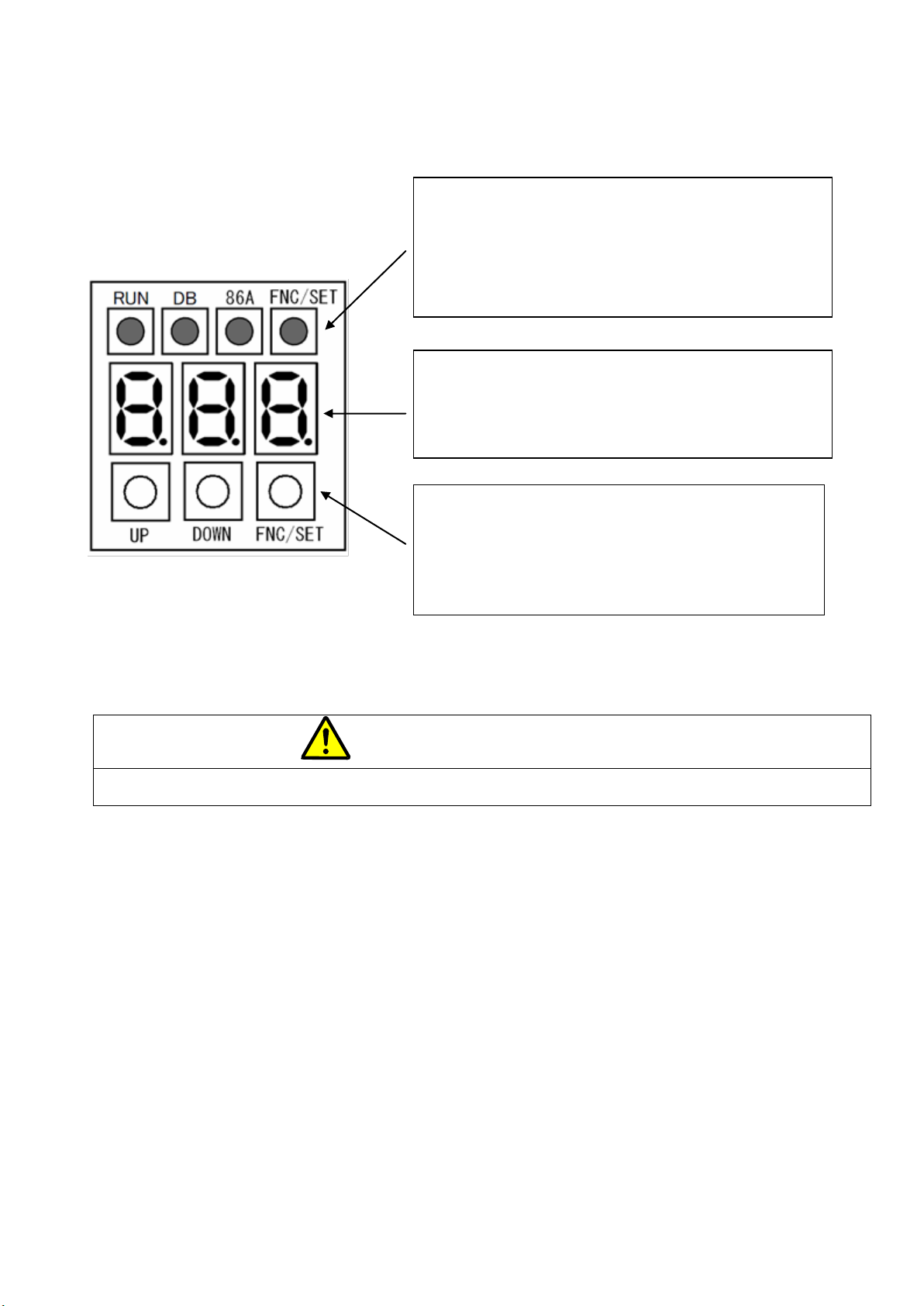

5.1.2 Display

Figure 5.2 Display for indication VFDB2009-Z PC board

DANGER [Operation]

Do not operate any switch with wet hands.

Doing so may expose you to shock hazard.

5.1.3 Operation method of a display for indication

If the power supply of an inverter is turned on, the inverter-middle D.C. voltage will rise and D.C. voltage will

be displayed on the display for indication of DB unit. Setup and adjustment of DB unit are possible by

operating a display for indication.

It changes from the display mode of D.C. voltage to a setup and adjustment of DBunit to setting mode. The

mode can be changed by pushing "FNC/SET" and "UP", and the "DOWN" button.

※"△" in a figure expresses the "UP" button, and "▽" expresses the "DOWN" button.

●Status display LED

RUN:Ligth when DB operation instruction input

DB:Light when during DB unit operation

86A: Light when during protected operation

FNC/SET: Light when setting mode

●Seven segment displays (LED)

Display of D.C. voltage (Vdc) / setting mode / setting

value / protection state

("." Displays a setting item)

●Push button

UP.DOWN:Change of setting mode/setting value

FNC/SET: [Under D.C. voltage display] shifts to another

setting mode.

[Under setting mode] shifts to set-up item.

18

FNC/

SET

FNC/

SET

FNC/

SET

RUN DB 86A FNC RUN DB 86A FNC RUN DB 86A FNC RUN DB 86A FNC

FNC/

SET

FNC/

SET

RUN DB 86A FNC RUN DB 86A FNC RUN DB 86A FNC

△▽

FNC/

SET

FNC/

SET

FNC/

SET

RUN DB 86A FNC RUN DB 86A FNC RUN DB 86A FNC RUN DB 86A FNC

FNC/

SET

FNC/

SET

RUN DB 86A FNC RUN DB 86A FNC RUN DB 86A FNC

△▽

△▽

▽

FNC/

SET

RUN DB 86A FNC

FNC/

SET

FNC/

SET

FNC/

SET

FNC/

SET

△

Power

ON

D.C. Voltage indicate MODE Indicate

MODE Indicate

MODE Indicate

MODE Indicate

DB Operation

voltage

Power supply

voltage Selection

DB Operation Stop

voltage width

Master/Slave

Selection

Station number

Set-up

Low lebel

Calculation

Hight lebel

Calculation

VDC Auto

Calculation

Gain of VDC Offset of VDC

Figure 5.3 The mode change state of a display for indication

If the "FNC/SET" button is pushed during the display of direct-current voltage, it will shift to setting mode

"F10" and LED"FNC/SET" will light up simultaneously. If "UP" or the "DOWN" button is pushed into setting

mode, it will shift to setting mode (F10-F40), and if the "FNC/SET" button is pushed, it will shift to the setting

item in each setting mode.

※If LED"RUN" lights up in set-up mode (DB operation instruction ON), it will switch to D.C. voltage display

mode compulsorily. Moreover, even if it pushes the "FNC/SET" button during lighting of LED"RUN", it does

not switch to setting mode.

Table 5.2 Set-up mode list

Setup mode

Dicription

F10

DB operation voltage setting mode

F20

Power supply voltage selection and Master/Slave selection and Station number set-up

mode

F30

The display gain / offset automatic adjustment mode of D.C. voltage

F40

The display gain / offset hand adjustment mode of D.C. voltage

※Refer to "5.4 Set-up items" for the details in each set-up mode.

19

5.2 Set-up before operation

Please be sure to perform the following setup before using DB unit. DB unit is common use in the power

supply voltage (200V series /400V series) of inveretr and single/parallel operation. Since power supply

voltage is set as 400V series and the mode of operation is set as single operation at the time of shipment, a

setup is changed according to application.

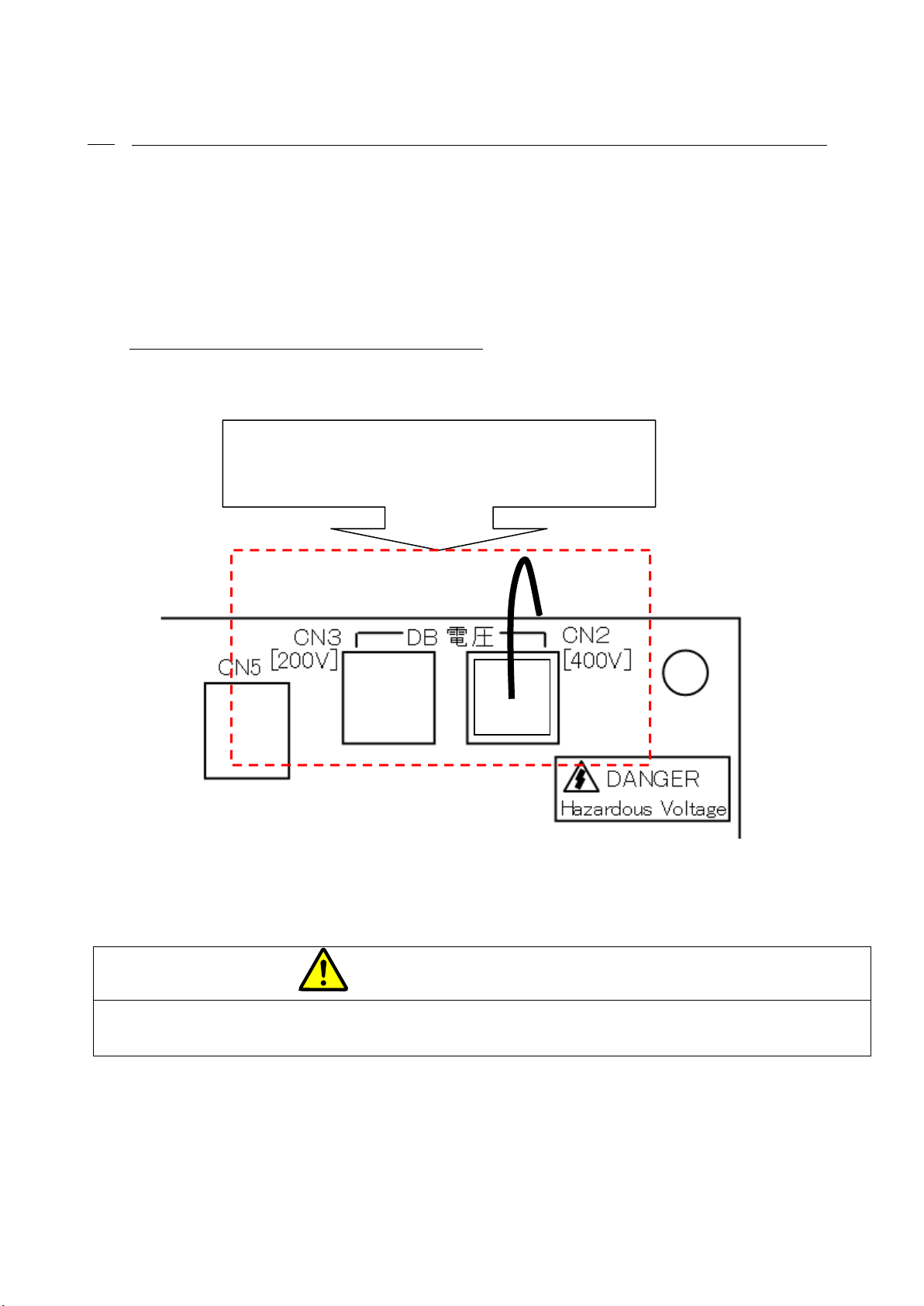

5.2.1 Change of a power supply voltage

Before turing on the power supply of an inverter,please switch connector CN2 and CN3 of

VFDB2009-Z PC board, according to the power supply voltage of the inverter to be used.

Connector is switched corresponding to the power

supply voltage of the inverter to be used.

[400V series]CN2,[200V series]CN3

系 系

Figure 5.4 Power supply voltage change connector

DANGER [Connector]

Before turnig on the power supply of an inverter, the position of a power supply voltage system change

connector is checked.

Failure to do so may cause part breakage.

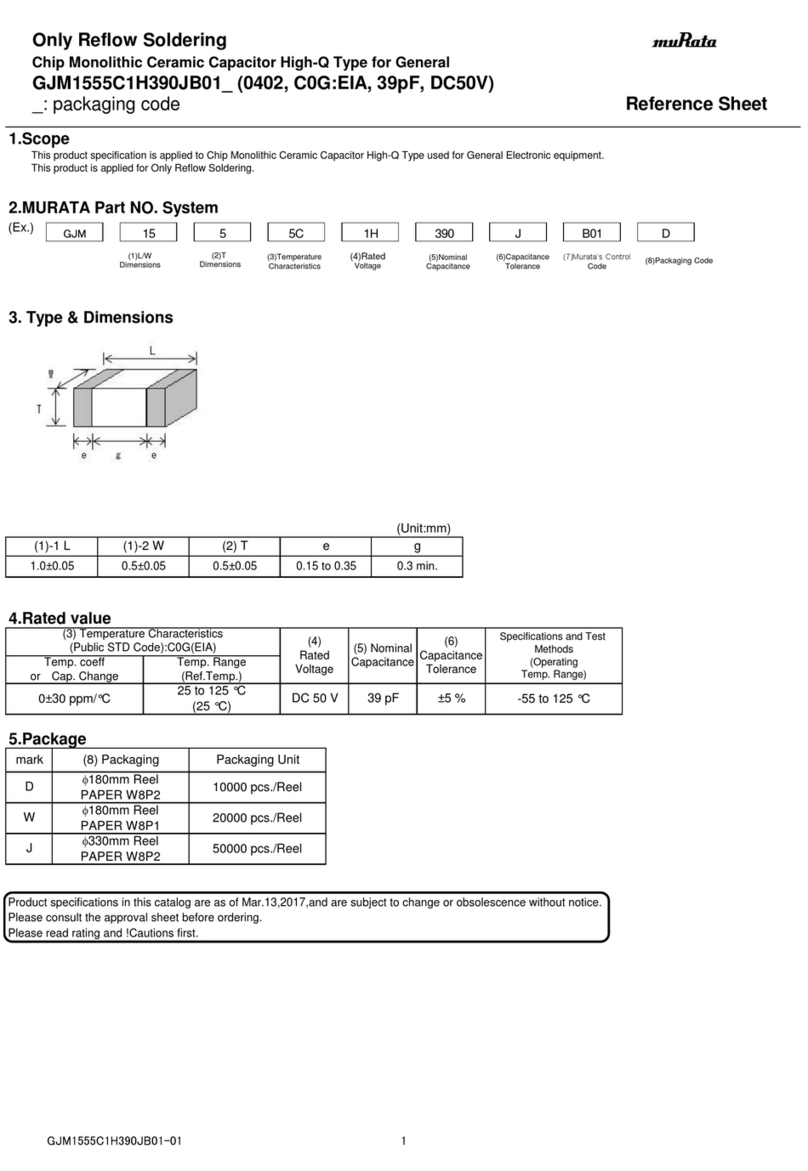

This manual suits for next models

3

Table of contents

Popular Industrial Electrical manuals by other brands

Murata

Murata GRM0225C1E6R5BA03 Series Reference sheet

Murata

Murata GRT188R61H225KE13 Series Reference sheet

Murata

Murata GRT31CR60J106ME01 Series Reference sheet

HEIDENHAIN

HEIDENHAIN LB 302 Mounting instructions

Murata

Murata GJM1555C1H390JB01 Series Reference sheet

Siemens

Siemens SIVACON 8PS BD01 installation instructions