Trak-Star 1" Gasoline Impact Wrench User manual

Serial #: Date:

operator’s manual

COVERS PART NUMBER 0012601

GASOLINE IMPACT WRENCH

1" Gasoline Impact Wrench

Welcome to Trak-Star®

Congratulations on your purchase of the Trak-Star®Gasoline Impact Wrench. Your model is designed to create

higher fastening torque quickly and efciently. Through constant innovation and development, Trak-Star®is

committed to provide you with tools and products that lead the industrial world.

Before attempting to operate your new Gasoline Impact Wrench, please read all instructions rst. These include

the Operators Manual and Warning Labels on the unit itself. With proper use, care, and maintenance, your model

will provide you with years of effective performance. Once again, thank you for selecting our product and

welcome to Trak-Star®.

SPECIFICATIONS

Engine...........................Two Stroke, Gas 46.5cc

Ignition...........................Electronic

Capacity.........................1-5/8" (41mm) Bolt Diameter

Net Weight.....................39.6 lbs. (18kgs) Without Fuel

Welcome to Trak-Star 2 Engine Breakdown & Parts List 13-15

Safety Instructions 3 Impact Unit & Gearbox Breakdown & Parts List 16-17

Technical Data 4-5 Ozat Sockets 18

Operating Instructions 6-7 Trak-Star Products 19

Trouble Shooting 8-9 Factory Authorized Warranty Repair Centers 20

Maintenance 10-12

2

0012601 - 1" Gasoline Impact Wrench

Read to fully understand and

observe the following safety

precautions and warnings. Careless

or improper use of tool may cause

serious or fatal injury.

WARNING! Indicates instant

possibility of severe personal

injury or loss of life, if instructions

are not followed.

Always wear eye, head and ear

protectors when using this tool.

SAFETY FIRST

InDeX

CAUTION! Indicates possibility

of personal injury or equipment

damage, if instructions are

not followed.

Work Area

Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as

in the presence of ammable liquids, gases or dust. Power tools

create sparks which many ignite the dust or fumes.

Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to loose control.

Operator Safety

• Always wear a safety face shield or goggles.

• Always wear heavy, long pants, boots and gloves. Do not wear

loose clothing, jewelry, short pants, sandals or go barefoot.

Secure hair so it is above shoulder length.

• Do not operate the tool when you are tired, ill or under the

inuence of alcohol, drugs or medication.

• Never let a child or inexperience person operate the machine.

• Wear hearing protection.

• Never start or run the engine inside a closed room or building.

Breathing exhaust fumes can kill.

• Keep handles free of oil and fuel.

• Keep hands away from anvil.

• Do not grab or hold the unit by rotating anvil.

• Hold the handles rmly with both hands and make sure to stand

on a rm base or ground.

• Do not touch spark plug or high voltage cord during operation

as it may cause electric shock.

• To avoid burn do not touch those places like engine, mufer

and exhaust. These parts get very hot during use, even after

engine is stopped.

• When operation is prolonged, take a break from time to time, so

that you may avoid possible whitenger disease. This is

caused by vibration.

Tool Safety

• Inspect the entire tool before each use. Replace damaged parts.

Check for fuel leaks and make sure all fasteners are in place and

securely fastened.

• Replace parts that are cracked, chipped or damaged in any way

before using the tool.

• Keep others away when making carburetor adjustments.

• Use only accessories as recommended for this tool by the

Manufacturer.

Fuel Safety

• Mix and pour fuel outdoors and where there are no sparks

or ames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or the tool or

while using the tool.

• When lling up fuel, stop engine and make sure engine is cool

and choose a well ventillated place where no amables are

present. 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, re and/or serious personal injury.

• Wipe up all fuel spills before starting engine.

• Move at least 3m away from fueling site before starting engine.

• Stop engine before removing fuel cap.

• Empty the fuel tank before storing the tool. It is recommended

that the fuel be emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

• Store tool and fuel in area where fuel vapors cannot reach

sparks or open ames from water heaters, electric motors,

switches and furnaces, etc.

Maintenance Safety

• Maintain the tool according to recommended procedures.

• Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

• Keep others away when making carburetor adjustments.

Use only genuine replacement parts as recommended by

the manufacturer.

Transport and Storage

• Carry the tool by hand with the engine stopped and the

mufer away from your body.

• Allow the engine to cool, empty the fuel tank, and secure the

tool before storing or transporting in a vehicle.

• Empty the fuel tank before storing the tool. It is recommended

that the fuel be emptied after each use. If fuel is left in tank,

store so fuel will not leak.

• Store tool out of reach of children.

• Clean the unit carefully and store in a dry place.

• Make sure engine switch is off when transporting or storing.

If situations occur which are not covered in this manual, take

care and have a good judgement. Contact your dealer if you

need assistance.

Service

Tool service must be performed only by qualied repair

personnel. Service or maintenance performed by unqualied

personnel could result in a risk of injury.

When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section of

this manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock

or injury.

WARNING

Never modify the tool in any way. Do not

use your tool for any job except that for

which it is intended.

WARNING

Antivibration systems do not guarantee that

you will not sustain whitenger disease or

carpal tunnel syndrome. Therefore,

conitinual and regular users should monitor

closely the condition of their hands and

ngers. If any of the above symptoms

appear, seek medical advice immediately.

4

TECHNICAL DATA

INTRODUCTION

The Trak-Star Gasoline Engine Impact Wrench is a high quality tool with a self-contained, heavy duty,

high power two cycle engine. It’s unique design, combining an impact mechanism, pneumatic

B-Hammer and small high powered 46.5 cc gas engine, produces an ultra light-weight 39.6 lbs. (18kg),

impact wrench that can produce high fastening torque.

Because of the self-contained, high power two cycle engine, it is very easy to carry by one man to any

construction sites in the rain forest, hill, desert or remote areas where electricity supply, air compressor

or generator are not available.

The capacity of this tool is 1-5/8" (41mm) bolt size and is ideal for fastening and loosening bolts of

wood sleepers at railroad construction sites and many more applications.

ENGINE Type Two Stroke, Forced, Air Cooled, Single Cylinder

Displacement 46.5cc, 44x34mm (Inner bore size by stroke)

Fuel Tank Capacity 1 Liter

Fuel Mixture Ratio 25:1 (gasoline : 2 cycle oil)

Revolution (Idling) ≤ 2700 rpm; Engagement Speed: ≥ 3400

Revolution (Loaded, Impact) 7120 rpm

Revolution ( Non loaded, max) 8500 rpm

Maximum Output 2.03 Ps/6500 rpm

Maximum Torque 0.34 kg-m/5500 rpm

Compression Rate 7.4 : 1

Fuel Consumption Rate 520g/kWh

IGNITION Type Electronic

Spark Plug Type L8RTC

CARBURETOR Type Diaphragm

IMPACT Square Drive Size 1" (25.4mm)

Fastening Torque Range 550 - 1700 N.m (406 - 1250 ft. lbs.)

Free Speed 1200 rpm

CAPACITY Bolt Diameter 1-5/8" (41mm)

WEIGHT Without Fuel 39.6 lbs. (18kg)

OVERALL Length 25-1/2"

DIMENSIONS Height 10-3/4"

Width 15"

ACCESSORIES Hex Key Wrench 5mm (1 pc)

6mm (1 pc)

8mm (1 pc)

Spark Plug Wrench (1 pc)

Spanner 10 - 13mm (1 pc)

Sound Pressure Level (LPA,d) 101 dB (A)

Sound Power Level (LWA,d) 112 dB (A)

Vibrations (m/s2) 8.0 m/s2

Noise emission with and without load according to prEN ISO 15744. DECLARED SINGLE-NUMBER NOISE EMISSION VALUES in accordance with ISO 4871.

Vibration level is measured at the handle with load according to ISO8662-7 Declared vibration emission value accordance with EN 12096.

NOTE: To improve the performance, the specications are subject to change without notice.

GOING EVERYWHERE,

NO ELECTRICITY & NO AIR POWER REQUIRED

5

Important notICe

Read all Safety Instructions listed at the beginning of this Operators Manual before operating

the GASOLINE IMPACT WRENCH.

1. Carefully read the instructions before operating.

2. Use only sockets and adapters, which are in good condition and are intended for use with power tools.

3. Adopt a suitable posture to counteract unexpected movement of the power tool.

4. If using a suspension device, ensure that the power to is securely xed.

5. Release the start and stop device in the case of an interruption of the energy supply.

6. The operator should have enough strength to hold the tool stably when using the tool.

7. Use #10 lubricant, thick machine oil is not recommended.

FUEL

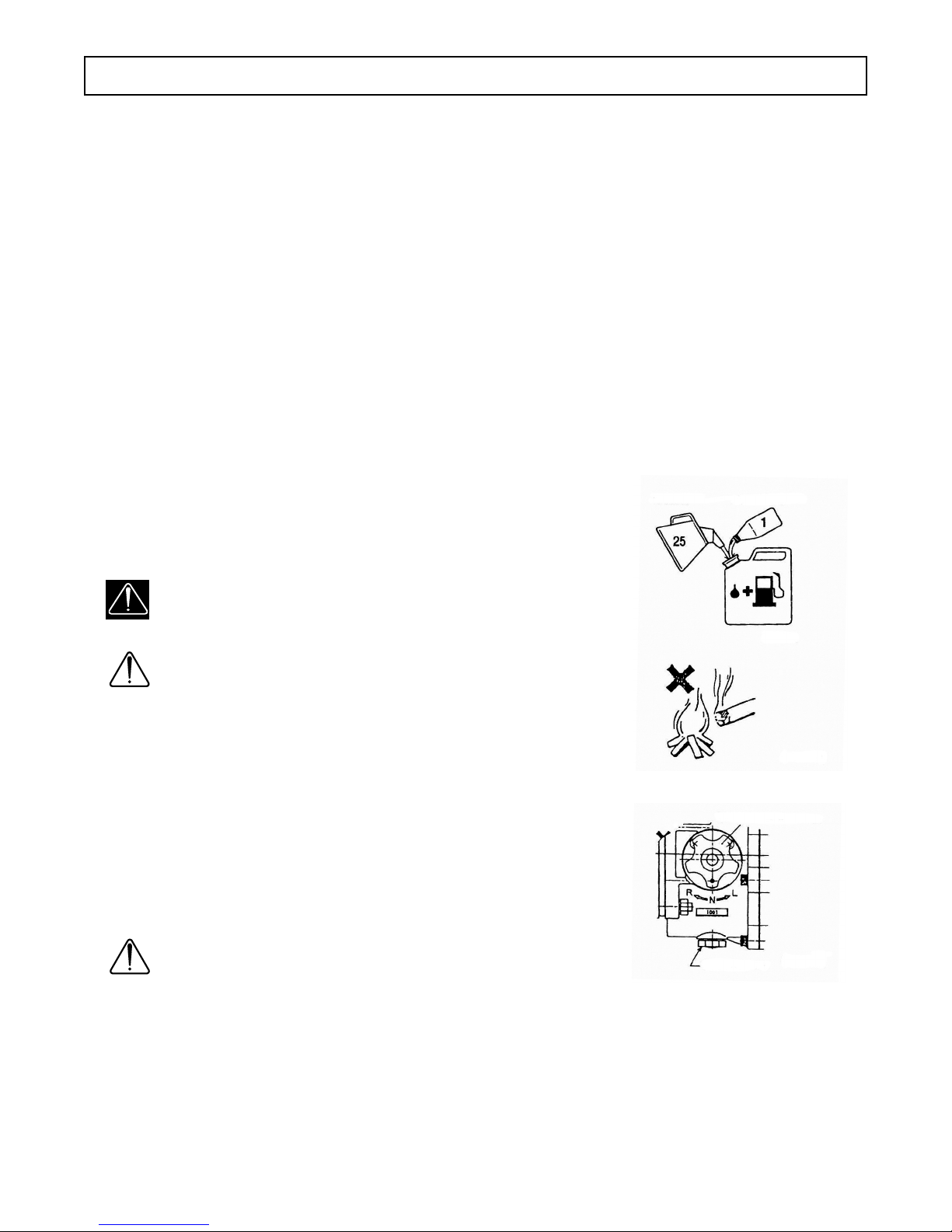

• Use only quality two cycle oil with gasoline at a mixture ratio of 25:1

(Gasoline : Two cycle oil) (Fig. 3)

• Never use gasoline only as engine will burn.

WARNING

Do not smoke and keep all other re away from the fuel tank during

lling fuel as it causes re it can burn yourself. (Fig. 3-1)

CAUTION

Wipe up all fuel spills before starting engine.

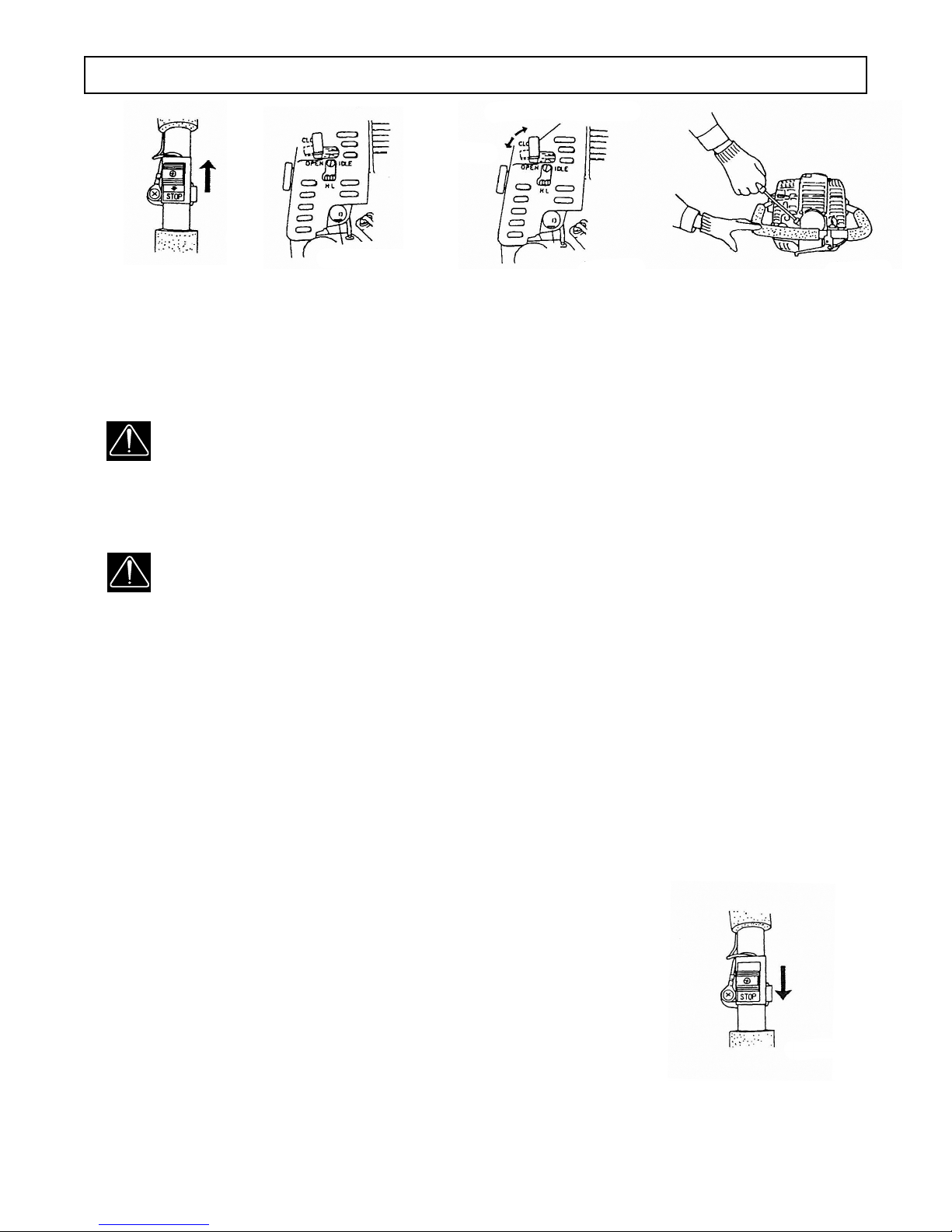

START UP ENGINE

1. Place the tool on a rm stand or solid oor.

2. Set gear change lever to neutral (N) position. (Fig. 3-2)

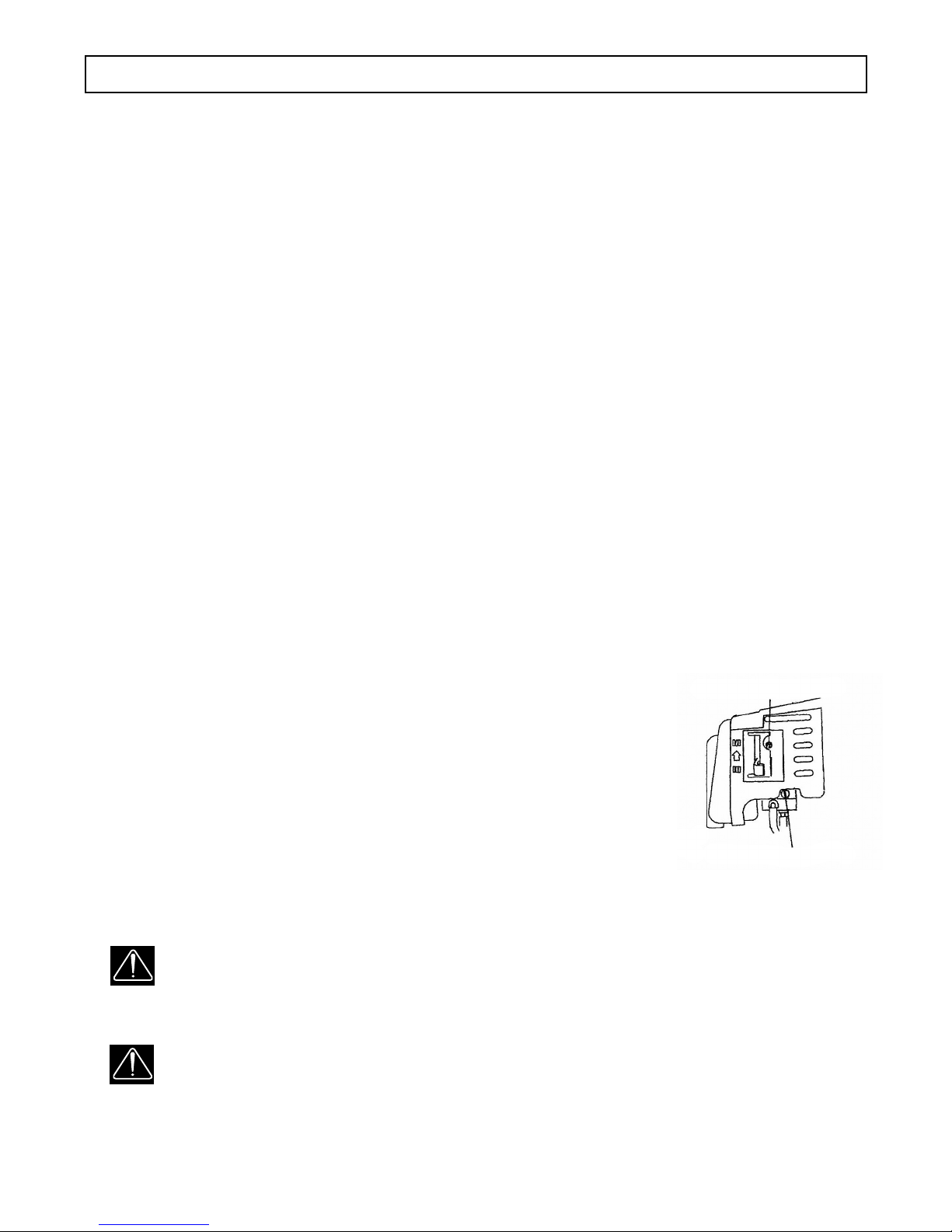

3. Slide stop switch to upward as shown. (Fig. 3-3)

4. Press priming bulb several times so that fuel slows through bulb

into carburetor. (Fig. 3-4)

5. Turn Choke lever to closed position. (Fig. 3-5)

6. Pull recoil starter handle strongly, taking care to keep the handle in

your grasp and not allow to withdraw rope until the end. (Fig.3-6)

CAUTION

Return recoil starter rope gently to its original position.

OPERATING INSTRUCTIONS

6

GASOLINE TWO CYCLE OIL

(FIG. 3)

(FIG. 3-1)

(FIG. 3-2)

OIL POT PORT

GEAR CHANGE LEVER

7. After initial re, engine will continue to run, return choke lever slowly to open position.

8. If engine stops after a few res by procedure (7), return choke lever to open position and pull recoil starter

handle strongly again.

9. If engine does not start by procedure (8), repeat procedures from (5).

10. After starting engine, return throttle lever to idle position for slow engine. Then allow the engine about 2-3

minutes to warm up before use. (Fig. 3-6).

WARNING

• Once engine is started, do not leave tool alone. Always hold handle tightly so that tool will not

move around on the stand or oor.

• Before and during operation, always take a rm stance and keep safety position from slipping or

falling down.

(FIG. 3-4)

PRIMING BULB

OPEN

(FIG. 3-5)

(FIG. 3-6)

CLOSED CHOKE LEVER

(FIG. 3-3)

WARNING

1. Power tools shall not be used in potentially explosive atmospheres unless specially designed

for that purpose.

2. Unexpected tool movement due to reaction forces or breakage of inserted tool may cause injuries.

3. Power tools shall be isolated from the energy source before changing or adjusting the

inserted tools.

4. Avoid the risk of being injured, keep hands away from the nut runner socket.

5. Avoid the danger to persons from high-speed splinters being emitted from impact wrenches

in the case of nut runner socket failure.

6. Unexpected direction of inserted tool movement can cause a hazardous situation.

7. Avoid inhaling the dust and ejected particles when operating the tool.

8. Continued use over prolonged periods of time can injure hands. If hands numb, ache or shows

white skin, operator should stop tool use and immediately seek medical attention.

OPERATING INSTRUCTIONS

6 7

OPERATION

1. Select R (for clockwise direction) or L (counter clockwise direction)

gear for fastening or loosening bolts and nuts.

2. Always release throttle lever to allow slow engine for idling and

turn gear change lever. DO NOT change gear when engine is accelerating.

3. Squeeze throttle lever for high speed to tighten or loosen bolts and nuts

and control engine speed with throttle lever.

4. Once bolts or nuts are fastened, release throttle lever for idling and not

allow driving shaft to turn. Remove socket from bolt of nut.

STOPPING ENGINE

1. Release throttle lever to decrease engine speed.

2. Return stop switch to stop position (Fig. 3-7)

3. Place the tool on rm stand or solid oor and turn gear change lever

to N (neutral) position.

(FIG. 3-7)

TROUBLE SHOOTING

89

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

ENGINE DOES FUEL SYSTEM Fill up fuel at mixture ration 25 gal : 1 two cycle oil

NOT START • Empty fuel or shortage 1. Remove spark plug

• Wet spark plug due to too much

intake of fuel

2. Exhaust exceeded fuel by pulling recoil starter

handle 5-6 times

3. Install spark plug

4. Turn choke lever to open position and pull

recoil starter handle

• Bent or disconnection of fuel pipe Repair

• Poor function of carburetor • Air leak from carburetor

• Incorrect carburetor adjustment

• Bad diaphragm in carburetor

• Incorrect carburetor valve hinge height adjust.

ELECTRICAL SYSTEM

• Ignition stop switch in stop position Turn to "on" position

• No spark 1. Bad connection/Ignition coil

2. Incorrect air gap/Ignition coil

3. Bad ignition coil

• Short circuit of stop switch lead wire Repair or replace

• Dirty plug Clean up or replace

• Wider spark plug gap Adjust correct gap to 0.6mm

• Poor connection of high voltage cord

in ignition with spark plug

Correct connection

ENGINE WILL FUEL SYSTEM

STOP SOON • Shortage of fuel Fill up fuel at mixture ration 25 gal : 1 two cycle oil

AFTER STARTING • Choke lever in closed position Turn to "open" position

OR IS LIKELY • Air goes through to fuel system Check for cracks on pipe or connector and pipe

is securely xed.

TO STOP

• Poor function of carburetor • Air leak from carburetor

• Incorrect carburetor adjustment

• Bad diaphragm in carburetor

• Incorrect carburetor valve hinge height adjust.

ELECTRICAL SYSTEM

• Bad spark plug Replace

• Bad ignition coil Replace

9

TROUBLE SHOOTING

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

ENGINE • Bad mixture ratio of fuel Fill up correct mixture ratio 25 gal : 1 two cycle oil

OVERHEATS • Wrong selection of spark plug Replace. Use pure and instructed parts only

• Clogged cylinder with dirt Clean up

• Clogged cooling duct with dirt Clean up

NON-REVOLUTION • Gear change lever in neutral Turn to R (clockwise direction) or L (counter

OF ANVIL SHAFT clockwise direction) position

• Worn out drum shoe on clutch arm Replace

OUTPUT POWER • Dirty air cleaner element Clean up

REDUCTION • Carbon deposits in mufer

exhaust port on cylinder

Clean up

• Poor cylinder pressure due to

worn piston, piston ring or cylinder

Replace

• Worn out Anvil Replace

• Worn out clutch Replace

• Worn out cam plate Replace

• Worn out hammer Replace

• Broken return spring Replace

MAINTENANCE INSTRUCTIONS

10

MAINTENANCE / CHECK-UP / REPAIRING

It is recommended to practice regular check-ups and maintenance in accordance with usage frequency to keep

your tool in its best condition and prolong life, reducing total running costs. This practice also protects you from

serious injury. Before maintenance, please release the start and stop device.

• Only use #10 lubricant, the tool should be lubricated at tool inlet.

• Do not replace the component or change the construction and design.

• If the component used is not the same as the original component supplied by the manufacturer,

the manufacturer shall not take responsibility.

• Keep the tool in a dry place when not in use.

DAILY CHECK-UP

• Check that all nuts and screws are securely tightened.

• Check fuel level. When lling up with fresh fuel, wipe up all spills and clean fuel tank.

• Check oil level of gear box through window. Oil level should be at the center of window. If lower than this

level, add oil.

WEEKLY MAINTENANCE

• Check the starter, especially the cord and return spring.

• Clean the exterior of the spark plug.

• Remove the spark plug and check the electrode gap. Adjust it to 0.6mm, or change the spark plug.

• Clean the cooling ns on the cylinder and check that the air intake at the starter is not clogged.

• Clean the air lter.

MONTHLY MAINTENANCE

• Rinse the fuel tank with gasoline.

• Clean the exterior of the carburetor and the space around it.

• Clean the fan and the space around it.

1. CARBURETOR ADJUSTMENT

1. When the engine is tested at the factory, the carburetor is properly adjusted.

Do not try to touch it.

2. When idle speed is higher or lower (engine will stop), adjust to correct speed

by idle adjustment screw. Turn clockwise for higher idle. Turn counter clock

wise for lower idle. (Fig. 5-1).

3. How to adjust the volume of inhaled oil (higher speed fuel adjustment)

Full open throttle lever, turn idle adjustment screw to right or left to look for the

peak idle speed. From this position, return adjustment screw to left 1/8-1/4 turn.

2. CHECK-UP SPARK CONDITION

1. Remove spark plug and touch it to metal part except spark plug mounting thread.

2. Pull recoil starter handle.

3. When in normal condition, you see a spark.

(FIG. 5-1)

VOLUME OF INHALED OIL

IDLE ADJUSTMENT SCREW

WARNING

Never touch spark plug to the area at spark plug mounting

thread since remaining gas might exploded.

WARNING

When pulling recoil starter handle, do not touch the metal part of

spark plug or you will get an electric shock.

Wipe and clean up fuel around spark plug area.

(FIG. 5-2)

REMOVE CARBON

0.6mm

11

MAINTENANCE INSTRUCTIONS

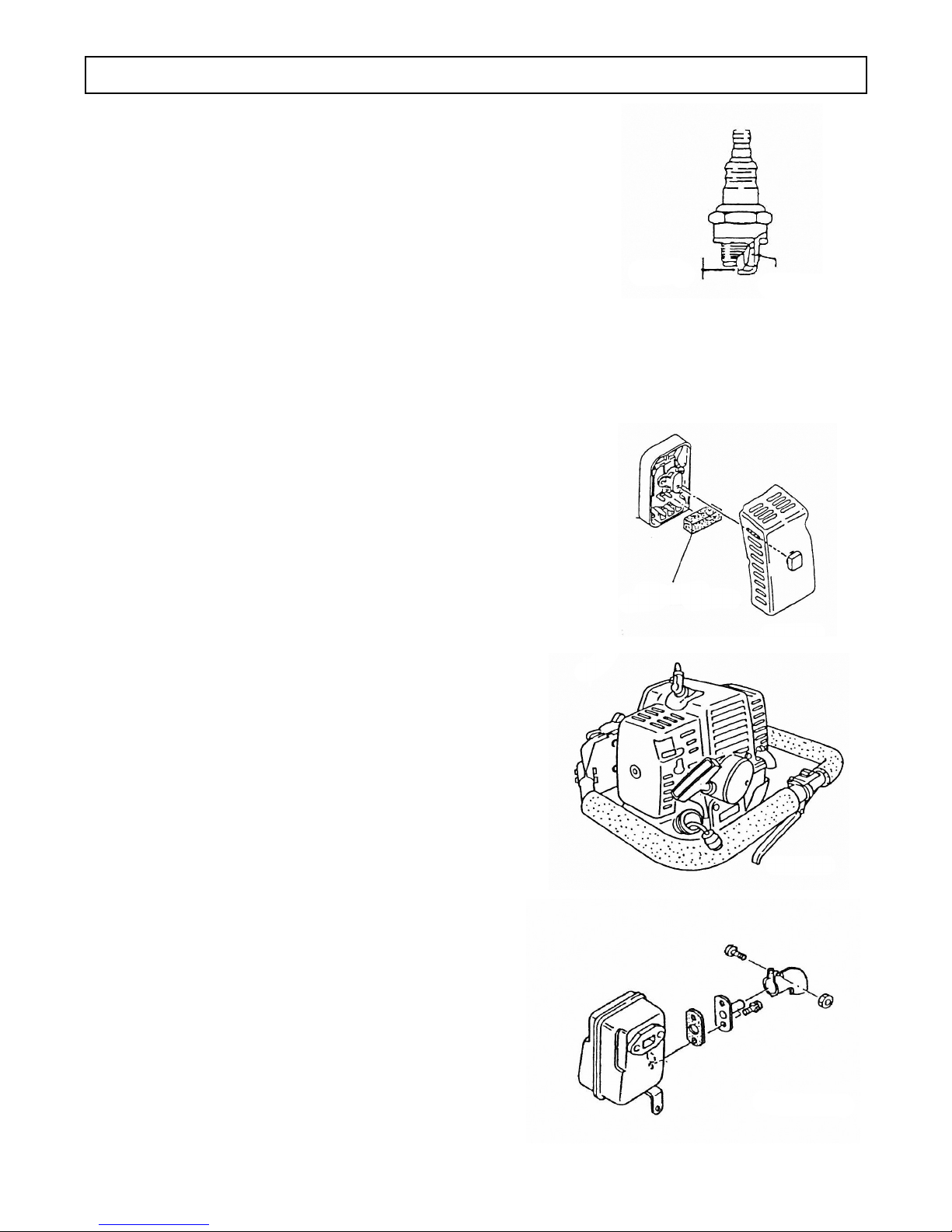

3. SPARK PLUG (Fig. 5-2)

1. Use only recommended type of spark plug.

2. In best operating condition, electrodes on the spark plug are dark brown.

Keep spark plugs dry. If the spark plug is dirty, clean it and check electrode gap.

If readjustment is necessary, the correct gap is 0.6mm.

The spark plug condition is inuenced by the following factors:

• An incorrect carburetor setting.

• Wrong fuel mixture (too much oil in gasoline).

• A dirty air lter.

• Hard running conditions (cold weather operations).

The spark plug should be replaced after 100 operation hours or earlier if the electrodes

are badly eroded.

4. AIR FILTER (FIG. 5-3)

1. When the air lter gets dirty and closed with dust, it will cause various troubles:

• Carburetor malfunctions.

• Starting problems.

• Engine power reduction.

• Unnecessary wear on engine parts.

• Abnormal fuel consumption.

2. Cleaning the air lter

Air lter must be cleaned from dust and dirt regularly and

damaged lter must be replaced with a new one.

• Remove the air lter cover and the lter.

• Rinse it in warm soapy water and wring tight. Let dry

before re-assembly.

• Damaged air lter must be replaced with a new one.

5. FUEL FILTER (Fig. 5-4)

1. If fuel lter is clogged with impurities in the fuel, fuel will

not ow into carburetor and it will make the engine

malfunction. Regular check-ups is recommended.

• Drain all fuel from fuel tank and pull out fuel lter

line from tank.

• Pull lter element out of holder assembly and rinse

element in warm water with detergent.

• Rinse thoroughly until all traces of detergent

are eliminated.

• Squeeze, but do not wring and let dry.

• If element is too dirty, replace.

6. MUFFLER (Fig. 5-5)

1. Engine power reduction might be caused by carbon

accumulation around the exhaust port on cylinder,

mufer inlet or outlet in the long use. Regular

clean-up is recommended.

• Remove the mufer and clean up any excess

carbon from the exhaust port or mufer inlet

every 100 hours of operation.

• When cleaning up, remove carbon carefully to not

damage piston. cylinder and do not let carbon into

crank case.

(FIG. 5-3)

AIR FILTER

(Cleaner Sponge)

(FIG. 5-4)

(FIG. 5-5)

12

MAINTENANCE INSTRUCTIONS

7. IMPACT MECHANISM

1. When contact places of anvil and hammer become worn-out by percussion, the tool becomes susceptible

to damage and can lead to breakage of parts.

• Empty all oil in the gear box and remove hammer housing completely and check the degree of

worn-out on anvil and hammer at least once every month. Grease around hitting area.

8. ADDING OIL

1. Use of the correct hydraulic oil is essential. Approved oils are Shell "TELLUS Oil" and Exxon

"TERESSTIC" (Part No. 75377). Grade #32 viscosity must be used. Check the unit specications. Make

sure that the work area and all equipment are clean so that no dirt, dust or other foreign material can get

into the hydraulic oil or pump area.

2. Remove Anvil plug (reference part no. 229 on page 16) and ll with #75377 Hydraulic oil.

3. Replace the Anvil plug and wipe up any excess oil.

9. STORAGE

1. Clean each part and apply two cycle oil on the metal part to prevent corrosion.

2. To keep tool for a long time (more than 3 weeks), drain fuel from fuel tank and keep running

engine without load until the engine will stop and exhaust all remaining fuel in the carburetor.

3. Remove spark plug and pure two cycle oil into cylinder and pull recoil starter handle several

times to spread oil.

4. Stop the recoil starter handle when you feel engagement.

5. Damaged parts should be repaired before storage.

6. Keep the tool in a place without dust or humidity, also the temperature below 50˚ C.

7. Store tool out of reach of children.

8. Keep fuel in safety container in a cool room or place where not ammable. Do not use

stale fuel as it cause engines troubles.

13

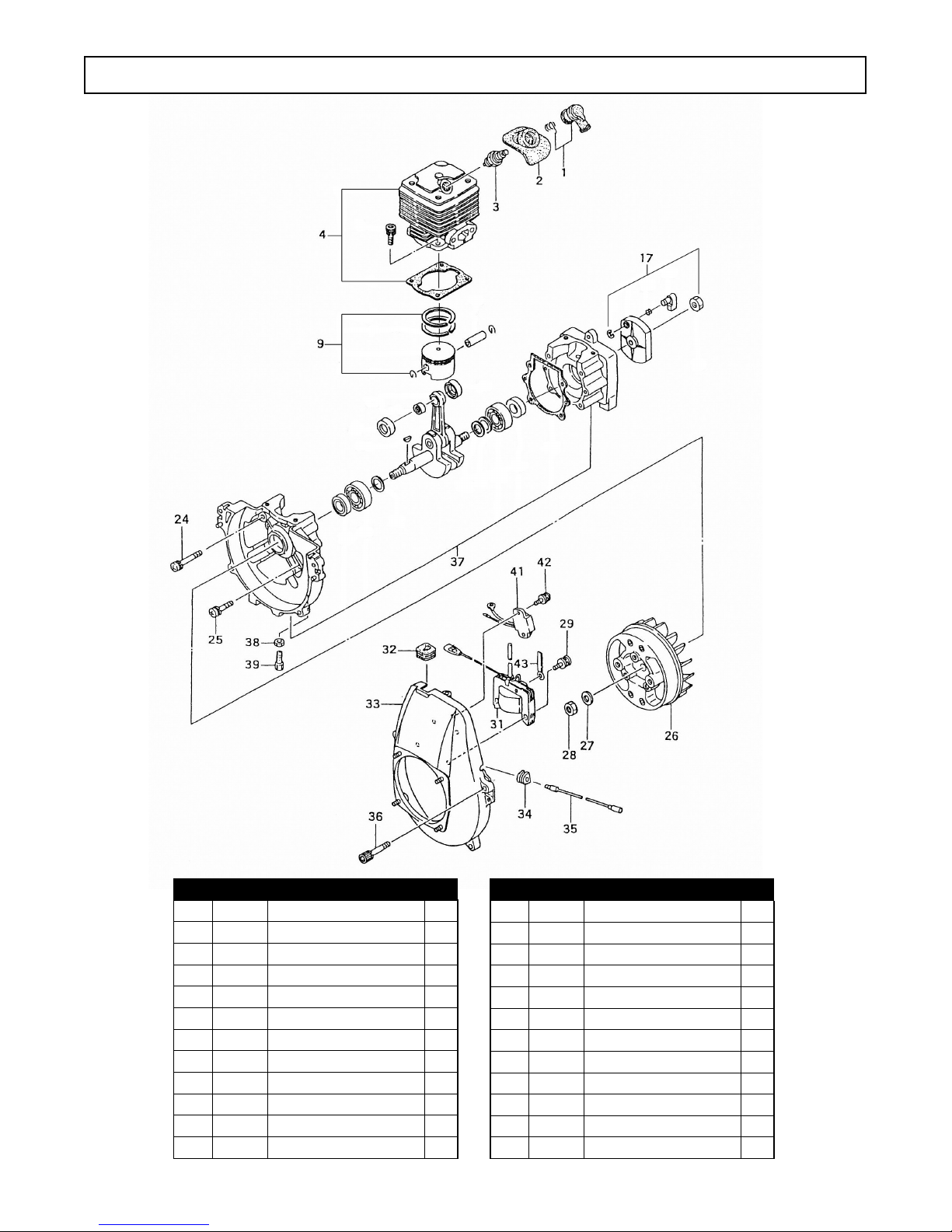

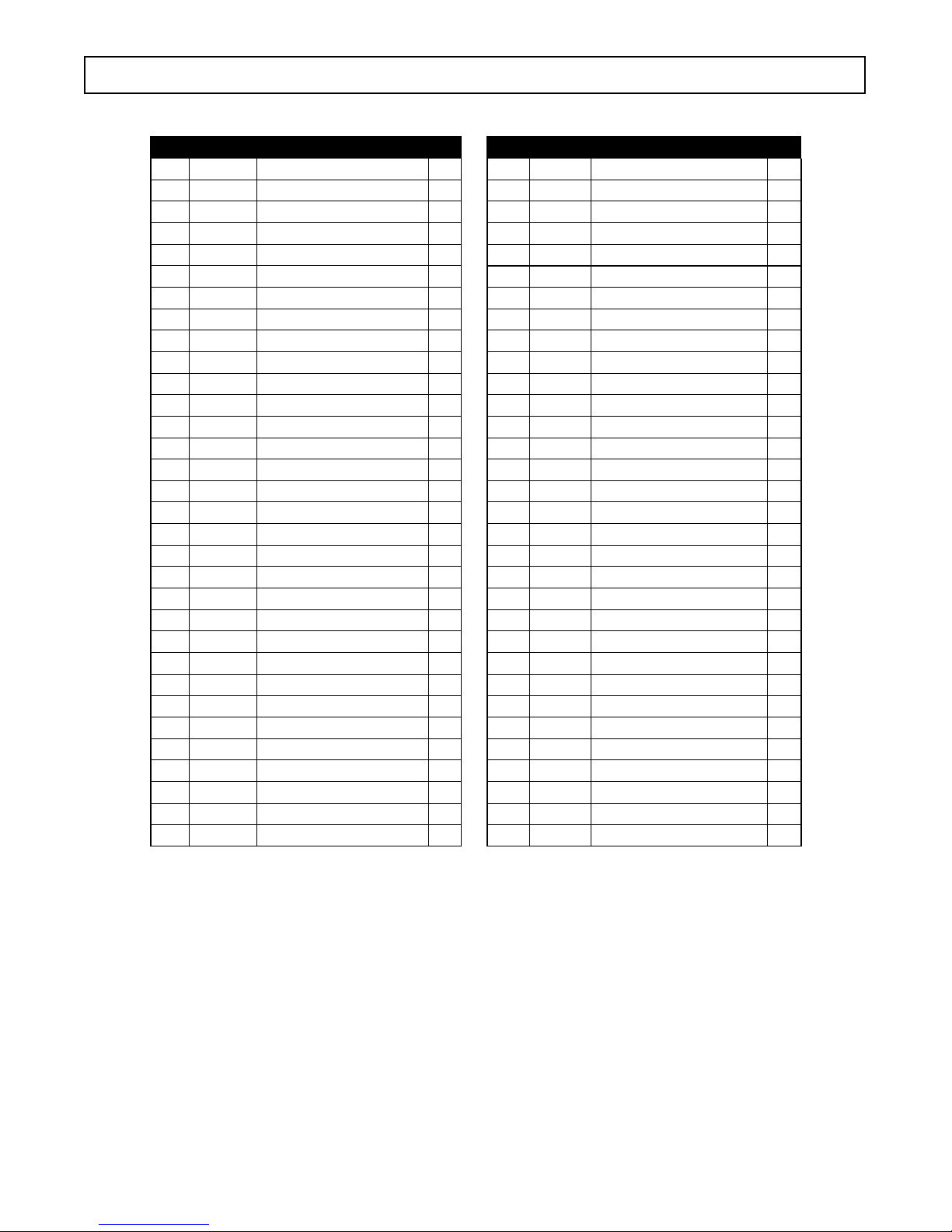

Item Part # Description Qty

107615 Spark Plug Ass’y 1

2 07616 Spark Plug Rubber Cover 1

3 07617 Spark Plug BPMR6A 1

4 07618 Cylinder Set 1

9 07619 Piston Set 1

17 07620 Starter Pulley 1

24 07726 Screw 6x45/S 2

25 07727 Screw 6x30 2

26 07621 Magnet Rotor Complete 1

27 07728 Small Washer .10 1

28 07729 Nut 10 1

29 07746 Screw 5x18/WS 3

ENGINE - EXPLODED VIEW

Item Part # Description Qty

31 07622 Ignition Coil Complete 1

32 07623 Primary Cord Grommet 1

33 07624 Fan Case Complete 1

34 07625 Primary Cord Grommet 1

35 07626 Stop Cord Complete 1

36 07731 Hex Bolt 6x20/S 4

37 07627 Crank Case Ass’y 1

38 07747 Nut 6 1

39 07628 Outer Receiver 1

41 07629 Ignitor Complete 1

42 07730 Screw 5x14/PS 2

43 07630 Cord Clamp Complete 1

14

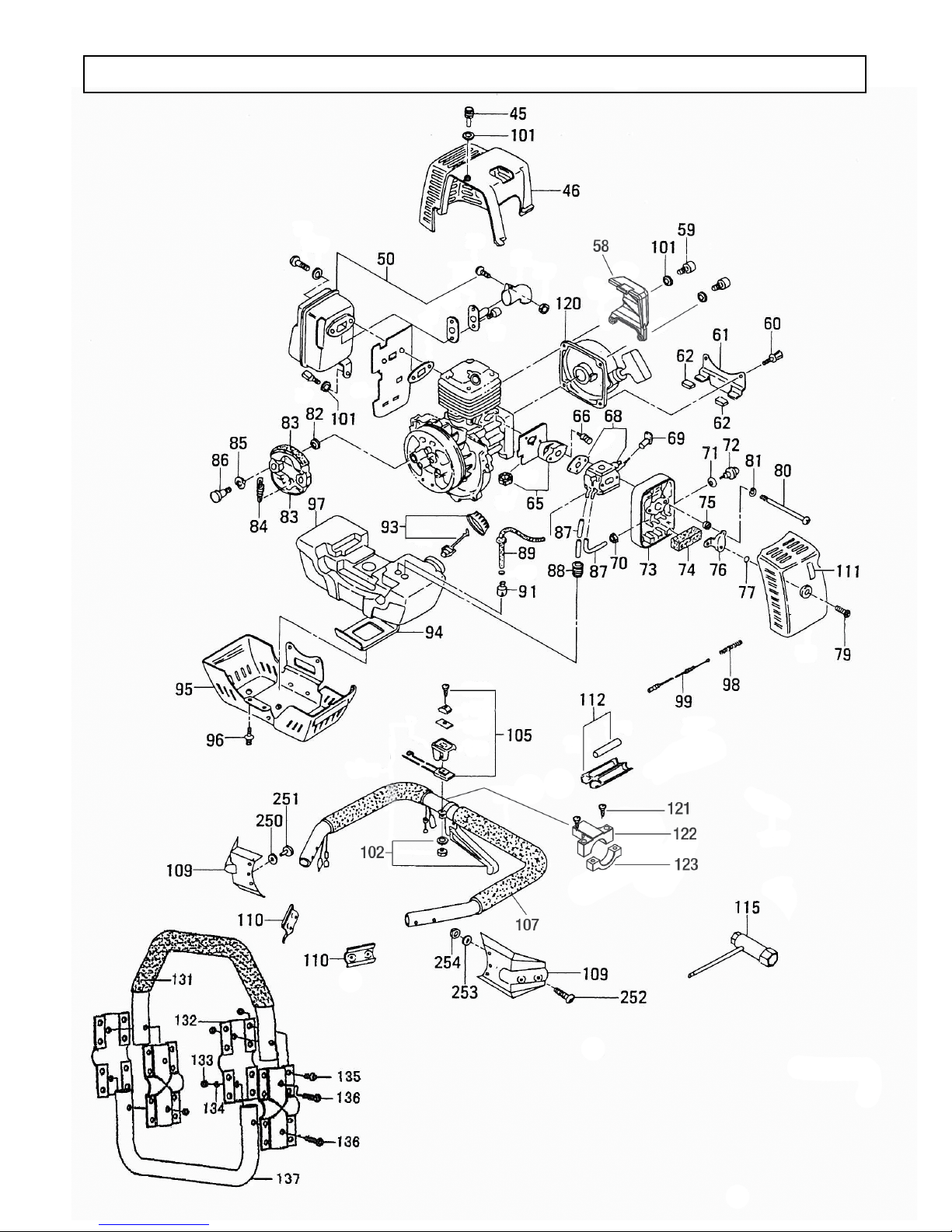

ENGINE COMPONENTS - EXPLODED VIEW

15

ENGINE COMPONENTS - PARTS LIST

Item Part # Description Qty

45 07748 Hex Bolt 1

46 07631 Mufer Protector 1

50 07632 Mufer Set 1

58 07603 Motor Vent Guard 1

59 05534 Hex Hole Bolt 2

60 07749 Hex Hole Bolt 1

61 07633 Tank Bracket 1

62 07634 Fuel Tank Cushion Rubber 2

65 07635 Carb. Insulator Set 1

66 07750 Hex Hole Bolt 2

68 07636 Carburetor Set 1

69 07637 Choke Lever 1

70 07733 Nut 1

71 07732 Inner Tooth Washer 1

72 07638 Priming Pump Complete 1

73 07639 Cleaner Body 1

74 07640 Cleaner Sponge 1

75 07641 Collar 2

76 07642 Blow Over Check Board 1

77 07643 O-ring 1

79 07644 Cleaner Cover Bolt 1

80 07751 Screw 2

81 07752 S. Washer 2

82 07645 Clutch Washer 2

83 07646 Clutch Arm Complete 2

84 07647 Clutch Spring 1

85 07753 Wave Washer 2

86 07648 Clutch Step Bolt 2

87 07649 Fuel Pipe 2

88 07650 Return Grommet 1

89 07651 Fuel Pipe Ass’y 1

91 07652 Pump Filter Body Ass’y 1

Item Part # Description Qty

93 07653 Tank Cap D Ass’y 1

94 07654 Cushion Rubber 1

95 07655 Tank Holding Metal Complete 1

96 07754 Hex Hole Bolt 2

97 07656 Fuel Tank, Vermilion 1

98 07657 Adjust Spring 1

99 07658 Throttle Wire Complete 1

101 07442 Washer 2

102 07614 Adjust Lever Ass’y 1

105 07660 Stop Switch Ass’y 1

107 07661 Handle Ass’y 1

109 07662 Handle Bracket 2

110 07663 Handle Holder 2

111 07664 Choke Mark 1

112 07665 Connector Case Ass’y 1

115 07666 Combi. Box Spanner 10x19 1

120 07667 Recoil Starter Body Ass’y 1

121 10558 SCR-BHC 10-32x1 2

122 07601 Guard - Switch 1

123 07600 Guard - Strap 1

131 07668 Auto-vibration Rubber 1

132 07669 Four Sides Handle Holder 4

133 07756 U-nut M6 20

134 07757 Washer Spring M6 20

135 07758 Hex Cap Bolt 16

136 07759 Hex Cap Bolt 4

137 07599 Kickstand 1

250 07767 Washer, Spring 6

251 07772 Hex Cap Bolt 6

252 07759 Hex Cap Bolt 4

253 07744 Washer, Jagged Spring 4

254 07756 U-nut 4

16

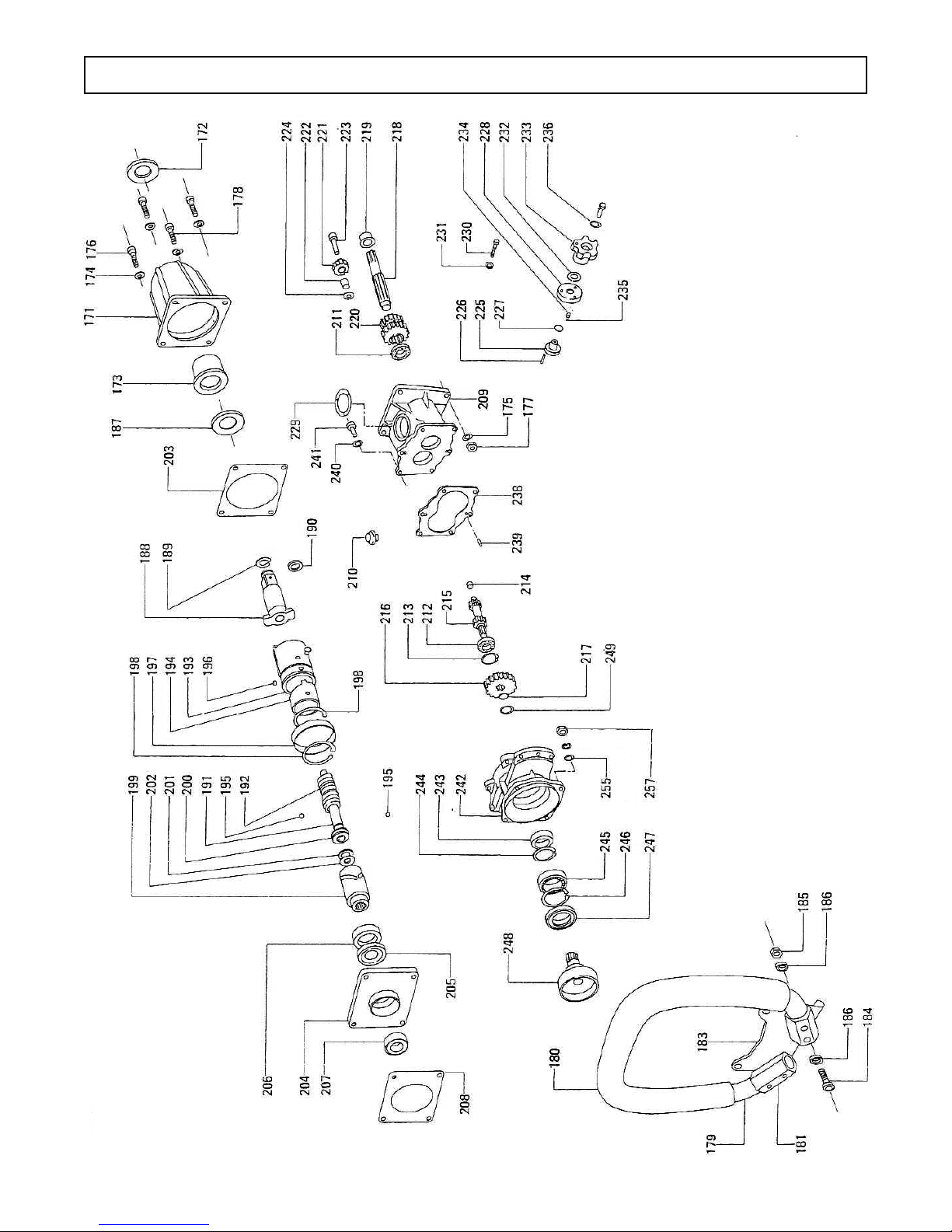

IMPACT UNIT & GEARBOX - EXPLODED VIEW

16 17

IMPACT UNIT & GEARBOX - PARTS LIST

Item Part # Description Qty

171 07671 Hammer Housing Complete 1

172 07672 Oil Seal 1

173 07673 Bushing 1

174 07760 Washer 2H-M8, Jagged Spring 4

175 07761 Washer M8, Spring 3

176 07762 Hex Cap Bolt 3

177 07763 U-nut M8, Hammer Housing 3

178 07764 Hex Cap Bolt M8x50 1

179 07674 Anti-vibration Handle Complete 1

180 07675 Anti-vibration Rubber 1

181 07676 Retainer, Anti-vibration Handle 2

183 07677 Foot Rest 1

184 07765 Hex Cap Bolt M6x45 4

185 07766 U-nut M6, Anti-vibration Handle 4

186 07767 Washer M6, Spring 8

187 07735 Washer, Thrust 1

188 07678 Anvil Complete 1

189 07736 Ring, Retainer 1

190 07679 O-ring P18, Retainer Ring 1

191 07680 Central Shaft 1

192 07681 Spring, Return 1

193 07682 Hammer Complete 1

194 07683 Cam Plate 1

195 07684 Roller Ball 13/32 2

196 07685 Plug 4

197 07686 Ring 1

198 07737 Snap Ring WR73 2

199 07687 Clutch 1

Item Part # Description Qty

228 07714 Gear Flange 1

229 07715 Packing, Gear Flange 1

230 07768 Hex Cap Bolt M5x10 3

231 07743 Washer 2H-M5, Jagged Spring 3

232 07745 Washer WW-16, Spring 1

233 07716 Lever, Gear Change 1

234 07717 Retainer Spring S3.8x7x0.6x6 1

235 07718 Steel Ball 4 1

236 07769 Washer M6, Spring 1

238 07719 Gasket, Gear Case 1

239 07720 Pin 4x13.8 2

240 07770 Washer 2H-M6, Jagged Spring 6

241 07771 Hex Cap Bolt M6x25 6

242 07721 Clutch Support, Flange Comp 1

243 07722 Ball Bearing 16005 1

244 07741 Snap Ring IRTW-47 1

245 07723 Ball Bearing 6907 1

246 07742 Snap Ring IRTW-55 1

247 07724 Oil Seal 1

248 07725 Clutch Ring 1

249 07740 Snap Ring STW-25 1

250 07767 Washer, Spring 6

251 07772 Hex Cap Bolt M6x12 6

253 07744 Washer 2H-M6, Jagged Spring 4

255 07773 Washer 2H-M6, Jagged Spring 4

257 07774 Screw M6 4

Item Part # Description Qty

200 07688 Bearing, Thrust 1

201 07689 Spacer 1

202 07690 Thrust 1

203 07691 Gasket, Hammer Housing 1

204 07692 Ring Flange Complete 1

205 07693 Oil Seal 1

206 07694 Ball Bearing 6007VV 1

207 07695 Ball Bearing 6006 1

208 07696 Gasket, Ring Flange 1

209 07697 Gear Case Complete 1

210 07698 Oil Pot Port PF3/8-19 1

211 07699 Ball Bearing 16004 1

212 07700 Ball Bearing 16003 1

213 07738 Snap Ring IRTW-35 1

214 07701 Bushing, Selector Shaft 1

215 07702 Shaft, Selector 1

216 07703 Gear 1

217 07739 Snap Ring STW-16 1

218 07704 Shaft, Bearing Complete 1

219 07705 Bushing, Bearing Shaft 1

220 07706 Gear Cluster 1

221 07707 Planetary Gear Complete 1

222 07708 Bushing, Planetary Gear 1

223 07709 Planetary Pivot 1

224 07710 Planetary Spacer 1

225 07711 Gear Selector Complete 1

226 07712 Spiral Pin 5x26, Gear Selector 1

227 07713 O-ring N14, Gear Selector 1

18

OZAT SOCKETS

Trak-Star now sells OZAT 8 point Impact Sockets. OZAT sockets are

superior to other sockets on the market because of their less-stress™

socket conguration. Each socket is made with a state of the art

electro-chemical machining process. OZAT sockets will result in longer

socket and fastener life.

Part No. Description

07100 1-1/4" OZAT socket

07101 1-5/16" OZAT socket

07102 1-3/8" OZAT socket

07103 1-7/16" OZAT socket

07104

1-1/2"

OZAT socket

07105

1-9/16"

OZAT socket

07106 1-5/8" OZAT socket

07107 1-11/16" OZAT socket

07108

1-3/4

OZAT socket

07109 1-13/16" OZAT socket

Order Today: 866-245-3745

3001 Hougen Dr • Swartz Creek, MI 48473

866-245-3745 • www.trak-star.com

Warranty

The Trak-Star warranty provides free replacement, to the original

purchaser, of any qualifying socket found to defective in either

workmanship, as indicated by breakage or premature wear.

Determination of free replacement will be made after an

examination by Trak-Star. Impact sockets, by their application,

are subject to extreme stresses. Products returned to Trak-Star

for warranty consideration must be shipped prepaid, with a

Trak-Star returned goods authorization (RGA) number issued

by the customer service department.

Part No. Description

07110

1-7/8"

OZAT socket

07111 2" OZAT socket

07112

2-1/8"

OZAT socket

07113 2-3/16" OZAT socket

07114 2-1/4" OZAT socket

07115 2-3/8" OZAT socket

07116 2-1/2" OZAT socket

07117 Retaining O-Ring

07118 Retaining Pin

19

Model RB28

Portable Gas Rail Drill

Portable Gas Bonding Drill

Model RB30

Power Feed Hydraulic Drill

Model RM42

OTHER PRODUCTS OFFERED BY TRAK-STAR

Modern, high speed railways and welded rails call for modern, high precision rail equipment.

Through our continual commitment, we now offer additional products that will be beneficial to

your specific applications.

Model BD17

Electric Bonding Drill

OTHER PRODUCTS OFFERED BY TRAK-STAR

Modern, high speed railways and welded rails call for modern, high precision rail equipment.

Through our continual commitment, we now offer additional products that will be benecial

to your specic applications.

1124

Hougen Manufacturing, Inc.

P.O. Box 2005 • Flint, MI 48501-2005

3001 Hougen Drive • Swartz Creek, MI 48473

Phone: (866) 245-3745 • Fax (800) 309-3299

E-Mail: info@trak-star.com

On-line: www.trak-star.com

OMIW0812 Printed in U.S.A.

© 2012 Hougen Manufacturing, Inc.

Hougen Manufacturing has received the

Association of American Railroads

Quality Assurance Program Certication

Hougen Manufacturing, Incorporated warrants its Trak-Star Rail Drills, Portable Magnetic Drills,

Electro-hydraulic Hole Punchers for one (1) year and other products for ninety (90) days from date of

purchase against defects due to faulty material or workmanship and will repair or replace (at its option) without

charge on any items returned. This warranty is void if the item has been damaged by accident or unreason-

able use, neglect, improper service, or other causes not arising out of defects in material or workmanship. No

other expressed warranty is given or authorized. Hougen Manufacturing, Inc., disclaims any implied warranty

of MERCHANTABILITY or FITNESS for any period beyond the expressed warranty and shall not be liable

for incidental or consequential damages. Some states do not allow exclusions of incidental or consequential

damages or limitation on how long an implied warranty lasts and, if the law of such a state governs your

purchase, the above exclusion and limitation may not apply to you. This warranty gives you specic legal

rights and you may also have other rights which vary from state to state.

To obtain warranty service, return the item(s), transportation prepaid, to your nearest Factory Authorized

Repair Center or to Hougen Manufacturing, Inc. 3001 Hougen Drive, Swartz Creek, Michigan 48473.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

© 2012 Hougen Manufacturing, Inc.

Commercial / Industrial Limited Warranty

Hougen Manufacturing, Inc. Kenbil Service Co.

3001 Hougen Drive 2900 Adams Street B-14

Swartz Creek, MI 48473 Riverside, CA 92504

(866) 245-3745 (951) 689-6633

Photographs and Specications shown are accurate in detail at time of printing. Manufacture reserves the

right to make improvements and modications without prior notice.

Hougen, Hougen-Edge, Trak-Star, and Punch-Pro are propriety trademarks of Hougen

Manufacturing, Inc. Ogura and the Ogura logo are proprietary trademarks of Ogura & Co., Ltd. Honda logo

appears courtesy of American Honda Motor Co.

FACTORY AUTHORIZED WARRANTY REPAIR CENTERS

This manual suits for next models

1

Table of contents

Popular Impact Driver manuals by other brands

Hitachi

Hitachi WH14DBL Handling instructions

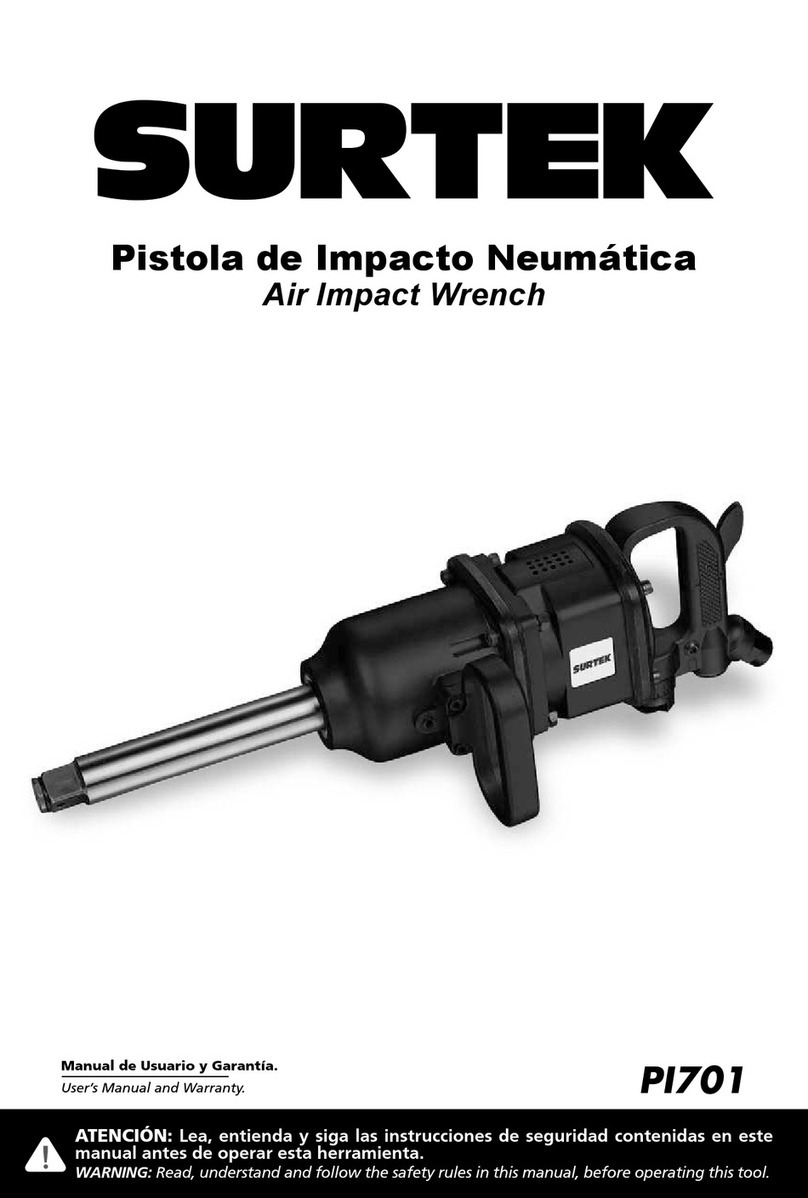

Surtek

Surtek PI701 User's Manual and Warrantly

Ingersoll-Rand

Ingersoll-Rand 2135Qi Product information

Panasonic

Panasonic EY75A7 operating instructions

Metabo HPT

Metabo HPT WR 22SE Instruction manual and safety instructions

Ingersoll-Rand

Ingersoll-Rand 2141 instruction manual