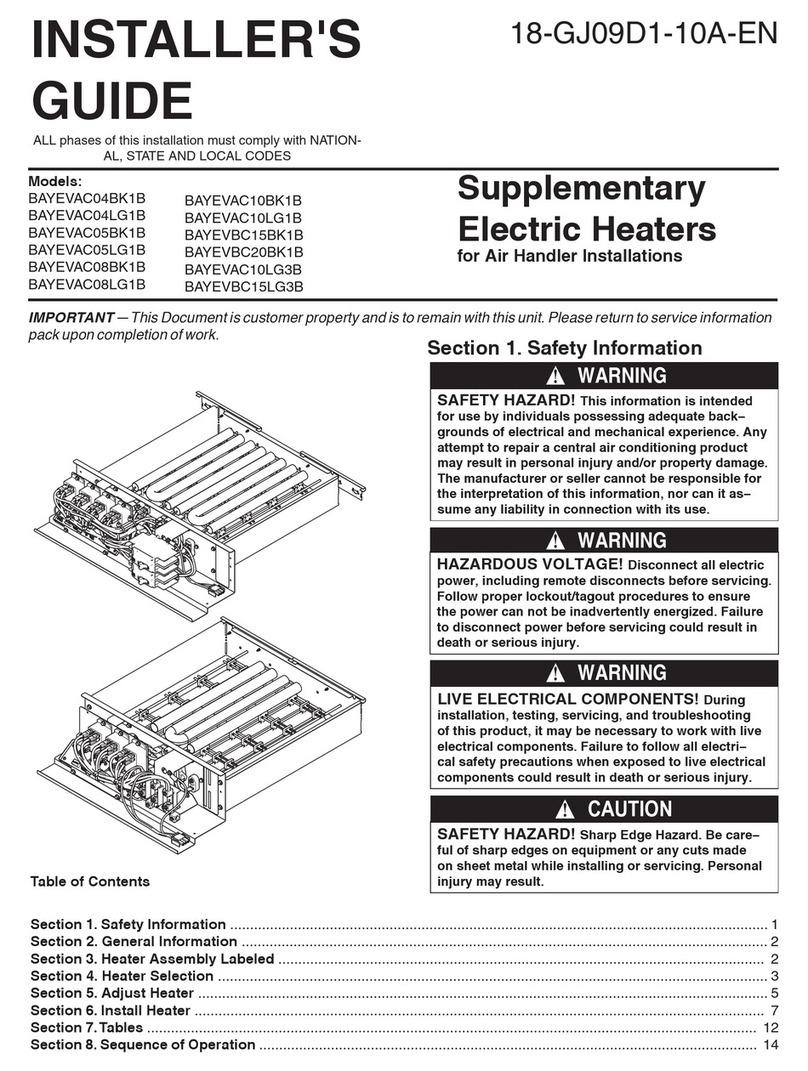

25 kW Supplementary

Electric Heater

for Air Handler Installations

INSTALLER'S

GUIDE

IMPORTANT—This Document is customer property and is to remain with this unit. Please return to service information

pack upon completion of work.

ALL phases of this installation must comply with NATION-

AL, STATE AND LOCAL CODES

18-GJ28D1-1C-EN

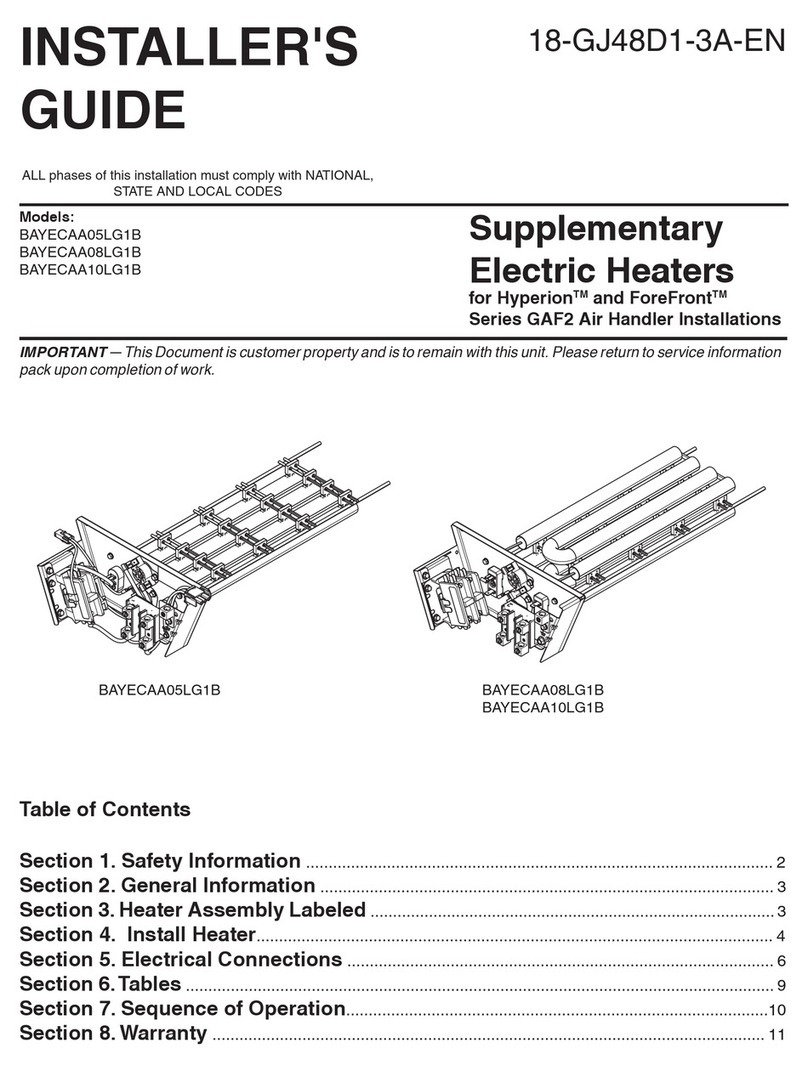

Models:

BAYEVCC25BK1B

Table of Contents

Section 1. Safety Information ....................................................................................................................................... 1

Section 2. General Information..................................................................................................................................... 2

Section 3. Heater Assembly Labeled ........................................................................................................................... 2

Section 4. Adjust Heater ............................................................................................................................................... 3

Section 5. Install Heater ................................................................................................................................................ 5

Section 6.Tables .......................................................................................................................................................... 11

Section 7. Heater Operation ....................................................................................................................................... 12

Section 1. Safety Information

SAFETY HAZARD! This information is intended

for use by individuals possessing adequate back-

grounds of electrical and mechanical experience. Any

attempt to repair a central air conditioning product

may result in personal injury and/or property damage.

The manufacturer or seller cannot be responsible for

the interpretation of this information, nor can it as-

sume any liability in connection with its use.

LIVE ELECTRICAL COMPONENTS! During

installation, testing, servicing, and troubleshooting

of this product, it may be necessary to work with live

electrical components. Failure to follow all electri-

cal safety precautions when exposed to live electrical

components could result in death or serious injury.

SAFETY HAZARD! Sharp Edge Hazard. Be care-

ful of sharp edges on equipment or any cuts made

on sheet metal while installing or servicing. Personal

injury may result.

HAZARDOUS VOLTAGE! Disconnect all electric

power, including remote disconnects before servicing.

Follow proper lockout/tagout procedures to ensure

the power can not be inadvertently energized. Failure

to disconnect power before servicing could result in

death or serious injury.