TRANSLAND Satloc Falcon User manual

Satloc Falcon Installation Guide 1875-3004-000 Rev A2

Overview: is installation guide lists all the parts in the

Falcon GPS System kit and provides instructions on installing the Falcon

GPS System components, associated cables, and switches.

Read this manual thoroughly before beginning the installation.

If you have any questions, contact your local dealer or Satloc Customer Service.

Satloc Falcon Installation Guide 2875-3004-000 Rev A2

Copyright Notice

Satloc, a company of Texas Transland, LLC

Copyright Satloc © (2022). All rights reserved.

No part of this manual may be reproduced, transmitted, transcribed, stored in a retrieval system or translated into any

language or computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical, manual

or otherwise, without the prior written permission of Satloc.

Latest Version of the Falcon Installation Guide

Satloc is dedicated to providing updated versions of installation guidebooks for its customers. For the latest version of the

Falcon Installation Guide, visit www.Satloc.com.

is device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. is device may not cause harmful interference, and

2. this device must accept any interference received, including interference that may cause undesired operation.

Notice to Customers

Contact your local dealer for technical assistance. To nd an authorized dealer near you, visit www.Satloc.com.

Transland

1206 Hatton Rd.

Wichita Falls, TX 76302

Phone: 940-687-1100

Fax: 940-687-1941

www.TranslandLLC.com

Documentation Feedback

Satloc, a division of Transland, is committed to the quality and continuous improvement of our products and services.

We encourage and appreciate any feedback regarding this guide and any of our products by writing to the following email

address: Sales@Translandllc.com.

Satloc Falcon Installation Guide 3875-3004-000 Rev A2

SAFETY INFORMATION

Read and Follow Safety Messages

• In these instructions, you may see the heading and/or the safety alert symbol . ey indicate

a hazardous situation that, if not avoided, could result in death or serious injury. e safety messages provide

information to identify a hazard associated with potential injury.

• Read and understand this manual and all the warnings below before installing, operating, or performing maintenance

or service. FAILURE TO DO SO MAY CAUSE IRREVERSIBLE DAMAGE TO YOUR SYSTEM.

• Keep this manual and all related safety information with the manuals for your aircra.

Plan your installation by considering the following:

• Cable lengths

• Clearance space

• Power source

• Aircra structure

• Visibility

Consider using existing hardware and hardware locations. Avoid drilling holes that may damage other

equipment (such as structural frame members, electrical cables, or uid lines).

Do not obstruct the view of, or access to, other instruments or the ying visibility of the operator.

Do not allow anyone to operate without instruction.

For trouble-free operation and maintenance of your Falcon system, avoid using Falcon in extreme

environmental conditions (40-140°F is recommended operating temperature range).

Satloc Falcon Installation Guide 4875-3004-000 Rev A2

TABLE OF CONTENTS

Safety Information: 3

Chapter 1: Getting Started 5

Chapter 2: Mounting the Components 9

Chapter 3: Connecting the CPU 23

Appnendix A: A21 GPS Antenna Mounting Dimensions 35

Satloc Falcon Installation Guide 5875-3004-000 Rev A2

Chapter 1: Getting Started

Parts Lists

Component Weights

Planning the Installation

Satloc Falcon Installation Guide 6875-3004-000 Rev A2

PARTS LISTS

The system modules that ship with the Falcon and connect to the CPU are:

• 7” or 9” color touchscreen

• Lightbar

• Antenna

• Optional switches (spray on/o, swath advance)

Table 1-1: Falcon and Falcon Pro CPU Kits (PN 900-4100-000 or PN 900-4101-000)

Read this entire manual before beginning installation. Failure to follow instructions in this manual could

void your warranty.

Pay careful attention to safety reminders and warnings to eliminate the possibility of personal injury or

damage to the system. Comply with all electrical connections and requirements to prevent damage to the

system.

Review the contents of your Falcon purchase to ensure the components are not damaged. If

chosen, a 7” display kit will replace the 9” display kit. Optional upgrade kits are only included with

additional purchase(s).

Component Part Number Qty

Satloc Falcon (CPU/Controller) 806-1060-000 1

A21 GPS antenna 150-0056-01 1

Antenna cable, TNC(M)-TNC(M) 5M 052-0005-000# 1

Antenna, monopole ADSB-IN 804-4000-000 1

Antenna, WIFI, dual band 804-4001-000 1

Cable, power / relay 050-2200-000 1

Cable, GPIO 050-2202-000 1

Cable, comports (COMM) 050-2203-000 1

Cable, ADS-B In 050-2522-000 1

Kit, Falcon, slide mount hardware 710-2001-000 1

Kit, Falcon control components 710-2007-000 1

PCA, IMU, Falcon, Calibrated* 725-2050-000 1

Kit, IMU mounting* 710-2004-000 1

Manual, Installation Guide, Satloc Falcon, (this manual) 875-3004-000 1

*Only included in the Falcon Pro CPU Kit.

Satloc Falcon Installation Guide 7875-3004-000 Rev A2

Table 1-2: Falcon Touchscreen Kit (9” Display) (PN 900-4200-000)

Component Part Number Qty

9” Display 806-4403-000 1

Cable, cockpit 050-2201-000 1

Cable kit, display to panel USB 050-2525-000 1

Cable, display encoder 050-2528-000 1

Cable, display IO 050-2529-000 1

Cable, display audio out 050-2536-000 1

Kit, display components 710-2006-000 1

Table 1-3: Falcon L8 Lightbar Kit (PN 900-4300-000)

Component Part Number Qty

L8 Lightbar 806-4400-000 1

Cable, extension 22 050-2205-000 1

Kit, L8 Lightbar mounting 710-0031-000 1

Table 1-4: Optional - Falcon Second GPS Upgrade Kit (PN 900-4104-000)

Component Part Number Qty

Novatel 7600 receiver 750-6000-000 1

A21, L1 GNSS, LBAND antenna 804-3036-000# 1

Cable, RF, MCX(M)-TNC(F) 050-2516-000 1

Cable, RF-X, TNC(M)-TNC(M), 5M 052-0005-000# 1

Kit, Novatel 7600 mounting components 710-2005-000 1

Satloc Falcon Installation Guide 8875-3004-000 Rev A2

COMPONENT WEIGHTS

Table 1-6: Falcon Component Weights

Component Weight

CPU 5 lbs

Complete cable set for CPU 8 lbs

9” Touchscreen and Cables 7 lbs (3 lbs for touchscreen, 4 lbs for cables)

L8 Lightbar 9 lbs (6 lbs for lightbar, 2 lbs for brackets, 1 lb for cables)

Antenna 1 lb

PLANNING THE INSTALLATION

• Turn o power before connecting or disconnecting cables. Failing to do so can damage the system.

• Plan your installation by considering the following: 1) cable lengths, 2) clearance space, 3) power source,

4) aircra structure, and 5) visibility.

• Consider using existing hardware and hardware locations. Avoid drilling holes that may damage other

equipment (such as structural frame members, electrical cables, or fluid lines).

• Do not obstruct the view of, or access to, other instruments or the flying visibility of the operator.

• Do not route cables alongside power generator wire and other high-noise electric sources. This will

cause interference.

• Do not kink or force cables into sharp bends. This can damage the cable.

• Store excess cable length with at least a 6-inch bend radius.

• Do not coil the cables. This will introduce noise in the system.

• Avoid high-temperature exposure (for example, exhaust manifold) when routing cables.

• Do not allow anyone to operate without instruction.

In planning the installation locations, see Chapter 3, “Connecting the CPU,” for a visual overview

of how the components are connected.

Satloc Falcon Installation Guide 9875-3004-000 Rev A2

Chapter 2: Mounting the Components

Mounting the CPU

Mounting the Touchscreen

Installing the Cockpit Switches

Mounting the Lightbar

Mounting the A21 GPS Antenna

Mounting the Monopole ADS-B In Antenna

Satloc Falcon Installation Guide 10 875-3004-000 Rev A2

MOUNTING THE CPU

Before mounting (installing) components, read the short section, “Planning the Installation”

in Chapter 1.

Review all warnings in Chapter 3, “Connecting the CPU,” before attempting to connect any of the

components together using the supplied cables. Connecting cables improperly can damage your system.

Consider using existing hardware and hardware locations. Avoid drilling holes that may damage other

equipment (such as structural frame members, electrical cables, or uid lines).

Where hardware such as screws, washers, and nuts, is not provided for a particular mounting or installation, you

will need to provide the hardware appropriate to your specic needs.

REF QTYPART NUMBER DESCRIPTION PHOTOGRAPH

AHorizontal Mounting Bracket Kit

Brackets

2

#710-2001-000

#710-2001-000 Hardware Kit

M4 Screw - part Ba

Washer, split-lock - part Bb

Vibration Isolator - part Bc

Bolt, 6-32 x 3/8” - part Bd

Washer, - part Be

Nut, locking 6-32 - part Bf

4

4

4

8

8

8

B

C601-1313-000 (Optional, not included in kits.

Dealer may request a template.)

Mounting Layout Template for

Falcon/IF3 Rack Mount

1

(Optional, not included in kits.

Dealer may request a template.)

Mounting Layout Template for

Falcon/IF3 Horizontal Mount

1

601-1317-000

D

Table 2-1: Falcon CPU Mount Parts

Satloc Falcon Installation Guide 11 875-3004-000 Rev A2

Mount the CPU in an available space on the aircra that has the necessary room and is sheltered from the elements.

For example, inside or around the baggage compartment, inside or around the cockpit. Ensure there is enough space

for making connections and cable bend radius. Access is needed behind the mounting surface to attach the nuts to the

bolts (Ref B). When you have selected the mounting location, use an optional plate stencil (Ref C or Ref D) as a template

to mark fastener positions or get appropriate dimensions from CPU. Use the appropriate drill bit size as called out in

instructions or on optional templates to drill holes for the fasteners and secure the Falcon CPU to the aircra using

hardware (Ref B).

Rack Mounting: It is recommended to use the Mounting Layout Template (PN 601-1313-000, Ref C) to assure

accuracy for locating the correct position of the vibration isolators. This template is available for purchase.

Horizontal Mounting: It is recommended to use the Mounting Layout Template (PN 601-1317-000, Ref D)

to assure accuracy for locating the correct position of the vibration isolators. This template is available for

purchase.

1. CPU Rack Mounted Upright (PN 601-1313-000, Ref C)

a) Vibration Isolators (Ref Bc) With Template

i) Place the template (Ref C) in the desired location while heeding the above recommendations.

ii) Use the template to mark the fastener hole locations of the four vibration isolator feet (Ref Bc). ere

are eight holes at #28 drill bit (0.140”).

iii) Drill holes being careful not to cause damage.

iv) Use references Bd, Be, and Bf to attach Bc to the airframe.

v) Use references Ba and Bb to attach the CPU rack system to vibration isolators (Ref Bc).

b) Vibration Isolators Without Template

i) Using references Ba and Bb attach vibration isolators (Ref Bc) to the CPU rack system.

ii) Place CPU in the desired location while heeding the above recommendations.

iii) Mark airframe fastener locations using the open holes in the vibration isolator feet.

iv) Drill holes being careful not to cause damage.ere are eight holes at #28 drill bit (0.140”).

v) Use references Bd, Be, and Bf to attach vibration isolators (Ref Bc) to approved structure.

2. CPU Horizontally Mounted With Vibration Isolators

a) Horizontal Mounts With Template (PN 601-1317-000, Ref D)

i) Place the template (Ref D) in the desired location while heeding the above recommendations.

ii) Use the template to mark the fastener hole locations of the four vibration isolator feet (Ref Bc). ere

are eight holes at #28 drill bit (0.140”).

iii) Drill holes being careful not to cause damage.

iv) Use hardware from the pre-assembled rack mount system to attach horizontal mounting brackets

(Ref A) to the CPU.

v) Use references Bd, Be, and Bf to attach vibration isolators (Ref Bc) to approved structure.

vi) Use references Ba and Bb to attach vibration mounts to horizontal mounting brackets (Ref A).

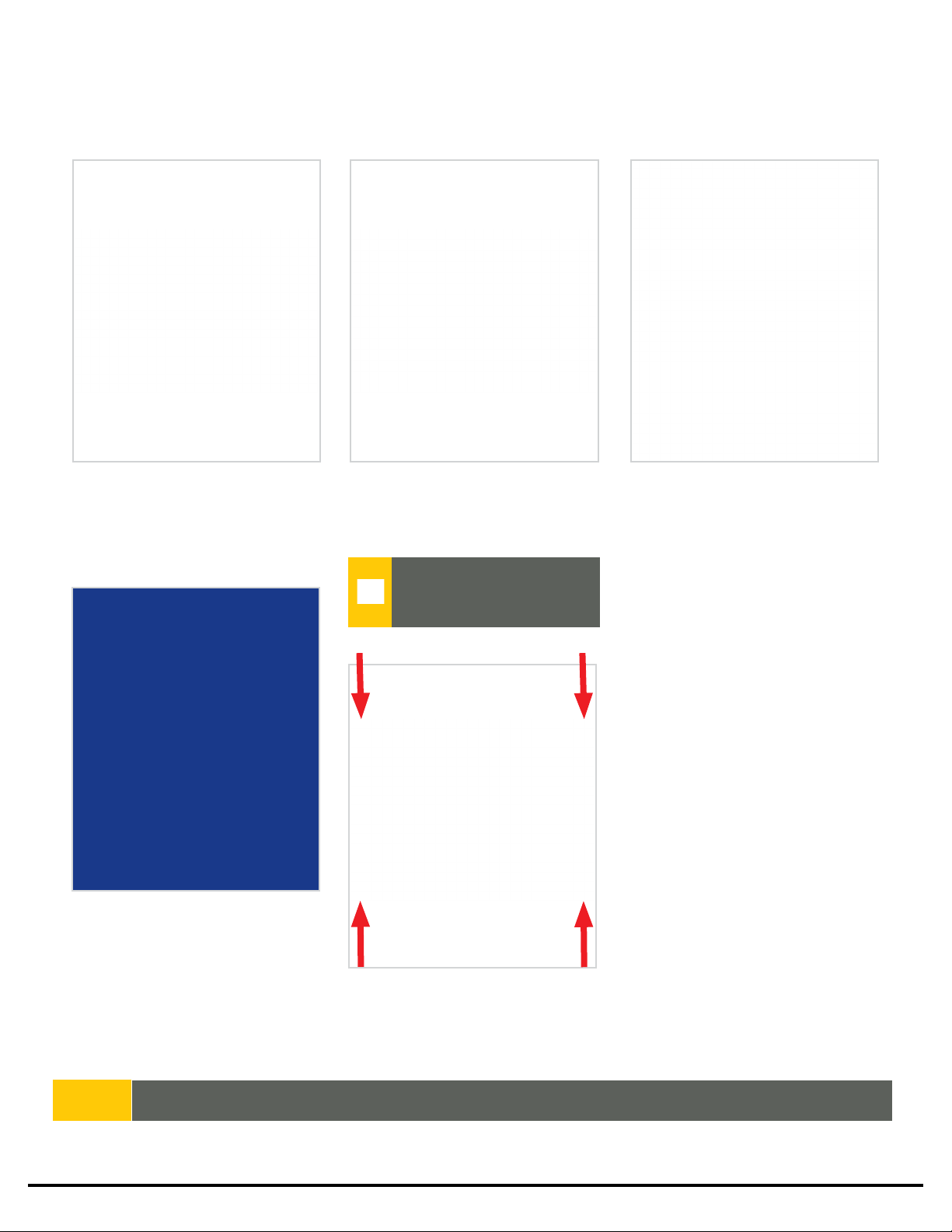

Figure 2-1: PN 601-1313-000 Mounting Layout

Template for Falcon/IF3 Rack Mount Figure 2-2: PN 601-1317-000 Mounting Layout

Template for Falcon/IF3 Horizontal Mount

Satloc Falcon Installation Guide 12 875-3004-000 Rev A2

b) Horizontal Mounts Without Template

i) Use hardware from the pre-assembled rack mount system to attach horizontal mounting brackets

(Ref A) to the CPU.

ii) Use references Ba and Bb to attach vibration isolators (Ref Bc) to horizontal mounting brackets.

iii) Place CPU in the desired location while heeding the above recommendations.

iv) Mark the fastener hole locations of the four vibration isolator feet. ere are eight holes at #28 drill bit

(0.140”).

v) Drill holes being careful not to cause damage.

vi) Use references Bd, Be, and Bf to attach vibration isolators (Ref Bc) to approved structure.

3) CPU Horizontally Mounted Without Vibration Isolators

a) Horizontal Mounts With Template (PN 601-1317-000, Ref D)

i) Place the template (Ref D) in the desired location while heeding the above recommendations.

ii) Use the template to mark the fastener hole locations of the 4 fastener locations. ere are four holes at

#16 drill bit (0.177”).

iii) Drill holes being careful not to cause damage.

iv) Use hardware from the pre-assembled rack mount system to attach horizontal mounting brackets

(Ref A) to the CPU.

v) Use locally sourced hardware to attach the CPU to approved structure.

b) Horizontal Mounts Without Template

i) Use hardware from the pre-assembled rack mount system to attach horizontal mounting brackets

(Ref A) to the CPU.

ii) Place CPU in the desired location while heeding the above recommendations.

iii) Mark the fastener hole locations of the four fastener locations. ere are four holes at #16 drill bit

(0.177”).

iv) Drill holes being careful not to cause damage.

v) Use locally sourced hardware to attach the CPU to approved structure.

Satloc Falcon Installation Guide 13 875-3004-000 Rev A2

Use only #10 screws when hard mounting the touchscreen. Larger screws could crack or otherwise damage

the screen. Do not drill holes in screen cover. This will void the warranty.

MOUNTING THE TOUCHSCREEN

Usually, the console is located in the front center of the cockpit, just below normal line of sight and within the operator’s

reach. Use the following parts list and instructions to hard mount the touchscreen on the cockpit dashboard. Mount the

touchscreen inside the cockpit of the aircra where it is:

• Easily visible while ying

• Within arm’s reach of the operator (pilot), depending on the pilot’s arm length, the display can be mounted either

further or closer to the pilot

• Mount the display far enough back as to not interfere with the yoke, with a gloved hand wrapped around it, when in

full nose down position

Do not obstruct the view of, or access to, other instruments or the flying visibility of the operator.

The following tools are needed to mount the touchscreen:

• Drill and #9 drill bit

• Phillips head screwdriver

• Four #10 screws for hard mount

• Marker pen

REF QTYPART NUMBER DESCRIPTION PHOTOGRAPH

A9” Display

1

806-4403-000

050-2201-000 Cable, cockpit

B

C050-2528-000 Cable, display encoder

1

Cable, display IO

050-2529-000

D

1

1

E050-2525-000 Cable kit, display to panel USB

1

Table 2-2: Falcon Touchscreen Mount Parts

Satloc Falcon Installation Guide 14 875-3004-000 Rev A2

Step One

Choose Mounting Location

Determine where, within easy

reach and visiblity of the operator

to mount the touchscreen.

Attach nuts to screws to secure

the display console in place.

Put #10 screws of the approprate

length through the four corner

holes and through the dashboard.

Step Two

Put #10 Screws in Corner Holes

Step Three

Attach Nuts to Screws

Do not drill holes in screen cover.

This will void the warranty.

Choose a location inside the

cockpit of the aircra where it is:

• Easily visible while ying

• Within arm’s reach of the

operator (pilot), depending

on the pilot’s arm length, the

display can be mounted either

further or closer to the pilot

• Mount the display far enough

back as to not interfere with

the yoke, with a gloved hand

wrapped around it, when in

full nose down position

NOTE: There is an optional dash mount bracket (PN 601-1321-000) that can be used with the touchscreen display. This is for

Air Tractor aircra.

Satloc Falcon Installation Guide 15 875-3004-000 Rev A2

e individual parts for the cockpit are part of kits PN 710-2006-000 and PN 710-2007-000.

• Use existing buttons on cockpit stick to control swath advance

• One encoder knob with a cap for lightbar dimming and for display control navigating

• One mechanical switch for dry gate control

• One On/O 7 1/2 amp toggle breaker switch for power (connect to aircra power 24 VDC)

Find appropriate locations in the cockpit to mount the individual cockpit parts. The parts must be within easy reach of

the operator and in an area where those can be connected to the GPIO cable (PN 050-2202-000) or power cable (PN

050-2200-000).

Do not obstruct the view of, or access to, other instruments or the flying visibility of the operator.

INSTALLING COCKPIT PARTS

MOUNTING THE USB PORT

In case WiFi is unavailable, a USB port can be installed for use with

the Falcon. Install USB port on the upper le or right dash, per pilot

preference. e cable from the USB port is 3’ to 4’ in length; please

keep this in mind when choosing the location to mount the USB port

PN 050-2525-000. With the cable, connect the port to the back of the

display.

Figure 2-3: Install Image of Optional USB Port

REF QTYPART NUMBER DESCRIPTION PHOTOGRAPH

AFalcon Display Components Kit

Knob, Concentric Encoder Outer Sha

Knob, Concentric Encoder Inner Sha

Cap, Concentric Cap

1

1

1

710-2006-000

710-2007-000 Falcon Control Component Kit

SW STR-Lever (075-4001-000#)

Breaker Switch (424-0003-000#)

1

1

B

Table 2-3: Falcon Cockpit Parts

REF QTYPART NUMBER DESCRIPTION PHOTOGRAPH

ACable kit, display to panel USB

1

050-2525-000

Table 2-4: USB Port Mount Parts

Satloc Falcon Installation Guide 16 875-3004-000 Rev A2

REF QTYPART NUMBER DESCRIPTION PHOTOGRAPH

MOUNTING THE L8 LIGHTBAR

AL8 for Falcon GPS

1

806-4400-000

602-1014-000

602-1012-000

602-1016-000 (RH) &

602-1017-000 (LH)

Lightbar brackets, standard, 5.25"

Lightbar brackets, short, 3"

Lightbar brackets, Wingman, 7.5" (RH

and LH)

2

2

Optional

B

C

E

F

G

602-1018-000 Top bracket

2

Bolt, #10-32 x 21/32"

Nut, #10-32

Washer, #10-32

4

4 (of 10)

4 (of 10)

*80922

*81202

Screw, #10-32 x 5/8"

Washer, Internal Lock, #10-32

4

4

*80013

*80570

*81219

*601-1045-000

Bolt, #10-32 x 25/32"

Nut, #10-32

Washer, #10-32

Backing plate

4

4 (of 10)

4 (of 10)

2

*86071 OR * 86436

*80007

*80570

*81219

Adel clamp

Bolt, #10-32 x 17/32"

Nut, #10-32

Washer, #10-32

2

2

2 (of 10)

2 (of 10)

*80011

*80570

*81219

D

Wingman L8 bracket not pictured

HL8 Lightbar cable for Falcon

*Part of Hardware Kit

P/N 710-2003-000

050-2205-000 1

A drill and 1/4" drill bit are required for this installation.

Table 2-5: L8 Lightbar Mount Parts

Satloc Falcon Installation Guide 17 875-3004-000 Rev A2

Do not obstruct the view of, or access to, other instruments or the flying visibility of the operator.

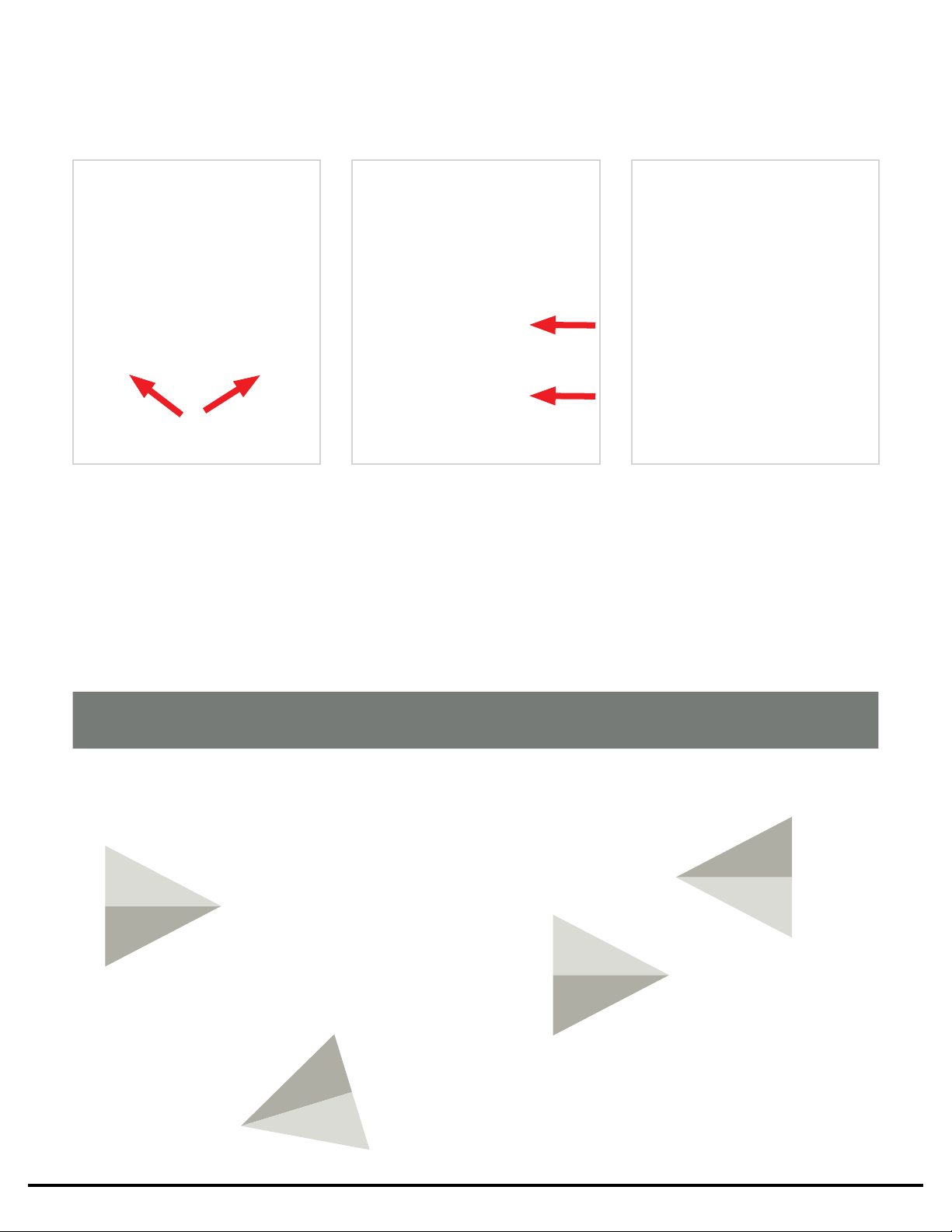

Step One

Assemble Lightbar

Mounting Brackets

Using hardware D, assemble two

mounting brackets using parts B

and C.

Note: There are three size options

for the mounting brackets.

Using the assembled lightbar and

brackets as a template, mark the

four mounting hole positions on

a suitable surface/location on

the aircraft. Using a 1/4" drill bit,

carefully drill the four holes.

Using hardware E, attach the

two mounting brackets to the

Lightbar.

Step Two

Attach Mounting Brackets

to Lightbar

Step Three

Marking Holes for Drilling

Tilting of lightbar brackets

is available in 2.5 degree

increments. Plus or minus 10

degrees. Examples shown below. Do not hit any wires or

hydraulics while drilling. Check

both sides of the aircra before

drilling.

Unpack the kit and identify the required parts as shown. Kit items are referenced A, B, C, etc. The references are used in the

installation steps and pictures. Be sure to mount the lightbar in front of the cockpit at a comfortable viewing distance.

Figure 2-4: Tilting Angles of L8 Lightbar

Satloc Falcon Installation Guide 18 875-3004-000 Rev A2

Step Four

Secure Lightbar to Aircraft

Step Five

Attach Cable

to Lightbar

Step Six

Tighten Hardware

Using hardware F, secure

the lightbar to the aircraft.

If required, use the backing

plates on the underside of the

mounting surface for additional

reinforcement (These provide

additional support to prevent the

bolts from pulling through the

surface under vibration).

When finished, tighten all

hardware.

Connect cable to the bottom of

the lightbar. Using hardware G,

attach the cable to the lightbar.

Be careful not to make any sharp

turns or bends.

Note: There are two size options

for the Adel clamps.

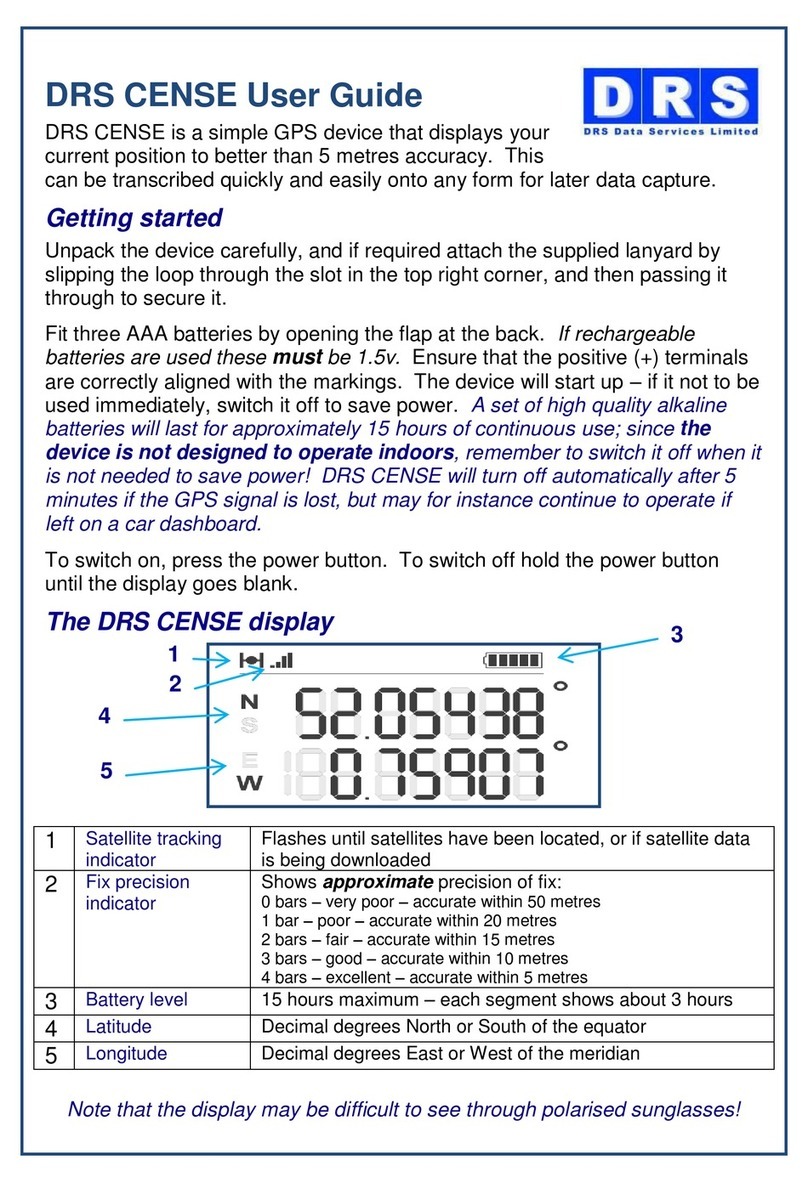

Exploded View

Step Two

REF C and E

X4

Step Five

REF B, G and H

X2

Step One

REF B, C and D

X4

Step Four

REF B and F

X4

Figure 2-5: Exploded View of L8 Lightbar Mount

Satloc Falcon Installation Guide 19 875-3004-000 Rev A2

MOUNTING THE A21 GPS ANTENNA

The following tools are needed to mount the antenna:

• Phillips screwdriver

• Four #8-32 screws

• Drill, 1/8” drill bit and 7/16” drill bit

• Marker pen

Antenna position is critical to system performance. erefore, these conditions must be met for proper system

operation:

• Mount the antenna at least 5 (1.524 m) from transmitting antennas of any frequency

• Mount the antenna at the highest practical point that will give a good view of the horizon.

• e positions that the receiver calculates are at the positions of the antenna. So, if using a swath guidance

system, mount the antenna on the aircra’s centerline.

Positioning the antenna less than 5 (1.524 m) from transmitting antennas of any frequency may cause

overloading of RF circuits.

NOTE: Satloc recommends flush mounting the antenna along the aircra’s centerline, with an unobstructed view of the sky

and horizon.

QTYPART NUMBER DESCRIPTION PHOTOGRAPH

A21, L1 GNSS, LBAND antenna

1

804-3036-000#

052-0005-000# Cable, RF-X, TNC(M)-TNC(M),

5M

1

Table 2-6: A21 GPS Antenna Mount Parts

REF

A

B

Satloc Falcon Installation Guide 20 875-3004-000 Rev A2

Step Four

Secure Antenna to Aircraft Surface

Use four #8-32 thread screws

to secure the antenna (PN

804-3036-000#) to the aircraft’s

surface. Black RTV silicone can be

used to seal around the antenna

base.

Step One

Use the A21 GPS Antenna Mounting

Dimensions Drawing (Appendix A)

Using the Antenna Mounting

Dimension Drawing (Appendix A)

as a guide (this is not a template),

mark the mounting position

and the antenna connector hole

locations on the aircraft’s outer

surface.

Step Two

Drill the Antenna Holes

Using a 1/8” drill bit, carefully

drill the four screw holes.

Step Three

Drill the Antenna Connector Holes

Using a 7/16” drill bit, carefully

drill the hole for the antenna

connector.

Step Five

Connect Wire to Antenna

Connect cable PN 052-0005-

000# to antenna PN 804-3036-

000#.

This manual suits for next models

1

Table of contents

Popular GPS manuals by other brands

Bryton

Bryton Rider 500 quick start guide

FALCOM

FALCOM FSA03 Getting started

Kenwood

Kenwood DNX5120 - Navigation System With DVD player installation manual

DRS

DRS CENSE user guide

Standard Communications

Standard Communications GPS Chart400 owner's manual

Socket

Socket Bluetooth GPS Nav Kit quick start guide