TRASOR MI P-117-3 MI Instruction Manual

P-117-3

02/18/2020

MI, Mineral Insulated

Snow Melting & De-Icing,

Installation & Maintenance

Manual

TABLE OF CONTENTS

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 3

General Information ................................................................................................................... 4

Receiving and Storage................................................................................................................ 4

Tools Required............................................................................................................................ 4

Maintenance................................................................................................................................ 4

Heater Construction and Operation ........................................................................................... 5

Heater Variables and Formulas .................................................................................................. 5

Heater Part Numbers ................................................................................................................. 6

Heater Forms ............................................................................................................................. 6

General Heater Layout ............................................................................................................... 7

Heating Cable Spacing Equation ............................................................................................... 7

General Installation Guidelines .................................................................................................. 8

Slab and Paving Construction Guidelines .................................................................................. 9

Installation Guidelines for Installation in Concrete, Asphalt and under Pavers .......................... 9

Heater Cold Lead and Pigtail Lengths ....................................................................................... 9

Installation Steps for Heaters with Standard Pigtails........................................................ 10 & 11

Installation Steps for Heaters with Extended Pigtails....................................................... 12 & 13

Installation Details in Concrete ................................................................................................. 14

Installation Details in Asphalt .................................................................................................... 15

Installation Details under Pavers .............................................................................................. 15

Installation Details Stairs ................................................................................................. 16 & 17

Installation Details for Securing Cable with Spacer Strip ......................................................... 17

Installation Detail for Crossing Control and Construction Joints .............................................. 18

Installation Detail for Crossing Expansion Joints ..................................................................... 19

Conduit Body Detail ................................................................................................................. 20

Heater Testing .......................................................................................................................... 21

Heater Installation & Inspection Log ........................................................................................ 22

Heater Maintenance & Inspection Log ..................................................................................... 23

GENERAL INFORMATION

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 4

This installation manual is for use with Trasor Mineral

Insulated (MI) snow melting and de-icing heaters. Since

1969, Trasor has been building safe and dependable

snow melting and de-icing systems. A safe and reliable

snow melting and de-icing system requires quality

products, proper design, installation and maintenance.

Read this instruction sheet and those enclosed with the

accessories to familiarize yourself with the products. Do

not hesitate to contact the factory or your local

representative.

Trasor Corporation

P.O. Box 470522

Tulsa, OK, 74147, USA

Tel (800) 324-1551

Fax (918) 251-6079

support@trasor.com

www.trasor.com

Electric Snow Melting & De-Icing Systems:

An electric snow melting and de-icing system consist of

Mineral Insulated (MI) heating cables embedded in a slab

to remove snow or freezing moisture plus controls and

sensors to control the heaters. The heaters are buried 2”

below the surface of the slab on 4” to 9” centers

depending on the application and slab material. Snow

melting and de-icing systems will typically generate 40 to

60 watts per square foot and the heating cables will

generate about 15 to 30 watts per cable foot.

Electrical Codes:

Article 426 of the National Electrical Code governs the

installation of fixed outdoor electric de-icing and snow

melting equipment. Installation of snow melting system

must comply will all national and local codes. Ground

fault protection of equipment shall be provided for all

outdoor electric de-icing and snow melting equipment.

Important:

All information contained in this manual is believed to be

accurate and reliable. Users should independently

evaluate this information for suitability for their particular

application. Trasor Corporation makes no warranties as

to the accuracy or completeness of the information, and

disclaims any liability regarding its use. Trasor

Corporation’s only obligations are those such expressed

in the sale of the particular product. In no case will Trasor

Corporation be liable for any incidental, indirect, or

consequential damages arising from the sale, resale, use

or misuse of the product.

Receiving and Storage:

Compare all received materials against the packing list.

Verify that no items have been damaged. It is important

to field test all MI heaters as shown on page 21 and

complete the heater installation and inspection record on

page 22. Do not remove any tagging information. Store

all materials in a clean dry area protected from weather

and mechanical abuse.

Tools Required for Installation:

500 or 1000 Volt DC Megger

Clamp on Amp meter

Multi meter

Lineman pliers

Two adjustable wrenches

Controls and Accessories:

All related controls and associated components must be

properly rated and approved for the area and application.

Controls should carry UL XAPX certification.

Maintenance:

Heater, control system and slab should be inspected

annually. Follow the procedures noted in Heater

Maintenance & Inspection Log on page 23.

General Information:

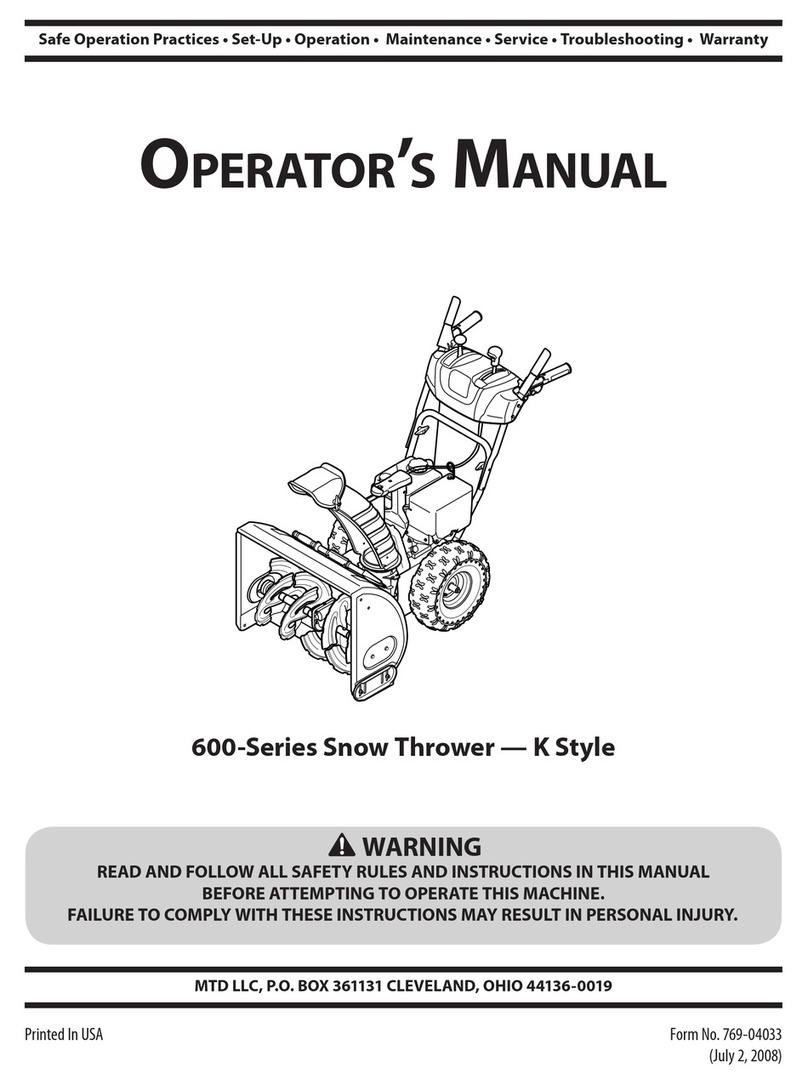

Internal View

HEATER CONSTRUCTION AND OPERATION

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 5

Supply

Voltage

Figure 2

Heater Output (w/ft)

Hot to Cold

Joint

Termination

Gland Fitting

Pigtail

General Heater Construction

Figure 1

Hot Section Cold Lead

V (L1) V (L2)

Cold Lead

Resistive Conductor

Copper

Conductors

Copper

Conductors

V Voltage = I * R

I Current = V ÷ R

W Wattage = V * I = I ² * R = V² ÷ R

w/ft Watts per foot = W ÷ L = I² * Ω/ft

R Resistance = L * Ω/ft = V ÷ I

L Heater length = R ÷ Ω/ft

Ω/ft Published cable resistance ≈ R ÷ L

Variables and Formulas:

Note, Form “B” one conductor heater is shown in the

above figures. Form “B” is the most common form used

in snow melting applications. It offers a comprehensive

selection of resistances. There is also a one

conductor form “C” and a two conductor form “A”.

See page 6.

General Operation:

MI heating cable is a series resistance heater that has

a constant output along the entire length of the heater.

It’s operation is consistent with Ohm’s Law.

Cold Lead

Termination

HEATER PART NUMBER SYSTEM & HEATER FORMS

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 6

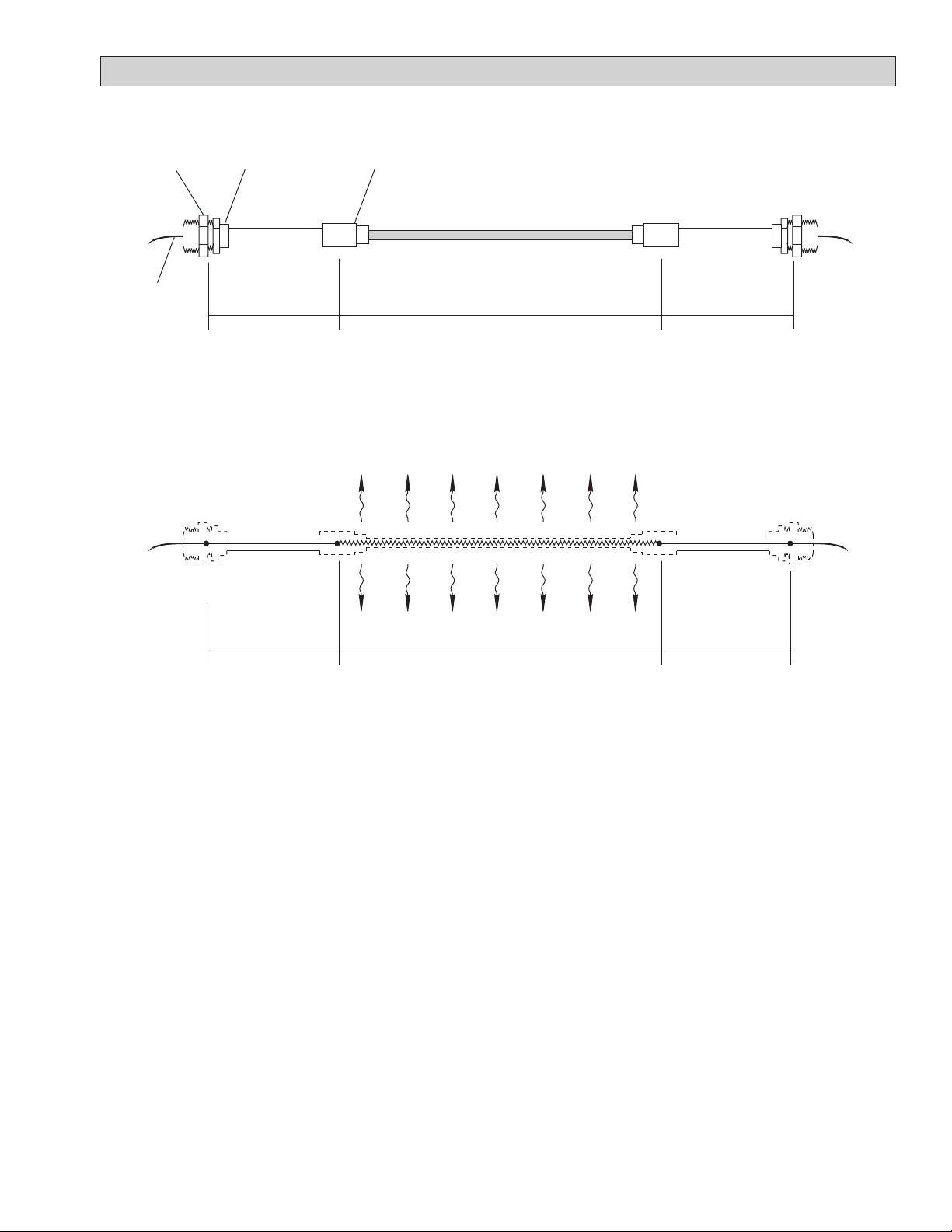

Heater Part Number System:

Cold Lead

Form A/AN

Two Conductor

Cold Lead

Hot Section

Hot Section Cold Lead

Heater Forms:

Form B/BN

One Conductor

End Cap

Termination Gland Fitting

Hot to Cold Joint

Pigtails

Figure 4

Figure 3

Cold Lead Termination

MIE - R21EH - B - 200 - 07 - 07 - X

Special feature, see datasheets for details

Cold section length (FT.)

Hot section length (FT.)

Heater unit form, see figures 3 & 4 for details

Heater unit hot section size, see datasheets for details

Heating cable type, see datasheets for details

Cold section #2 length (FT.), if applicable

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 7

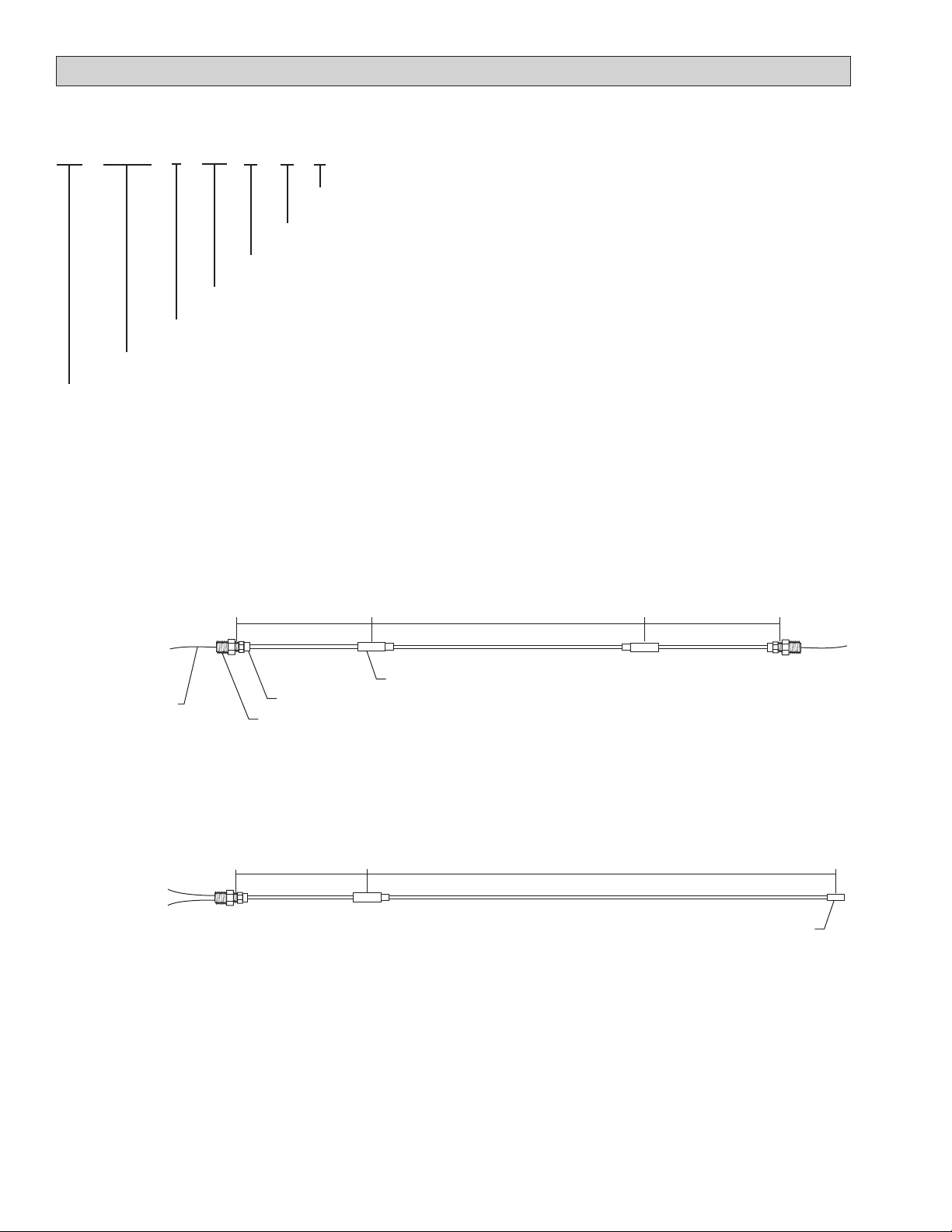

GENERAL HEATER LAYOUT & CABLE SPACING

(S/2)(S/2)

(S/2)

(S/2)

(S), Cable Spacing

General Cable Layout

Layout heating cable as shown in Figure 5 or layout

drawings. When installation and layout drawings are

provided, verify heated areas match what are shown on

the drawings and confirm all dimensions. Follow pattern

and cable spacing (S) on drawings. If drawings are not

provided calculate cable spacing using equation 1.

2

Heated Area (ft) 12 (in/ft)

Heater Length (ft) X

Example:

2

Heated Area = 120 ft

Heater Length = 180 ft

2

120 ft 12 (in/ft) = 8” spacing

Spacing (S) =

180 ft X

Figure 5

Spacing (S) =

Equation 1

Slab

Hot to Cold joint

Heating cable

Cold lead, see details pages 10 thru 13

(S/2)

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 8

INSTALLATION GUIDELINES

Project Coordination Meeting:

Before the project begins, a project coordination meeting

should be held with all trades that will be involved with the

installation of the heating cable, pouring of the slab and

cutting or drilling into the slab. Coordination of these

trades is extremely important. It can be catastrophic for a

heater to be cut through with a saw or drilled into for a rail

post. The following topics should be covered:

1. Review of all layout drawings and instructions.

2. Review slab construction and support media for

cable. Confirm cable depth and cable spacing.

3. Confirm all expansion and construction joint locations

and mark in the field on the slab forms so they are

apparent to all crafts.

4. Confirm all locations of rail supports, doorstops, signs

or drains.

5. Confirm heating termination method to be used. See

pages 10 thru 13.

6. Confirm junction box and control locations.

7. Confirm locations and make provisions for slab

sensors or warning markers.

8. Coordinate testing and record keeping between

installation procedures. See pages 21 and 22.

General Installation Notes:

1. Follow all installation and layout drawings. Verify

heated areas match what are shown on layout

drawings and confirm that all dimensions on drawings

match field dimensions.

2. Unpack and test all heaters to verify there was no

damage from shipping. Reference testing

procedures on page 21 and record values in table 1

on page 22. Make copies of table 1 for each heater.

Test heaters again before installation, after they are

secured to the reinforcement media, while the heaters

are being embedded in slab and after slab is

complete.

3. The heater, cold lead termination and pigtails must be

kept dry, protected from weather and mechanical

abuse before, during and after installation.

4. Protect heating cable from being walked on, driven

on, sharp materials, weld slag or being cut.

5. Verify proper heater is selected for area shown on

drawing. Heaters cannot be randomly switched. All

heaters are provided with a stainless nameplate. The

nameplate will have tagging information and

electrical ratings.

6. Confirm proper slab reinforcement is in place and at

proper depth. Heating cable must be secured at a

minimum depth of two inches from slab surface. It is

not recommended to exceed a depth more than three

inches. This will extend the heat up time and reduce

heat getting to the surface.

7. Prepare area for heating cable. Follow layout

drawings for proper cable spacing and routing path.

Mark cable paths with chalk or spray paint. Do not

locate heating cable within six inches any future slab

penetrations, such as handrails, drill holes or drains.

8. If layout drawings are not provided calculate cable

spacing using equation 1 on page 7.

9. Uncoil or roll out the heater. Do not pull cable from

center of coil into a spiral.

10. Minimum bending radius of heating cable is 6 x the

cable diameter.

11. Do not bend the cable within 3” on any hot to cold joint,

termination or splice joint. Almost all heaters that are

broken during installation occur at the hot to cold joint

due to mishandling.

12. Do not repeatedly bend and straighten the cable.

13. Do not install cable so that it may touch or be within 3”

of another cable pass.

14. Do not pass heating cable through expansion, control

or construction joints unless using methods shown in

detail 9, 10 or 11 on pages & 10 on page 18.

15. If any cable is damaged or broken, stop installation

and seal break with silicone and contact the factory.

16. Start heater installation with the first cold lead.

Secure with nylon ties three inches from each side of

the hot to cold joint.

17. Handle hot to cold joint carefully. Support both sides

when moving and positioning cold lead.

18. Secure heating cable to rebar or reinforcement mesh

every 12 to 18 inches with nylon ties. Do not use steel

ties.

19. When approaching the end of a heater installation,

adjust the last few passes as need so the end of the

heater is at the point specified in the layout drawing.

20. Note any variations of cable routing or termination

locations on project drawings and return to owner and

factory. This is valuable information if repairs or

trouble shooting is required in the future.

21. Terminate heaters to junction box as shown on pages

10 or 12.

22. IMPORTANT: The termination gland fitting is the

grounding mechanism for the heater. This must be

connect by an NEC approved grounding method.

23. Junction boxes and enclosures for electrical

connections to the heating cable must be listed and

approved for the environment in which they are

installed.

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 9

INSTALLATION GUIDELINES

Slab & Paving Construction Guidelines:

Proper slab design is essential to a successful system.

The size, thickness, reinforcing media, and general

design must be such that the slab will not crack, causing

damage to the heating cable.

The slab base should be smooth and adequately

compacted to prevent settlement, and care should be

taken to make certain that tree roots will not cause future

heaving.

Proper design should include provisions for water runoff.

This water could cause the slab to heave if it accumulated

in the base, or it could cause a dangerous ice condition at

the foot of a sloping drive. If adequate natural drainage is

not available it may be necessary to install a drain. In

some instances the drain may have to be heated to

prevent freezing.

Installing Cable in Concrete:

Rebar is the preferred reinforcement material for

embedded heating cable in concrete. It provides

maximum strength and is more apt to keep heating cable

at a consistent depth. The spacing of the rebar is often

wider than reinforcement mesh. This makes it easer for

the installer to step into the area while securing the cable.

See detail 1 on page 14.

It is recommended that a ground-supported slab be no

larger than 20 feet by 20 feet, with a minimum thickness of

4 inches for walkways or 6 inches for areas supporting

motor vehicles.

Cable depth should be 2 to 3 inches below the finished

surface of the slab. The cable should be secured to rebar

or reinforcement mesh with nylon ties. Do not use steel tie

wire. Secure cable every 12 to 18 inches.

When installing cable on an existing slab or using a two

pour method, secure the cable to the first slab using

spacer strip. See detail 2 on page 14.

If heater is damaged while concrete is being pored, box

off 24” square area around damaged cable and clear out

concrete. Seal break with silicon and contact the factory.

Installing Cable in Asphalt:

The base or foundation course must be designed so that

the heater unit will not be damaged due to movement.

The heated area of an asphalt slab must be held well in

from the edges unless there is adequate provision made

to prevent the possible collapse of the edges.

The top course of asphalt should have a minimum

thickness of 2 inches after compaction.

The heater should be installed into a uniform pattern as

specified and held in position on the base slab using

spacer strip. For added security, reinforcement mesh

should secured over the cable and spacer strip. See

detail 3 on page 15.

After the cables are in position, place a layer of asphalt

about 1” thick over the cable by hand. Roll this with a

small roller. This will protect the cable from tools or

paving equipment during placement of top course.

Do not dump piles of asphalt in small area of cable and

spread out. This may damage jacketed heating cable

from the concentrated heat of the asphalt.

Installing Cable under Pavers and Bricks:

Secure the cable to masonry reinforcing over a concrete

base or 1 inch of well compacted sand or lime stone

screenings. Cover the heating cable with 1” of

compacted sand or lime stone screenings. See detail 4

on page 15. Use caution when setting pavers not to

damage heating cable.

Note: Cable spacing is typically tighter under pavers (4 to

6 inches) due to the poor conductivity of brick and pavers.

Heater Cold Lead and Pigtail Lengths:

Each heater has cold leads and pigtails. The lengths of

these components can vary per system design and

requirements.

Heaters with standard 11” pigtails are used when the

junction box locations are local and close to the slab. The

locations are specified and will not vary in the field.

Typically these heaters will have 7' to 15' cold leads to

reach the junction box. See pages 10 and 11.

Heaters with extended pigtails are used when the

junction box locations are remote. The locations are field

located and may be 20 to 50 feet from slab. Typically

these heaters will have 2' cold leads with long pigtails to

reach the junction box. See pages 12 and 13.

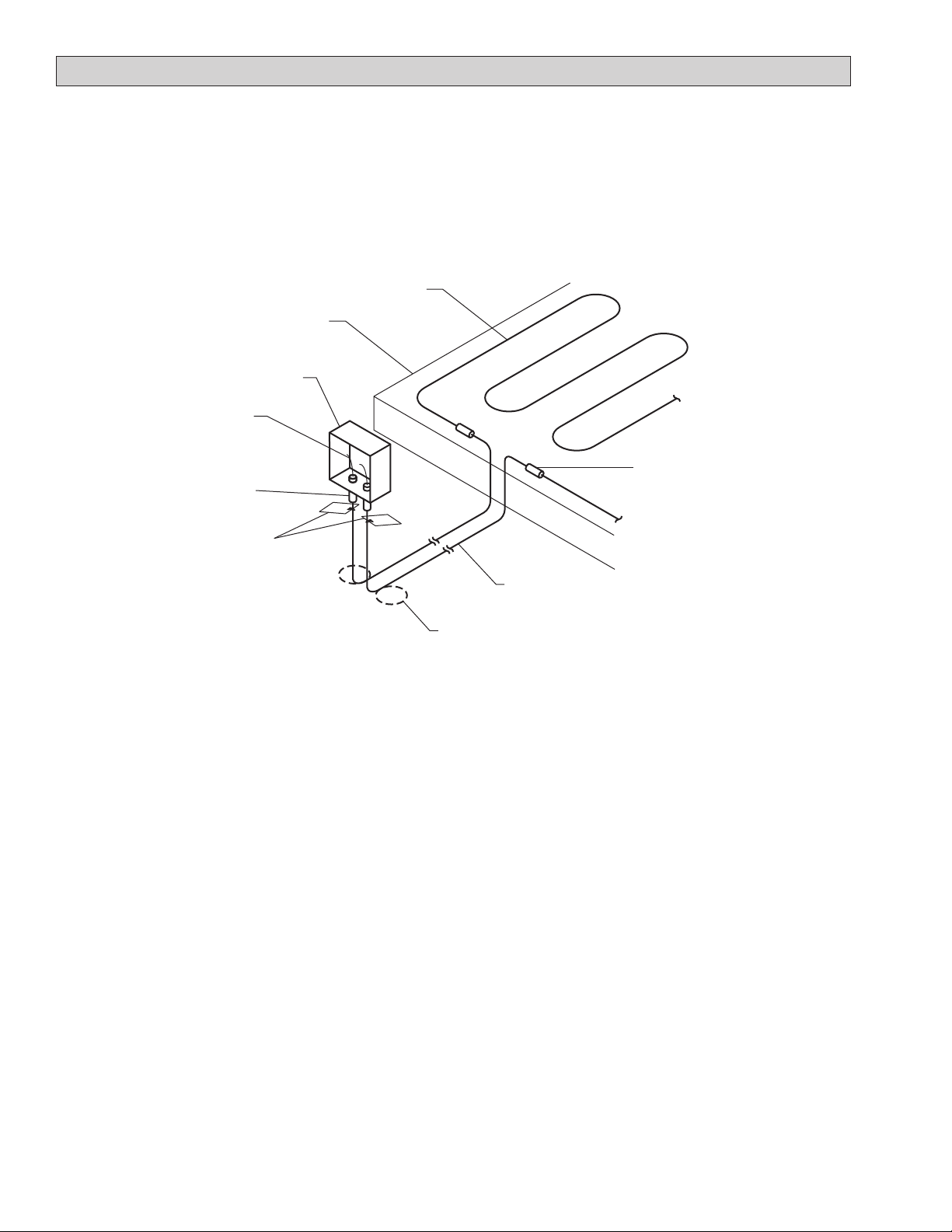

INSTALLATION STEPS FOR HEATERS WITH STANDARD PIGTAILS

The cold leads for heaters with standard 11” pigtails will

extend out of the slab and terminate directly into a local

junction box. The cold leads are typically 7 to 15 feet or

longer. This method is used when the junction box

locations are specified and will not vary in the field. Note,

cold lead lengths cannot be modified in the field.

Figure 6

Coil extra cold lead into 4” to 6”

coils and bury under junction box.

Above grade junction box

Heating cable

Cold lead

Hot to cold joint

Stainless name tags

Slab

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 10

Pigtails

Installation Steps for Heaters with Standard 11” Pigtails:

1. Secure the hot to cold joint of the first cold lead to the

reinforcement media. Place ties 3 inches from each

side of the hot to cold joint.

2. When possible pass the cold lead out through the

bottom of the slab.

3. Install heating cable as described in the previous

sections.

4. Secure the second cold lead to the reinforcement

media as describe in step one. Note, heater forms

“A” and “C” will not have a second cold lead.

5. Route the cold leads back to the junction box. Bury

any extra cold lead in small 4”+ coil underneath the

junction box. Note, cold lead lengths cannot be

modified in the field.

6. Secure termination gland fitting to junction box or

controller.

7. Pass pigtails through termination gland fitting.

8. Push cold lead termination midway into termination

gland fitting. Tighten ferrule side of the gland fitting.

Use care not to twist termination or cold lead cable.

9. Test insulation resistance (Megger) and heater

continuity and record values. See pages 21 and 22.

10. Note: Termination gland fitting provides ground

connection for heater. NEC approved grounding

method must be used at junction box.

11. Junction boxes and enclosures for electrical

connections to the heating cable must be listed and

approved for the environment in which they are

installed.

Terminating Heaters with Standard Pigtails:

Termination gland fitting

Note, Form “B” heater shown. Forms “A”

and “C” are shown on the following page.

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 11

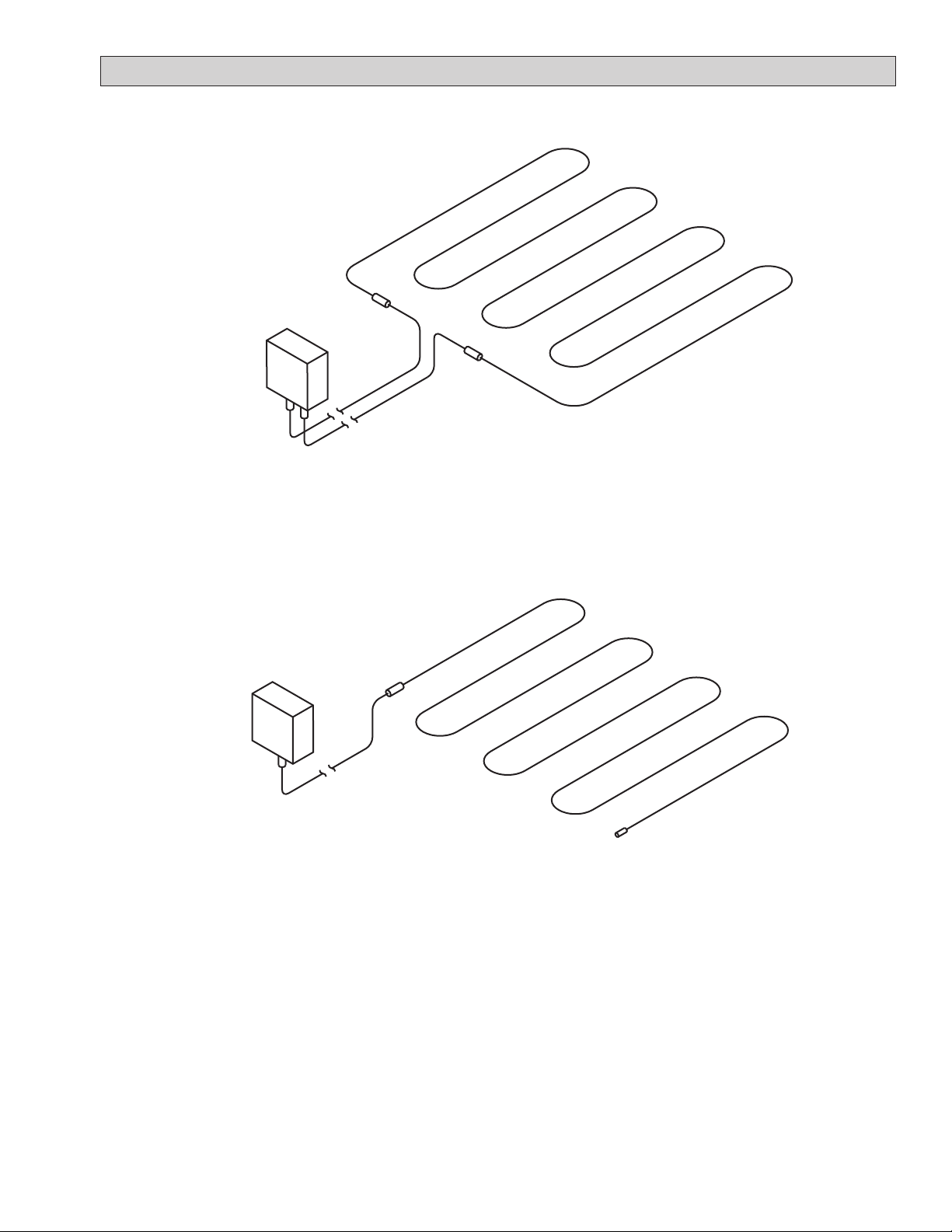

INSTALLATION STEPS FOR HEATERS WITH STANDARD PIGTAILS

Figure 7

Figure 8

Form “B” Heater:

Termination of form “B” heater with standard pigtails.

Form “A” Heater:

Termination of form “A” heater with standard pigtails.

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 12

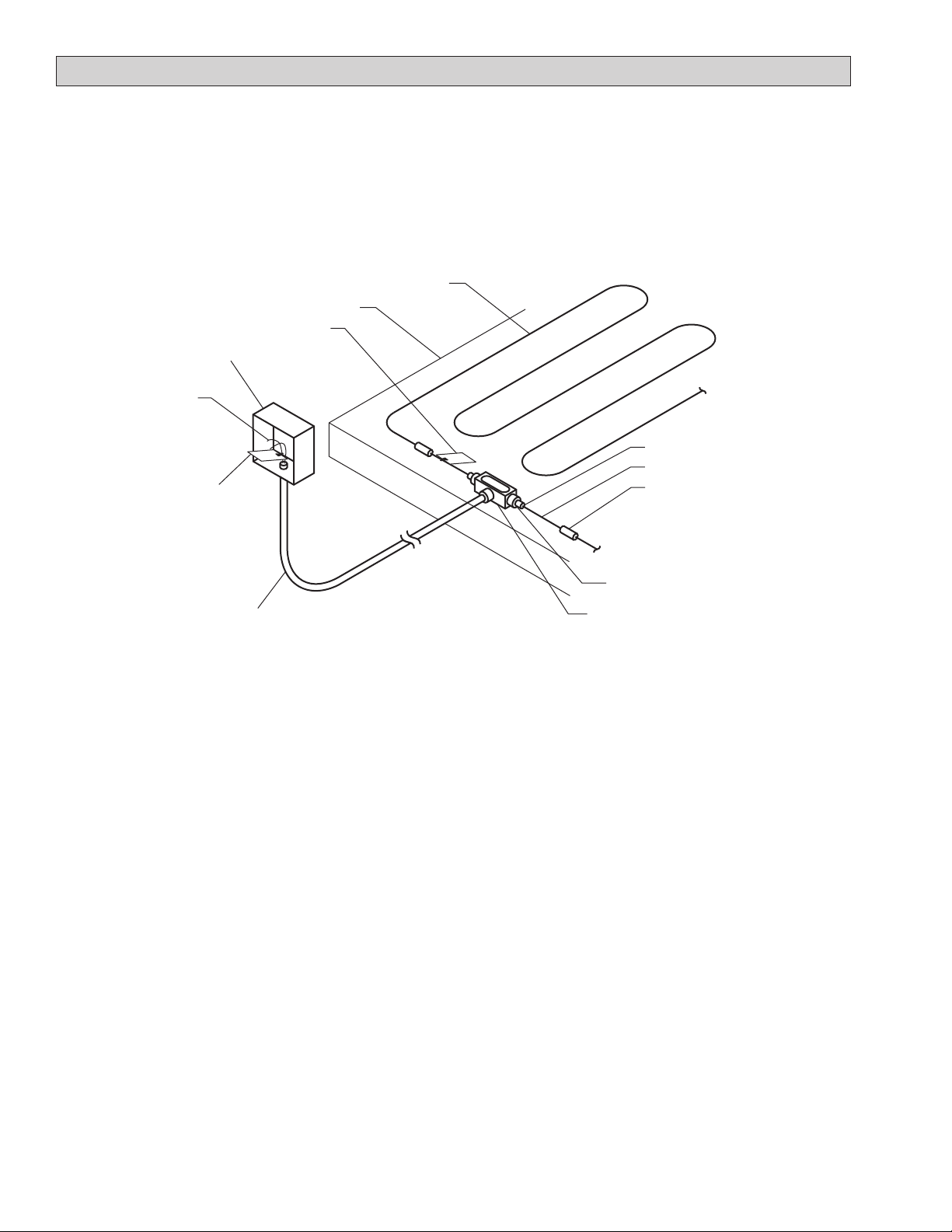

INSTALLATION STEPS FOR HEATERS WITH EXTENDED PIGTAILS

1. Uncap conduit body and verify it is dry and free of

moisture.

2. Install conduit body so that opening is facing up.

3. Secure termination gland fitting into conduit body.

4. Carefully pass the pigtails from the first cold lead

through the termination gland fitting.

5. Push cold lead termination midway into the

termination gland fitting. Tighten ferrule side of the

gland fitting and use care not to twist termination or

cold lead cable.

6. Install and secure heating cable as described in

previous sections.

7. Using the pigtails from the second cold lead, follow

step 3,4 & 5. Note, heater forms “A” and “C” do not

have a second cold lead.

8. Pull pigtails and ground wire, if required, through

conduit to the junction box or controller. Ground

wire must be provided when using plastic piping.

See detail 13, page 20.

9. Remove one of the stainless nameplates from a cold

lead and secure it to a one of the pigtails at the

junction box. This tags has important electrical

ratings and part number information.

10. NEC approved grounding method must be used at

junction box.

11. Test insulation resistance (Megger) and heater

continuity and record values. See pages 21 and 22.

12. Apply duct seal between conduit body and conduit.

IMPORTANT, Fill conduit body with 3M Scotch Cast

8882. See details 12 and 13, page 20.

13. Junction boxes and enclosures for electrical

connections to the heating cable must be listed and

approved for the environment in which they are

installed.

Figure 9

Hot to cold joint

Above grade junction box

Heating cable

Cold lead

Field routed conduit

3/4” metallic conduit, See detail 12, page 20.

3/4” PVC with ground wire. See detail 13, page 20.

Metallic conduit body

See details 12 & 13, page 20

Pigtails

Termination gland fitting

Stainless name tag

Slab

Stainless name tag

Cold lead termination

Installation Steps for Heaters with Extended Pigtails:

Terminating eaters with igtailsH Extended P :

Note, Form “B” heater shown. Forms “A”

and “C” are shown on the following page.

The cold leads for heaters with extend pigtails will

terminate into a conduit body located within the slab. The

pigtails will be pulled through field routed conduit and

terminate into a remote junction box. The cold leads will

typically be 2' long and have stranded pigtails that may be

20 to 50 feet in length. This method is used when there is

a long distance between the heater and the junction box.

Heaters with pigtails longer than 1 foot are noted as

having extended pigtails. The part numbers for thess

heaters will have a special feature suffix “T**”. The ** will

indicate the pigtail length in feet.

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 13

INSTALLATION STEPS FOR HEATERS WITH EXTENDED PIGTAILS

Figure 11

Form “B” Heater:

Termination of form “B” heater with extended pigtails.

Form “A” Heater:

Termination of form “A” heater with extended pigtails.

Figure 10

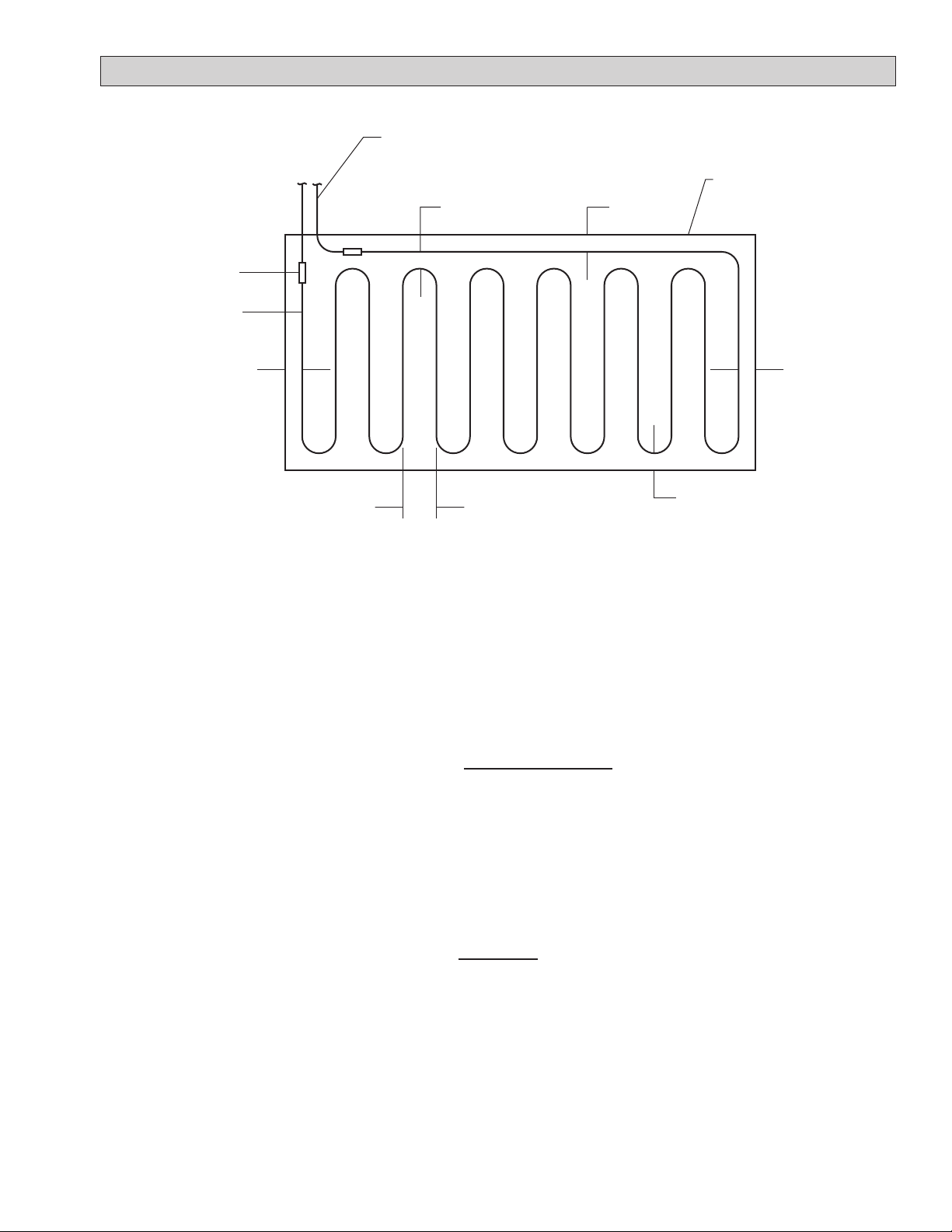

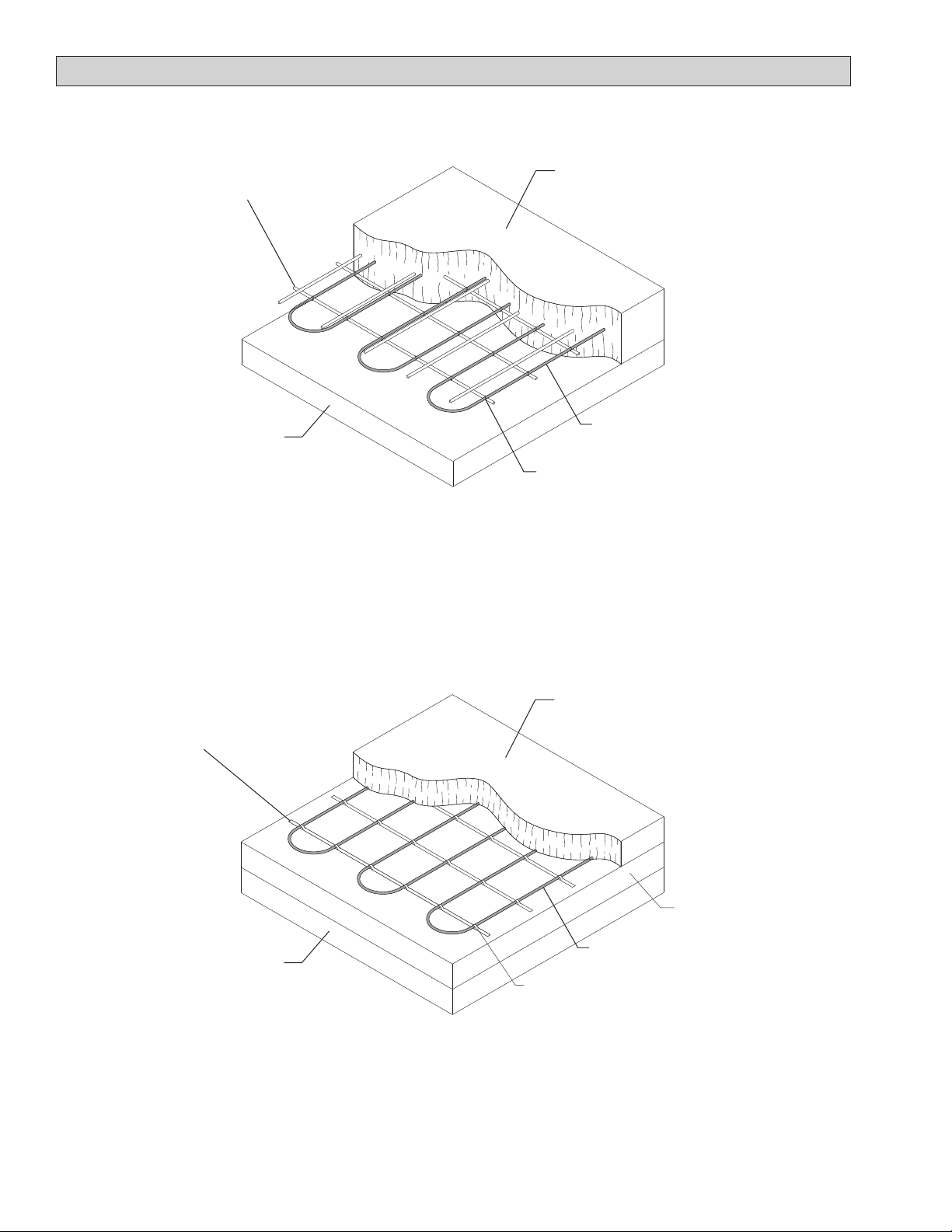

SLAB INSTALLATION DETAILS

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 14

Heating cable

Secure cable to rebar or mesh with nylon ties

ever 18 to 24 inches and at turns and loops.

Concrete, 2” minimum cover over

heating cable.

Rebar or reinforcing mesh.

Installing in Concrete, Single Pour Slab

(Heating cable secured to rebar or wire mesh)

Structurally sound,

well drained base.

Concrete base

Secure cable under tabs of spacer strip.

See detail 8, page 17.

Spacer strip nailed to base pour.

Heating cable

Structurally sound,

well drained base.

2” to 3” Concrete cap over heating cable.

Installing in Concrete, Two Pour Slab

(Heating cable secured with spacer strip)

Detail 1

Detail 2

SLAB INSTALLATION DETAILS

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 15

Secure spacer strip to asphalt

base with concrete nails.

Structurally sound well,

drained base.

Installing in Asphalt

(Heating cable secured with spacer strip & covered with wire mesh)

2” Minimum asphalt base.

Secure cable under tabs of spacer strip.

See detail 8, page 17.

Heating cable

2” to 3” Asphalt cap.

Cover heating cable with wire

mesh and anchor to base.

Masonry reinforcement on 36” centers.

Structurally sound well,

drained base.

Installing under Pavers

(Heating cable secured with masonry reinforcement)

1” Sand or limestone

screenings.

Secure cable with nylon ties.

Heating cable

2” to 3” Pavers

1” Limestone screenings or

sand over heating cable.

Detail 3

Detail 4

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 16

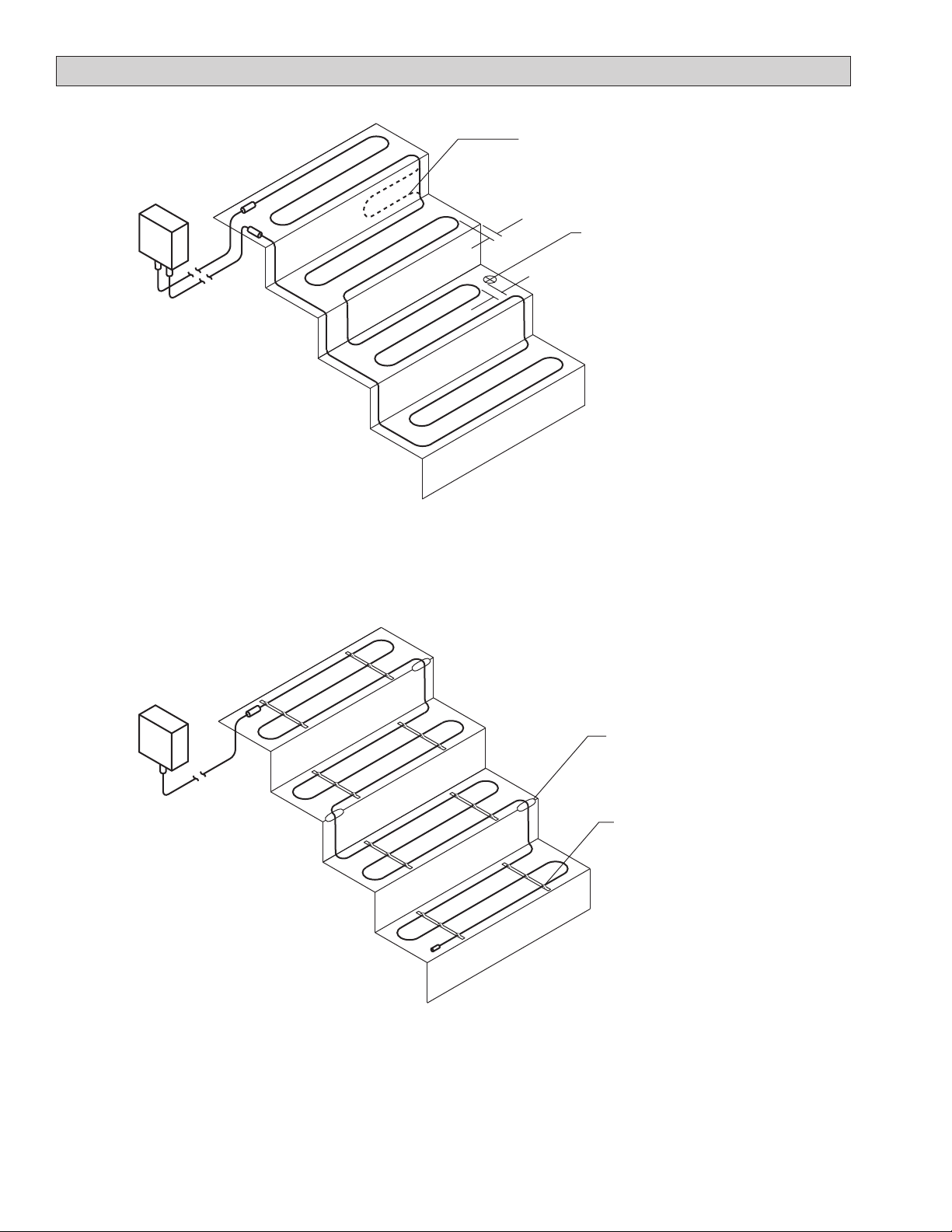

INSTALLATION IN STAIRS

Installing in Stairs, Single Pour Method

(Heating cable secured with rebar. See detail 1, page 14.)

Form “B” heater shown

Installing in Stairs, Two Pour Slab

(Heating cable secured with spacer strip. See detail 2, page 14 & detail 8, page 17.)

Form “A” heater shown

Detail 5

Detail 6

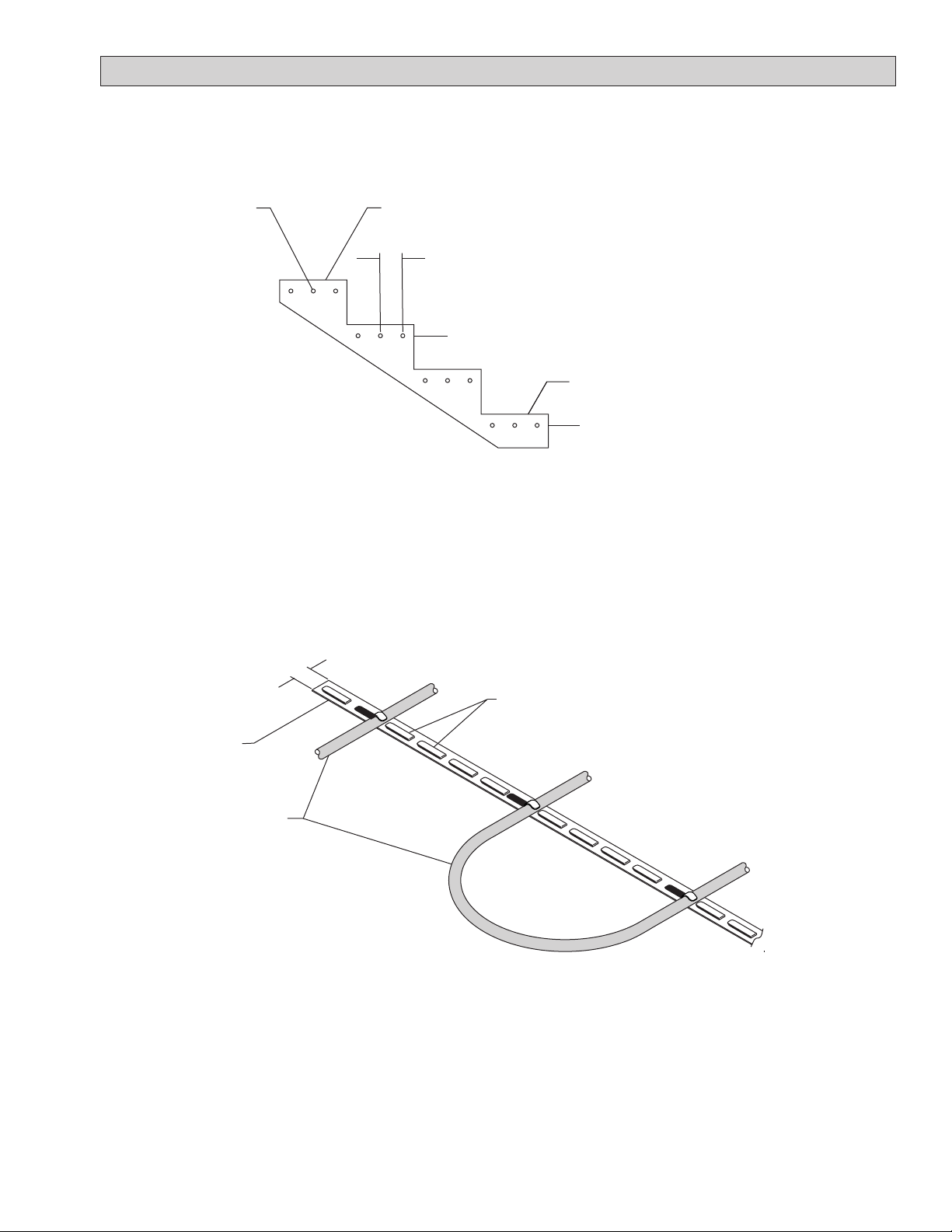

Mark locations where hand rail posts

will be installed. Keep heating cable

at least 6” away from these areas to

avoid damaging the cable when rail

posts are installed.

6”

4”

Round corners off to prevent

cable damage.

Secure heating cable to first slab

with spacer strip. See Detail 2

page 14 & Detail 8 page 17.

Use up any extra cable on risers,

landings or add an extra pass.

Maintain at least 3” spacing.

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 17

STAIR INSTALLATION DETAIL

2” Cover over heating cable.

4” Typical spacing, 6” Max

Keep edge pass 2” from Riser and Tread.

Tread

Riser

Heating cable

Side View, Heating Cable in Stairs

(Secure cable to rebar with single pour method. See detail 1, page 14.)

Secure cable with spacer strip with two pour method. See detail 2, page 14.

Detail 7

Spacer Strip Detail

(Securing heating cable with spacer strip)

Detail 8

Spacer strip

Tabs at 1” spacing

Nail spacer strip to sub surface.

Bend tabs over heating cable to

hold cable at uniform spacing.

Heating cable

½”

INSTALLATION DETAILS

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 18

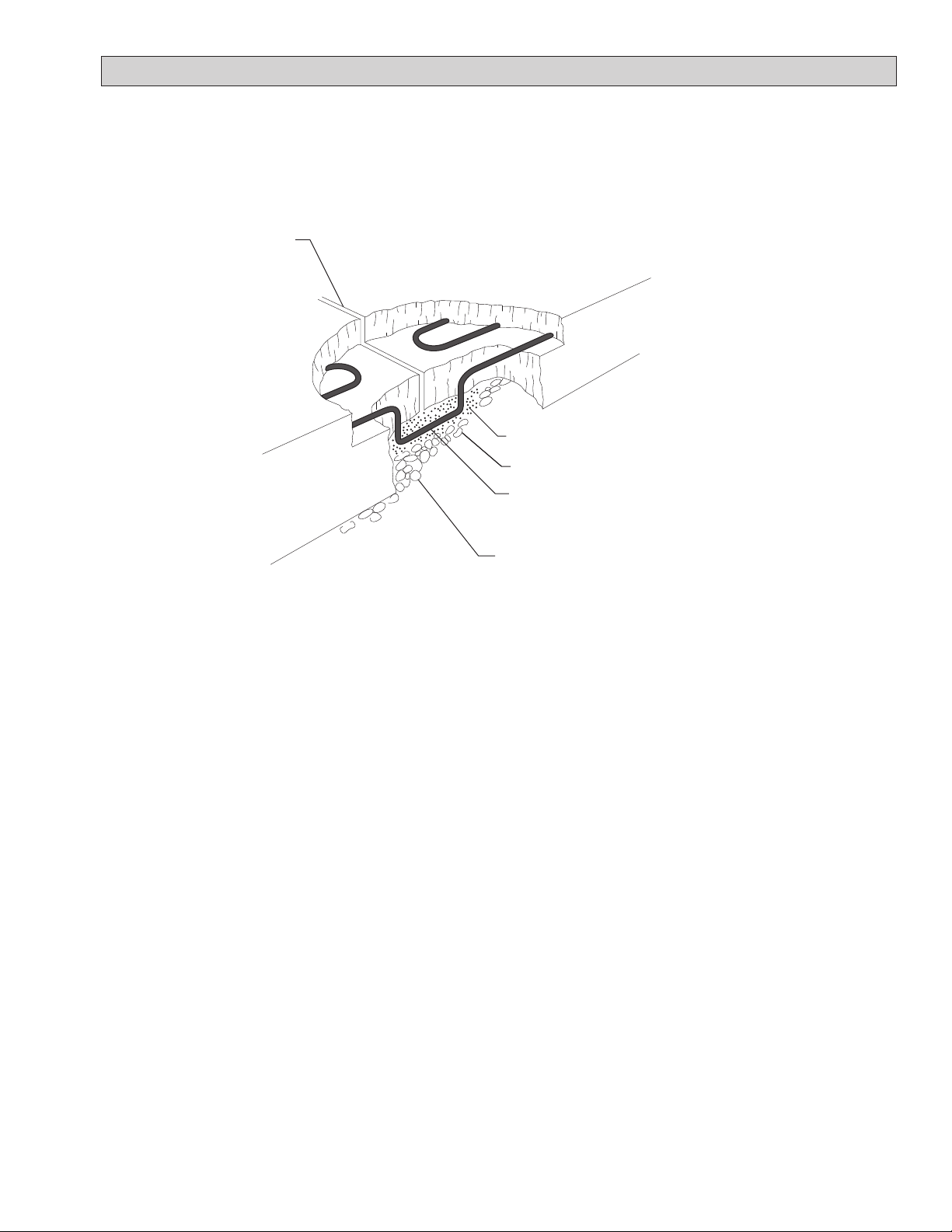

Crossing Control or Construction Joint

(Single pour slab)

Control or construction joint

Detail 10

Crossing Control or Construction Joint

(Two pour or single pour slab)

1” x 1” x 12” Angle iron filled with silicon

Control joint

Heating cable

Detail 9

Control joints are intended to control where that slab will

crack. It is important that the locations of these joints are

specified before the cable is installed or slab is poured.

Because of the reinforcement in the slab, there is rarely a

shearing action caused by differential vertical movement

between the concrete on either side of the crack. As a

precautionary measure, use either of the two methods of

crossing as shown in detail 9 or 10. When possible

minimize the number of times the joint is crossed as

shown in detail 9. When installing cables using the two

pour method, control joint must be placed in the base slab

and the surface slab.

Construction joints are joints that occur when the

concrete pour is going to stop but will resume at a later

date. The reinforcement should be left protruding out of

the first pour so that it enters the next pour and therefore

shearing action rarely occurs. Use either of the two

methods of crossing as shown in detail 9 or 10.

Crossing Control or Construction Joints:

Rebar

Heating Cable

Secure heating cable to rebar with nylon ties.

Slab

Structurally sound,

well drained base.

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 19

INSTALLATION DETAILS

Expansion Joint Detail

(Heating cable passed under joint)

Gravel base

Sand

Heating Cable

Expansion Joint

Detail 11

Expansion joints are placed where a concrete slab abuts

some structure, such as a building, slab, or a foundation.

Because the reinforcement does not cross expansion

joints, differential movement will occur between the slab

and the adjoining structure. Avoid crossing expansion

joints with the heating cable. If this is not possible,

expansion joints can be crossed using method shown in

detail 11.

Cable Crossing Expansion Joints:

Solid pocket of base to hold sand.

INSTALLATION DETAILS

Phone: (800) 324-1551 Fax: (918) 251-6079 www.trasor.com Page 20

Conduit Body Detail - Metallic Conduit

(Heater termination with long pigtails. See pages 12 & 13.)

Conduit Body Detail - Plastic Conduit

(Heater termination with long pigtails. See pages 12 & 13.)

Fill conduit body with 3M Scotch

Cast 8882.

Metallic 3/4” NPT conduit body.

Termination gland fitting

Cold lead termination

Metallic conduit

Long pigtails

Seal around pigtails

with duct seal putty.

Fill conduit body with 3M Scotch

Cast 8882.

Metallic 3/4” NPT conduit body with

internal ground screw.

Termination gland fitting

Cold lead termination

Detail 13

Detail 12

Long pigtails

Ground wire

Plastic conduit

Seal around pigtails

with duct seal putty.

Ground wire attached to

internal ground screw.

IMPORTANT:

Metallic conduit body provides

ground path for heater sheath.

All heaters must be grounded

by an NEC approved method.

IMPORTANT:

Metallic conduit body and metallic

conduit provides ground path for

heater sheath. All heaters must be

grounded by an NEC approved

method.

Cold lead

Cold lead

Table of contents

Popular Snow Blower manuals by other brands

Craftsman

Craftsman 247.886510 owner's guide

Husqvarna

Husqvarna 924SBE Illustrated parts list

Briggs & Stratton

Briggs & Stratton 1695979 Safety, operation & maintenance manual

Poulan Pro

Poulan Pro 437139 owner's manual

Grizzly

Grizzly ESF 2046 L Translation of the original instructions for use

Toro

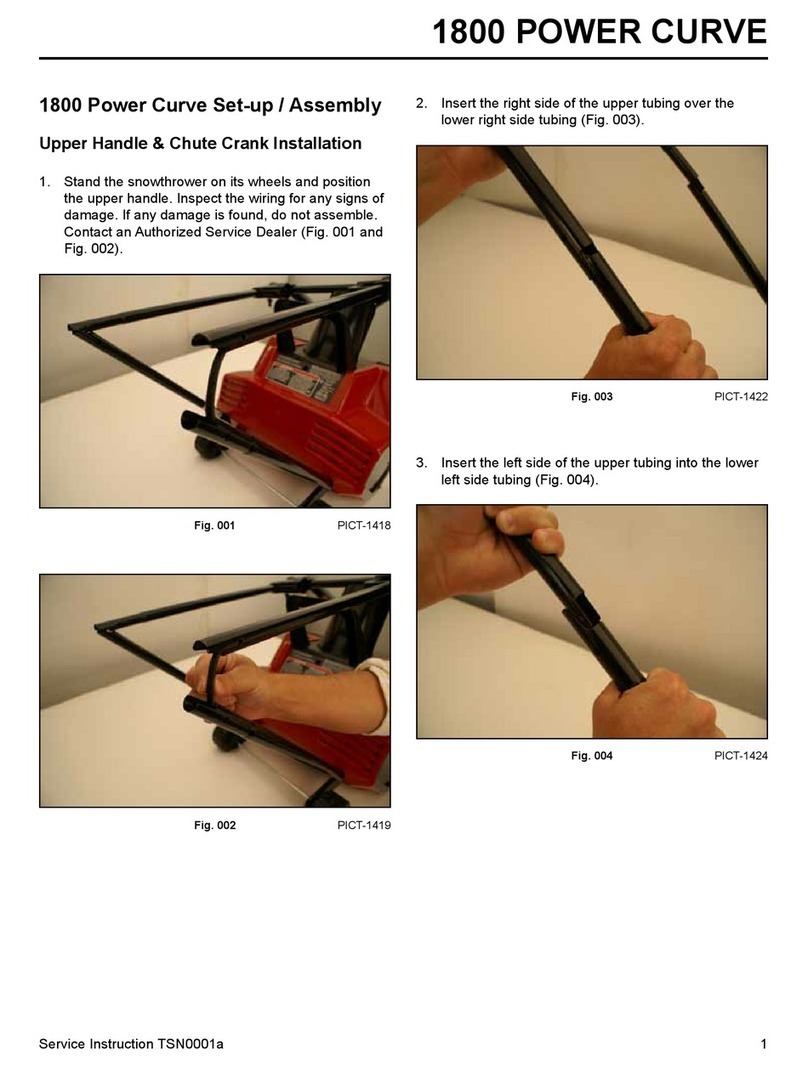

Toro 1800 Power Curve Set-up/Assembly