Trek 50 User manual

OPERATOR’S MANUAL

MODEL 50/750

HIGH-VOLTAGE AMPLIFIER

TREK INCORPORATED 1 800 367-8735

11601 MAPLE RIDGE ROAD TEL: (585) 798-3140

MEDINA, NY 14103-9710 FAX: (585) 798-3106

www.trekinc.com

50/750 9203

Thank-you

for buying Trek’s Model 50/750 High-Voltage Amplifier. This product has been designed and

built to very high standards to give you years of trouble-free service.

If you have any questions, please feel free to contact your Trek Representative at:

WRITE: TREK, INC.

11601 Maple Ridge Road

Medina, NY 14103-9710 USA

FAX: (585) 798-3106

PHONE: In the United States: 1 800 367-8735 (FOR TREK)

International Customers: (585) 798-3140

Again, thank you for buying a Trek Product.

TABLE OF CONTENTS

GENERAL INFORMATION

Introduction...........................................................................1

Specifications.......................................................................2

Incoming Confidence Test.................................................3

INSTALLATION

Mounting ...............................................................................4

AC Line Cord Connection..................................................4

How to Assemble the High Voltage Connector..............4

Load Connections ...............................................................5

Digital Enable Connection..................................................5

Changing the Output Voltage Range...............................6

OPERATION

Front Panel Controls and Indicators.................................7

Rear Panel Connector........................................................8

Operating Procedure ..........................................................8

Adjusting the Gain...............................................................8

Adjusting the AC Response Controls...............................8

Protective Circuitry..............................................................9

MAINTENANCE

Safety....................................................................................10

Preventative Maintenance .................................................10

Servicing the Fuses ............................................................10

Customer Assistance..........................................................11

APPENDIX A

Active Load Limitations ......................................................A

SECTION I

GENERAL INFORMATION

WARNING: THIS INSTRUMENT IS NOT RATED FOR AN EXPLO-

SIVE ENVIRONMENT. DO NOT USE IT IN AN EXPLOSIVE ENVI-

RONMENT OR AN EXPLOSION MAY OCCUR.

INTRODUCTION

This manual provides instructions to install

and operate the Model 50/750 High-Voltage

Amplifier. The Model 50/750 is a two-channel

amplifier. This manual describes the installa-

tion and operation of a typical channel and

applies to either channel of the instrument.

The Model 50/750 is a high-voltage amplifier

with a 1500-volt output range at 50 mA

continuous, 100 mA peak (for 10 µs into

capacitive or resistive loads). It uses a

floating output driver, allowing the instrument

to be strapped to produce an output voltage

range of 0 V to +1500 V, 0 V to -1500 V or

-750 V to +750 V. As such, the user may

select bipolar of full unipolar operation.

It features adjustable DC gain in the range of

15 to 300 V/V and AC response controls that

permit handling of different capacitive loads.

The four-quadrant output stage sources or

sinks current into capacitive or resistive loads

anywhere within the output voltage range.

1

SPECIFICATIONS

All specifications are with no load unless otherwise noted.

OUTPUT

Output Voltage Range

0 to +1.5 kV DC or peak AC, or

0 to -1.5 kV DC or peak AC, or

0 to ±750 V DC or peak AC

(jumper pin programmable).

Output Current Range

0 to ±50 mA DC, continuous

(100 mA peak for 10 µs).

AMPLIFIER INPUT

Input Voltage Range

0 to ±10 V DC or peak AC.

Input Impedance (Noninverting)

100 kΩ, nominal.

FEATURES

The Model 50/750 consists of a power supply module

with up to two modular amplifier channels which can

be mounted together in a half rack enclosure.

Digital Enable (Power Supply Module)

An input providing a connection for a TTL

compatible signal to turn on and off the high-

voltage output. A TTL low turns on the high-

voltage output. A TTL high turns off the high-

voltage output.

Gain Control

The DC gain of the Model 50/750 can be adjusted

using a potentiometer from 15 to 300 V/V.

Dynamic Adjustment

Two graduated potentiometers are used to

optimize the damping and response of the output

signal.

Zero Adjustment

A multi-turn potentiometer can adjust for zero volt

output when a zero volt input is applied.

PERFORMANCE

DC Voltage Gain

15 to 300 V/V, adjustable.

DC Voltage Gain Accuracy

Better than 0.1% of full scale.

Offset Voltage

Less than ±500 mV.

Output Noise

0 to +1500 V range or

0 to -1500 V range

Less than 50 mV rms to 20 kHz for a 1 nF

load (measured with the true rms feature of

the Hewlett Packard Model 34401A digital

multimeter).

0 to ±750 V range

Less than 60 mV rms to 20 kHz for a 1 nF

load (measured with the true rms feature of

the Hewlett Packard Model 34401A digital

multimeter).

Slew Rate (10% to 90%)

Greater than 125 V/µs.

Large Signal Bandwidth (1% distortion)

DC to greater than 8 kHz.

Small Signal Bandwidth (-3 dB)

DC to greater than 30 kHz.

Settling Time to 1%

Less than 50 µs when critically damped.

Stability

Drift with Temperature

Less than 50 ppm/°C.

Drift with Time

Less than 10 ppm/hr, noncumulative.

2A

SPECIFICATIONS, cont.

All specifications are with no load unless otherwise noted.

GENERAL

Dimensions

148 mm H x 216 mm W x 432 mm D

(5.8” H x 8.5” W x 17” D).

Weight

Model 50/750-1 (one channel)

6 kg (14 lb).

Model 50/750-2 (two channels)

8 kg (18 lb).

High-Voltage Output Connector

MHV coaxial connector.

Amplifier Input

BNC coaxial connector.

Digital Enable Connector

BNC coaxial connector.

Power Requirements

Line Supply

Factory set for one of two ranges:

90 to 127 V AC or 180 to 250 V AC,

at 48 to 63 Hz.

Power Consumption

100 VA, per channel.

AC Line Receptacle

Standard three-prong AC line connector, with

an integral fuse holder, that supplies power to

all the amplifier channels of the instrument.

Operating Conditions

Temperature

0°C to 40°C.

Relative Humidity

To 85% noncondensing.

ACCESSORIES SUPPLIED

Operator’s manual, MHV mating connector for

each amplifier channel, and line cord.

CERTIFICATION

Trek, Inc. certifies that each Model 50/750

is tested and calibrated to specifications

using measurement equipment traceable

to the National Institute of Standards and

Technology or traceable to consensus

standards.

2B

INCOMING CONFIDENCE TEST

The 50/750 undergoes extensive checks

and adjustments at the factory and should

require no initial calibration. However, you

may wish to perform an incoming confi-

dence test as part of the incoming inspec-

tion on the instrument. This incoming

confidence test is intended to confirm that

the instrument was not damaged in transit.

Applying a test signal to the INPUT connec-

tor and measuring the signal at the OUT-

PUT connector constitutes a reasonable

incoming confidence test.

We recommend that you familiarize yourself

with the information in INSTALLATION

(page 4) and OPERATION (page 7) before

performing this test.

WARNING: Do not plug in the 50/750 or

turn it on until instructed to do so. An

electrical shock could result if this pre-

caution is not observed.

Incoming Confidence Test Procedure

The following test requires a DC voltage

reference and a digital voltmeter capable of

withstanding more than 1500 V at its input

terminals.

This test procedure is written for the 50/750

unit configured as a 0 to +1500 V amplifier

or as a -750 V to +750 V amplifier. To test

a 50/750 unit configured as a 0 to -1500 V

amplifier, substitute the value indicated in

parenthesis. Perform this test for each

channel.

1. Insure that the power switch is OFF

before beginning this test.

2. Plug the AC line cord into the AC line

cord receptacle on the rear panel.

3. Plug the 50/750 into a power source.

WARNING: Make no attempt to bypass

the ground prong in the AC line cord.

Any attempt to negate this safety feature

could result in an electrical shock.

4. Connect a digital voltmeter to the OUT-

PUT receptacle on the front panel. Turn

on the voltmeter.

5. Connect a +1 V (-1 V) reference supply

to the INPUT receptacle on the front

panel. Turn on the reference supply.

6. Turn on the 50/750 POWER switch.

7. Note the voltage on the digital voltmeter.

It must indicate +100 V (-100 V).

NOTE: The output voltage of 100 V

(-100 V) will be seen, given a gain

setting of 100 V/V. Readjustment of this

gain can be set using the front panel

GAIN adjustment control.

This completes the Incoming Confidence

Test. Turn off the POWER switch. Discon-

nect the reference power supply and the

digital voltmeter.

3

SECTION II

INSTALLATION

MOUNTING

The 50/750 is designed for operation as a

tabletop instrument.

CAUTION: The 50/750 is air cooled. Do

not impair the airflow through the vent holes

in the top and bottom covers, or the rear-

panel fan.

AC LINE CORD CONNECTION

1. Insure that the 50/750 POWER switch is

off.

2. Plug the AC line cord into the AC line

cord receptacle on the rear panel.

3. Plug the 50/750 into a 115 V power

source.

WARNING: Make no attempt to bypass

the ground prong in the AC line cord.

Any attempt to negate this safety feature

could result in an electrical shock.

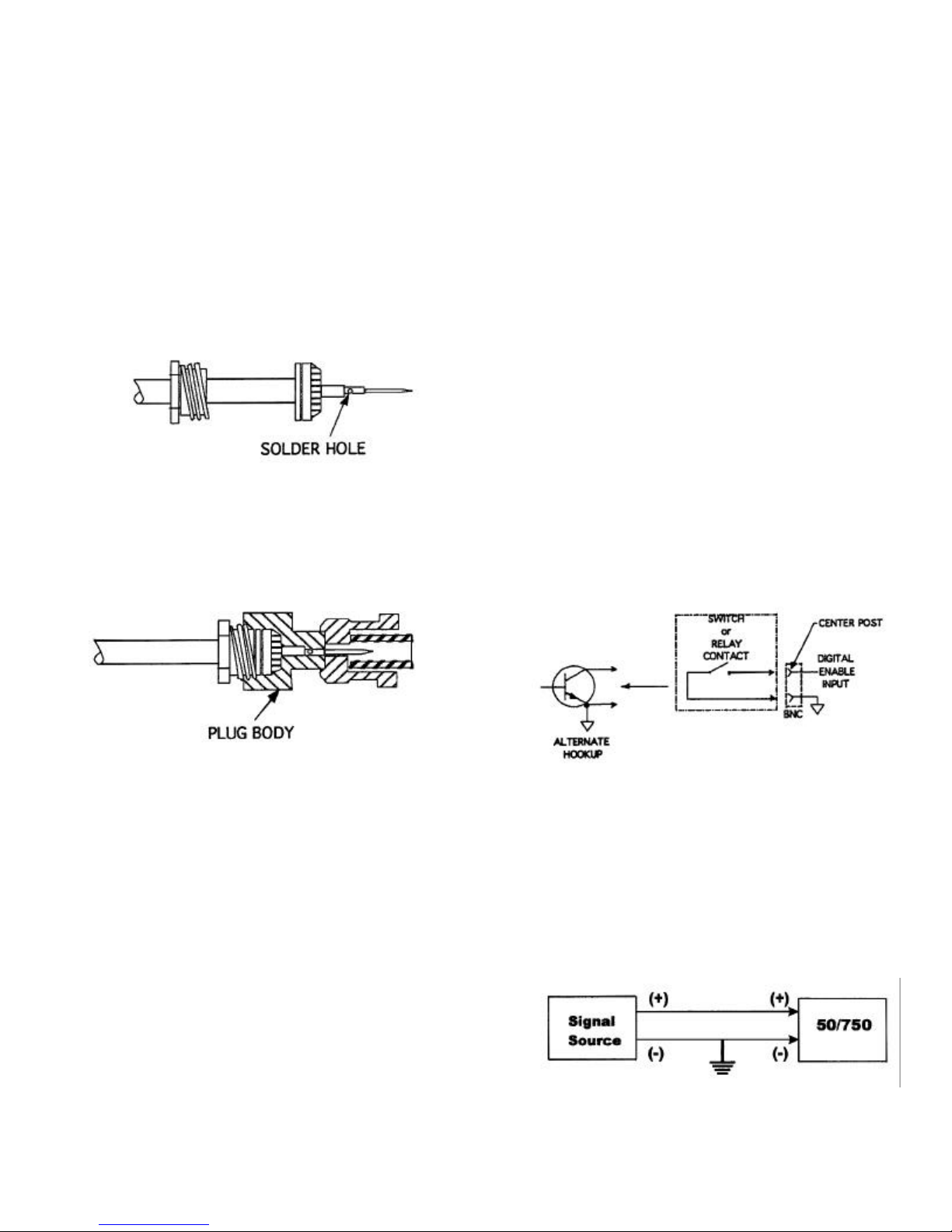

HOW TO ASSEMBLE THE

HIGH VOLTAGE CONNECTOR

A load is connected to the 50/750 using the

high-voltage plug provided.

CAUTION: Use only high-voltage coaxial

cables and high-voltage connector plugs

(MHV type). Do not use BNC plugs (they

are typically rated to only 500 V). The MHV

connector provided must be used with a

coaxial cable having a voltage rating of at

least 1200 V rms. The MHV connector will

accept a coaxial cable with an outer dia-

meter up to .212 inches or 5.4 mm.

Connect the HV plug to the cable as follows:

1. Cut the cable and square up the end.

Strip the cable jacket back 0.65 in.

2. Slide the connector parts onto the cable

jacket. Slide the nut on first, next the

washer, then the gasket, and finally the

clamp. The clamp’s inner shoulder

should fit squarely against the end of the

cable jacket.

3. With the clamp in place, comb out the

braid and fold the fibers back over the

clamp. Trim the center conductor to

0.15 in. Tin the center conductor.

4

4.Solder the contact onto the conductor

through the solder hole. The contact

should butt flush against the dielectric.

Remove excess solder from outside of

the contact.

CAUTION: Avoid applying excess heat

to the contact. This will cause the

dielectric to swell and interfere with the

connector body.

5. Push the contact assembly into the con-

nector body. Screw the nut into the

body with a wrench until tight. Do not

rotate the connector body on the cable

assembly to tighten.

This completes the high voltage connector/

cable assembly procedure.

LOAD CONNECTIONS

Load connections should be made as short

and direct as possible.

1. Connect the center conductor of the

high-voltage cable to the “hot” side of

the load.

2. Return the low side of the load to the

shield of the coaxial cable or to the

green, five-way binding post on the rear

panel of the amplifier.

DIGITAL ENABLE CONNECTION

The DIGITAL ENABLE connection is made

at the DIGITAL ENABLE BNC connector on

the front panel of the POWER SUPPLY

module. To control the 50/750 from a

remote device, connect this input to ground

through a switch or relay contact, or connect

it to the output of a controlling device such

as an open collector transistor or TTL gate

that has a current sinking capability of

approximately 2 mA. When contact is made

from the center post to ground (or the BNC

connector shield), both channels are

enabled. When contact is broken, the high-

voltage rails to both channels are disabled.

When a remote enable/disable function is

not required, connect the cap over the

DIGITAL ENABLE receptacle. This shorts

the DIGITAL ENABLE input and allows the

50/750 to operate.

INPUT CONNECTIONS

To prevent noise pickup, the ground refer-

ence for the input signal must be connected

to the input BNC connector shield. See

diagram below.

5

CHANGING THE OUTPUT VOLTAGE

RANGE

The 50/750 output voltage can be pro-

grammed for any of the three output voltage

ranges: 0 to +1500 V, 0 to -1500 V, or -750

V to +750 V. The programming is accom-

plished by a programming plug located on

the power supply module. The program-

ming plugs are supplied with the loose-parts

kit that accompanies the instrument. Pro-

gramming plugs for 0 to +1500 V and for 0

to -1500 V are supplied in the loose-parts

kit. The programming plug for -750 V to

+750 V is installed on the power supply

module.

NOTE: Observe the following safety precau-

tions when changing the output voltage

range of the 50/750 unit:

1. Hazardous voltages exist within the

instrument enclosure. Always turn off

the 50/750 and disconnect it from its

power source before attempting to make

any output voltage range wiring

changes. Failure to observe this

precaution could result in electrical

shock.

2. Allow a cool-down period to reduce the

danger of burns from heated parts such

as transistors and heat sinks.

3. Refer all maintenance procedures to

qualified personnel.

Locating the Programming Plug

Remove the power supply module. The

programming connector is a white Molex

connector that is located at the rear of the

power supply board near the gold PC fin-

gers.

Programming the Output Voltage Range

Connect the appropriate programming plug

for the output voltage range required to the

programming connector on the power sup-

ply board.

Install the programming plug so that the

ridge of the plug faces away from the gold

fingers of the power supply board.

6

SECTION III

OPERATION

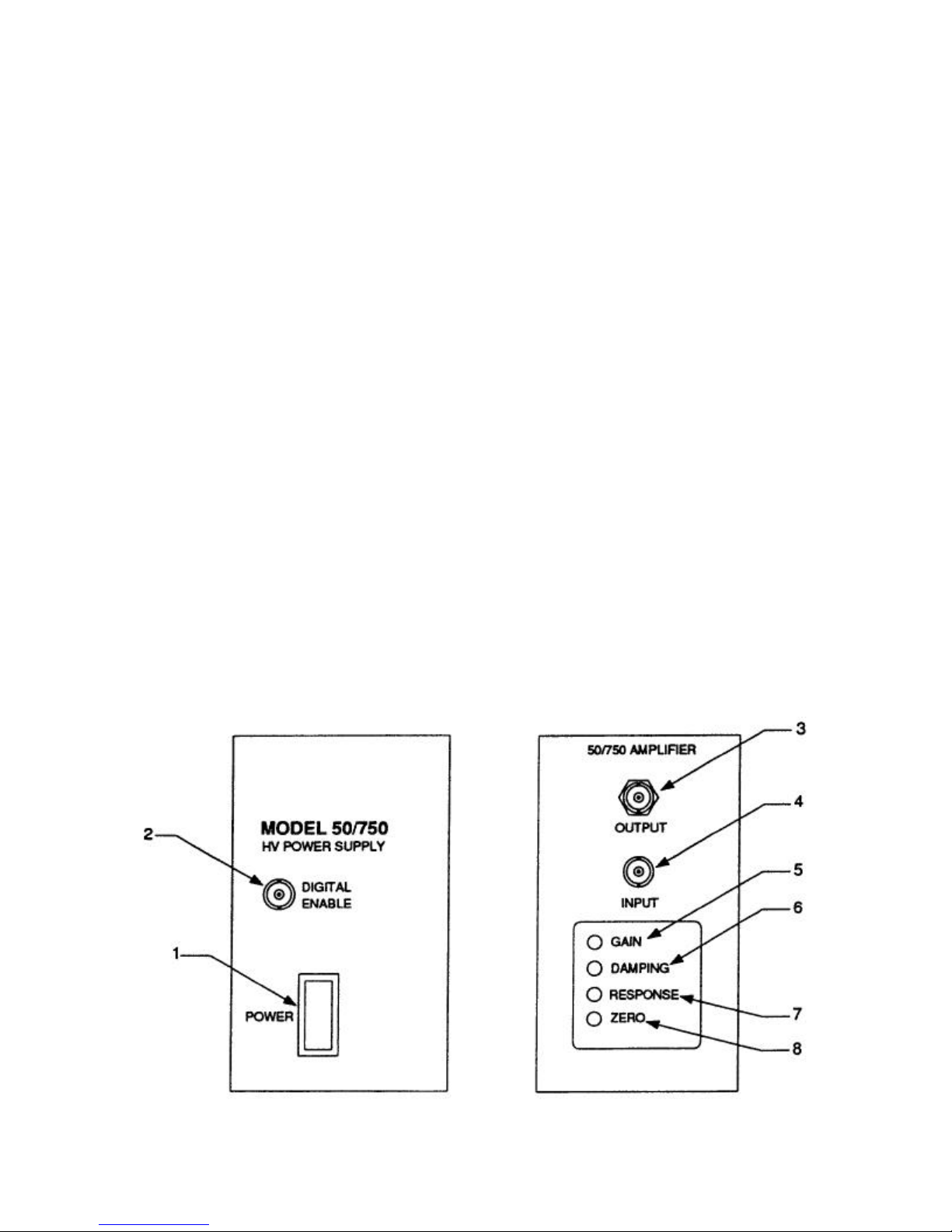

FRONT PANEL CONTROLS and INDICATORS

Refer to figure below for the location of the

controls and indicators.

1. POWER Switch: This switch turns the

50/750 on and off. A red lamp in this switch

assembly glows when the 50/750 is on.

2. DIGITAL ENABLE: Connect a switch,

relay, or TTL control signal to this input to

turn the high voltage on and off.

3. H.V. OUTPUT: This receptacle, using the

MHV connector (provided), is for the

connection to the load device.

4. AMPLIFIER INPUT: This BNC input

connector is for the connection to an

external, low voltage signal source.

5. GAIN Control: The gain control allows the

user to adjust the DC gain from 15 to 300

V/V. The gain is factory set at 150 V/V

unless otherwise specified when ordered.

6. DAMPING Control: Use this control in

conjunction with the RESPONSE control to

optimize the step response characteristics

of the amplifier.

7. RESPONSE Control: Use this control in

conjunction with the DAMPING control to

optimize the step response characteristics

of the amplifier.

8. ZERO Control: Use this control to produce

zero voltage at the OUTPUT when the input

signal is zero.

7

REAR PANEL CONNECTOR

The rear panel includes a green, five-way

binding post. This is a return connection for

the low side of the load and/or a ground ref-

erence point for other equipment.

OPERATING PROCEDURE

The 50/750 may be used as either a high-

voltage amplifier or as a high voltage refer-

ence supply. The operation is the same for

both applications: an external, low voltage

signal is applied to the input connector and

a proportional high-voltage signal is deliv-

ered through the output connector to the

load device.

WARNING: The high-voltage OUTPUT con-

nector carries high voltage. DO NOT touch

the high voltage OUTPUT connector or the

load circuit while the 50/750 is operating.

An electrical shock could result. Always

turn off the amplifier before making changes

to the load connection.

1. Ensure that the POWER switch is off

before connecting the input signal and

the load.

2. Connect the input signal to the INPUT

receptacle. Ensure that the amplitude of

the input signal does not exceed the

input voltage range specified for the

selected channel and that the source

current is limited to 100 mA.

3. Connect the output signal to the load

circuit using the high-voltage connector/

cable assembly previously constructed.

4. Turn on the POWER switch.

ADJUSTING THE GAIN

NOTE: Unless a different gain was speci-

fied at the time of order, the gain was set at

150 V/V when the 50/750 was shipped from

the factory.

To set the Gain for a different value:

1. Ensure that the 50/750 POWER switch

is off before connecting the input signal

and the digital voltmeter.

2. Connect the output of a DC reference

supply to the INPUT of the 50/750.

3. Connect the output signal to a digital

volt-meter. Ensure that the digital

voltmeter has an input voltage rating

higher than ±1500 V.

4. Turn on the POWER switch.

5. Adjust the gain potentiometer until the

desired gain is obtained. The gain pot is

accessed through the GAIN hole in the

front panel. Use a small screwdriver,

preferably nonconductive.

ADJUSTING THE AC RESPONSE

CONTROLS

As shipped from the factory, the AC

response controls, RESPONSE and DAMP-

ING, are optimized for a no-load condition.

You may desire to readjust these controls

for your load.

NOTE: If it is not feasible to apply the test

signal stated below to your particular load

device, substitute an equivalent RLC load

for the purpose of setting the AC response

controls.

Optimizing the AC Response with a Load

Connected

1. Apply a 100 Hz square wave to the input

of the 50/750. The amplitude of the

square wave must cause a full scale

output excursion: ±5 V in for -750 V to

+750 V out, 0 to +10 V in for 0 to +1500

V out, and 0 to -10 V in for 0 to -1500 V

out (values for a gain of 150).

8

2. Monitor the output of the 50/750 with an

oscilloscope. Use a compensated high-

voltage probe with the oscilloscope if

necessary to limit the oscilloscope input

to a safe voltage level.

3. Adjust the DAMPING and RESPONSE

potentiometers for the best square wave

response (no undershoot or overshoot

and flat tops).

Given the fast response and high

stability of this amplifier, fine wave-

shapes are obtainable. When viewing

the waveshape under certain loads, a

slight overshoot may exist that will not

be adjusted out using the DAMPING

and RESPONSE potentiometers. This

helps maintain the high speed of

response of the amplifier.

PROTECTIVE CIRCUITRY

The Model 50/750 includes internal protect-

tion for high reliability.

Current Limiting

The Model 50/750 is a voltage-regulated

amplifier by controlling output current. The

output current is internally limited for protec-

tion against short circuits and overloading

conditions.

Thermal Limiting

The Model 50/750 is forced-air cooled to

remove any internal accumulation of heat.

If the internal temperature of the amplifier

rises above a safe level, the amplifier will

automatically reduce its output current

capability until the amplifier returns to a safe

area of thermal operation.

Overvoltage Protection

The Model 50/750 is designed for driving

active loads (loads capable of returning

energy into the output of the amplifier). It

incorporates output terminal voltage protect-

tion against high voltage from the load. If

the voltage at the load exceeds approxi-

mately 15% of the rated output voltage of

the amplifier, an internal clamp absorbs

additional energy from the load.

When the voltage of an active device (load)

is within the output voltage range of the

50/750, there is no practical limitation to the

amount of energy that the 50/750 must

absorb.

However, a limitation for the amount of

energy the 50/750 can absorb occurs when

the voltage of the active device exceeds the

voltage range of the 50/750. The amount of

energy that the output can absorb is a com-

plex function of the voltage, of the duration

of the current, and their effects upon differ-

ent components in the protective circuit. A

discussion of this limitation is given in

Appendix A.

9

SECTION IV

MAINTENANCE

SAFETY

Observe the following safety precautions

when performing maintenance procedures

on the 50/750:

1. Hazardous voltages exist within the

instrument enclosure. Always turn off

the 50/750 and disconnect it from its

power source before cleaning or

inspecting it. Failure to observe this

precaution could result in an electrical

shock.

2. Allow a cool-down period to reduce the

danger of burns from heated parts such

as transistors and heat sinks.

3. Refer all maintenance procedures to

qualified personnel.

PREVENTATIVE MAINTENANCE

Preventative maintenance consists of

inspecting and cleaning the instrument.

Preventative maintenance performed on a

regular basis may prevent instrument failure

and improve reliability.

ACCESS: Remove the top cover to expose

all assemblies for inspection and cleaning.

INSPECTION: Visually inspect the instru-

ment for loose or damaged components or

other undesirable conditions such as heat-

damaged parts.

CLEANING: Clean the 50/750 as operating

conditions require. Dust and dirt on

components act as an insulating blanket and

prevent efficient heat dissipation. This can

cause overheating and component failure.

Dust and direct also provide an electrical

conduction path that can result in instrument

failure, especially under conditions of high

humidity that can cause arcing in the high-

voltage sections.

Use dry, low-pressure compressed air to

blow the accumulated dust and dirt from the

interior of the instrument. Use a brush to

dislodge dirt and dust that is not readily

dislodged by the compressed air.

Clean the exterior of the instrument with an

equal part solution of denatured alcohol and

water. The use of stronger solvents may

damage the finish or plastic components. A

small brush is effective in removing dirt from

the front and rear panel controls and

connectors.

SERVICING THE FUSES

WARNING: Never attempt to service the

fuses when the instrument is plugged into a

power source. An electrical shock could

result. Refer servicing of the fuses to

qualified personnel.

1. Disconnect the 50/750 from its power

source before changing the fuses.

2. Remove and replace the fuses with new

ones of the same style and value.

If the 50/750 continually blows fuses, a more

serious problem may exist within the

instrument. In this instance, contact the

Customer Service Department at Trek, Inc.

and request instructions.

10

CUSTOMER SERVICE ASSISTANCE

In the event that you require assistance on a

maintenance item, direct your request for

assistance to the Customer Service Depart-

ment at Trek, Inc.

Telephone assistance is usually effective for

obtaining additional maintenance information

that is beyond the scope of this manual.

Troubleshooting advice that is given over the

telephone may be useful for solving the

simpler malfunctions or confirming that the

instrument should be returned to the factory

or to an authorized service organization for

repair.

Factory Repairs:

The terms and conditions of the warranty are

given in the warranty statement that is found

in this manual.

CAUTION: The warranty is voided if the

instrument is serviced within the warranty

period by anyone other than Trek, Inc. or

one of its authorized service organizations.

In the event of a malfunction, and the

instrument must be returned to the factor for

repair:

a) Notify the Customer Service Department

at Trek, Inc., giving full details about the

difficulty, including the model number

and serial number of the instrument.

Obtain a return authorization number,

which will be issued by the Customer

Service Department.

b) If a return authorization number is issued,

forward the instrument (prepaid) with the

return authorization number prominently

displayed on the shipping container and

the packing list, to Trek, Inc. for repair.

If we determine that the malfunction is not

covered by the terms and conditions of the

warranty, an estimate will be submitted for

customer approval before the commence-

ment of repairs.

FAX: (585) 798-3106

TELEPHONE:

In the United States

1 800 367-8735 (FOR-TREK)

International Customers

(585) 798-3140

11

APPENDIX A

ACTIVE LOAD LIMITATIONS

The Model 50/750 is designed for driving

active loads. Active loads are loads capable

of returning energy into the output of the

amplifier. An example of an active load is a

piezoelectric transducer. A piezoelectric

transducer will develop a voltage across

itself when forced to expand or contract.

The amount of energy that can be generated

by the piezoelectric transducer or any active

load is determined by the formula:

Energy in joules = 1/2CV2,

where C is the capacitance value of the

active load and V is the voltage created by

the stress on the active load.

When the voltage created by an active load

is within the output voltage range of the

50/750, there is no practical limitation to the

amount of energy that the 50/750 must

absorb.

However, a limitation for the amount of

energy the 50/750 can absorb occurs when

the voltage created by the active device

exceeds the voltage range of the 50/750.

The amount of energy that the output can

absorb is a complex function of the voltage,

of the duration of the current, and of their

effects upon different components in the pro-

tective circuit.

A limitation for the amount of energy that the

50/750 can absorb is based on the maximum

energy that certain components in the

50/750 can dissipate. Please refer to Figure

1 for the following discussion. D1 and D2

become forward biased when the voltage

created by the active device exceeds the

value of V1 or V2. (V1 and V2 represent the

high voltage supplies of the 50/750.) When

this occurs, V1 or V2 act as capacitors and

begins charging until the voltage rating of

ZD1 or ZD2 is reached. At this point ZD1 or

ZD2 absorbs the energy produced by the

active load.

NOTE: ZD1 and ZD2 are idealized repre-

sentations of different components in the

50/750. The specific components (zener

voltage values) are different when the

50/750 is operated in different output voltage

ranges.

A1

To calculate the maximum energy in joules

that the ZD1 and ZD2 can dissipate, use the

formula:

Maximum energy in joules = (Vm)(Is)(Ts),

Where V

mis the voltage rating of ZD1 or

ZD2, I

sis the maximum surge current that

ZD1 or ZD2 can absorb for a certain duration

(Ts), and Tsis the maximum duration of the

particular surge current from the load that

ZD1 and ZD2 can withstand. The calcula-

tions for the different voltage ranges of the

50/750 are shown in Table 1.

Now the energy that can be supplied by an

active load can be compared to the

maximum energy dissipation of the 50/750

for a certain output voltage range.

If the energy that can be supplied by the

active load device is greater than the

maximum energy dissipation of the 50/750

for a certain output voltage range, then

additional external protection is required.

Some examples of external protection are

adding series impedance to the output or

using a spark gap device.

TABLE 1

VOLTAGE

RANGE

DESIGNATION

VOLTAGE

RATING

NONRECURRENT

SURGE

CURRENT (MAX.)

CURRENT

DURATION

(MAX.)

MAXIMUM

ENERGY

(in Joules)

0 to ±750 V

ZD1

ZD2

+1000 V, ±5%

-1000 V, ±5%

0.005 amps

0.35 amps

0.85 amps

2 amps

continuous

100 ms

10 ms

1 ms

-

35

8.5

2

0 to +1500 V

0 to -1500 V

ZD1

ZD2

+2000 V, ±5%

-2000 V, ±5%

0.005 amps

0.35 amps

0.85 amps

2 amps

continuous

100 ms

10 ms

1 ms

-

70

17

4

0 to +1500 V

0 to -1500 V

ZD2

ZD1

-115 V, ±10%

+115 V, ±10%

0.01 amps

1.2 amps

2 amps

5 amps

continuous

100 ms

10 ms

1 ms

-

13.8

2.3

0.575

A2

This manual suits for next models

2

Table of contents

Popular Amplifier manuals by other brands

Cloud

Cloud 46 Series Installation and user guide

Princeton

Princeton 124A Operating and service manual

CEOPA

CEOPA CE-1070P user manual

Clarion

Clarion APA4400G Operation and installation instructions

Pioneer

Pioneer GM-D8400M - Amplifier owner's manual

Altec Lansing

Altec Lansing 1407A POWER AMPLIFIER Specifications