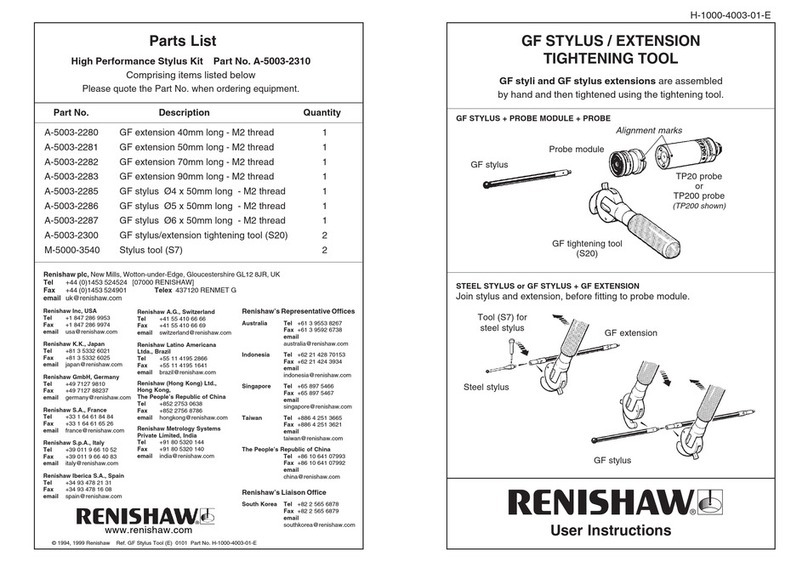

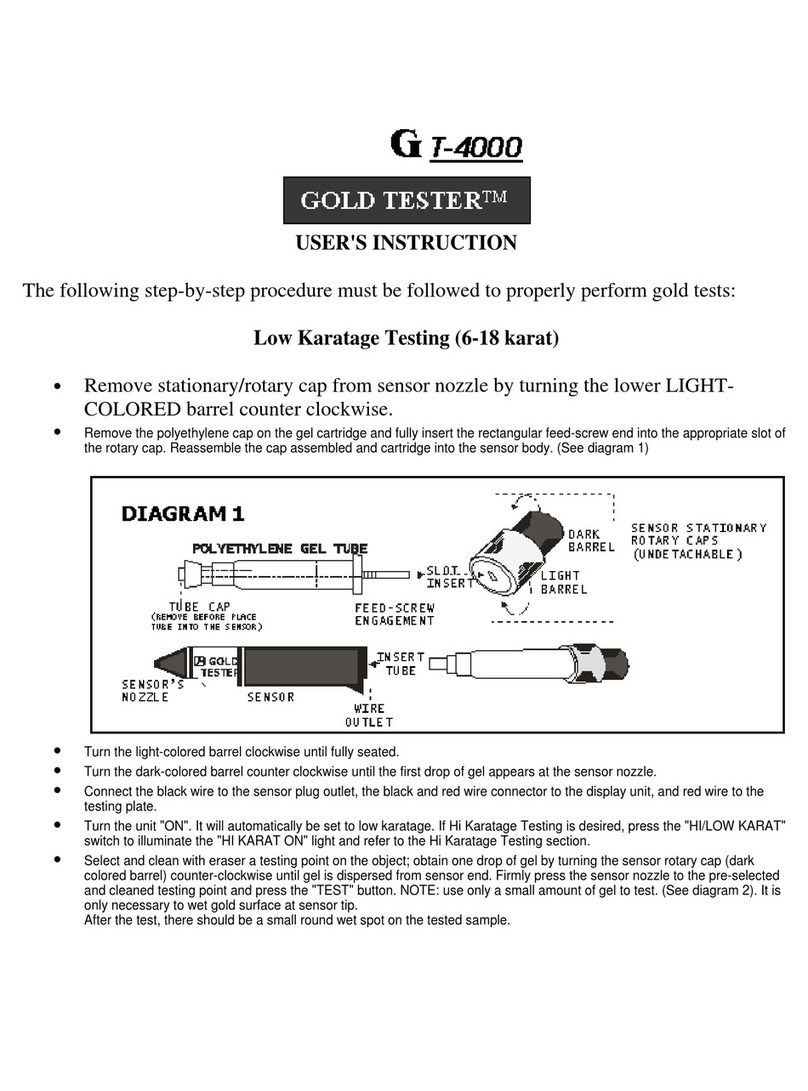

3. Insert the Feed Screw Engagement (Diagram 3, #7) into the appropriate slot of the

Rotary Cap. Be sure that the Feed Screw is fully engaged.

4. Take off tube Cap (Diagram 3, #1)

5. Insert the polyethylene gel tube, which is fully lodged in the Stationary/Rotary Cap,

into the sensor and turn the bright colored barrel (Diagram 2) clockwise until fully

seated. Do not turn the dark colored top barrel (Diagram 2, # 7) clockwise or it will

damage the mechanism.

6. Turn the Rotary Cap counter clockwise several times until the first drop of gel

appears at the sensor nozzle.

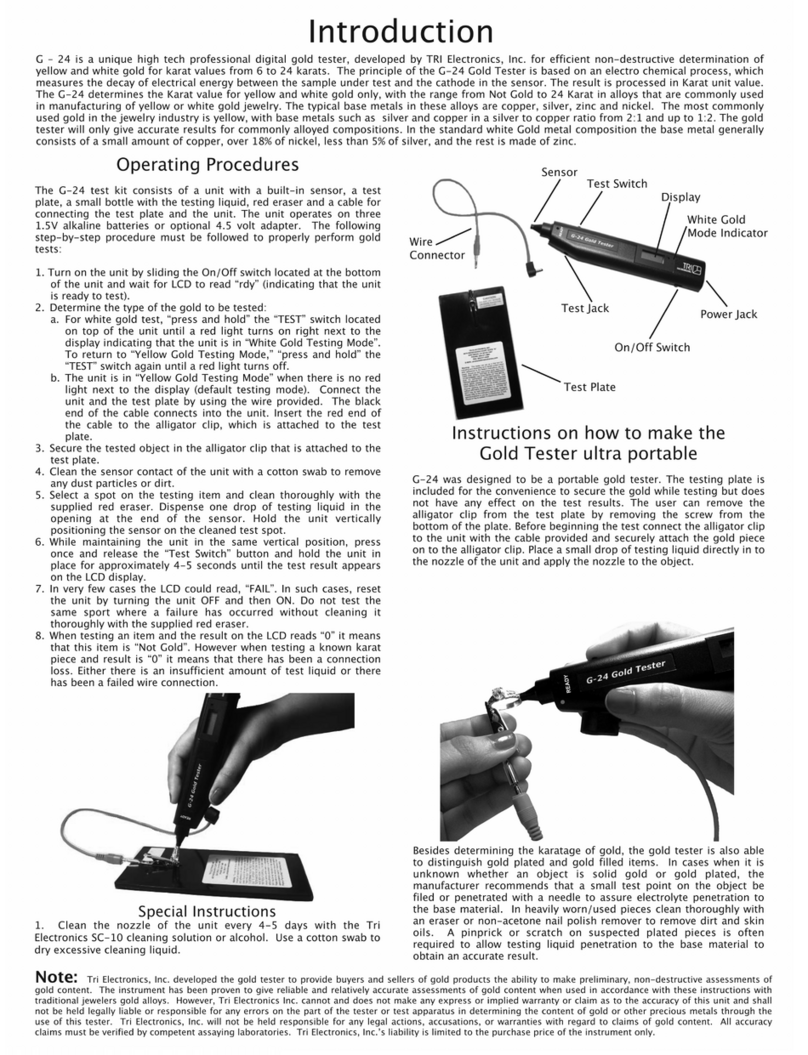

OPERATION PROCEDURE

1. Load the polyethylene gel tube.

2. Connect the black wire to the sensor's plug outlet, the black and red wire

connector to the display unit and the red wire to the testing plate.

3. Turn the unit "ON". (See Diagram 1, #7 for switch). The unit should display:

display: "G-XL-18 READY TO TEST…"

4. Select a testing point on the object close to, BUT NOT TOUCHING, the alligator

clip.

5. Holding the sensor in the vertical position with the nozzle down, twist the Rotary

Cap counter clockwise, a click at a time, until a drop of gel appears on the tip. Wipe

this first drop of gel on the towel and turn (usually one or two clicks) until a small

gel sample appears. Immediately touch the sensor to pre-selected cleaned point on

the test object.

DO NOT LET GEL OR SENSOR NOZZLE TOUCH THE ALLIGATOR CLIP!

6. Press one of the following buttons: Y-Yellow, W-White, R-Red, or G-Green

depending on the color of the gold (See Diagram 1, #4 for button location).

7. Maintain the sensor in the vertical position for approximately 5 seconds while the

instruments calibrates the gold value.

SERVICE

If there are any problems regarding the GXL-18, please contact us:

TRI Electronics Inc.

9570 Ridgehaven Court SUITE "A"

San Diego, CA 92123

Attn. Service Dept.

Phone 858) 571-4881

FAX (858) 571-5404