Triad TRIUMPH SS2 SERIES Operating instructions

TRIUMPH SS2 SERIES

High Efficiency Condensing Boiler

3000MBH –5500MBH

OPERATING AND MAINTENANCE MANUAL

TRIAD Boiler Systems, Inc.

West Chicago, IL 6018

888-526-5245

5/22/2014

2 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

Contents

FORWARD...................................................................................................................................................... 5

Documents Unique to your boiler ............................................................................................................. 7

Supplementary Manuals............................................................................................................................ 8

Definitions, Standards, & Sources ............................................................................................................. 8

Introduction to safety................................................................................................................................ 9

What to do if you smell gas ..................................................................................................................... 10

Approvals & Recordkeeping .................................................................................................................... 10

Applicable Regulations in the U.S. market .............................................................................................. 10

Warnings...................................................................................................................................................... 11

1 Labeling, Signage, Handling Options ........................................................................................................ 12

2.0 Boiler Component Identification ........................................................................................................... 16

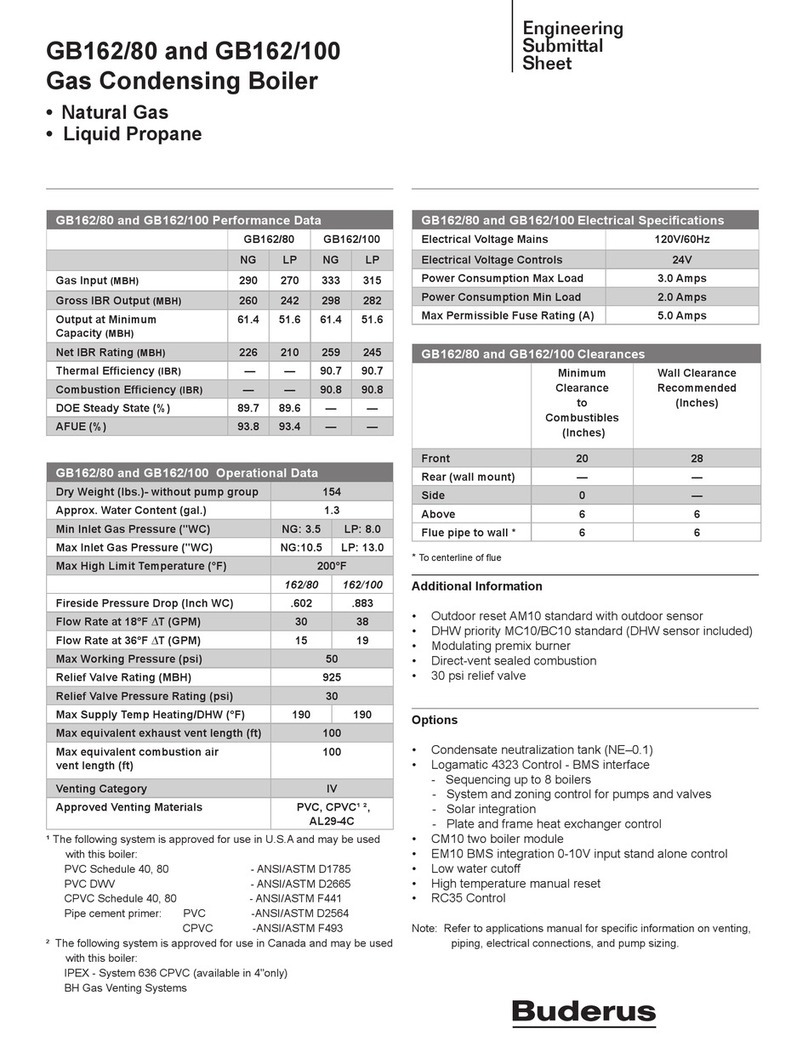

2.1 Boiler Specifications and Dimensions.................................................................................................. 177

2.1.1 Cutaway of Combustion Chamber and Heat Exchanger………………………………………………………………….17

2.1.2 Installing Boiler Insulation and Jacket……………………………………………………………………………………………20

2.2 Typical basic water level and temperature controls ........................................................................... 234

2.3 Burner Mount ........................................................................................................................................ 24

2.4 Gas Train…………………………………………………………………………………………………………………………………………..25

2.5 Example fuel train schematics............................................................................................................. 245

3.0 Specifications....................................................................................................................................... 256

4.0 Boiler Installation................................................................................................................................... 27

4.1 Receiving the boiler ............................................................................................................................... 27

4.2 Unloading the boiler-burner unit .......................................................................................................... 28

4.3 Boiler unloading instructions................................................................................................................. 28

4.4 The boiler room ..................................................................................................................................... 29

Fresh & Ventilation air............................................................................................................................. 29

Lighting .................................................................................................................................................... 29

4.5 Installing the Boiler................................................................................................................................ 29

Flue ........................................................................................................................................................ 280

Condensate Drain .................................................................................................................................. 290

Water Connections................................................................................................................................ 290

Inverting Door Aperture .......................................................................................................................... 31

Pressurized Boiler Connection............................................................................................................... 301

Furnace Drawer .................................................................................................................................... 312

4.6 Extended storage procedure for boilers not yet installed. ................................................................. 312

3 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

4.7 Installation of Loose shipped items..................................................................................................... 322

4.8 Electrical Installation ........................................................................................................................... 323

Power for Electrically Operated Controls.............................................................................................. 334

Remote Emergency shutdown switches ............................................................................................... 334

4.9 Miscellanies installation guidelines ..................................................................................................... 345

Software & Safety.................................................................................................................................. 345

Flame Safeguard .................................................................................................................................... 345

Venting of Gas Controls......................................................................................................................... 345

4.10 Boiler stack connection ..................................................................................................................... 345

4.11 Vent material selection ..................................................................................................................... 356

5 Plumbing your boiler .............................................................................................................................. 357

5.1 Fuel supply & connections................................................................................................................... 367

5.2 Boiler connections, general ................................................................................................................... 37

5.3 Water connections ................................................................................................................................ 37

5.4 Hot water boilers supply & return connections .................................................................................... 37

5.5 Drains..................................................................................................................................................... 38

5.6 Drain connections.................................................................................................................................. 38

5.7 Safety relief valves (SRV) ....................................................................................................................... 39

5.8 SRV discharge piping ............................................................................................................................. 39

6 Boiler start-up........................................................................................................................................... 39

6.1 Operating data..................................................................................................................................... 390

6.2 Start-up guidelines............................................................................................................................... 390

6.3 Tools & gauges..................................................................................................................................... 401

6.4 Fuel guidelines..................................................................................................................................... 401

6.5 Cleaning and filling a new boiler ......................................................................................................... 401

6.6 Firing a new boiler ............................................................................................................................... 412

6.7 Boil-out procedure .............................................................................................................................. 412

6.8 Start-up of hot water boilers............................................................................................................... 434

6.9 Good Practice recommendations for hot water boilers...................................................................... 445

6.10 Guide lines for hot water boiler heating system................................................................................. 45

Condition: Boiler Warm –System Warm ................................................................................................ 45

Shut down of hot water boiler heating system..................................................................................... 456

7 Operation................................................................................................................................................ 456

7.1 Safety relief valves............................................................................................................................... 456

7.1.2 Safety relief valve tests..................................................................................................................... 456

Try Lever Test ........................................................................................................................................ 456

4 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

Safety Relief Valve Test: ........................................................................................................................ 467

7.2 Gauges ................................................................................................................................................... 48

7.2.1 Pressure gauges:................................................................................................................................. 48

7.2.3 Pressure gauge range: ........................................................................................................................ 48

7.2.4 Pressure gauge accuracy: ................................................................................................................... 48

7.2.5 Pressure gauge calibration ................................................................................................................. 48

7.2.6 Temperature gauges........................................................................................................................... 49

7.2.7 Pressure or altitude gauges................................................................................................................ 49

7.2.8 Stack thermometers........................................................................................................................... 49

7.3 Temperature controls............................................................................................................................ 49

7.3.1 High limit: ........................................................................................................................................... 49

7.3.2 Operator: ............................................................................................................................................ 49

7.3.3 Firing rate control:.............................................................................................................................. 49

7.4 Maintenance on temperature limiting controls.................................................................................. 490

7.5 Example of control set point adjustment procedure .......................................................................... 490

7.7 Water level controls ............................................................................................................................ 490

7.7.1 Electric probe type low-water fuel cutoffs......................................................................................... 50

7.7.2 Low-water fuel cutoff and water feeder maintenance. ................................................................... 501

7.7.3 Pushbutton Shunt............................................................................................................................. 501

7.7.4 LWCO ................................................................................................................................................ 501

7.7.5 Water level manual reset ................................................................................................................. 501

7.8 Water level operations ........................................................................................................................ 501

7.8.1 Maintaining Proper Water Level ...................................................................................................... 501

7.9 Water Treatment................................................................................................................................. 512

7.9.1 Heating boilers.................................................................................................................................. 523

7.9.2 Water treatment guidelines ............................................................................................................. 523

Get professional help ............................................................................................................................ 523

Oil & water don't mix ............................................................................................................................ 533

Heating boilers should not breathe....................................................................................................... 534

7.10 Access openings and burner mount.................................................................................................. 534

7.10.1 Burner mount ................................................................................................................................. 534

7.10.2 Refractory ....................................................................................................................................... 534

8 Maintenance........................................................................................................................................... 534

8.1 Spare Parts........................................................................................................................................... 545

8.2 Maintenance schedule ........................................................................................................................ 545

8.2.1 Daily procedure, also reference the burner manual’s procedures. ................................................. 545

5 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

8.2.2 Weekly procedure, also reference the burner manual’s procedures. ............................................. 555

8.2.3 Monthly procedure, also reference the burner manual’s procedures. ........................................... 555

8.2.4 Semi-Annual procedure, also reference the burner manual’s procedures........................................ 57

8.2.5 Annual procedure, also reference the burner manual’s procedures................................................. 58

8.3 Detailed Empty inspection..................................................................................................................... 59

Safety Checklist for Inspection ................................................................................................................ 59

Water Side Checklist................................................................................................................................ 59

Fire Side Checklist.................................................................................................................................... 59

Look for corrosion of pressure parts: .................................................................................................... 590

Look for erosion:.................................................................................................................................... 590

External Checklist: ................................................................................................................................. 590

8.4 Limit control tests................................................................................................................................ 590

8.4.1 High & Low gas pressure switch limit test & adjustment................................................................. 601

For setting and testing the gas pressure switches: ............................................................................... 601

8.4.2 Electrical Limit Controls.................................................................................................................... 601

9 TROUBLESHOOTING ............................................................................................................................... 601

To stop burner ....................................................................................................................................... 612

Burner adjustments............................................................................................................................... 612

Switch problems .................................................................................................................................... 612

Leaking................................................................................................................................................... 612

Fan rotation ........................................................................................................................................... 612

10 Out of service operations ..................................................................................................................... 623

10.1 Shutdown........................................................................................................................................... 623

10.2 Boiler taken out of service................................................................................................................. 623

10.3 Boiler laid up dry................................................................................................................................ 634

10.4 Boiler laid up wet procedure............................................................................................................. 634

10.5 Re-commissioning ............................................................................................................................. 634

FORWARD

TRIAD Boiler Systems has a manufacturing history of over 80 years. TRIAD patented the original isolated,

modular boiler system concept. Each boiler / burner package has been specifically matched to provide

6 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

optimal performance. The boilers, however, are only a part of the complete operating system. They can only

meet their ratings if the system is properly designed and if the boilers receive proper care.

Two major things must be focused on to achieve successful implementation: Proper System Design and

Proactive Preventive Maintenance. While the TRIAD Boiler website www.triadboiler.com may address some

issues, a design engineer should be involved. This Operations and Maintenance Manual addresses many

issues regarding usage.

It is important that the system design matches the performance of the boiler. A compatible design that

addresses combustion air, correct system sizing, fuel and water supply, and breeching is crucial, and should

be the responsibility of the system design engineer who must also ensure local code compliance. The boilers

will meet their full potential when part of an appropriate system design.

Efficient burner operation is highly dependent on proper adjustment, adequate combustion air, and correct

breeching. Make sure you carefully read the burner Operating and Maintenance Manual. Incorrectly dealing

with these issues can result in, among other things, a loss of efficiency, higher operating costs, sooting,

frequent cleaning, and high carbon monoxide (CO) output.

The successful, long-term operation of the boiler is dependent on the quality of its water. Failure to provide

suitable water will result in corrosion and the build-up of scale and mud / sludge / sediment causing

inefficient thermal transfer, an associated loss of efficiency, higher operating costs, and eventually lead to

premature boiler failure.

Being cognizant of these issues, and taking proper steps when required, should result in many years of

successful boiler operation.

TRIUMPH SS2 HIGH EFFICIENCY BOILERS

TRIAD is pleased to introduce a new line of High Efficiency boilers, the TRIUMPH SS2 series. This product line

is designed with a large horizontal combustion chamber matched with a specially engineered vertical

condensing section in stainless steel AISI 316 Ti. These elements are immersed in water contained in a

horizontal boiler drum with a vertical column to which the system inlet and outlet connections are fitted. All

the burners, controls, and pumps are all first quality name-brand OEM components.

These boilers reach very high efficiency levels as the flue gases not only are released at a temperature little

higher than that of the system return water, but also a large part of the water vapor contained in the flue

gases is condensed, recovering the latent heat of condensation.

Because the flame path is designed to go through the combustion chamber without inversion, the formation

of Nitrogen Oxides (NOx) is limited as much as possible. This is because NOx typically forms when the flame

remains at high temperature in the combustion chamber for long periods.

The boiler body, is composed of:

7 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

Top section which contains a large diameter corrugated 316ti furnace; access is provided by a large

double hinged front door. The burner hinges also open for access.

Large diameter 316ti SS pipes connected directly to the furnace and the front tube plate forming the

second pass.

Corrugated horizontal flue passages of 316ti SS with proprietary surfaces to increase surface area and

heat transfer from the third pass. The corrugated flue passages are inserted into the bottom tubesheet

in an inclined fashion for easy drainage. This section constitutes the third pass and is accessed by a large

double hinged door.

Boiler shell complete with boiler flow, constant temperature return, variable temperature return, fittings

for control thermostats and safety devices.

Rear smoke box also drains the condensate, and a chimney connection drain condensate from the

chimney.

All boiler parts in contact with flue gases are manufactured in stainless steel AISI 316 Ti. The large diameter

and ample furnace volume of these boilers also serve to reduce thermal NOx production.

The TRIUMPH SS2 series boilers place no limit on the return water temperature, and reach the highest

performance when the return temperature is lower than 135°F. At higher temperatures (as with any

condensing boiler) when there is no condensation (water vapor) in the flue gas, latent heat will not not

recovered. The efficiency of Triumph SS2 boilers is very good (90%+) even when it is installed in a traditional

higher-temperature heating system.

The high boiler efficiency is due to optimum combustion efficiency combined with high density 3”

fiberglass insulation the boiler is designed to exceed the requirements of the Department of Energy and is

confirmed by BTS-2000 testing.

READ AND SAVE THESE INSTRUCTIONS FOR REFERENCE. These manual and associated documents are to

be kept with the boiler and in legible condition for the life of the boiler.

This manual will refer to the burner manual (Powerflame or Weishaupt) when appropriate. A double asterisk

(**) is used to indicate that your boiler manual should also be checked for information on the topic being

covered unless otherwise noted. In addition to the boiler and burner working together, there are controls,

switches, valves, and other components on your boiler assembled specific to each end user. A list of exact

components, and information about them, are appended to this manual. All of these documents and devices

work together to safely operate your boiler.

Documents Unique to your boiler

Triad documents are created unique to each boiler and are appended to this manual

Document # of pages Page #/Location

Specification sheets 4 Appendix 1

Ratings and dimension drawing, 1 Appendix 2

Recommended spare parts, 1 to 3 Appendix 3

List of component manuals 1 to 4 Appendix 4

8 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

ASME data reports 1 to 12 pages Appendix 6

MSDS Information (If supplied) 0 to 9 Appendix 7

Wiring drawing(s) can be large format Last

Supplementary Manuals:

This manual is intended to be used in conjunction with other documents.

Burner manual, and manuals that comes with the burner. Appendix 10

Manuals for other components supplied with the boiler. Appendix 11

NOTE: Warranty validation/Start-up report information sheet must be filled out and return to TRIAD within

three weeks of when the burner is first turned on and within two months of shipment of boiler to maintain

your warranty. Also note that boil-out procedures, a slow initial warm up, and proper water treatment are

required to maintain your warranty.

DEFINITIONS AND TERMINOLOGY

ASME: American Society of Mechanical Engineers

ASME CSD-1: Controls and Safety Devices for Automatically Fired Boilers

BPVC: ASME boiler and pressure vessel code.

Section IV: Portion of BPVC that applies to water boilers not exceeding 160 PSIG or 250°F and Steam boilers

not exceeding 15 PSIG

Heating boiler: hot water boiler

Water boiler: Boiler that supplies hot water

LWCO: Low-water cutoff, or Low-water fuel cutoffs

Aux LWCO: Auxiliary Low water cutoff

LWCO mark: Vertical position on boiler where the primary LWCO operates

ANSI: American National Standards Institute

150# class: ANSI standard of flanged piping connections,

NPS: Nominal pipe size

NPT: National pipe thread (tapered)

MAWP: Maximum allowable working pressure

Set point: A specific value of pressure or temperature used in a control where it will switch on or off.

Aquastat: Water temperature control device

BHP: Boiler horse power is equivalent to 33,475 Btu/Hr.

PSI: Pounds per square inch

PSIG: PSI gage reading.

In. WC: Inches of water column. Units of pressure where one (1) PSI = 28 In. WC (28” WC)

UL: Underwriters Laboratories Inc.

UL Mark: Signage on the boiler designating UL approval

UL 795: Commercial-Industrial Gas Heating Equipment

UL 353: Limit Controls

cUL: Verification to Canadian Requirements by Underwriters Laboratories Inc.

CSA: Canadian Standards Association

Notice!

9 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

CSA 22.1: Canadian Electrical Code Part 1

CSA B149: Natural Gas & Propane Code

NFPA: National Fire Protection Agency

NFPA 54: National Fuel Gas Code

NFPA 70: National Electric Code, AKA: NEC

IFGC: International Fuel Gas Code

R&D drawing: Ratings and Dimensions drawings. AKA: General Arrangement.

Introduction to safety

WARNING! The improper installation, adjustment, service, maintenance, or operation of this

equipment can result in fire, explosion, series injury, or death.

Refer to this Triumph manual and the PowerFlame burner manual. For assistance or additional

information consult a qualified installer, service agency, or fuel supplier as appropriate.

DO NOT STORE OR USE GASOLINE OR ANY OTHER FLAMMABLE LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE. DO NOT USE GASOLINE, CRANKCASE DRAININGS, OR ANY OIL CONTAINING GASOLINE.

NEVER BURN GARBAGE OR PAPER IN THE UNIT, AND NEVER LEAVE COMBUSTABLE MATERIAL AROUND IT.

All Personnel involved with the startup, maintenance, or adjustment of this boiler must read and understand

the entire contents of this manual prior to any startup or adjustment being made to the boiler and related

components. Installation and service must be performed by a qualified installer or certified service

technician.

Safe and reliable operation is dependent to a large extent upon the skill and attentiveness of the operator

and the maintenance personnel. Operating skill implies the following:

Knowledge of fundamentals

Familiarity with equipment

Suitable background of training and experience

Full and effective use should be made of manufacturer's instruction books on operation and maintenance.

Of special importance are written procedures prepared expressly for each installation by the manufacturers'

service engineers and qualified personnel from the operating organization before and during the

commissioning period. These procedures are based on actual experience and often include invaluable

information on what the equipment is expected to do. Limitations critical to safe and reliable operations are

also given. Control systems vary in complexity from computer control to manual operation.

Regardless of the type of system used, the operators should be thoroughly trained so that they can maintain

safe and continuous operation during changeover from automatic to manual control as well as to continue

operation by manual control if the automatic systems are out of service. The operator should have

instrumentation at the point of manual operation to permit him to be aware of operating conditions at all

times. Regularly scheduled auto-manual changeover, manual operation, and emergency drills to prevent loss

10 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

of these skills are recommended.

What to do if you smell gas:

Do not try to light any appliance

Do not tough any electrical switch

Do not use any phone in your building

Immediately call your gas supplier from a neighbors phone

Follow the gas supplier’s instructions

If you cannot reach your gas supplier, call the fire department.

Approvals & Record keeping

All TRIAD boilers are designed, manufactured, and stamped to the ASME PRESSURE VESSEL CODE. Refer to

the signage information section to determine the approvals that have been applied to your boiler.

THE INSTALLATION OF THIS BOILER SHALL BE IN ACCORDANCE WITH LOCAL CODE AND REGULATIONS OF

AUTHORITIES HAVING JURISDICTION.

BOILERS SHALL BE OPERATED BY QUALIFIED PERSONNEL. BOILERS SHALL BE INSTALLED AND SERVICED BY

QUALIFIED PERSONNEL ONLY OR THE WARRANTY WILL BE INVALIDATED.

Boilers intended for Canadian markets, refer to the following regulations as applicable:

The equipment shall be installed in accordance with the current Installation Code for Gas Burning Appliances

and Equipment, CSA B149, and applicable Provincial Regulations for the class; which should be carefully

followed in all cases. Authorities having jurisdiction should be consulted before installations are made.

Wiring shall be in accordance with the CSA 22.1 Canadian Electrical Code, Part I.

The installation of the unit shall be in accordance with the regulations of the authorities having jurisdiction

APPLICABLE REGULATIONS FOR US MARKET:

NFPA54: National Fuel Gas Code

NFPA70: National Electrical Code

IFGC: International Fuel Gas Code

All drawings, wiring diagrams, schematic arrangements, manufacturers’ descriptive literature, and spare

parts lists, and written operating instruction should be kept permanently in the boiler room or other suitable

location so it will be available to those who operate and maintain the boiler. Where space permits, drawing

and diagrams should be frame or sealed in plastic and hung adjacent to the related equipment. Other

materials should be assembled and enclosed in a suitable binder. When change or additions are made, the

data and drawings should be revised accordingly.

READ AND SAVE THESE INSTRUCTIONS FOR REFERENCE.

11 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

Some states and municipalities require licensing or certification of personnel who operate or maintain

heating equipment. Also, some authorities require posting of inspection certificates in the boiler room. The

supervisor in charge of a given installation should make sure such requirements are met.

GENERAL WARNINGS

Each boiler is provided with a data plate that can be found in the envelope with the boiler documents. The

plate lists:

Serial number or identification code;

Rated thermal output;

Furnace thermal output;

Types of fuels that can be used;

Max operating pressure.

A manufacturer's certificate is also provided which certifies the hydrostatic pressure test.

The installation must be performed in compliance with the regulations in force by professionally qualified

personnel. The term “professionally qualified personnel” means persons with specific technical skills in the

sector of heating system components.

INCORRECT INSTALLATION MAY CAUSE DAMAGE TO PERSONS, ANIMALS OR OBJECTS FOR WHICH THE

MANUFACTURER CANNOT BE HELD RESPONSIBLE.

At the first start up, all regulation and control devices positioned on the control panel should be checked for

efficiency. The guarantee shall be valid only upon compliance with the instruction given in this manual.

IMPORTANT: This boiler has been designed to heat hot water to a temperature lower than the boiling point

at atmospheric pressure and must be connected to a heating plant and/or a domestic hot water plant within

the limits of the boiler performance and output.

WARNING!

THE BOILER MUST BE INSTALLED IN A ROOM WHICH COMPLIES WITH THE APPROPRIATE

VENTILATION REQUIREMENTS. READ THE INSTALLATION AND USER INSTRUCTION BEFORE

INSTALLING AND LIGHTING THE BOILER.

12 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

1.0 BOILER LABELING AND SIGNAGE:

Supply Water Label:

Low Temperature Return Water Label:

Medium Temperature Return Water Label:

Warning plate:

Every boiler includes

this warning mounted on the front doors of the boiler close to eye level.

.

13 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

LWCO mark:

Used to determine the correct elevation of the LWCO switch. Line this up with the primary level

mark on the LWCO

.

ASME Drum stamping:

The ASME “H” Stamp is riveted directly to the boiler frame when ASME approval is given and

is located above the medium temperature return to the left.

Load Bearing Point sticker:

Besides the lifting lugs, this shows the only locations the boiler should be lifted from.

14 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

Handling Options:

The only lifting points are the lifting lugs on the top of the boiler OR the skid below the

boiler.

When using a forklift, the weight of the boiler must be balanced. Make sure the forks are

positioned equidistantly from the center of gravity which is marked on the sides.

15 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

Baffle Warning Label

UL and CUL boiler stickers:

16 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

2.0 Boiler Cutaway

2.1.1 Model 3000 - 5500

Rear

smokebox

Supply Nozzle

Handhole

Cleanout

Plug on

Rear lid

Rear tubesheet

Bridge

(Refractory)

KEY

N1 Boiler flow

N2 Medium temperature return

N3 Accessory socket

1

. Level probe with integrated glow plug (not supplied as standard) - G1/2“

2

. Available connection - G1“1/2

3

. Expansion vessel fitting - G1“1/2

4

. Safety valve fitting - G1“1/4

5

. Available connection - G1/2“

6

. Temperature control fitting - G1/2“

7

. Pressure switch fitting - G1/2“

8

. Thermometers/thermostats fitting - G1/2“

9

. Fuel shut-off valve fitting- G1/2“

Air vent fitting - G3/4“

Minimum level probe fitting - G1/2“

17 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

1 Hydraulic disconnect switch

2 ‘Y’ strainer

3 Water flow switch

4 Filling unit

5 Relief Valve with articulated joint

6 Pressure gauge

7 Acid condensate neutralizer

8 Boiler switchboard

9 Inspection well

10 Safety pressure switch

11 Pressure gauge cock

12 Thermometer probe

13 Safety thermostat probe

14 Regulation thermostat probe n°1

15 Regulation thermostat probe n°2

16 Fuel shut-off valve probe

17 Thermometer

18 Regulation thermostat n°1

19 Regulation thermostat n°2

20 Manual reset safety thermostat

21 Shock absorbing pipe

22 Safety valve

23 Fuel shut-off valve

24 Manual shut-off valve

25 Manual shut-off valve for gas

26 Expansion vessel

27 Level probe glow plug (optional)

28 System flow

29 Probe sleeves inside the boiler

30 Gas inlet

31 Low temperature return

32 Return water inlet from the plant

33 Medium temperature return

34 Boiler exhaust

35 Acid condense outlet

36 Neutralized condense outlet

37 Outlet flue gas

38 Air vent valve

39 Burner

18 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

TRIUMPH SS2 BOILER EFFICIENCY

Heat

Input

MBH

Firing

Rate %

RETURN WATER TEMPERATURE

80

100

120

130

140

160

4000

100%

93.5

91.3

88.9

88.1

88.1

87.5

3000

75%

95.0

92.6

89.5

88.4

88.4

87.8

2000

50%

96.8

93.9

90.1

88.8

88.6

88.1

1000

25%

97.5

95.3

91.5

89.6

88.7

88.2

TRIUMPH SS2 Pressure Drop in WC

Heat

Input

MBH

Heat

Output

MBH

Temp Drop (∆T) oF

20

30

40

50

60

70

80

90

100

Pressure Drop, in WC

3000

2850

13.14

5.84

3.29

2.10

1.46

1.07

0.82

0.65

0.53

4000

3800

23.36

10.38

5.84

3.74

2.60

1.91

1.46

1.15

0.93

5000

4750

36.50

16.22

9.13

5.84

4.06

2.98

2.28

1.80

1.46

5500

5225

44.17

19.63

11.04

7.07

4.91

3.61

2.76

2.18

1.77

Pressure Drop Vs Delta T

0

10

20

30

40

50

50

10

20

30

40

60

70

80

90

100

TEMPERATURE DROP, Deg F.

T

3000

MBH

4000

MBH

5000

MBH

5500

MBH

19 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

Ensure that the hydraulic pressure measured after the reduction valve on the supply pipe does not

exceed the operating pressure specified on the rating plate of the component (boiler, heater etc.).

As the water contained in the heating system increases in pressure during operation,

ensure that its maximum value does not exceed the maximum hydraulic pressure specified

on the component rating plate.

Ensure that the safety valve outlets of the boiler and hot water tank, if any, have been

connected to drain in or-der to prevent the valves from flooding the room if they open.

Ensure that the pipes of the water and heating system are not used as an earth connection

for the electrical system as this can seriously and very rapidly damage the pipes, boiler,

heater and radiators.

Once the heating system has been filled, you are advised to close the supply cock and keep

it closed so that any leaks from the system will be identified by a drop in hydraulic pressure

indicated on the system pressure gauge.

IMPORTANT!

IF THE BOILER IS NOT SUPPLIED WITH ACID CONDENSATE NEUTRALIZER, A SIPHON MUST BE

FITTED ON THE CONDENSATE DRAIN IN ORDER TO AVOID FLUE GAS LEAKAGE.

NOTE: IF ONLY ONE RETURN IS REQUIRED, ALWAYS USE THE LOW TEMPERATURE ONE (CLOSEST

TO FLOOR)

2.1.2 Insulation of the Boiler Body

The boiler is supplied fixed to a wooden supporting base (1) to allow handling and to facilitate the

insulation process. The glass wool insulation, consisting of 3 layers, is fitted at the factory and

wrapped on the parts shown in the figure and fixed to the connection sides by clamps

1

1

20 TRIAD Boiler Systems, Inc.

West Chicago, IL

www.triadboiler.com

Once the glass wool is attached, the wooden support can be removed and the boiler can be placed

in its final position.

Details on the Removable Boiler Jacket

Staves can be removed if required, as shown in the figure

This figure shows the front struts attached to the plate using the appropriate screws and nuts.

Table of contents

Other Triad Boiler manuals

Popular Boiler manuals by other brands

Viessmann

Viessmann Vitodens 200-W B2HA series Installation and service instructions

iQe

iQe COMFORT?30 User instructions

Biasi

Biasi 28S User manual and installation instructions

Extraflame

Extraflame TERMOPELLET TC30 Installer manual

Bosch

Bosch WORCESTER GREENSTAR Ri ErP Series Installation, commissioning and servicing instructions

Immergas

Immergas AVIO 24 2 ERP Instruction booklet and warning

PEERLESS

PEERLESS Pinnacle PI-399 Installation and operation manual

IDEAL

IDEAL he24 user guide

Ariston

Ariston GENUS PREMIUM EVO HP 45 user manual

Baxi

Baxi Assure 500 Combi 2 Installation and service manual

ACV

ACV GLASS BL 50 Installation and operation manual

Strom

Strom Combi E-Boiler Series installation guide