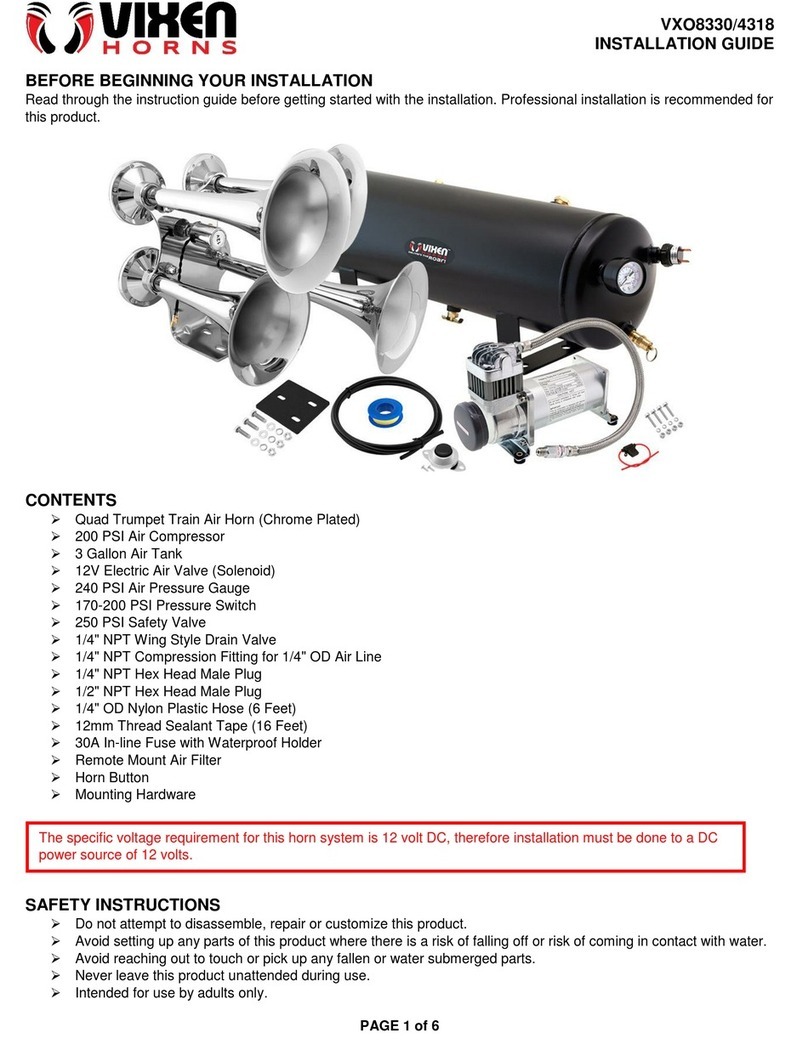

TRIGA TR-HRL User manual

1 I56-5844TRG-002

2/1/2021

For use with the following models:

Horns: TR-HRL, TR-HWL

Compact Horns: HGRL, HGWL

Chimes: CHRL, CHWL

PRODUCT SPECIFICATIONS

Standard Operating Temperature: 32°F to 120°F (0°C to 49°C)

Humidity Range: 10 to 93% Non-condensing

Nominal Voltage: Regulated 12VDC or regulated 24DC/FWR

Operating Voltage Range (includes fire alarm panels with built in sync): 8 to 17.5V (12V nominal) or 16 to 33V (24V nominal)

Operating Voltage with MDL3 Sync Module: 8.5 to 17.5V (12V nominal) or 16.5 to 33V (24V nominal)

Input terminal wire gauge: 12 to 18 AWG

DIMENSIONS FOR PRODUCTS AND ACCESSORIES MOUNTING BOX OPTIONS

WALL PRODUCTS Length Width Depth

Horn and Chime Compact Horn

Horn/Chime

5.6" (143mm) 4.7" (119mm) 1.25" (32mm)

4" x 4" x 1½", Single Gang,

Double Gang, 4" Octagon,

SBBRL/WL

Single Gang,

SBBGRL/WL

Compact Horn

5.25" (133

mm) 3.45" (88 mm) 1.25" (32 mm)

Horn/Chime with SBBRL/WL

Surface Mount Back Box 5.9" (149 mm) 4.9" (125 mm) 1.9" (47 mm)

Compact Horn with SBBGRL/WL

Surface Mount Back Box

5.5" (140.5

mm) 3.7" (94.5 mm) 1.6" (39 mm)

NOTE: SBBRL/WL Surface Mount Back Box intended only for standard horns and chimes.

SBBGRL/WL Surface Mount Back Box intended for compact horns.

NOTICE: This manual shall be left with the owner/user of this equipment.

GENERAL DESCRIPTION

These notification appliances offer a wide range of audible devices for life

safety notification. Our horns and chimes come with 10 field selectable

tone and volume combinations for a wide range of systems. Horns come in

two attrac-tive mounting designs, standard and compact. They are intended

for indoor applications and approved for wall and ceiling mount

installations.

These horns are public mode notification appliances intended to alert

occu-pants of a life safety event. Chimes are private mode notification

appliances used to alert trained personnel to investigate possible

emergency situations and take appropriate action. Both the horn and the

chime are listed to ANSI/UL 464 requirements.

These notification appliances are designed to be used in 12 VDC, 24VDC, or

24V FWR (full wave rectified) systems. AV devices can be activated by a

compat-ible Triga fire alarm control panel or power supply. The power

from these supplies can be either regulated or coded (pulsing) power

supplies. Refer to the appropriate fire alarm control panel manufacturer or

power supply for more information.

These wall horns and chimes come enabled with System Sensor

synchro-nization protocol which requires connections to a power supply

capable of generating the System Sensor synchronization pulses, a FACP

NAC output configured to System Sensor synchronization protocol, or the

use of MDL (3) module to generate the synchronization protocol.

FIRE ALARM SYSTEM CONSIDERATIONS

The National Fire Alarm and Signaling Code, NFPA 72, requires that all au-

dible notification appliances, used for building evacuation installed after July

1, 1996, produce temporal coded signals. Signals other than those used for

evacuation purposes do not have to produce the temporal coded signal. Triga

recommends spacing notification appliances in compliance with NFPA 72.

SYSTEM DESIGN

The system designer must make sure that the total current draw by the devices

on the loop does not exceed the current capability of the panel supply, and

that the last device on the circuit is operated within its rated voltage. The cur-

rent draw information for making these calculations can be found in the tables

within the manual.

When calculating the voltage available to the last device, it is necessary to

consider the voltage due to the resistance of the wire. The thicker the wire, the

smaller the voltage drop. Wire resistance tables can be obtained from electri-

cal handbooks. Note that if Class A wiring is installed, the wire length may

be up to twice as long as it would be for circuits that are not fault tolerant.

The total number of strobes on a single NAC must not exceed 69 for 24 volt

applications.

AVAILABLE TONES

The product line offers a wide variety of horn and chime tones for your life

safety needs, including temporal 3 pattern (½second on, ½second off, ½sec-

ond on, ½second off, ½second on, 1½off and repeat) which is specified by

ANSI and NFPA 72 for standard emergency evacuation signaling.

Both the horn and chime are compatible with coded power supplies. Coded

power supplies power the NAC and all connected AV devices with certain

power pattern that can be programmed from such power supplies. In this

mode there is no delay in device operations after the power is applied, the

sound will stop after the power is removed.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Selectable Output

Horns and Chimes

– Wall Mount

TRIGA Life Safety Systems, LLC

7600 Olde Eight Rd.

Hudson, Ohio 4426-1057

I56-5844TRG-002

2 I56-5844TRG-002

2/1/2021

TABLE 3. HORN CURRENT DRAW (mA)

Pos Tone Volume

8-17.5

Volts 16-33 Volts

DC DC FWR

1 Temporal High 39 44 54

2 Temporal Low 28 32 54

3 Non-Temporal High 43 47 54

4 Non-Temporal Low 29 32 54

5 3.1 KHz Temporal High 39 41 54

6 3.1 KHz Temporal Low 29 32 54

7 3.1 KHz Non-Temporal High 42 43 54

8 3.1 KHz Non-Temporal Low 28 29 54

9 Coded High 43 47 54

10 3.1 KHz Coded High 42 43 54

TABLE 4. HORN SOUND OUTPUT (dBA)

Pos Tone Volume

8-17.5

Volts 16-33 Volts

DC DC FWR

1 Temporal High 84 89 89

2 Temporal Low 75 83 83

3 Non-Temporal High 85 90 90

4 Non-Temporal Low 76 84 84

5 3.1 KHz Temporal High 83 88 88

6 3.1 KHz Temporal Low 76 82 82

7 3.1 KHz Non-Temporal High 84 89 89

8 3.1 KHz Non-Temporal Low 77 83 83

9 Coded High 85 90 90

10 3.1 KHz Coded High 84 89 89

TABLE 5. CHIME CURRENT DRAW (mA)

Pos Tone Volume

8-17.5

Volts 16-33 Volts

DC DC FWR

1 1 second chime High 5 8 9

2 1 second chime Low 589

3 ¼ second chime High 6 10 10

4 ¼ second chime Low 599

5 Temporal 3 chime High 7 10 10

6 Temporal 3 chime Low 699

7 5 second whoop High 12 15 16

8 5 second whoop Low 710 11

9 1 chime (coded) High 12 15 16

10 NOT TO BE USED

TABLE 6. CHIME SOUND OUTPUT (dBA)

Pos Tone Volume

8-17.5

Volts 16-33 Volts

DC DC FWR

1 1 second chime High 61 62 62

2 1 second chime Low 56 55 55

3 ¼ second chime High 67 70 70

4 ¼ second chime Low 61 61 61

5 Temporal 3 chime High 64 66 66

6 Temporal 3 chime Low 59 60 60

7 5 second whoop High 76 78 78

8 5 second whoop Low 62 64 64

9 1 chime (coded) High 76 78 78

10 NOT TO BE USED

To select the tone, turn the rotary switch on the back of the product to the

desired setting. (See Figure 1.)

FIGURE 1. AUDIO SETTINGS

A0473-00

Available horn settings can be found in Table 1. Available chime settings can

be found in Table 2. Tones listed as coded are intended to be used with coded

power supplies.

TABLE 1. HORN TONES

Pos Tone Volume Setting

1 Temporal High

2 Temporal Low

3 Non-Temporal High

4 Non-Temporal Low

5 3.1 KHz Temporal High

6 3.1 KHz Temporal Low

7 3.1 KHz Non-Temporal High

8 3.1 KHz Non-Temporal Low

9 Coded High

10 3.1 KHz Coded High

TABLE 2. CHIME TONES

Pos Tone Volume Setting

1 1 second chime High

2 1 second chime Low

3 ¼ second chime High

4 ¼ second chime Low

5 Temporal chime High

6 Temporal chime Low

7 5 second whoop High

8 5 second whoop Low

9 1 chime (coded) High

10 NOT TO BE USED

CURRENT DRAW AND AUDIBILITY RATINGS

For the horn, the current draw for each setting is listed in Table 3 and the au-

dibility ratings can be found in Table 4. For chime, the current draw for each

setting is listed in Table 5 and the audibility ratings can be found in Table 6.

Tones listed as coded are intended to be used with coded power supplies.

3 I56-5844TRG-002

2/1/2021

TAMPER SCREW

For tamper resistance, the standard captive screw may be replaced with a Torx

screw, ordered separately.

1. To remove the captive screw, back out the screw and apply pressure to the

back of the screw until it disengages from the housing. Replace with Torx

screw. (See Figure 5.)

FIGURE 5. TAMPER SCREW

T15 Torx

#6-32, 5/8"

SCREW-TMPR-50

A0478-01

INSTALLING A SURFACE MOUNT BACK BOX

1. The surface mount back box may be secured directly to the wall or ceiling.

Use of grounding bracket with ground screw is optional. (See Figures 6 and 7.)

2. The wall mount box must be mounted with the up arrow pointing up. (See

Figure 8.)

3. Threaded knockout holes are provided for the sides of the box for ¾ inch

and ½ inch conduit adapter. Knockout holes in the back of the box can be

used for ¾ inch and ½ inch rear entry.

4. To remove the ¾ inch knockout, place the blade of a flat-head screwdriver

along the outer edge and work your way around the knockout as you strike

the screwdriver. (See Figure 9.)

NOTE: Use caution not to strike the knockout near the top edge of the

surface mount back box.

5. V500 and V700 raceway knockouts are also provided. Use V500 for low

profile applications and V700 for high profile applications.

6. To remove the knockout, turn pliers up. (See Figure 10.)

FIGURE 6. STANDARD SURFACE-

MOUNT BACK BOX

A0479-00

FIGURE 7. COMPACT SURFACE-

MOUNT BACK BOX

A0480-00

FIGURE 8. SURFACE MOUNT BACK BOX UP ARROW

A0481-00

FIGURE 9 AND 10. KNOCKOUT AND WIRE MOLD REMOVAL FOR SUR-

FACE MOUNT BACK BOX

½ inch

or ¾ inch

Wire Mold Removal

A0465-01 A0466-01

NOTE: Use caution not to strike the knockout near the top edge of the wall

version of the surface mount back box.

WIRING AND MOUNTING

All wiring must be installed in compliance with the National Electric Code

and the local codes as well as the authority having jurisdiction. Wiring must

not be of such length or wire size which would cause the notification appli-

ance to operate outside of its published specifications. Improper connections

can prevent the system from alerting occupants in the event of an emergency.

Wire sizes up to 12 AWG (2.5 mm²) may be used with the mounting plate. The

mounting plate ships with the terminals set for 12 AWG wiring.

Make wire connections by stripping about

3

/

8

" of insulation from the end of

the wire. Then slide the bare end of the wire under the appropriate clamping

plate and tighten the clamping plate screw.

We provide a wire strip guide. See Figure 2 for wiring terminals and strip

guide reference.

CAUTION

Factory finish should not be altered: Do not paint!

CAUTION

Do not over tighten mounting plate screws; this may cause mounting plate

to flex.

SHORTING SPRING FEATURE

These notification appliances come with a shorting spring that is provided be-

tween terminals 2 and 3 of the mounting plate to enable system continuity

checks after the system has been wired, but prior to installation of the final

product. (See Figure 2.) This spring will automatically disengage when the

product is installed, to enable supervision of the final system.

FIGURE 2. WIRING TERMINALS, SHORTING SPRING, AND STRIP GUIDE

Shorting Spring

Strip Guide

WIRING TERMINALS

1. Negative (-). Line in and out

2. Positive (+). Line in and out

3. Positive (+). Line in and out

A0475-01

MOUNTING AND REMOVING APPLIANCE

1. Attach mounting plate to junction box. (See Figures 3 and 4.)

2. Connect field wiring according to terminal designations. (See Figure 2.)

3. If the product is not to be installed at this point, use the protective dust

cover to prevent contamination of the wiring terminals on the mounting plate.

4. To attach product to mounting plate:

a. Remove the protective dust cover.

b. Hook the tabs on the top of the product housing into the grooves on

mounting plate.

c. Pivot the product into position to engage the terminals on the mounting

plate. Make sure that the tabs on the back of the product housing fully

engage with the mounting plate.

d. Hold product in place with one hand, and secure product by tightening the

single mounting screw in the front of the product housing.

FIGURE 3. STANDARD DEVICE FIGURE 4. COMPACT DEVICE

A0476-00 A0477-00

4 I56-5844TRG-002

©2021. 2/1/2021

SYSTEM WIRING

The horn and chime only require two wires for power and supervision. (See

Figure 11.) Please consult your FACP manufacturer or power supply manu-

facturer for specific wiring configurations and special cases. (See Figure 12.)

FIGURE 11. 2-WIRE CIRCUIT

+

–

+

–

INPUT

FROM

FACP

OR

PRIOR

DEVICE

OUTPUT

TO

NEXT

DEVICE

OR EOL

A0367-02

FIGURE 12.

Horn

(+)

(–)

(+)

(–)

E

O

L

(+)

(–)

(+)

(–)

Horn/strobe Horn

Two Wire System

Any Mix of Models

Wired for Tandem

Operation

Horn

Synchronization Module

(+)

(–)

(+)

(–)

E

O

L

(+)

(–)

(+)

(–)

Horn/strobe Horn

Two Wire System

Any Mix of Models

Wired for Tandem

Operation

MDL(3)

A0345-01

NOTE: 2W horn strobe shown in these figures.

Triga™ is a trademark of TRIGA Life Safety Systems, LLC. System Sensor®is a registered trademark of Honeywell International, Inc.

FCC STATEMENT

These Strobes and Horn/Strobes have been tested and found to comply with the limits for a Class

B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide rea-

sonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

The horn or chime will not work without power. The horn and

chime gets its power from the fire/security panel monitoring the

alarm system. If power is cut off for any reason, the notification

appliance will not provide the desired audio warning. The horn

or chime may not be heard. The loudness of the horn or chime

meets (or exceeds) current Underwriters Laboratories’ standards.

However, the horn or chime may not alert a sound sleeper or one

who has recently used drugs or has been drinking alcoholic bev-

erages. The horn or chime may not be heard if it is placed on a

different floor from the person in hazard or if placed too far away

to be heard over the ambient noise such as traffic, air condition-

ers, machinery or music appliances that may prevent alert persons

from hearing the alarm. The horn or chime may not be heard by

persons who are hearing impaired.

WARNING

THE LIMITATIONS OF HORNS AND CHIMES

This manual suits for next models

1