Trimax Warlord 3 Series User manual

1

SPARE PARTS

INSTRUCTIONS # 51

Date Created: 31/05/2017

Product: Warlord S3

Title: Rotor Removal and Replacement

SAFETY! Before attempting to make any adjustments or carry out maintenance on the mower, review

the hazard identification table (section 3a of your Operator Manual) and take all necessary precautions.

Due to the specialized nature of Rotor removal and replacement, it is recommended that this procedure is

only attempted at a fully equipped General Engineering Workshop.

Read through this entire process prior to starting. Take note of where parts are removed from!

Ensure all appropriate protective equipment is used.

Heavy Lifting Equipment is required for this process, ensure all Lifting Equipment is suitably rated!

REQURIED SHIM THICKNESS

Warlord Series 3 Mowers:

0.45 –0.5mm (0.018 –0.020”) thick.

IMPORTANT:

Two strips of shim material are required for this

operation.

These should be a little longer than one side of the

square rotor bearing housing and about 10-15mm

(3/8 - 5/8”) wide.

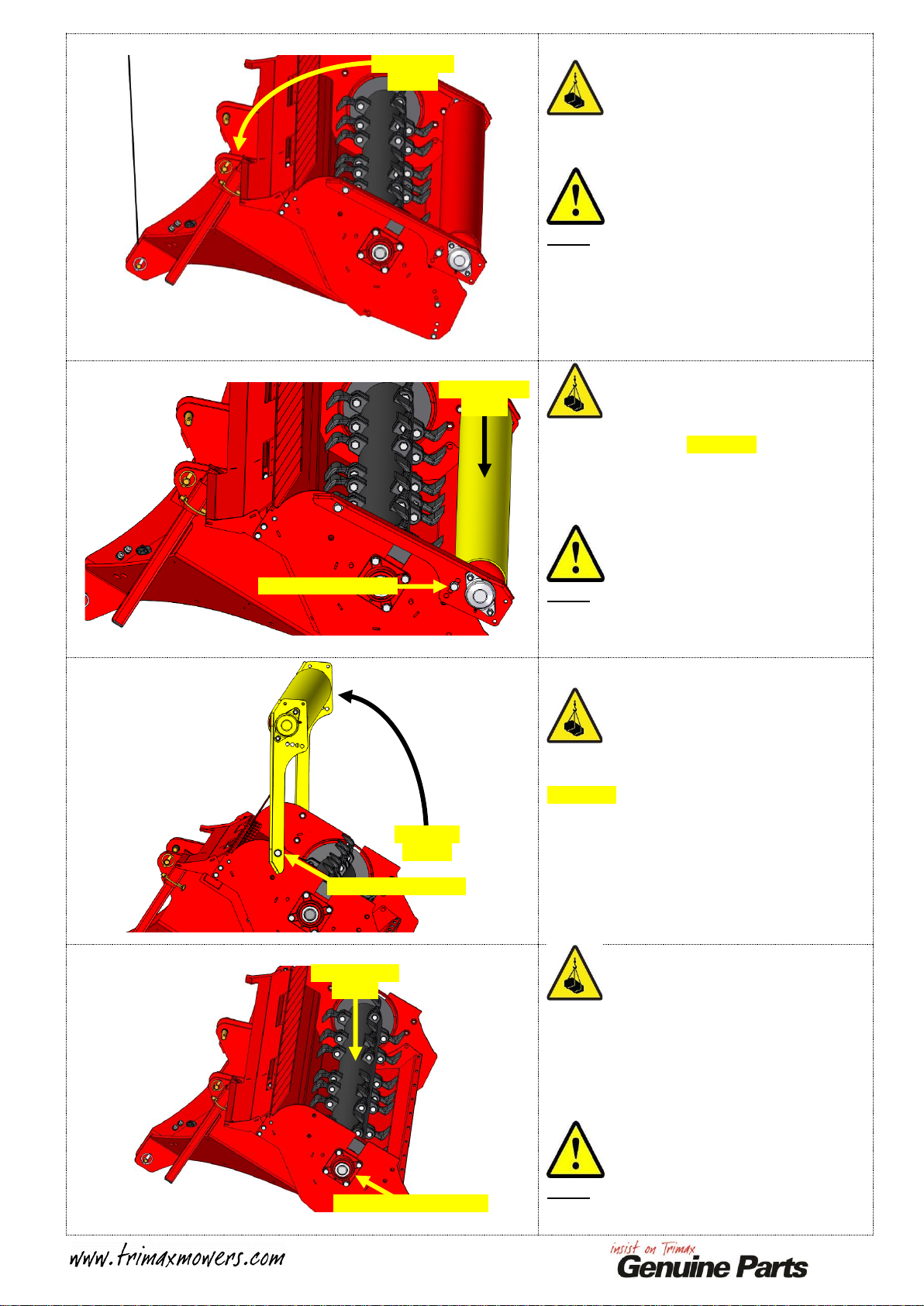

Use the Tractor hydraulics to position the

Headstock CENTRALLY in relation to the

Mower.

Disconnect the Warlord S3 and P.T.O Shaft from

the Tractor.

Remove the P.T.O Shaft from the Warlord S3.

This is detailed in the Operators Manual for the

Mower.

IMPORTANT:

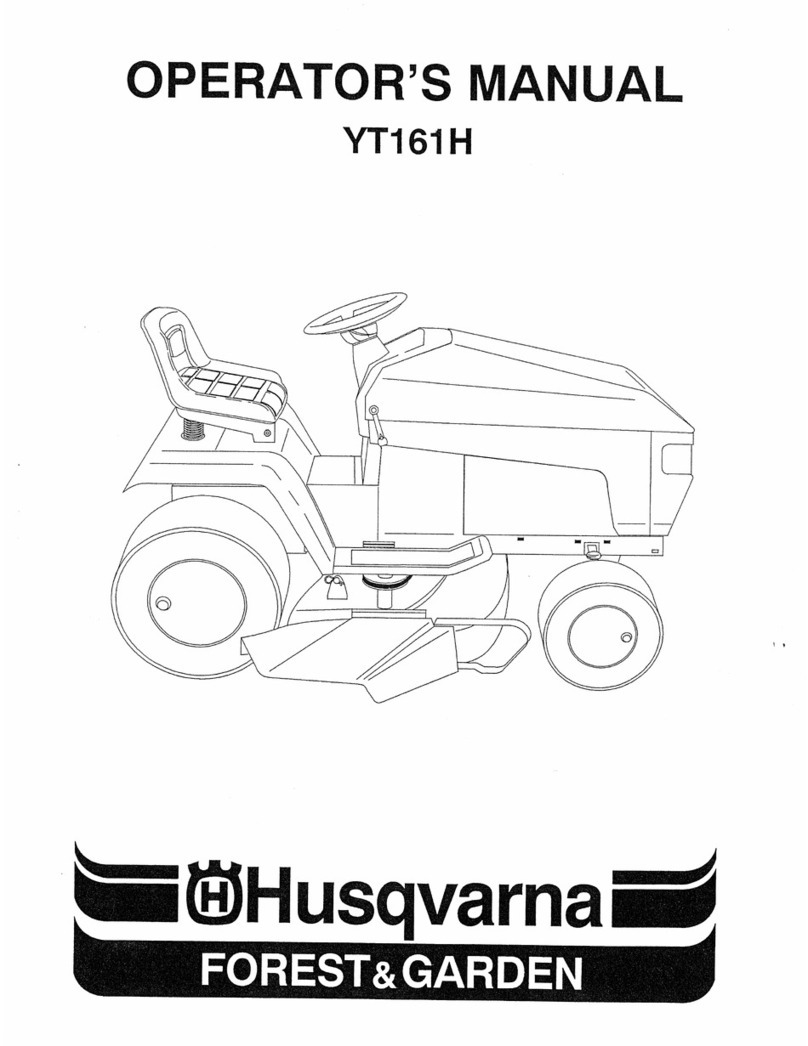

A Warlord S3 175 Right-Hand Offset is shown

opposite, however this process applies for ALL

models and sizes.

The end with the Pulleys is ALWAYS referred to

as the DRIVE END. If your Warlord S3 is a

Left-Hand offset, the drive end will be

OPPOSITE to what is shown. However, the

process is IDENTICAL!

DRIVE END

2

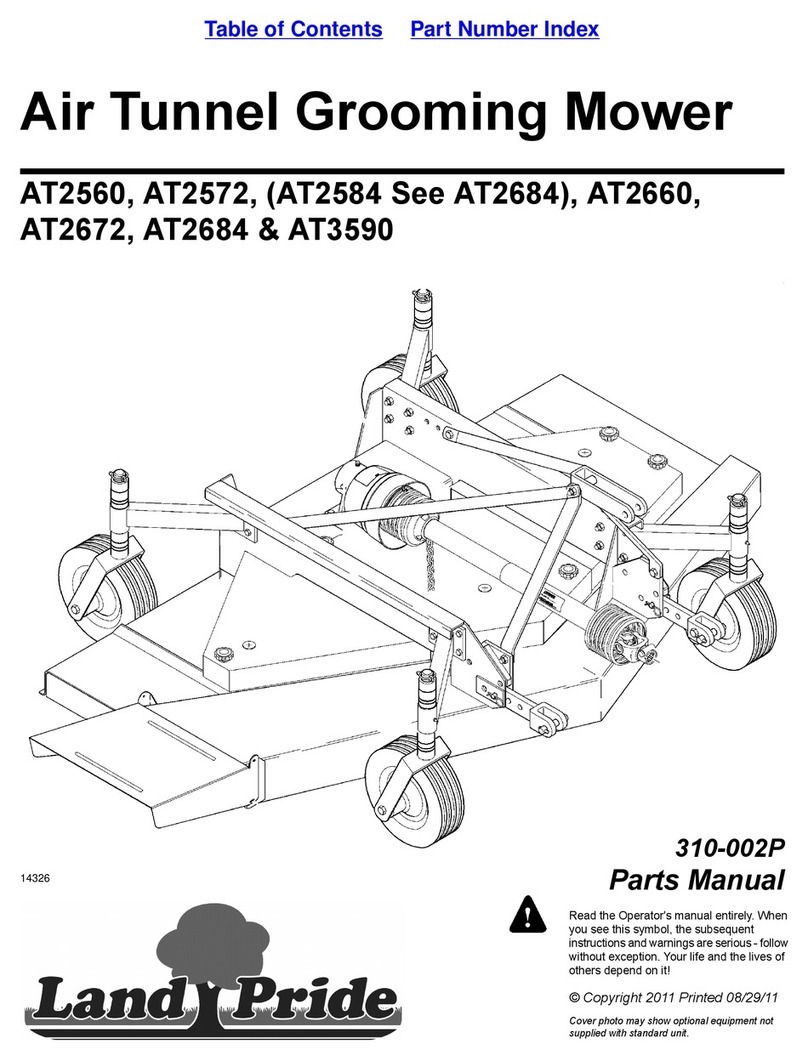

Remove the Rotor Bearing Guard from the

NON-DRIVE end of the Mower as shown in

YELLOW.

Place the Rotor Bearing Guard and fasteners to

one side.

Remove the Belt Guard from the Drive-end of the

Mower as detailed in the Operators Manual.

Remove the Belts as detailed in the Operators

Manual.

At the Rotor Pulley, remove the two Grub Screws

shown.

Reinsert one Grub Screw into the unused hole in

the Pulley.

Gradually tighten this Grub Screw.

As it is tightened, the Pulley will contact the

Bearing Housing and then begin to drive the Taper

Lock Bush off the Rotor Stub.

Remove Belt Guard

and Belts

Remove Grub Screws

Reinsert Grub Screw

Remove Rotor

Bearing Guard

3

Once the Taper Lock Bush has been driven off as

far as possible, remove the Grub Screw.

Insert a Flat Bladed Screwdriver into the Slot

opposite the Removal Hole as shown.

Use this to lever the Taperlock Bush open slightly.

Slide the Taper Lock Bush off the Rotor Stub.

Note:

USE CAUTION, apply the absolute MINIMUM

amount of leverage to slide the Bush off!

If too much leverage is applied, the bush may

fracture through its thinnest point!

Remove the Rotor Pulley from the Rotor Stub.

Place the Rotor Pulley Components to one side.

Remove the Key from the Rotor Stub.

Sling the Mower around the Headstock Link Pin.

Lift the Mower until standing on its end as shown

in the RIGHT image.

Note:

Ensure that the Hydraulic Hoses are tucked away

so they do not get damaged!

Remove Grub Screw

Flat Bladed

Screwdriver in place

Pulley removed

Taper Lock Bush driven

as far as possible

Sling around Pin

Lift to this

position

Remove Key

4

Lower the Mower back down so that the TOP of

the Headstock is now contacting the Ground and

the Rotor is facing UPWARDS as shown.

Note:

The Mower may require some assistance to move

past its tipping point.

USE EXTREME CAUTION DURING THIS

STEP!

Using suitable Lifting Equipment, support the

Rear Roller, shown in YELLOW.

Once supported, remove the two M16 x 35 Bolts

and M16 Nordloc Washers used to secure the

Trailing Arms to the Body near the Roller. One

side shown.

Note:

Take note of the hole position used near the

Roller, this will be needed to set the Mower back

to the same cut height later in this process!

Slacken the remaining two M16 x 35 Bolts.

Lift the Transport System to position as shown in

YELLOW.

Then, remove the two M16 x 35 Bolts and M16

Nordloc Washers.

One side shown.

Remove the entire Transport System and place to

one side with the fasteners.

Using suitable Lifting Equipment, support the

Rotor.

Once supported, remove the four M16 x 50 Bolts

and M16 Spring Washers from each of the Rotor

Bearings.

One side shown.

Note:

Take note of the Rotor Bearing Grease Nipple

direction!

Lower to this

position

Sling Roller to

support

Lift to this

position

Then remove this Bolt

Then remove this Bolt

Sling Rotor to

support

Then remove these Bolts

5

Slacken the Rotor Bearing Locking Nut shown.

DO NOT remove!

Use a suitable section of Tube as a Drift to drive

the Rotor Locking Nut and Taper Sleeve

INWARDS towards the Rotor. This will release

the Rotor Bearing from the Rotor Stub Shaft.

Note:

There is a Locking Tab for this Nut. This will need

to be bent out of the way!

Slide the Rotor Bearing off the Rotor Stub Shaft.

Place the Bearings and Fasteners to one side.

Repeat at the opposite end of the Mower to

remove the second Rotor Bearing.

Note:

If the Rotor Bearings require replacing, please see

you Spare Parts Listing for detail.

Remove the two Rotor Rings from between the

Body and the Rotor.

Place these to one side.

Using the Lifting Equipment, extract the Rotor

from the Body.

Place the damaged Rotor to one side.

Note:

Save any Flails that are in usable condition! These

can be used as spares when the Mower is back in

operation.

Slacken Locking Nut, then

drive INWARDS

Slide the Rotor Bearing

off Rotor Stub Shaft

Remove Rotor Rings

Remove Rotor

6

Collect the replacement Rotor using suitable

Lifting Equipment.

Clean the Rotor Stub Shafts and ALL Rotor

Bearing and Rotor Pulley Components using

White Spirits and a Clean Cloth to remove

contaminants.

IMPORTANT:

Position alongside the damaged Rotor.

Ensure that the LONG Rotor Stub Shafts are

BOTH facing the same direction.

Check that the Flails are facing the SAME

direction as the damaged Rotor!

Prepare the Rotor Bearings for fitment.

Separate out the Taper Sleeve Assembly as shown.

Apply Copper Anti-Seize to the THREADS of the

Taper Sleeve.

Apply Copper Anti-Seize to the BEVELLED face

of the Locking Nut.

Insert the Taper Sleeve, thread first, into the

REAR of the Rotor Bearing as shown.

Fit the Locking Washer over the Taper Sleeve as

shown.

Align the Inner Tab with the slot in the Taper

Sleeve.

The Outer Tabs MUST face away from the Rotor

Bearing as shown.

Taper Sleeve

Locking Nut

Locking Washer

Locking Washer in place

Insert Taper Sleeve

7

Fit the Locking Nut to the Taper Sleeve.

The Bevelled face of the Locking Nut MUST face

TOWARDS the Rotor Bearing.

Wind the Locking Nut on a few turns. DO NOT

TIGHTEN!

Repeat the above Bearing fitment process for the

second Rotor Bearing Assembly.

Sling the replacement Rotor using suitable Lifting

Equipment.

Lift in to position over the Body.

Ensure that the LONG Rotor Stub is facing the

DRIVE-END of the Body.

Note:

The DRIVE END is the end of the mower with

Drive Pulleys!

Carefully lower the replacement Rotor into place

in the Body.

Leave the Lifting Equipment in place to support

the Rotor.

Note:

An assistant may be required to help guide the

Rotor into place.

Loosely fit the Rotor Rings back into place at each

end of the Body.

Ensure that the FLAT side of each Rotor Ring

faces AWAY from the Rotor.

Locking Nut in place

Rotor in place over Body

LONG Stub at

DRIVE END

Rotor lowered into Body

Refit Rotor Rings

8

Mount the NON-DRIVE END Rotor Bearing.

Ensure the Grease Nipple is facing in the right

direction before fitting the mounting bolts.

FULLY TIGHTEN THE MOUNTING BOLTS.

Ensure the fasteners are fitted as original!

Note:

A medium strength thread locker is required for

use on the mounting bolts.

The NON-DRIVE END is the end of the mower

with NO Drive Pulleys!

Mount the DRIVE END bearing housing, also

ensuring the Grease Nipple faces as originally

fitted!

HAND TIGHT ONLY AT THIS STAGE!

Ensure the fasteners are fitted as original!

Note:

A medium strength thread locker is required for

use on the mounting bolts.

The DRIVE END is the end of the mower with

Drive Pulleys!

Ensure the Rotor is CENTRALIZED.

The gap between the end of the Rotor and the

inside of the Endplate MUST be the same at

BOTH ends!

At the NON-DRIVE END insert a wedge or

similar means to prevent Rotor from shifting.

Insert a Pry Bar between the Locking Washer and

the Inner Race of the Rotor Bearing.

Carefully apply leverage to move the Taper Sleeve

OUTWARDS as far as possible.

IMPORTANT:

If the Rotor moves during this process,

re-centralize before proceeding!

Use caution to not damage the Bearing Seal!

NON-DRIVE END Bearing in place

FULLY tighten mounting bolts

DRIVE END Bearing in place,

DO NOT tighten mounting bolts

Centralize Rotor

Move the Taper Sleeve

OUTWARDS

Pry Bar

9

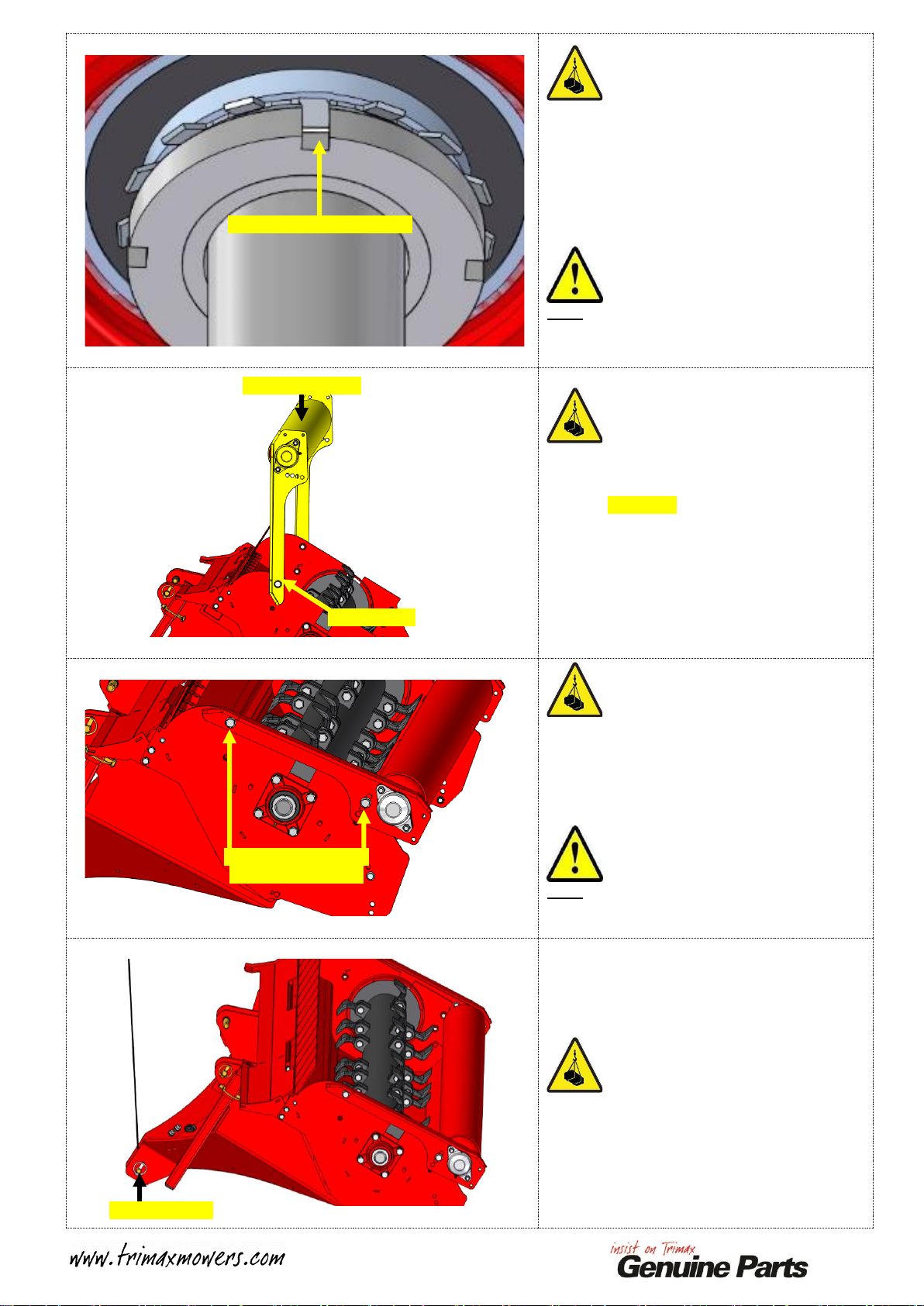

Hand tighten the NON-DRIVE END Locking Nut

as tight as possible so the Taper Sleeve begins to

lock onto the Rotor Shaft.

Use a suitable “C” spanner to tighten the Locking

Nut one half of a turn (180°)

Note:

If a “C” spanner is not available, tighten the

Locking Nut using a suitable pin punch and a light

hammer.

Align one of the slots in the Locking Nut with the

nearest tab on the Locking Washer.

Bend the tab into the slot in the Locking Nut to

secure.

Note:

It may be necessary to tighten the Locking Nut

slightly to achieve this.

Move to the DRIVE END.

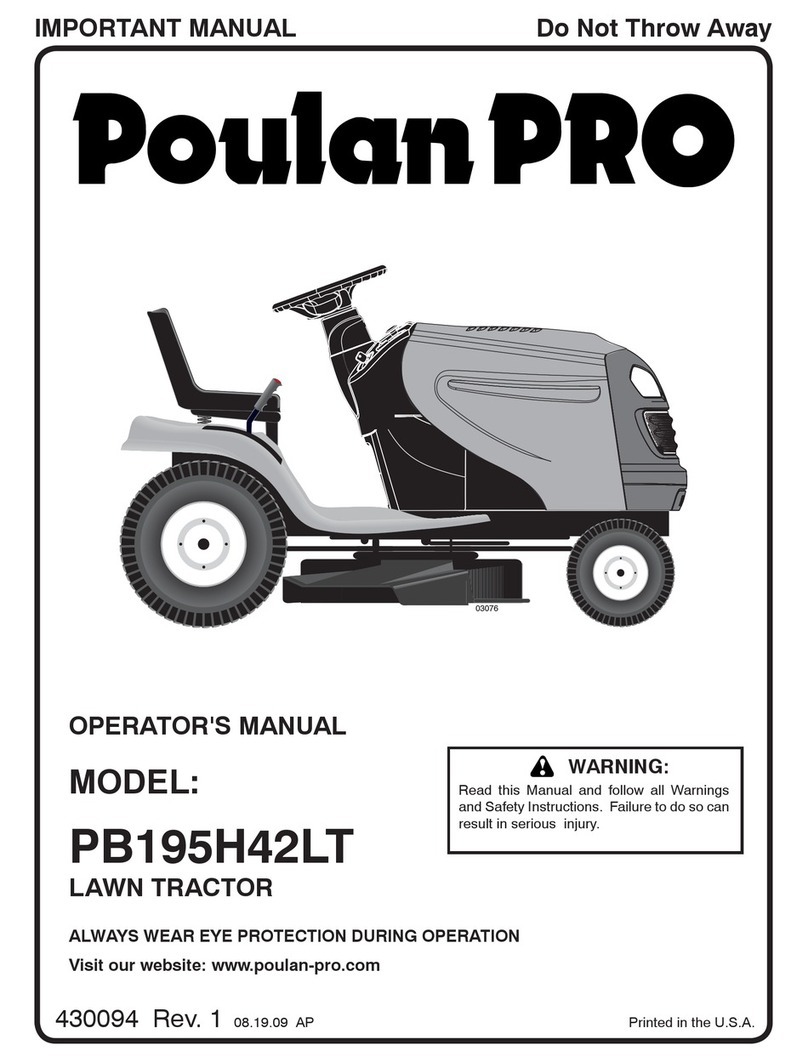

Fit the strips of shim material to opposite sides of

the Bearing Housing between the Endplate and the

Bearing Housing as shown in YELLOW.

Note:

The details for the shim material are detailed on

PAGE 1.

Tab aligned and bent into slot

Hand tighten the NON-DRIVE END Locking Nut as tight as possible

Tighten the NON-DRIVE END Locking Nut a further 180°

Shims fitted

10

Slide the Bearing Assembly HARD up against the

shims.

DO NOT try to move the Bearing by tightening

the bearing housing mounting bolts!

If the Taper Sleeve locks up and prevents the

Bearing from moving inwards, loosen the Locking

Nut slightly and gently tap it inwards to release the

taper.

LEAVE THE MOUNTING BOLTS HAND

TIGHT ONLY AT THIS STAGE!

With the bearing housing remaining firmly pressed

against the shims, insert a Pry Bar between the

Locking Washer and the inner race of the DRIVE

END Rotor Bearing.

Carefully apply leverage to move the Taper Sleeve

OUTWARDS as far as possible.

Note:

Use caution to not damage the Bearing Seal!

Hand tighten the DRIVE END Locking Nut as

tight as possible so the Taper Sleeve begins to lock

onto the Rotor Shaft.

Remove the shims.

Use a suitable “C” spanner to tighten the

DRIVE END Locking Nut half of a turn (180°)

As the Locking Nut is tightened the Bearing

Housing should gradually move towards the

mower endplate until there is no gap when the

Locking Nut is fully tightened.

Note:

If a “C” spanner is not available, tighten the

Locking Nut using a suitable pin punch and a light

hammer.

Push DRIVE END Bearing

HARD against shims

Pry Bar

Move Taper Sleeve

OUTWARDS

Hand tighten Locking Nut,

then remove shims

Tighten a further 180°

11

Align one of the slots in the Locking Nut with the

nearest tab on the Locking Washer.

It may be necessary to tighten the Locking Nut

slightly to achieve this.

Bend the tab into the slot in the Nut to secure it.

FULLY TIGHTEN THE DRIVE END

MOUNTING BOLTS.

Ensure the fasteners are fitted as original!

Note:

A medium strength thread locker is recommended

for use on the mounting bolts.

Sling the Rear Roller as before.

Lift the Transport System back into place as

shown in YELLOW.

Secure the FRONT to positions using two

M16 x 35 Bolts and M16 Nordloc Washers.

Hand tight ONLY at this stage!

One side shown.

Lower the Transport System into its original

position. Align the holes in the Trailing Arms with

the Body.

Refit the remaining M16 x 35 Bolts and M16

Nordloc Washers. Torque ALL four M16 x 35

Bolts to 185Nm (137ft/lbs)

Note:

This torque figure is critical to ensure the

Transport System is secured correctly to the Body!

As before, sling the Mower around the Headstock

Link Pin.

Tab aligned and bent into slot

Lift to this position

Refit this Bolt

Torque M16 x 35 Bolts

to 185Nm (137ft/lbs)

Sling around Pin

12

Lift the Mower until standing on its end.

Lower the Mower back down so that the

Headstock is facing UPWARDS as shown on the

RIGHT.

Note:

The Mower may require some assistance to move

past its tipping point.

USE EXTREME CAUTION DURING THIS

STEP!

Refit the Bearing Guard to the NON-DRIVE End

of the Mower as shown in YELLOW.

Secure using the M12 Spring Washers and M12

Plain Nuts.

Fully tighten.

Refit the Key to the Keyway in the DRIVE END

of the Rotor Shaft.

Note:

High Strength Retaining Compound is

reccomended to secure the key!

Apply Medium Strength Thread Locking

Compound to each of the Grub Screws.

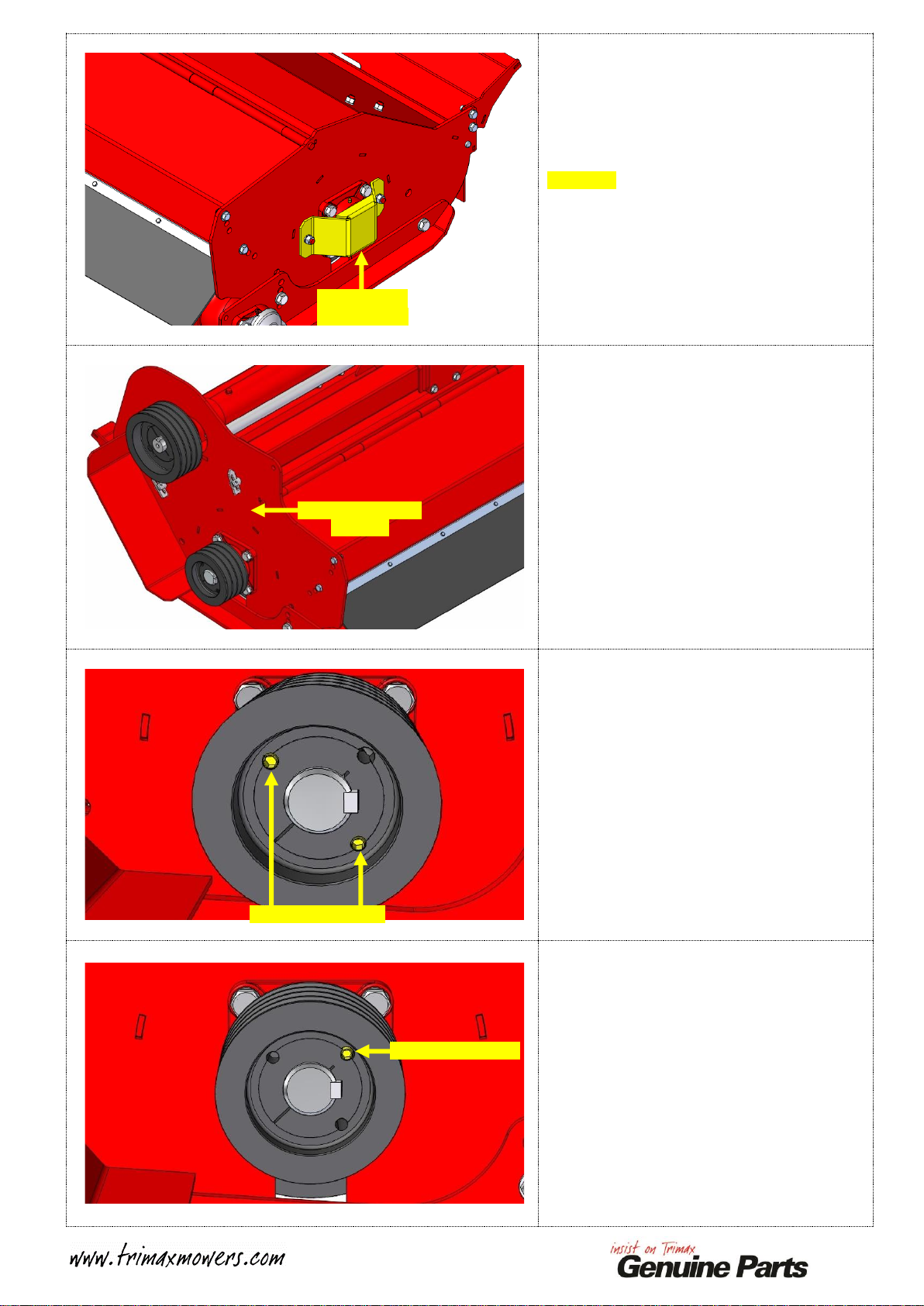

Insert the Taper Lock Bush (402-060-710) into the

Gearbox Extension Pulley (403-361-270)

Align the holes as shown.

Fit the Grub Screws loosely using the Holes

shown.

Note:

DO NOT place a Grub Screw in the location

highlighted RED, this is only used for pulley

removal!

Reinsert Grub Screws into

Gearbox Extension Pulley

Lift to this

position

Lower to this

position

Refit the Bearing Guard

Refit the Key

13

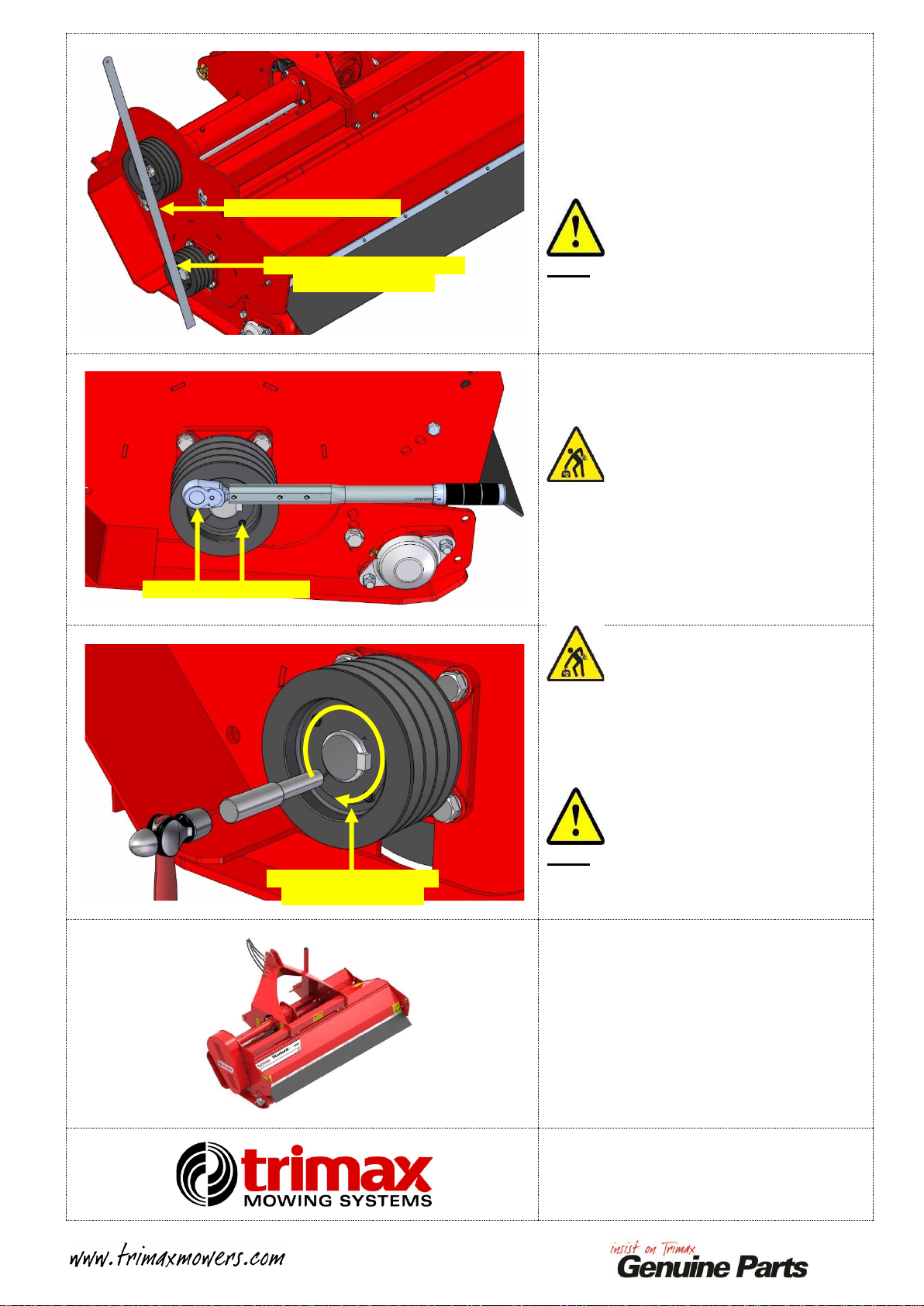

Adjust the position of the Extension Shaft Adjuster

so that the Extension Shaft is running

PARALLEL with the Mower Body.

Note:

It is CRITICAL that the Extension Shaft is

PARALLEL to the Body when fitting the Pulleys!

This is to ensure the correct alignment of BOTH

the Rotor and Gearbox Extension Pulleys!

IMPORTANT:

There are TWO types of Rotor Pulley used on

Warlord.

•The TYPE 2 Rotor Pulley has a FLAT back

side.

•The TYPE 4 Rotor Pulley has a RECESSED

back side.

Inspect your Rotor pulley and determine which

type you have.

The positioning of these two types of Rotor

Pulleys is slightly different, however the securing

process is identical!

See below for positioning details for each type.

Flat Back - Type 2 Pulley Position

Align the keyway in the Taper Lock Bush with the

Key fitted to the Rotor Stub.

Slide/lightly tap the Rotor Pulley onto the Rotor

Stub until the back of the Pulley is against the

Rotor Bearing Locking Nut as shown opposite.

Note:

There are TWO types of Rotor Pulley used on

Warlord, see above for detail.

Recessed Back - Type 4 Pulley Position

Align the keyway in the Taper Lock Bush with the

Key fitted to the Rotor Stub.

Slide/lightly tap the Rotor Pulley onto the Rotor

Stub until the back of the Pulley is just over the

edge of the Rotor Bearing Housing as shown

opposite.

Note:

There are TWO types of Rotor Pulley used on

Warlord, see above for detail.

Rotor Pulley contacting

Rotor Bearing Locking Nut

Rotor Pulley just over Rotor

Bearing Housing

Set Extension Shaft

PARALLEL

Extension Shaft Adjuster

14

Check the Pulley alignment using a

Long Straight Edge from the Extension Shaft

Pulley. Ensure that the Straight Edge is positioned

as shown opposite.

Adjust the position of the Rotor Pulley so it is

approximately 1mm (1/16”) INWARDS from the

Straight Edge.

Very lightly nip up the Grub Screws.

Note:

The Rotor Pulley will pull OUTWARDS when

tightened! It is CRITICAL these Pulleys are

aligned correctly, otherwise premature Drive

failure may occur!

Using a Hex Socket and a Torque Wrench, tighten

the Grub Screws gradually and alternately.

Torque the Grub Screws to 50Nm (39ft/lbs)

Using a Hammer and a suitible Drift, tap around

the Taper Lock Bush.

Re-torque the Grub Screws to 50Nm (39ft/lbs)

REPEAT THIS STEP THREE TIMES.

Note:

This will ensure that the Taper Lock Bush is

seated square in the taper bore of the Rotor Pulley

and is secured correctly!

Grease the Rotor Bearings as detailed in your

Operator Manual.

Fit and tension the Drive Belts as detailed in your

Operator Manual.

Fit the Belt Guard as detailed in your Operator

Manual.

This Fitment process is now complete.

Straight Edge across Pulleys

Set in 1mm (1/16”) INWARDS

from the Straight Edge

Tap around Bush, re-torque

to 50Nm (39ft/lbs) x 3

Torque to 50Nm (39ft/lbs)

This manual suits for next models

1

Other Trimax Lawn Mower manuals