Trion HERRMIDIFIER Herrmidicool Instruction manual

TRION®| www.trioniaq.com

Herrmidicool™

Installation, Operation & Maintenance

READ & SAVE THESE INSTRUCTIONS

Herrmidicool

Installation, Operation & Maintenance Manual

2www.trioniaq.com

TABLE OF CONTENTS

Warranty ............................................................................................................................................... 3

I. Introduction ........................................................................................................................................4

II. Operational Characteristics ..............................................................................................................4

III. Mounting ..........................................................................................................................................4

IV. Plumbing..........................................................................................................................................4

V. Controls ............................................................................................................................................5

VI. Control Board Operation .................................................................................................................5

VII. Start-up Checklist ...........................................................................................................................6

VIII. Start-up ......................................................................................................................................... 7

IX. Atomizing Head Operation ..............................................................................................................7

X. Pressure Settings .............................................................................................................................7

XI. Maintenance.................................................................................................................................... 7

XII. Extended Shutdown .......................................................................................................................7

XIII. Atomizing Head Adjustment .......................................................................................................... 7

XIV. Nozzle Troubleshooting.................................................................................................................8

XV. Nozzle Diagram.............................................................................................................................9

XVI. Wiring Diagram .............................................................................................................................10

Herrmidicool

Installation, Operation & Maintenance Manual

3

www.trioniaq.com

I. WARRANTY

Limited 2-Year Warranty

Seller warrants the equipment of its manufacturing to be free

from defects in workmanship and material for a period of 24

months after shipment or 24 months after initial commissioning,

whichever occurs rst. This warranty is limited, however, to the

repair or replacement of defective equipment, which is returned,

freight prepaid, to Seller’s factory.

This limited warranty does not apply to any part or component

that is damaged in transit or when handling, has been subject

to misuse, negligence or accident, has not been installed, oper-

ated or serviced according to Seller’s instructions, or has been

operated beyond the factory-rated capacity or has been altered

in any way.

Seller’s liability is limited to replacement of defective parts or

components and does not include any cost of labor (including,

but not limited to, labor required to remove and/or reinstall any

defective part) other than TRION/HERRMIDIFIER factory labor.

TRION/HERRMIDIFIER shall not be responsible for loss of use

of any product, loss of time, inconvenience, or damage to other

equipment, or any other indirect or consequential damage with

respect to property whether as a result of breach of warranty,

neglect, or otherwise.

THE WARRANTIES AND LIABILITIES SET FORTH ARE IN

LIEU OF ALL OTHER WARRANTIES AND LIABILITIES, EX-

PRESSED OR IMPLIED, IN LAW OR IN FACT, INCLUDING IM-

PLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR PARTICULAR PURPOSE.

The foregoing shall constitute the total liability of seller in the

case of defective performance of all or any of the equipment or

services provided to Buyer. Buyer agrees to accept and hereby

accepts the foregoing as the sole and exclusive remedy for any

breach or alleged breach of warranty by Seller.

II. GENERAL WARNINGS & INSTALLER RESPONSIBILITY

WARNING

INSTALL, OPERATE, AND MAINTAIN UNIT IN ACCORDANCE

WITH MANUFACTURER’S INSTRUCTIONS TO AVOID ANY

CIRCUMSTANCES THAT MAY CAUSE PERSONAL INJURY

OR PROPERTY DAMAGE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE, OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY, OR DEATH. THIS APPLIANCE MUST BE

INSTALLED BY A LICENSED CONTRACTOR OR QUALIFIED

SERVICE PERSONNEL. READ THESE INSTALLATION,

OPERATING, AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THE UNIT.

DANGER OF BURNS

THE HUMIDIFIER CONTAINS HIGH TEMPERATURE

COMPONENTS AND DELIVERS STEAM AT 100°C/212°F.

ATTENTION

READ THIS MANUAL, FACTORY INSTALLED OPTIONS

MANUAL, UNIT SUBMITTAL DATA SHEETS AND ALL

LABELS ATTACHED TO THE UNIT CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE, OR SERVICE

THESE UNITS. CHECK DATA PLATES FOR ELECTRICAL

SPECIFICATIONS AND MAKE CERTAIN THAT THESE

AGREE WITH THOSE AT THE POINT OF INSTALLATION.

DANGER OF ELECTRIC SHOCK

INSTALL, OPERATE AND MAINTAIN UNIT IN ACCORDANCE

WITH MANUFACTURER’S INSTRUCTIONS TO AVOID ANY

CIRCUMSTANCES THAT MAY CAUSE PERSONAL INJURY

OR PROPERTY DAMAGE.

DANGER OF WATER LEAKS

THE HUMIDIFIER AUTOMATICALLY AND CONSTANTLY

FILLS/DRAINS CERTAIN QUANTITIES OF WATER.

MALFUNCTIONS IN THE CONNECTIONS OR IN THE

HUMIDIFIER MAY CAUSE LEAKS. A DRAIN PAN IS

RECOMMENDED UNDER THE UNIT TO PROTECT

PROPERTY FROM DAMAGE IN THE CASE OF WATER

LEAKAGE OR SPILLAGE.

Important

• The installation of the product must include an earth

connection.

• The environmental and power supply conditions must

conform to the values specied on the product rating labels.

• The product is designed exclusively to humidify rooms

either directly or through distribution systems (ducts).

• Only qualied personnel who are aware of the necessary

precautions and able to perform the required operations

correctly may install, operate, or carry out technical service

on the product.

• Only water with the characteristics indicated in this manual

must be used for steam production.

• All operations on the product must be carried out according

to the instructions provided in this manual and on the labels

applied to the product. Any uses or modications that are not

authorized by the manufacturer are considered improper.

Seller declines all liability for any such unauthorized use.

• Do not attempt to open the humidier in ways other than

those specied in the manual.

• Observe the standards in force in the place where the

humidier is installed.

• Keep the humidier out of the reach of children and animals.

• Do not install and use the product near objects that may

be damaged when in contact with water (or condensate).

Seller declines all liability for direct or indirect damage

following water leaks from the humidier.

• Do not use corrosive chemicals, solvents, or aggressive

detergents to clean the inside and outside parts of the

humidier, unless specically indicated in the user manual.

• Do not drop, hit, or shake the humidier, as the inside parts

and the linings may be irreparably damaged.

Herrmidicool

Installation, Operation & Maintenance Manual

4www.trioniaq.com

I. INTRODUCTION

The Herrmidicool system is an in-duct air/water atomization

system designed to introduce atomized water into the

airstream. The unit uses a native BACnet controller that

responds to an analog 0-5 VDC demand signal to start the

humidication process. An input for proving airow prior to

starting the system is provided as well as alarm indication.

The touchscreen display allows the operator to interact with

the system. Network communications are available to allow

system monitoring and control.

II. OPERATIONAL CHARACTERISTICS

Upon an increase in demand signal above 20%, the controls

will energize the compressed air solenoid valve. An air

pressure switch will close if sufcient air pressure is present

to allow for proper atomization. When the air pressure switch

contacts close, the water solenoid valve will energize and

atomization will begin. Each nozzle is equipped with a clean

out pin that helps keep the water orice clear of mineral build-

up each time the nozzle is cycled. Periodically, the controls

will de-energize the water solenoid valve in order to actuate

the clean-out pin to keep the water orice clear. During

operation if the air proving switch contacts open, the system

will stop. If the system on/off switch is opened the system

will stop. See the Controls section for additional details.

Allowable Operating Conditions

Ambient Temperature: 40°-120°F (4°-50°C)

Ambient Relative Humidity: 0% - 90%

Line Voltage: -15% to +10% Nominal

Frequency: 50/60 Hz

Supply Air Pressure: 60-200 psig

Supply Air Quality: Filter clean and dry to 35°F dewpoint.

Supply Water Temperature: 40°-100°F (4°-38°C)

Supply Water Pressure: 50-100 psig

Supply Water TDS less than 50 ppm: Consult Factory

with water analysis and application data prior to selecting

equipment.

NOTE: If units are mounted in outdoor enclosures, conditions

inside enclosure must be maintained as listed above.

III. MOUNTING

The Herrmidicool system consists of two basic components:

the control cabinet and the atomizing-head manifold

assembly. The control cabinet should be mounted so that the

water outlet of the control cabinet is level or below the water

manifold in the air handler. Air vents must be mounted on

any loops necessary to connect the cabinet to the manifolds.

Minimum Cabinet Clearances:

Top: 1” Bottom: 12”

Sides: 2” Front: 4”

32” Working Area Clearance

Hang the cabinet on the wall or unistrut mounting frame.

Two keyhole slots and two additional mounting holes are

provided. Be sure the unit is level and mounted directly

to the wall to wood studs as least 2” thick (or equivalent).

The atomizing head manifolds consisting of air manifolds,

atomizing heads, water manifold and unistrut brackets are to

be located as shown on specic layout drawings with each

job. Typically, a “unistrut” style mounting structure is eld

fabricated to support the atomizing manifold.

Manifold Installation:

1. Install the air/water manifolds per the layout drawing

included with this package.

2. Use only copper, plastic or stainless steel piping as

specied in your print package.

3. Keep runs between control cabinets and heads as short

as possible.

4. Piping runs between control cabinets and manifolds

should be as direct as possible. If loops are unavoidable,

automatic air vents must be supplied and installed.

IV. PLUMBING

Each cabinet has an air inlet, water inlet, air outlet(s), water

outlet(s) and a drain. All air connections are ½” and all water

connections, including drain, are ½”.

1. Drain loop must extend 3” above highest location of

heads or water outlet port on cabinet. This loop allows water

pressure to be relieved on system shutdown.

2. Piping from control cabinet to manifolds without draining

should be ¾” for the air and ½” for the water piping unless

otherwise shown on your job specic drawings provided for

your project.

Herrmidicool

Installation, Operation & Maintenance Manual

5

www.trioniaq.com

NOTE:

Inlet water pressure must be in range of 50-100 psig. Consult

the factory if you are outside this range.

Supply Power

1. Supply power of 120 VAC, 5 amps is required.

2. Field wiring of the main power supply is connected directly

to the line power-lter in the control cabinet. A ground lug is

provided for the ground wire.

3. Install external overcurrent protection and provide wiring

in accordance with the NEC, state and local codes.

4. Power supply must be “clean;” free of spikes, surges and

sags; +10%, -15% of nominal. Ground should be true earth

ground.

V. CONTROLS

Controls may be supplied by the factory or others. The following

information applies to all controls factory supplied or furnished by

others. All external electrical control circuits are to be connected

to the unit using the terminal strip located in the electrical

compartment. Field wiring from humidistat to humidier and

between safety devices, such as high limit humidistat and air

proving switches, should be 18 AWG stranded or 20 AWG solid

wire. Wall devices should be mounted at a height similar to

that of a typical thermostat and should be located in an area

that will provide good representation of the overall space being

humidied. Do not mount wall devices directly in the air stream

of a supply grille or room distribution unit.

Duct control devices should be mounted in a location where

the humidity and temperature are uniform, usually the return

duct.

Duct high limit devices should be mounted downstream of the

evaporative surface far enough that under normal conditions

in the air stream, the water has been completely evaporated,

typically 10 ft. The device should be located such that it can

sense humidied air as it approaches saturation. Do not

mount in dead air spaces such as inside of comers.

Air proving devices should be mounted so that they sense

airow (or the absence of it). Wire the device so that it closes

when airow is present and will open when there is no airow.

The purpose of the device is to prove that airow is present

before mist is distributed into the duct.

Your application specic wiring diagram, included with this

package will detail exact led wiring connection points for

your unit.

Control Circuit Connections

On/Off (OPTIONAL – Limited Application)

1. Control Input - Unit will operate with any two-position

device. Demand for humidity will close the contact.

2. Limit Input - Unit will operate with any two-position device.

The humidistat contact will open on humidity rise.

VI. CONTROL BOARD OPERATION

The Herrmidicool system is equipped with a native BACnet

controller. When power is applied to the system, the display

turns on and displays the STANDBY screen (shown below).

The STANDBY screen displays System Enable Staus

(enabled or disabled), the System Output, and the cumulative

hours of runtime. The number indicated represents the total

number of hours that the system solenoid valves have been

energized and spraying water for humidication.

Touching the screen anywhere will take you to the HOME

screen (shown below).

The HOME screen is a gateway to other screens. The

system may be Enabled or Disabled by touching the box next

to System Enable Status. A window will pop-up and the user

can make their selection. Upon being enabled, the system

will respond to increases or decreases in the Demand Input

WARNING

Do not mount any controls inside the unit or tap power

from any location in the unit, except as stated in these

instructions. Do not place objects near the cabinet.

Do not attach to dry wall without studs.

CAUTION

Any minerals that are in the water will be injected into

the airstream. Your application/process may require

some means of air or water ltration to complete a

successful application. Consult the factory if you

should have any questions. Softening the water

only increases the TDS level.

Herrmidicool

Installation, Operation & Maintenance Manual

6www.trioniaq.com

(0-5 VDC). When the demand is greater than 20% (1 VDC),

the system will enable the compressed air solenoid valve;

starting the system. On any screen, the user may return

to the HOME screen by touching the house pictured in the

upper left of the screen.

The STATUS, PARAMETERS, & ALARM, screens are

described below.

The STATUS screen (shown above) displays the state of

the inputs and outputs. The demand Input displays the

percentage of demand being supplied to the controller input.

This screen will show the user the status of the inputs and

ouputs.

The PARAMETERS screen (shown above) allows the user

to change the way the system works regarding nozzle

cleanout. If enabled, at the interval set by the parameter,

the water solenoid will de-energize for the duration set by

the Cleanout Duration parameter. If Nozzle Cleanout is

disabled, the system will operate continuously whenever

there is a demand input.

The ALARM screen (not shown) allows the user to check the

status of active alarms and alarm history. Whenever the red

exclamation point is shown on the screen, there is an active

alarm. If the exclamation point is gray, there are no active

alarms. The user may go to the alarm screen at any time

to check the history of alarms that have returned to normal

conditions.

There are two possible alarm conditions that may present

themselves during operation. They are the Air Proving Switch

and the Compressed Air Pressure Switch. After a demand

is present and the unit attempts to start, if either of these two

switch inputs fails to close, the unit will shut down and an

alarm will be present. Once the condition is corrected, the

unit will commence normal operation automatically.

The SETUP and MODULE STATUS screens are gateways to

lower level settings that should only be adjusted by a system

administrator. CHANGING SOME OF THESE SETTINGS

MAY RENDER THE FACTORY WARRANTY VOID

When touching SETUP or MODULE STATUS, the

administrator will be prompted for a password. Enter 2222 to

log in to the controller. Network settings, date and time may

be adjusted via the SETUP screen. The MODULE STATUS

screen should not be used without the direction of the factory.

The CLOCKSET screen allows the date, time, and daylight

savings time details to be programmed into the controller.

Unless the date & time are set, the controller will report

incorrectly on the ALARM screen.

VII. START-UP CHECKLIST

This Check List is intended to highlight critical installation

points. A poor installation frequently results in start-up

difculties, and always results in less than ideal operation of

the humidier.

1. Insure all valves and valve cocks through the system

(especially at every head) are shut-off.

2. Electric power is connected to the control cabinet per the

diagram.

3. All sensors, airow switches and external inputs are

connected to the cabinet.

4. Air compressor is primed, oiled and air supply is

connected to the cabinet.

5. Air supply line has been purged and blown down to

remove any installation dirt.

6. Air supply line has been charged, leak tested and has a

minimum of 60 psi pressure to the cabinet.

7. Water supply is connected to the cabinet and has been

purged and blown down to remove installation dirt.

8. Water supply is charged and leak tested and has a

minimum of 50 psi pressure at the cabinet.

9. Drain loop has been connected to the bottom of the

cabinet and has been plumbed to an open drain.

10. Drain piping is installed with a loop a minimum of 3”

above atomizing heads and all piping after the cabinet.

11. All water piping from the cabinet to the manifolds is level

and without loops or automatic oat type air vents have

been installed at high points to remove trapped air.

12. Air handler is completely operational and has been

balanced.

13. All air and water lines at the ends of the manifolds have

been terminated with hose bibs.

14. Mist eliminators, if used, have been installed properly

over drain pan that is trapped.

Herrmidicool

Installation, Operation & Maintenance Manual

7

www.trioniaq.com

VIII. START-UP

After all checklist items are completed (and the total

installation is complete) the Herrmidicool system is ready to

start. Refer back to the Start-Up Checklist prior to Start-Up

below.

IMPORTANT:

Before scheduling factory start-up, please have any issues

relating to the “Check List” resolved. If additional trips are

required, additional start-up costs will be incurred!

1. Blow out air and water lines to the control cabinet.

2. Set all controls to their lowest setting (control and limit if

applicable). This allows the system to be turned “on” without

the atomization process being started.

3. Once the units get the signal to run and unit is turned

“on,” the air solenoid will energize within 5 seconds. Once

the air pressure switch detects sufcient air pressure, the

water solenoid will open.

4. With individual air and water valves at atomizing heads

closed, blow out the air and water lines through the hose

bibs.

5. A factory-trained technician will complete the balance of

the start-up.

If used, blowdown tanks, air vent check valve assemblies,

and balancing air regulators are installed as shown on the

installation layout drawing provided with this manual.

Call your local TRION/HERRMIDIFIER representative to

schedule a trouble-free start-up. Minimum two week notice

is required.

IX. ATOMIZING HEAD OPERATION

The HERRMIDIFIER atomizing heads operate with the

water pressure higher than the air pressure. As air enters the

atomizing head, it ows in a centrifugal motion inside the air

nozzle and outside of the water nozzle. As the water enters

the atomizing head, it creates pressure against the diaphragm

and compresses the spring located on the opposite side of

the diaphragm. The motion of the diaphragm pulls the water

seat away from the bottom of the water nozzle allowing water

to ow through the water nozzle. As the water exits the water

nozzle, it become atomized by the compresses air inside the

air nozzle and exits the atomizing head as a ne spray.

X. PRESSURE SETTINGS

IMPORTANT: The air and water pressures to the atomizing

head should only be adjusted when the humidier is at full

output. In other words, when the modulating water valve is

100% open the controls are calling for maximum capacity.

Do not attempt to adjust the air and water pressure settings

at any other time. The instructions below assume that the

atomizing heads are installed at the same elevation as the

water control section. Adjustment from this standard must be

made to compensate for any elevation differences between

the water control section and the atomizing head manifold.

1. Set the air pressure at 30 psig.

2. Set the water pressure at 33-38 psig according to the

atomizing head capacity as listed below:

a. 6 lb/hr. 34.5 psig

b. 8 lb/hr. 38 psig

c. 10 lb/hr. 33 psig

d. 12 lb/hr. 34.5 psig

e. 15 lb/hr. 37 psig

The water pressure settings listed above will allow the

atomizing heads to perform at their rated capacity (lb/hr.).

It may be desired to deviate slightly (1-2 psig) from the

standard settings in order to enhance performance. Slightly

lower water pressures will result in a ner atomized spray

(smaller droplet size). Be aware that any adjustments such

as this will also reduce the rated capacity of the heads. Use

caution accordingly.

XI. MAINTENANCE

• Air Compressor – follow manufacturer’s recommended

instructions.

• Atomizing Heads – clean dust and debris from outside of

heads as required. If raw water is used, we recommend

removing the atomizing nozzles and strainer screens once

a year for disassembly and cleaning. DO NOT use a wire or

other foreign object to clean nozzle as this could ruin orice.

• Air & Water Lines – blow out once a year. Check joints for

leaks once a year.

• Strainers on air/water control sections should be cleaned

once a year.

• Sensors/transmitters should be checked once per year

• Solenoid valves should be checked once a year for proper

operation and closure.

XII. EXTENDED SHUTDOWN

After an extended shutdown, air and water lines should be

blown out prior to resuming normal operation

XIII. ATOMIZING HEAD ADJUSTMENT

The atomizing heads are factory adjusted and tested. Typically,

no adjustment is required unless the atomizing heads have

been disassembled for maintenance. Do not adjust individual

atomizing heads to reduce capacity or enhance performance.

This is done only by changing the operating pressures for the

entire system.

1. Turn the Herrmidicool System on to full output and check

that the air and water pressures are correct.

2. Remove the cap from the back of the atomizing head.

3. Using a screwdriver, slowly turn the spring tension nut

clockwise until the atomizing heads stops spraying.

4. Note the position of the spring tension nut.

5. Back the spring tension nut out two full turns

counterclockwise.

6. If head is not spraying at start of procedure, back out spring

tension nut until head starts to spray and then begin step 3.

Herrmidicool

Installation, Operation & Maintenance Manual

8www.trioniaq.com

XIV. NOZZLE TROUBLESHOOTING

A. Heavy spray pattern (droplets too large)

1. All heads – This is caused by incorrect air and water

pressure settings. Review settings and adjust as required.

Never allow air pressure to exceed the water pressure.

2. Individual Heads – These heads are not getting enough

air for one of the following reasons:

a. Foreign matter may be clogging the screen (AH-21) in

the air strainer union of the head. Clean or replace it.

b. One or more of the heads may have been improperly

adjusted or the individual shut-off valve may be throttled.

No valves should ever be throttled. Readjust if necessary.

c. Water nozzle (AH-942) orice may have been enlarged

due to bent cleaning needle. Replace parts as required.

d. Atomizer nozzle (AH-941) orice may have been

enlarged due to improper cleaning or dirty air. Replace

part as required. Standard air orice sizes for the various

heads are as follows.

6 lbs/hr 0.95 mm

8 lbs/hr 1.10 mm

10 lbs/hr 1.15 mm

12 lbs/hr 1.35 mm

15 lbs/hr 1.45 mm

B. Spray pattern too light at full capacity

1. All heads – This is caused by incorrect air and water

pressure settings. Review settings and adjust as required.

Never allow air pressure to exceed the water pressure.

2. Individual heads – These heads are not getting enough

water for one of the following reasons:

a. One or more of the heads may have been improperly

adjusted or the individual shut-off valve may be throttled.

No valves should ever be throttled.

b. Foreign matter may be restricting water ow in the

water nozzle (AH-942). Turn off the air and water valves

at the head.

Remove the atomizer nozzle and water nozzle. Blow

water nozzle with air. Do not use wire or other hard

object that will score the inside of the nozzle.

C. Sputtering heads – air pressure at the atomizing heads

exceeds water pressure.

1. Adjust air and water pressures to correct operating

pressures.

2. Normally open drain solenoid on water control section

may have a malfunction allowing water to leak into drain

line during operation. Solenoid valve seat may have

foreign matter under the seat causing it to leak. Solenoid

may have defective seat.

D. Inoperative heads (all heads)

1. The atomizing heads may be shutdown because the

system controls and setpoints are satised.

2. If the desired RH level has not been achieved, check

calibration of the controls and adjust as required.

3. Air and water supply valves are not open.

4. No supply air pressure. If supply valves are open and

the gauges indicate no air pressure, check compressed

air source.

5. No power to the air and water solenoid valves. Check

controls and control cabinet fuses.

Individual heads

6. Be sure air and water valves to the atomizing heads

are open.

7. Possible defective parts inside atomizing head. Shut-off

air and water valves to the head and remove head from the

system. Disassemble and examine internal parts. Repair

and reassemble as required. Rebuilding kits are available

from your local TRION/HERRMIDIFIER representative.

Perform a complete restart and readjustment of the

atomizing head upon reassembly and repair.

E. Air Without Water – Be sure water valve to control

section is open. Check modulating water valve, water

solenoid and drain solenoid on water control section.

Herrmidicool

Installation, Operation & Maintenance Manual

9

www.trioniaq.com

Brass Nozzle Consists of: SS Nozzle Consists of:

Part # Description Part # Description

253205-001 Nozzle Body 253205-002 Nozzle Body

253209-001 Bonnet 253209-002 Bonnet

AH-941-1-”X” Air Nozzle AH-941-2-”X” Air Nozzle

AH-942-1(R) Water Nozzle AH-942-2(R) Water Nozzle

253206-001 Cap 253206-002 Cap

253207-001 Spring Tension Nut 253207-002 Spring Tension Nut

253208-001 Spring Nut 253208-002 Spring Nut

AH-12(R) Valve Stem w/ Needle AH-12(R)-SS Valve Stem w/ Needle

AH-19A Air Port AH-19ASS Air Port

AH-18A Union Tail Piece AH-18ASS Union Tail Piece

AH-20 Union Nut AH-20SS Union Nut

AH-1RK (Note 1) Rebuild Kit AH-1RK Rebuild Kit

“X” Denotes nozzle rating in pounds/hour (6, 8, 10, 12 or 15 lb/hr).

Notes:

1. AH-1RK Kit includes: AH-10, AH-122 “O” Ring, AH-14 Air Nozzle Gasket, AH-15 Water Nozzle

Gasket, AH-16 Valve Disk, AH-21 Strainer Screen, AH-23 Diaphragm Washer, AH-8 Spring, FV-17-

1 Union Washer

2. Always specify nozzle rating in lbs/hr on any nozzle parts order.

3. The notation for (R) is used when capacity of head is 6 or 8 lbs/hr.

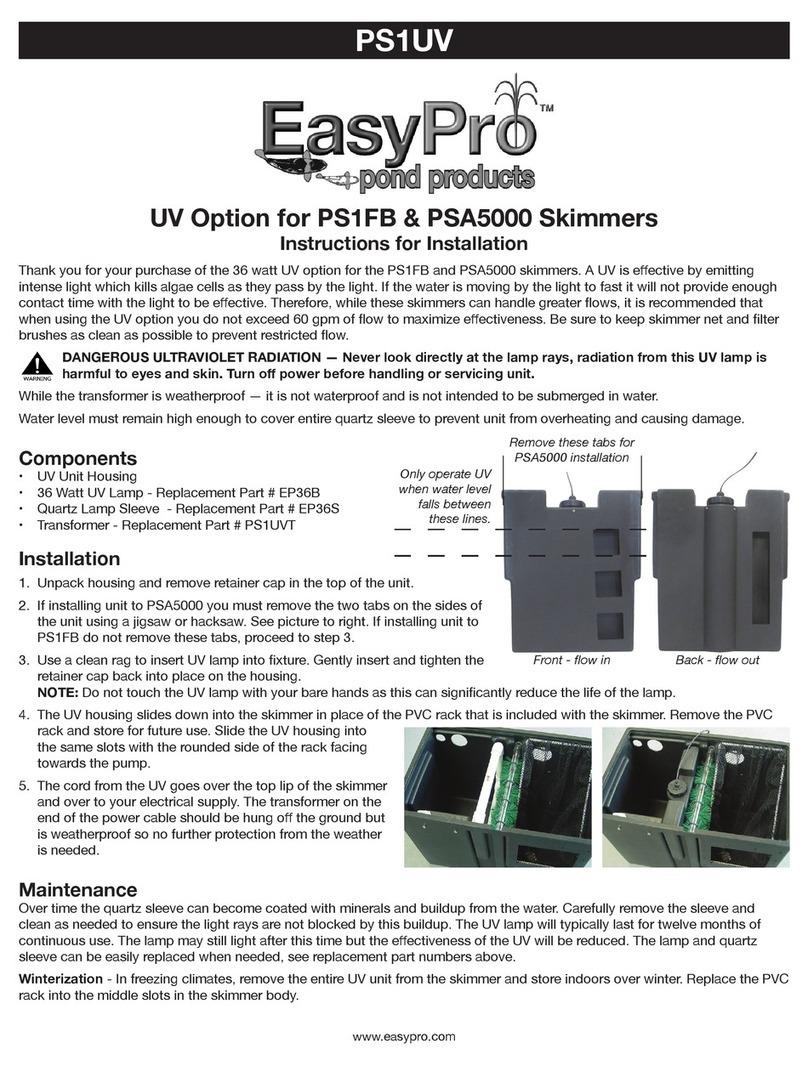

XVI. NOZZLE DIAGRAM

Herrmidicool

Installation, Operation & Maintenance Manual

10 www.trioniaq.com

XVI. WIRING DIAGRAM

WARNING

Absolutely no other components may be mounted

inside or electrically tapped into the humidier

without voiding the warranty..

Herrmidicool

Installation, Operation & Maintenance Manual

11

www.trioniaq.com

THIS PAGE INTENTIONALLY LEFT BLANK.

© 2018 TRION. All Rights Reserved.

TRION®

101 McNeill Rd. | Sanford, NC 27330

Form No. 269604-001 Rev. 06/18

Table of contents

Popular Water System manuals by other brands

Grundfos

Grundfos Auto ADAPT ALPHA2 Installation and operating instructions

EasyPro

EasyPro PS1UV manual

Armstrong

Armstrong 3760 ProVDG Series Installation and operating instructions

VWR

VWR Puranity TU3+ instruction manual

Stuart Turner

Stuart Turner Mainsboost Plus Installation, operation & maintenance instructions

Everpure

Everpure E-20 EV9795-90 Specification sheet