T550i

1

1 PLUMBING NOTES

1.1 All installations must comply with Water

Regulations/Byelaws.

1.2 Supply pipes must be flushed thoroughly

to clear debris before connecting to the

pump and shower.

1.3 DO NOT connect the pump unit to the

mains cold water supply as it would

damage the unit and also, the installation

would be in breach of the guidance notes

contained in ‘1’ above.

1.4 DO NOT use excessive force when making

connections to the flexible connector hoses.

1.5 DO NOT turn on the electrical supply to

the pump until the plumbing connections

and commissioning procedure have been

completed. The pump must not be

operated dry without water.

1.6 DO NOT solder pipes or fittings within

300mm of the pump, as heat transfer can

damage the components.

1.7 A dedicated cold water supply must be

taken directly from the cold water cistern

to the pump. This draw-off must be on

the opposite side of the cistern to the float

operated valve.

1.8 The action of the pump is to increase the

flow rate. If the supply pipework cannot

handle the resulting flow rate then:

1.8.1 The anticipated flow rate may not

be achieved.

1.8.2 Air may be drawn into the hot

supply from the vent pipe causing

spluttering and temperature fluctuations at

the sprayhead.

1.9 A high level hot feed pipe run must not rise

above the level of water in the cistern. To

reduce the risk of air locks pipes should be run

level with or below the base of the cistern.

1.10 Standard gate valves or full way lever

valves MUST be fitted on the hot and

cold water supplies to the pump as an

independent means of isolating the water

supplies should maintenance or servicing

be necessary.

DO NOT use stop taps or ball-o-fix type

valves which restrict flow.

1.11 If the pump unit is installed on a common

supply which feeds an adjacent tap, the

maximum static inlet pressure for the

unit will, under certain circumstances be

exceeded. The action of closing the tap

can cause a pulse in the supply pressure

which may result in damage to the unit.

This can be resolved by the installation

of a suitably sized mini expansion vessel,

sited as close as possible to the tap and

pressurised to 50kPa (0.5 bar).

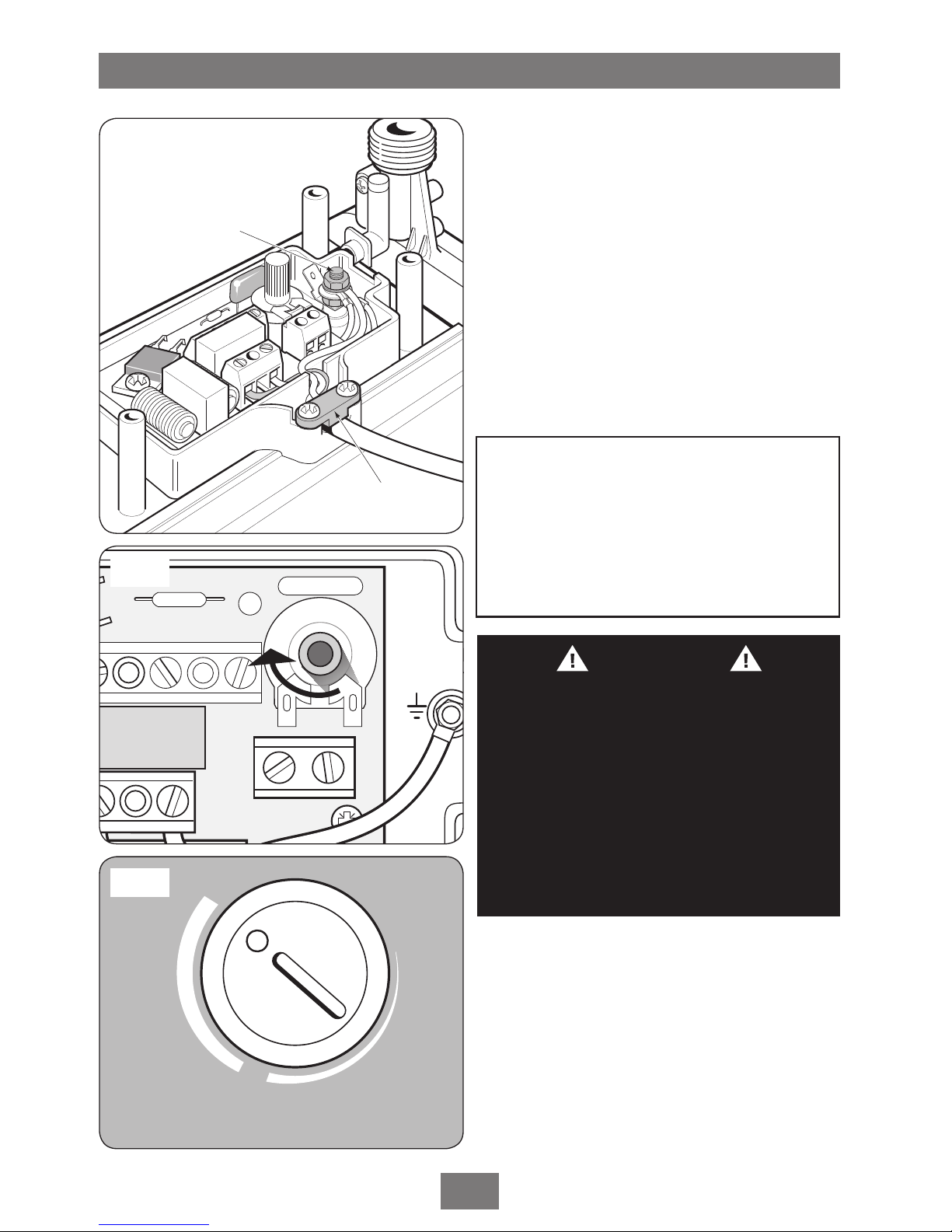

2ELECTRICAL NOTES

2.1 The installation must comply with BS 7671

‘Requirements for electrical installations’

(IEE wiring regulations). Ensure the

incoming hot and cold water supplies to

the pump are adequately earth bonded.

2.2 DO NOT turn on the electrical supply to

the pump until the plumbing connections

have been completed. The pump must

not be operated dry without water.

2.3 The mains supply must be 230-240V, at

50Hz, connected to the pump via a double

pole switched 3 Amp fused connection

unit (not supplied) with a minimum 3mm

contact separation gap in each pole.

2.4 In accordance with ‘The Plugs and Sockets

etc. (Safety) Regulations 1994’, the pump

is intended to be permanently connected

to the fixed electrical wiring of the mains

system.

2.5 To enhance electrical safety a 30mA

residual current device (RCD) should be

installed in all UK electric and pumped

shower circuits. This may be part of the

consumer unit or a separate unit.

Replacement parts can be ordered from Triton

Customer Service. See ‘spare parts’ for details.