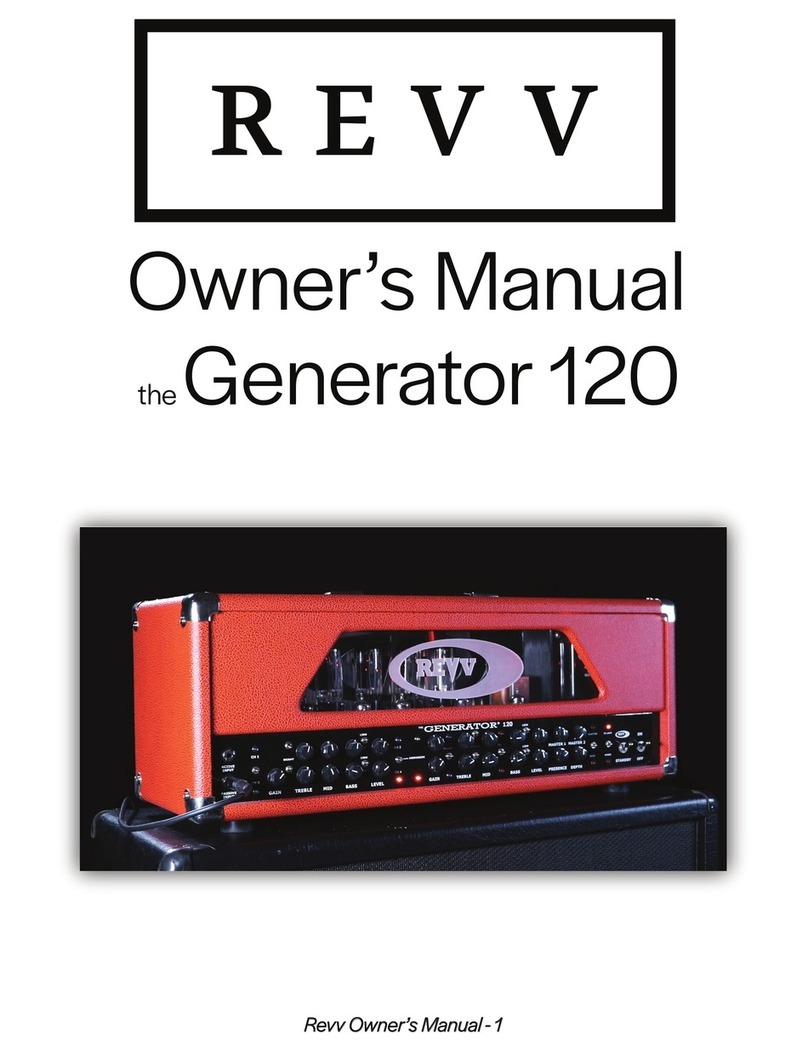

True Systems pT2-500D User manual

pT2-500D

PRECISION

DYNAMIC MICROPHONE

PREAMPLIFIER

with Direct Input and

Low-Frequency Adjust Control

500 series compatible module

OPERATION MANUAL

Version 1.0

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

2

©2011 TRUE Y TEM

CERTIFICATION

Declaration of Conformity

Sunrise Engineering and Design Inc. hereby declares the True ystems pT2-500D

single channel microphone preamplifier module to be in material conformity with the

following EC directives and related standards:

•2006/95/EC Low Voltage Directive

•2004/108/EC EMC Directive

•EN60065: 1998 Safety requirements for audio equipment

•EN55103-1: 1997 Electromagnetic compatibility of audio equipment: Emission

•EN55103-2: 1997 Electromagnetic compatibility of audio equipment: Immunity

Technical files are maintained at corporate headquarters of Sunrise Engineering and

Design Inc., 1630 S. Research Loop, Suite 150, Tucson, Arizona 85710, U.S.A

RoHS

Certificate of Compliance

This is to certify that the True ystems pT2-500D is RoHS compliant and meet the

requirements and specified limits of restricted substances according 2002/95/EC

directive.

WEEE

pT2-500D is marked with the WEEE symbol to comply with the European Union’s

Waste Electrical & Electronic Equipment (WEEE) Directive 2002/96/EC. The symbol

indicates that this product should not be treated as household waste. It must be

disposed and recycled separately as electronic waste. Please assist to keep our

environment clean.

Above declarations are void by modification of the device without approval,or unau-

thorized servicing.

Tucson, 09-01-2011

Tim Spencer, president

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

3

©2011 TRUE Y TEM

SAFETY & OPERATING PRECAUTIONS

Important symbols:

This symbol appearing on the product or in this manual indicates the

presence of dangerous voltage within the product enclosure that presents

the risk of electric shock injury. When this symbol appears next to an

operation discussed in this manual, only qualified technical personnel should

perform that operation.

This symbol indicates important operating or maintenance instructions that

should be read carefully. Failure to observe these instructions could result in

damage to this product or other equipment.

WARNINGS:

While no hazardous voltage is present within this product during normal

operation, please observe the following warnings regarding any AC-powered

equipment into which this product is installed:

•To reduce the risk of electric shock injury, do not remove the access

covers on AC-powered equipment. Refer servicing to qualified personnel.

•This unit is intended for indoor operation only

•Do not operate this unit in the presence of rain, liquids or condensing

moisture.

•Do not expose the unit to dripping or splashing liquids.

•Do not place liquid-filled objects on the unit.

•Do not defeat the earth ground connection in the AC power cable.

•Do not defeat intended AC power connection polarization.

•Do not use a damaged or excessively worn cord to connect the equipment

to AC power.

CAUTIONS:

•Severe damage to pT2-500D will occur if incorrect power supply

voltages are applied to the card edge connector. Please consult the

“CONNECTIONS” section in this manual for proper power supply

specifications/connections.

Disclaimer:

Product failure caused by improper voltage application cannot be

covered under warranty.

•Liquid entering the product enclosure is likely to cause performance

degradation or failure. Failures due to moisture entering the enclosure

cannot be covered under warranty. Should liquid spill on the unit,

immediately disconnect it from the AC power source and contact TRUE

ystems for servicing instructions

•This product is designed to operate in an ambient temperature range of

10°C to 50°C (50°F to 122°F).

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

4

©2011 TRUE Y TEM

CONTENTS

CERTIFICATIONS…………………………………………………………...

CE

RoHS

WEEE

2

SAFETY and OPERATING PRECAUTIONS…………………………….

3

TABLE of CONTENTS……………………………………………………...

4

PRODUCT OVERVIEW……………………………………………………..

New Type 2 Circuit Design

Features

5

INSTALLATION……………………………………………………………...

Unpacking

Card Rack Installation

Card Edge Connections

Ventilation

6

OPERATION………………………………………………………………….

Connections

Output

Microphone Input

Instrument Input and Thru (DI)…………………………………………………..

A Word About Cables……………………………………………………………………

Cable Types

Instrument cables

Microphone and Line Level cables

Front Panel Layout……………………………………………………………………….

Controls

Gain, LO/HI

Low Frequency Adjust

Phantom Power

Instrument Input

Level Indicators

7

8

9

10

SPECIFICATIONS…………………………………………………………...

11

TROUBLESHOOTING………………………………………………………

12

13

WARRANTY & SERVICE INFORMATION……………………………..

Registration and Warranty

Service and Support……………………………………………………………………..

14

15

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

5

©2011 TRUE Y TEM

PRODUCT OVERVIEW

Thanks for using our product! We appreciate the confidence you place in TRUE

ystems by purchasing the

pT2-500D

microphone preamplifier/instrument DI. We

design our products to deliver stunning musical accuracy, uniquely useful features,

exceptional value, and reliability. Every aspect of this product design was determined by

careful listening tests and extensive user feedback. Please feel free to contact us with

questions or comments.

The

pT2-500D

utilizes our Type 2 design to achieve ultra-resolution musicality and

provide optimum performance with dynamic mics, ribbon mics, and self-powered tube

mics. We’ve eliminated the components required for phantom power in order to provide

higher input impedance and reduced distortion and noise. More preamp gain is typically

required by dynamic and ribbon microphones, so we’ve provided up to 76dB – in two

ranges selected for easy control.

Lo-F Adjust (low frequency adjustment control):

The Lo-F Adjust selector allows nuanced attenuation of low-end signal content. The five

frequency selections are reciprocal to proximity effect characteristics of various

commonly-used microphone types, and can be particularly effective in removing low

frequency “mud“ from vocals and bass instruments.

FEATURES

API™ 500 series module format

Totally Balanced Topology for:

•insensitivity to ground noise/loops

•Insensitivity to EMI, both external and from adjacent modules/power supplies

•reduced distortion

Rail-to-Rail design for:

•higher internal headroom

•higher maximum input level without pad (up to +21dBu)

•higher output level without transformer and excessive power supply current

0.1% precision resistors for:

•exceptional Common-Mode and Output Signal Balance performance

•excellent unit-to-unit sonic consistency

“Real DI” IN and THRU jacks for:

•Easy hookup to amps for simultaneous DI and amp’d tracking or live sound

•Easy hookup to other DI’s or effects for simultaneous tracking or live sound

Detented, continuous Gain Control and Dual Gain Ranges for:

•easy gain resetability

•easy gain setting over wide gain ranges

Steel Enclosure for:

•protection from EMI and RFI

•protection from ESD and handling contamination/damage

Lo-F Adjust control

4-Level Signal Meter

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

6

©2011 TRUE Y TEM

INSTALLATION

Unpacking

Please read and follow instructions on the Caution sticker on the anti-static bag

enclosing the pT2-500D:

•Please ground yourself to dissipate static electricity before opening anti-static bag

and handling the pT2-500D.

•Save the anti-static bag, carton, and foam supports for future storage or ship-

ment.

Card Rack Installation

1. Turn off card rack AC power and remove AC power cord.

2. Carefully align the pT2-500D with the desired card slot edge connector. This is a

blind installation, so take your time in order to avoid scratching this unit or adjacent

units in the card rack.

3. Press the unit firmly and evenly until you feel it seat in the card edge connector.

4. If you have difficulty inserting this unit, check for debris in the card rack edge

connector. It may help to rearrange adjacent modules in the card rack.

5. Secure the front panel with two 4-40 flat head philips mounting screws (supplied with

API™ card racks and Lunchbox™).

6. Reconnect the AC power cord and turn on the rack power.

Card Edge Connections

Note:

Disclaimer:

If you are using a custom card rack, or a

card rack not manufactured by API™, please

verify the following power supply

terminations:

Pin 12 = +16VDC

Pin 13 = Power Common

Pin 14 = -16VDC

Pin 1 is located at the top of the card edge

connector.

Damage caused by incorrect power

supply termination or voltage cannot be

covered under warranty.

Ventilation

We recommend that the card rack containing the pT2-500D have adequate ventilation

to maintain the unit within an operating ambient temperature range of 10°C to 50°C

(50°F to 122°F).

15 +48VDC

14

13

12

11

10

9

8

7

6

5

4

3

2

1

-16VDC

POWER COMMON

+16VDC

NC

+INPUT

NC

-INPUT

NC

NC

AUDIO COMMON

-OUTPUT

NC

+OUTPUT

CHASSIS GROUND

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

7

©2011 TRUE Y TEM

OPERATION

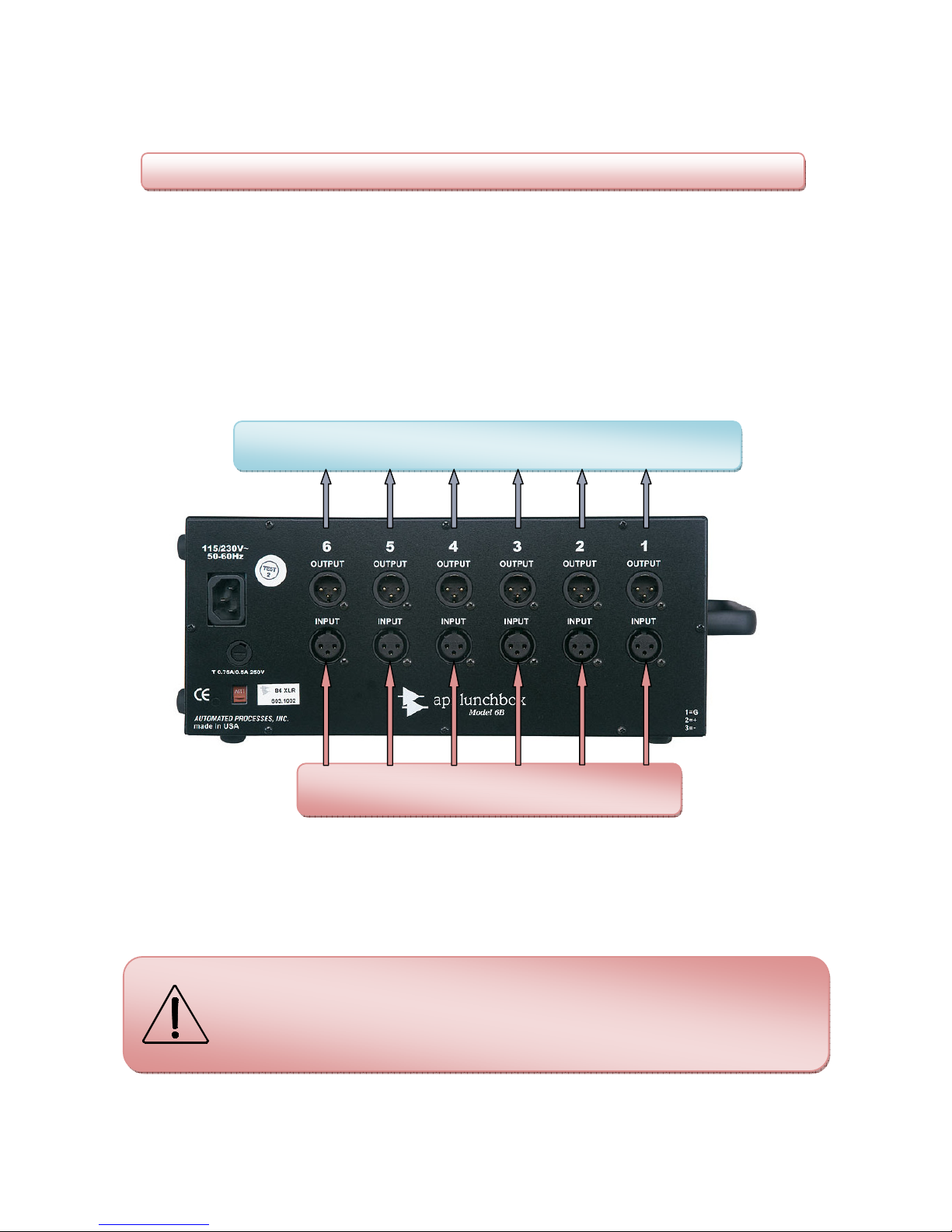

Connections

Read “Safety and Operating Precautions”on page 3, and “Installation” on page 6 of

this manual before making any connections to the pT2-500D.

1. Connect output signal cables from the XLR OUTPUT connectors on your 500-series

compatible card rack to the analog line-level inputs of your DAW, recorder, mixer,

A/D converter, signal processor, etc.

XLR outputs used with unbalanced cable configuration must be wired correctly.

See page 9 “Output Cable Connection – unbalanced”.

DAW, Recorder, Mixer, A/D Converter, Signal Processor, etc.

Microphones

(for card slots with Mic Preamps installed)

2. Connect microphone cables to the XLR INPUT connectors on card slots that contain

your pT2-500D or other mic preamp.

Do not attempt to connect unbalanced microphones to the pT2-500D

It is not intended to operate with this type of microphone.

NOTE: The input and output connector locations on some 500-series

compatible card racks are different than on API™ units. In order to prevent

time-consuming errors and possible damage to your equipment, please

consult the manufacturer’s documentation for the particular card rack you are

using.

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

8

©2011 TRUE Y TEM

Instrument Input and Thru (DI)

1. Connect your instrument cable to IN. This interrupts the microphone input on the rear

panel and routes your instrument to the discrete FET DI in the pT2-500D. This

input is intended for unbalanced signal sources.

DO NOT use TRS plugs for this input or the DI will not be activated

2. If desired, connect a cable from THRU to a guitar/bass amp, another DI, or additional

signal processing device.

3. The IN and THRU jacks are directly connected as in any typical standalone DI. Since

the input impedance of the pT2-500D FET DI is 2.5 Megohms, it does not provide

any significant electronic load to the instrument pickup. When connection is made via

the THRU jack to an amp or other device, the input impedance of that device will

essentially determine the electronic load on the instrument pickup. Keep in mind that

lower impedance may alter the tonal character of your instrument.

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

9

©2011 TRUE Y TEM

A Word About Cables…

Most users of the pT2-500D have invested much time and money in their selection of

microphones and preamplifiers. We recommend that you give some consideration to the

microphone, instrument and output cables you select, as well.

•Use high-quality, low capacitance cable. Braided shielding and “star quad” type mic

cables will perform better in electrically noisy environments. Manufacturers such as

Canare, Mogami(and others) make high performance cable of this type.

•Some “house brand” cables are made by quality manufacturers, but others can be

inferior. Be careful. Use cables with high-quality connectors (Neutrik, Switchcraft,

etc.).

•Our studio testing has shown that some of the more esoteric guitar/instrument

“super-cables” do, indeed, sound better. Noticeable improvement, but at a stiff price.

Try before you buy!

•Avoid excessive cable length.

•Replace damaged connectors.

Cable Types

There are two styles of audio cables used for connections to the pT2-500D in a 500-

series rack:

•Shielded / single-conductor type for unbalanced signals (Instrument cables)

•Shielded / twisted-pair type for balanced signals ( Microphone / Line level cables)

We recommend that all interconnecting cables are wired according to the following

standards. Failure to do this can result in malfunction or audible distortion.

For Instrument cables (unbalanced)

on TS connectors:

•Tip = positive (+) signal

•Sleeve = shield

tip

sleeve

TS connector (¼” plug, mono)

For Microphone and Line level cables (balanced)

on XLR connectors:

•Pin 1 = shield

•Pin 2 = positive (+) signal

•Pin 3 = negative (-) signal

female male

XLR connector (front side)

Output cable connection – unbalanced

NOTE: When connecting an XLR output from pT2-500D to a subsequent

audio device with an unbalanced input, the negative signal lead (from Pin 3)

must be wired to shield (Sleeve) at the TS connector. For this type of

connection, the Maximum Output Level is reduced to +23dBu.

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

10

©2011 TRUE Y TEM

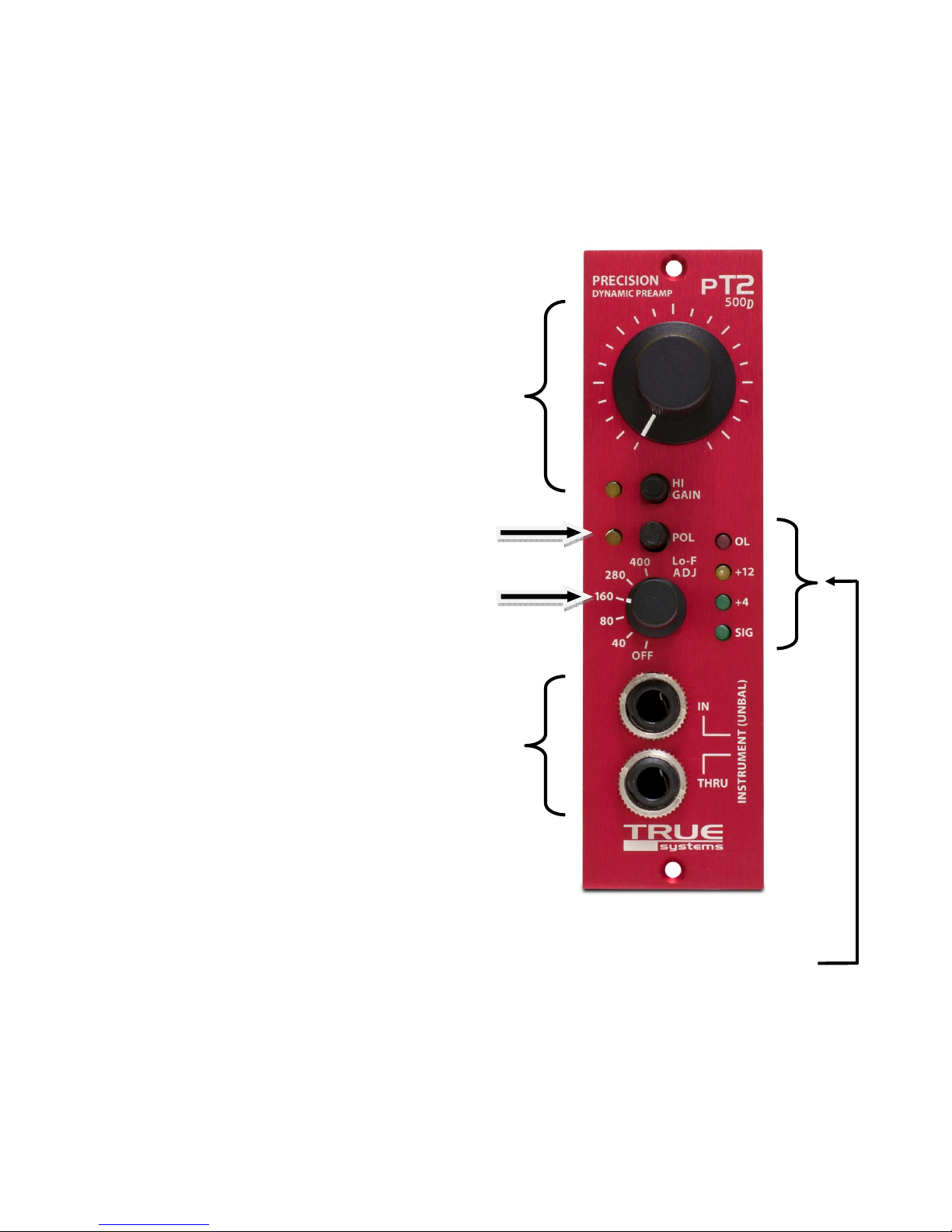

Front Panel Layout

CONTROLS

Gain

The detented rotary gain control along with the

HI GAIN button setting determines the overall

gain through the preamp. When HI GAIN is off,

the rotary gain control range is from 6.5dB to

60dB and maximum input level is

approximately +21dBu. When HI GAIN is on,

the rotary gain control range is from 24dB to

76dB with maximum input of +10dBu.

Polarity

Output signal polarity is reversed when the

POL button is depressed.

Low Frequency Adjust

The Lo-F ADJ switch activates a -6dB per

octave filter at the selected frequency.

CONNECTIONS

Instrument Input

Discrete FET Instrument Direct IN. Connect

your instrument cable to the IN jack

(unbalanced instrument cable only). If desired,

connect a cable from THRU to a guitar/bass

amp, another DI, or additional signal

processing device. See previous section for

details.

LEVEL INDICATORS

The level indicators show output signal level. SIG illuminates at -24dBu and indicates

that a signal is present on the channel. +4 illuminates when the output signal reaches

normal operating level of +4 dBu. +12 illuminates when the output signal reaches

+12dBu. OL illuminates when the output signal level exceeds +26dBu which is 3dB

below actual preamp overload.

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

11

©2011 TRUE Y TEM

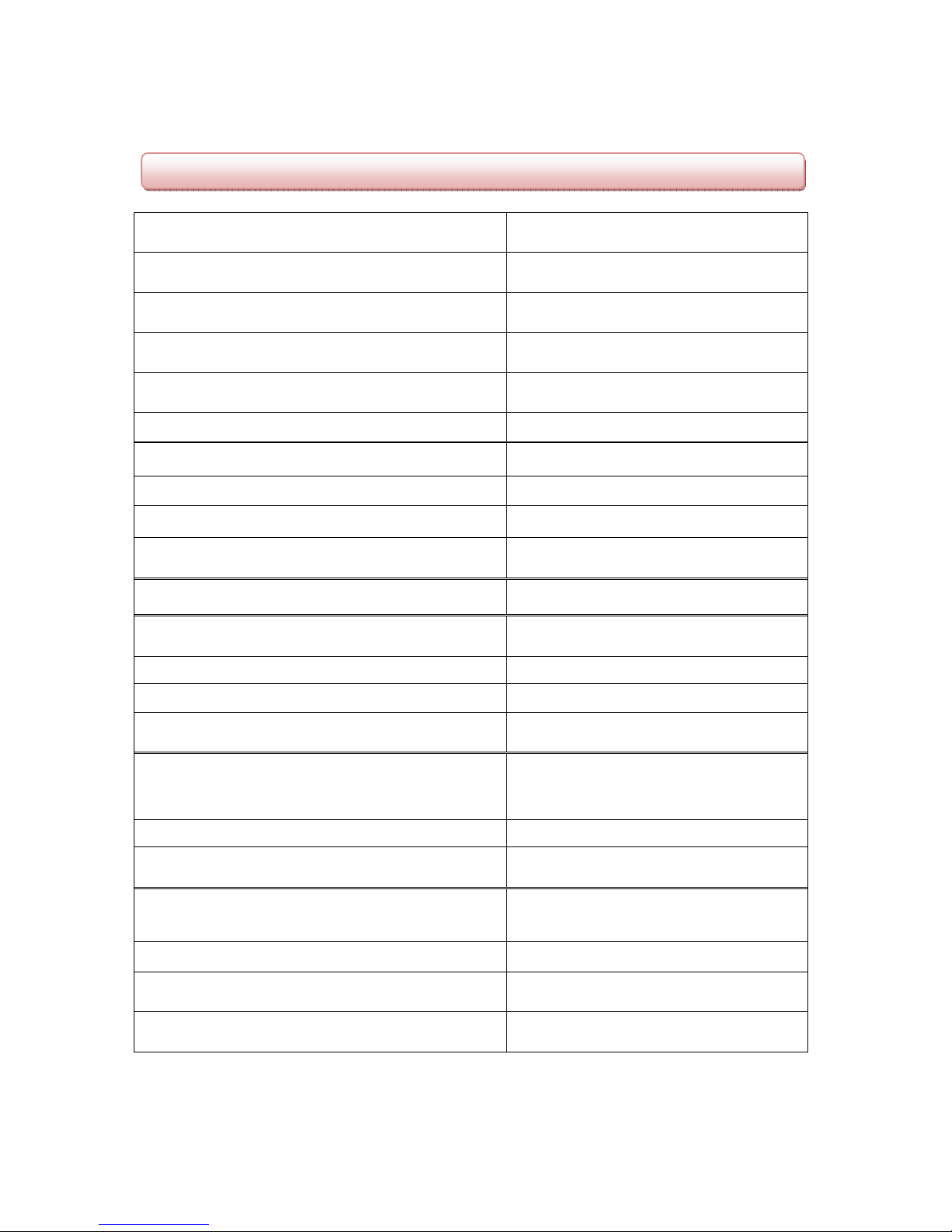

SPECIFICATIONS*

Frequency Response

@ 40dB gain (-3 dB) 1.5 Hz – 550 kHz

THD+N

@ 40dB gain,+26 dBu out, 20Hz to 20kHz BW 0.0004%

Intermodulation Distortion

SMPTE/DIN 4:1 (60Hz/7kHz), @40dB, +26dBu

0.0009%

Noise (E.I.N)

Rs = 0 Ohms -133 dB

CMRR

@40dB gain, Vcm = +10dBu 85 dB

Slew Rate 50 V/us

Microphone Input 1x balanced (XLR-type)

(via card edge connector)

Maximum Input Level + 21 dBu

Input Impedance 10 kOhm

Gain +6.5 to +60 dB (LO gain)

+24 to +76 dB (HI gain)

Low Frequency Filter Selection (-6dB/Oct) Off, 40, 80, 160, 280, 400Hz

Instrument Input (DI)

FET discrete circuit

1x unbalanced, (TS jack)

(IN jack on front panel)

Maximum Input Level (DI) +11 dBu

Input Impedance (DI) 2.5 MOhm

Gain (DI) -10 to +43.5 dB (LO gain)

6.5 to +60 dB (HI gain)

Output 1x balanced (XLR)

(via card edge connector)

1x unbalanced (TS jack)

(THRU jack on front panel)

Output Impedance 100 Ohm (50 X 2)

Maximum Output Level

+29 dBU

Power Requirements ±16 VDC

(power supply - 500 format rack)

(via card edge connector)

Power Consumption 65 mA = 1.04 W (±16V)

Dimensions

1.5“ x 5.25“ x 6.05“ (W x H x D)

38.1 x 133.4 x 153.8 mm

Weight

1.4 lbs. (0.64 Kg)

*Typical performance. Specifications subject to change without notice.

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

12

©2011 TRUE Y TEM

TROUBLESHOOTING

Symptom Solution

No signal output. Main power switch

on rack power supply is ON, but no

LED’s illuminate on pT2-500D.

•Check AC power source and cord connection

•Check fuse on rack power supply.

•Check that preamp card edge connector is

properly seated.

No signal output. Main power switch

on rack power supply is ON and

appropriate LED’s illuminate on

pT2-500D.

•Check status of phantom power.

•Check continuity of mic and electric

instrument cables.

•Check continuity of output cables.

•Make sure GAIN control is adjusted.

Output signal is distorted. Outputs

are connected for balanced

operation.

•Make sure GAIN is adjusted so that the OL

indicator does not activate during the audio

program.

•Make sure the high output capability of this

unit is not overloading the device or

monitoring system to which it is connected.

•Check continuity of output cable.

•Make sure outputs are not connected to a

load impedance of less than 600 ohms.

Output signal is distorted. Outputs

are connected for unbalanced

operations.

•Make sure the minus (-) output signal pins

are connected to the shield and not left

unconnected. See “Output Cable

Connection” section, page 9.

•Check troubleshooting tips for balanced

operation (above).

Hum can be heard in the audio

program.

•Check continuity of output cables

(particularly shields).

•Alternatively, disconnect shields on one end

of output cables (not appropriate for

unbalanced connections).

Electric instrument connected to a

Direct Input does not produce a

signal or signal is distorted.

•Check continuity of electric instrument

cables.

•Check the batteries or AC power source of

any “foot pedal” effects processors

connected to the Direct Input.

•Make sure that the instrument cables have

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

13

©2011 TRUE Y TEM

Symptom Solution

standard tip-sleeve ¼” phone plugs.

DO NOT use TRS plugs!

Radio Frequency Interference can

be heard in the audio program

(swishing sound or audio from a

radio transmitter)

•Make sure that mic cables are of good

quality and that the shield is properly

connected. Avoid excessive length.

•Make sure that earth ground connection is

maintained via the AC power cord.

DO NOT use an isolator!

•Make sure the unit is located away from

known sources of radio frequency energy.

(e.g. cell phone, walky-talky etc.)

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

14

©2011 TRUE Y TEM

WARRANTY & SERVICE INFORM

ATION

REGISTRATION

Don’t forget to register your pT2-500D by completing the registration form online at our

website www.synthax.de (Support / Product Registration). Alternatively, fill out the

enclosed Registration Card and return it to us. This allows Synthax GmbH to contact you

regarding any updates, upgrades or applications information that may become available.

WARRANTY

Synthax GmbH warrants the TRUE systems pT2-500D to be free from defects in

material and manufacture, when properly installed and used according to instructions in

the Operation Manual, for a period of two years from the date of sale to the original

purchaser. Units returned for warranty repair to Synthax GmbH or an authorized TRUE

ystems repair facility will be repaired or replaced at the manufacturer’s option, free of

charge. Supplementary shipping charges will apply to units returned to addresses

outside the continental USA. All units returned to Synthax GmbH or authorized TRUE

systems repair facility must be prepaid, insured and properly packaged. Purchaser

must obtain a Return Authorization (RA) number from Synthax GmbH prior to returning a

product. Synthax GmbH may require proof of the purchase date in the form of a copy of

a dated original retail invoice.

This warranty is void if, in the sole judgment of Synthax GmbH, the product has been

abused, neglected, misapplied, or has been damaged by an accident, modification, or

attempted repair by unauthorized personnel. This warranty will not apply to cosmetic

damage incurred due to normal handling and use. Synthax GmbH reserves the right to

change or improve the product design at any time without prior notice. Incorporation of

design changes in future versions of the product does not imply the availability of

upgrades for existing units.

This warranty is in lieu of all other warranties, expressed or implied, and Synthax GmbH

specifically disclaims all implied warranties, including, but not limited to, warranties of

merchantability and fitness for a particular purpose. The purchaser acknowledges and

agrees that in no event shall Synthax GmbH be held liable for any special, indirect,

incidental or consequential damage, or for injury, loss or damage sustained by any

person or property, that may result from the use of, or failure of this product to operate

correctly at any time.

pT2-500D Microphone Preamplifier OPERATION MANUAL

Version 1.0

15

©2011 TRUE Y TEM

SERVICE and SUPPORT

Other than cleaning the exterior surfaces of your pT2-500D and occasional inspection

of the audio cables for damage, no maintenance procedures should be attempted by the

user. Cleaning can be performed using a lint-free cloth dampened with Windex.

There are no user-serviceable components inside the product enclosure. Many of the

electronic components are selected and matched at the factory. For this reason, as well

as personal safety considerations, we recommend that you refer service requirements to

Synthax GmbH or authorized repair facilities.

All units returned to Synthax GmbH or authorized TRUE systems repair facility must be

prepaid, insured and properly packaged. Purchaser must obtain a Return

Authorization (RA) number from Synthax GmbH prior to returning a product.

Synthax GmbH Tel: +49 (89) 97 880 38-0

Semmelweisstraße 8 Fax: +49 (89) 97 880 38-19

Table of contents

Other True Systems Amplifier manuals