5). Dischargethe refrigerant.

Close the valveon thecharging cylinderand

dischargethe refrigerantbyloosening the flare

nuton the 2-wayvalveapproximately45’until the

gaugeindicates 0.3to0.5Mpa.

6). Disconnectthe chargesetand thecharging

cylinder,and setthe 2-wayand 3-wayvalves to

the open position

Besuretouse ahexagonalwrenchtooperatethe

valvestems.

7). Mountthe valvestemsnutsand the service

port cap

Besuretouseatorquewrench totighten the

service port cap toatorque18N.m.

Besuretocheckthe gas leakage.

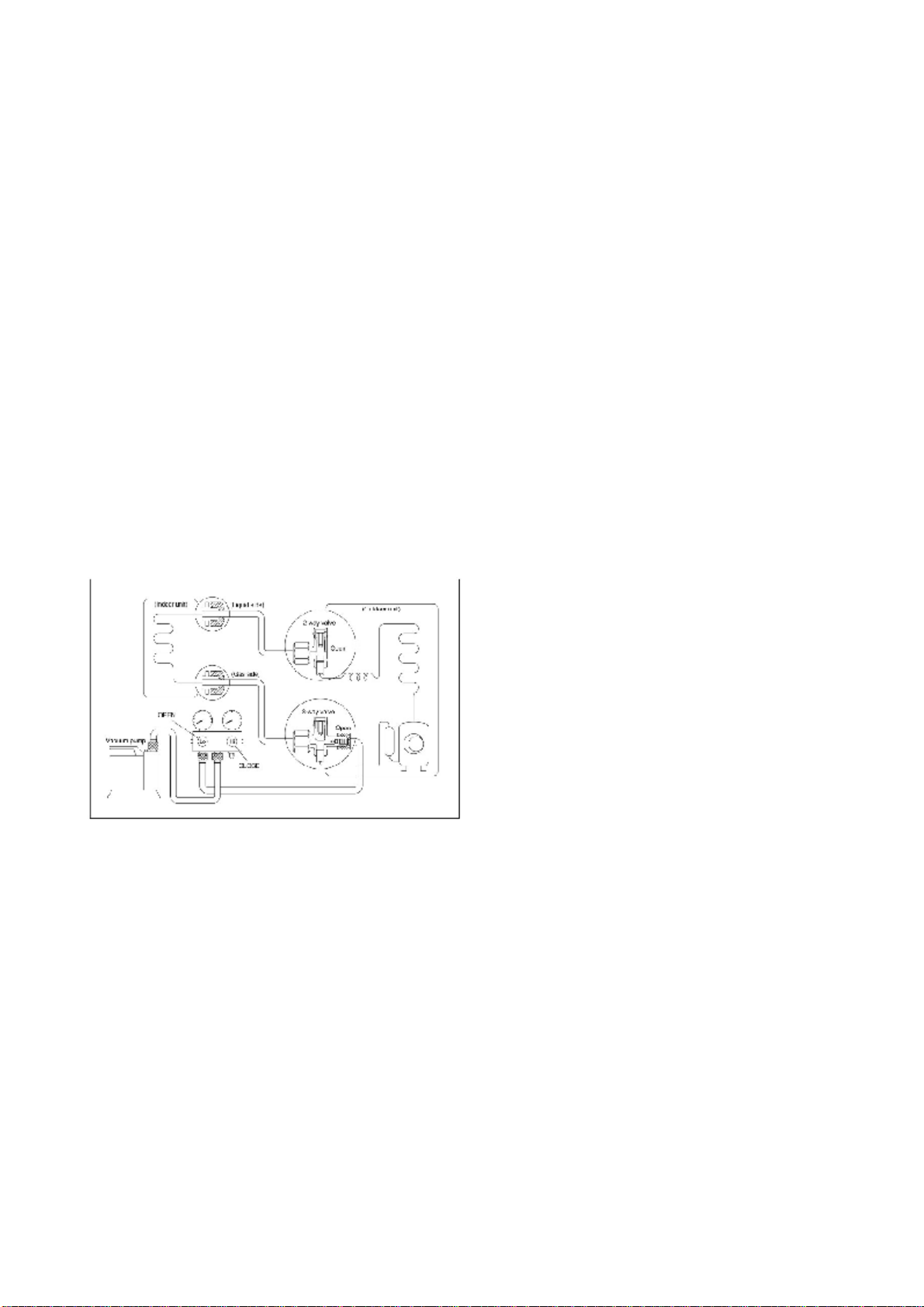

1.Evacuationfor thewholesystem

Procedure:

1). Confirmthatboththe2-wayand 3-way

valves areset tothe opened position.

2). Connectthe vacuumpumpto3-wayvalve’s

service port.

3). Evacuation forapproximatelyone hour.

Confirmthatthe compound meterindicates

-0.1Mpa.

4). Close the valve(Lowside)on the charge set,

turnoffthe vacuumpump,and confirmthatthe

gaugeneedledoes notmove(approximately5

minutesafter turningoffthe vacuumpump).

5). Disconnectthe chargehose fromthe vacuum

pump.

2.Refrigerant charging

Procedure:

1). Connectthe charge hose tothe charging

cylinder,open the 2-wayvalveand the 3-way

valve

Connectthe charge hose which you

disconnected fromthevacuumpumptothe

valveatthe bottomofthe cylinder.Ifthe

refrigerantisR410A,make the cylinderbottom

up toensureliquidcharge.

2). Purge the air fromthe charge hose

Open the valveatthe bottomofthe cylinder

and pressthe checkvalveon the charge setto

purge the air(be carefulofthe liquid

refrigerant).

3)Putthe charging cylinderontothe electronic

scaleand recordthe weight.

4). Open the valves (Lowside)on the chargeset

and charge the systemwithliquidrefrigerant

Ifthe systemcannotbe charge withthe specified

amountofrefrigerant, orcan be charged witha

littleatatime(approximately150g each time),

operating theairconditionerinthe cooling cycle;

however,one timeisnotsufficient, wait

approximately1minuteand then repeatthe

procedure.

5).When the electronicscaledisplaysthe proper

weight, disconnectthe chargehosefromthe

3-wayvalve’sservice port immediately

Ifthe systemhas beenchargedwithliquid

refrigerantwhileoperatingthe airconditioner,

turnoffthe airconditionerbeforedisconnecting

the hose.

6). Mountedthe valvestemcapsandthe service

1.7Re-installation whiletheoutdoor unit

needtoberepaired