2

17. 06. 20. Document Number 671789Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA |nuaire.co.uk

UNI-X

Installation Manual

1.2 Important Information

This manual contains important information on the safe and

appropriate assembly, transport, commissioning, operation,

maintenance, disassembly and simple troubleshooting of the product.

While the product has been manufactured according to the accepted

rules of current technology, there is still a danger of personal injury or

damage to equipment if the following general safety instructions and

the warnings contained in these instructions are not complied with.

•Read these instructions completely and thoroughly before

working with the product.

•Keep these instructions in a location where they are accessible

to all users at all times.

•Always include the operating instructions when you pass the

product on to third parties.

1.3 Personal Protective Equipment

The following minimum Personal Protective Equipment (PPE) is

recommended when interacting with Nuaire product:

•Protective Steel Toed Shoes - when handling heavy objects.

•Full Finger Gloves (Marigold PU800 or equivalent) - when

handling sheet metal components.

•Semi Fingerless Gloves (Marigold PU3000 3DO or equivalent)

- when conducting light work on the unit requiring tactile

dexterity.

•Safety Glasses - when conducting any cleaning/cutting operation

or exchanging filters.

•Reusable Half Mask Respirators - when replacing filters which

have been in contact with normal room or environmental air.

Nuaire would always recommend a site specific risk assessment by a

competent person to determine if any additional PPE is required.

2.0 INTRODUCTION

The UNI-X ceiling void unit range is designed to provide mechanical

supply and extract ventilation with heat recovery, which incorporates an

automatic HX bypass feature.

The units are fitted with two high efficiency centrifugal fans with EC Motors,

which have speed control over three different ventilation rates; trickle, boost and

max. A counterflow plate heat exchanger is also used to recover up to 85% of

the extracted air heat, whilst G3 Filters provide protection to the unit and ensure

filtered air is supplied, guaranteeing the unit is ErP 2018 compliant.

The HX bypass damper shall open automatically via a wax actuator allowing the

air to bypass the heat exchanger to deliver fresh filtered air during the warmer

months.

General information regarding performance and specifications for the

equipment may be obtained from our Technical Literature, and/or project

specific documentation.

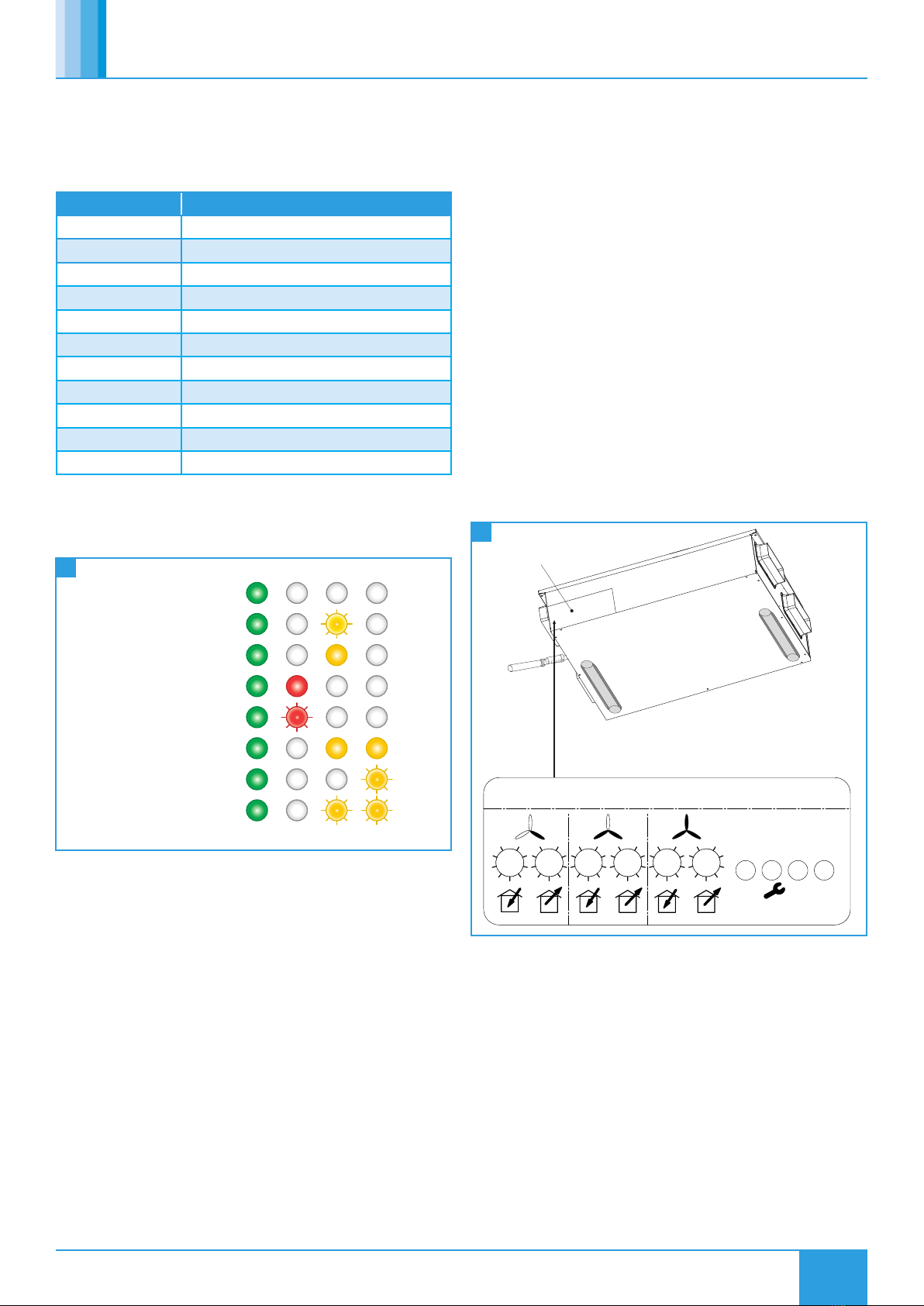

2.1 Code Description:

UNI - X 220 - C

1-23-4

1. Range: Student Accommodation

2. HX Type X = Plate Heat Exchanger

3. Unit Size: 220, 360, 580

4. Spigot Type: No Suffix = Rectangular (220 x 90mm)

C = Circular (150mm Ø)

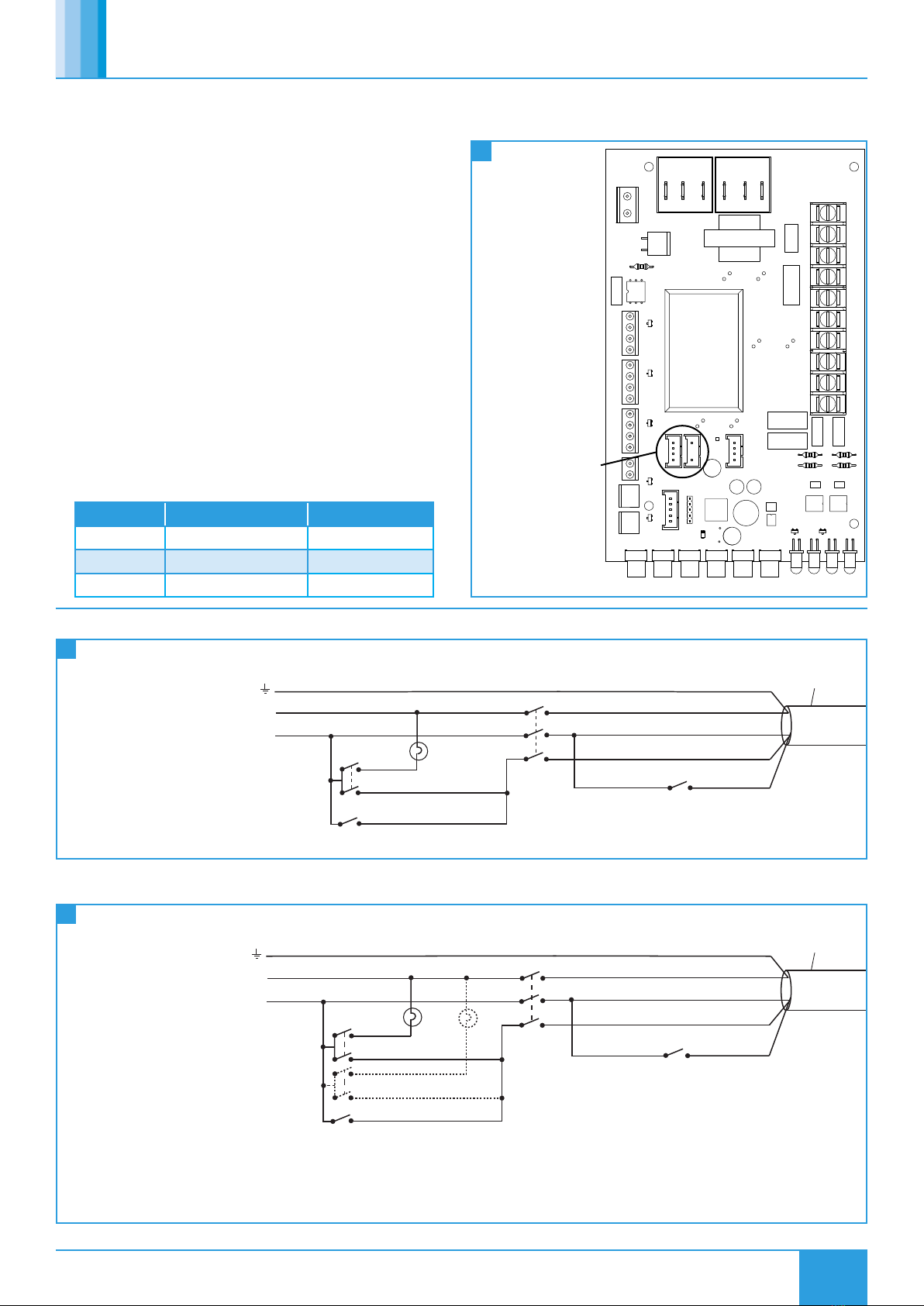

3.0 MECHANICAL INSTALLATION

The UNI-X ceiling void unit range is designed to provide mechanical

supply and extract ventilation with heat recovery, which incorporates an

automatic HX bypass feature.

The units are fitted with two high efficiency centrifugal fans with EC Motors,

which have speed control over three different ventilation rates; trickle, boost and

max. A counterflow plate heat exchanger is also used to recover up to 85% of

the extracted air heat, whilst G3 Filters provide protection to the unit and ensure

filtered air is supplied, guaranteeing the unit is ErP 2018 compliant.

The HX bypass damper shall open automatically via a wax actuator allowing the

air to bypass the heat exchanger to deliver fresh filtered air during the warmer

months.

General information regarding performance and specifications for the

equipment may be obtained from our Technical Literature, and/or project

specific documentation.

3.1 Delivery of Equipment

3.1.1 Receipt of Equipment

All equipment is inspected prior to despatch and leaves the factory in

good condition. Upon receipt of the equipment an inspection should be

made and any damage indicated on the delivery note.

Particulars of damage and/or incomplete delivery should be endorsed

by the driver delivering the goods before offloading by the purchaser.

No responsibility will be accepted for damage sustained during the

offloading from the vehicle or on the site thereafter. All claims for

damage and/or incomplete delivery must be reported to Nuaire within

two days of receipt of the equipment following guidance in our terms &

conditions of sale.

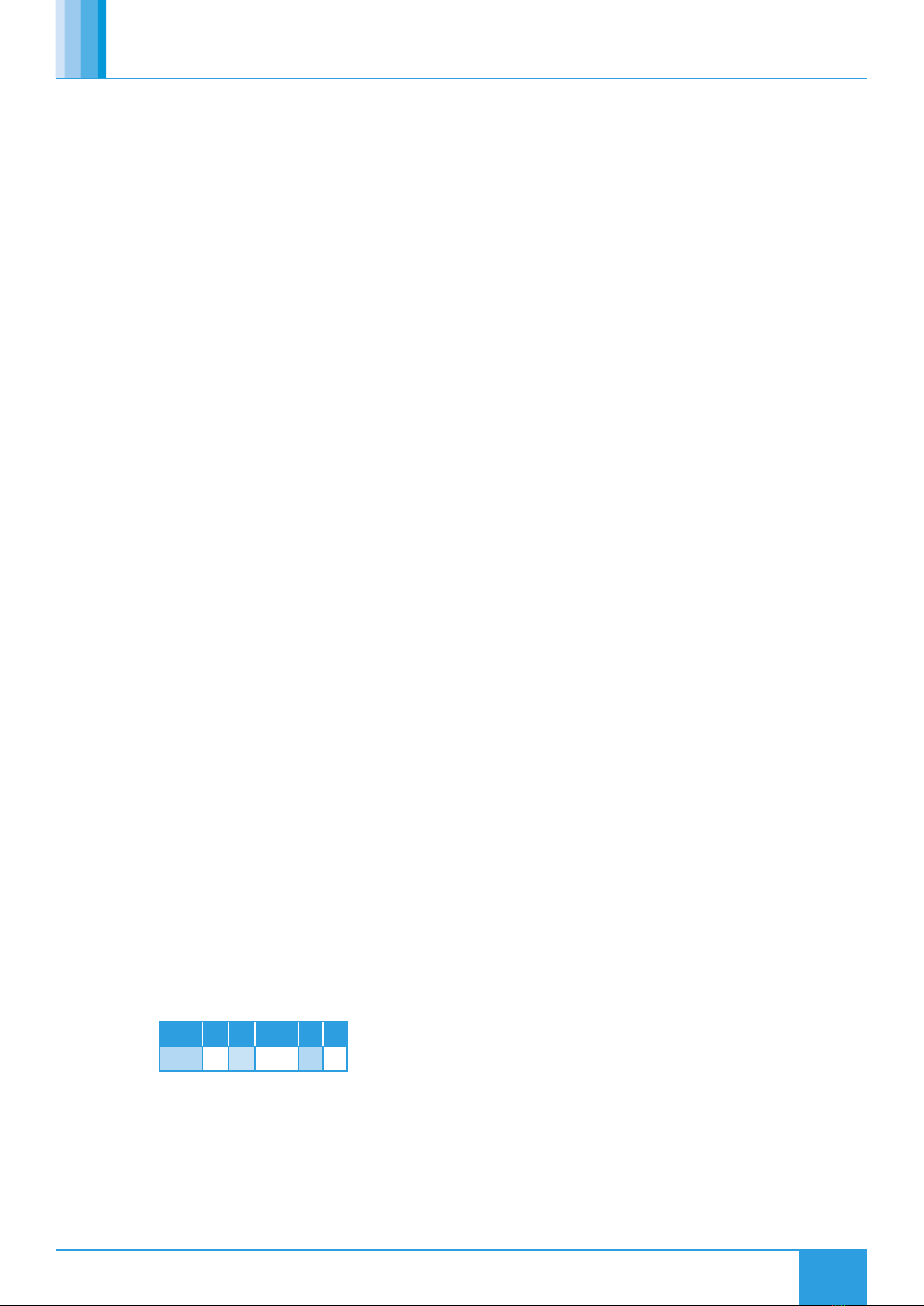

3.1.2 Offloading and Handling

The weight of the unit modules and palletised items is displayed on

the unit rating plate or on the packaging. Some of the modules have an

uneven weight distribution, and this will be indicated by labelling where

appropriate. Ensure that lifting and handling equipment is adequately

rated. Offloading and positioning of the equipment is the responsibility

of the purchaser.

Spreaders should be used when lifting with slings to avoid damage

to the casings. Care must be taken to ensure that slings are correctly

positioned to avoid crushing and twisting of the unit castings.

Where channels and/or support frames are bolted to the underside of

the unit casing, slings or fork-lift arms should be positioned to locate in

the apertures in the channels. If lifting eyes have been supplied / fitted

it is recommended that they are used.

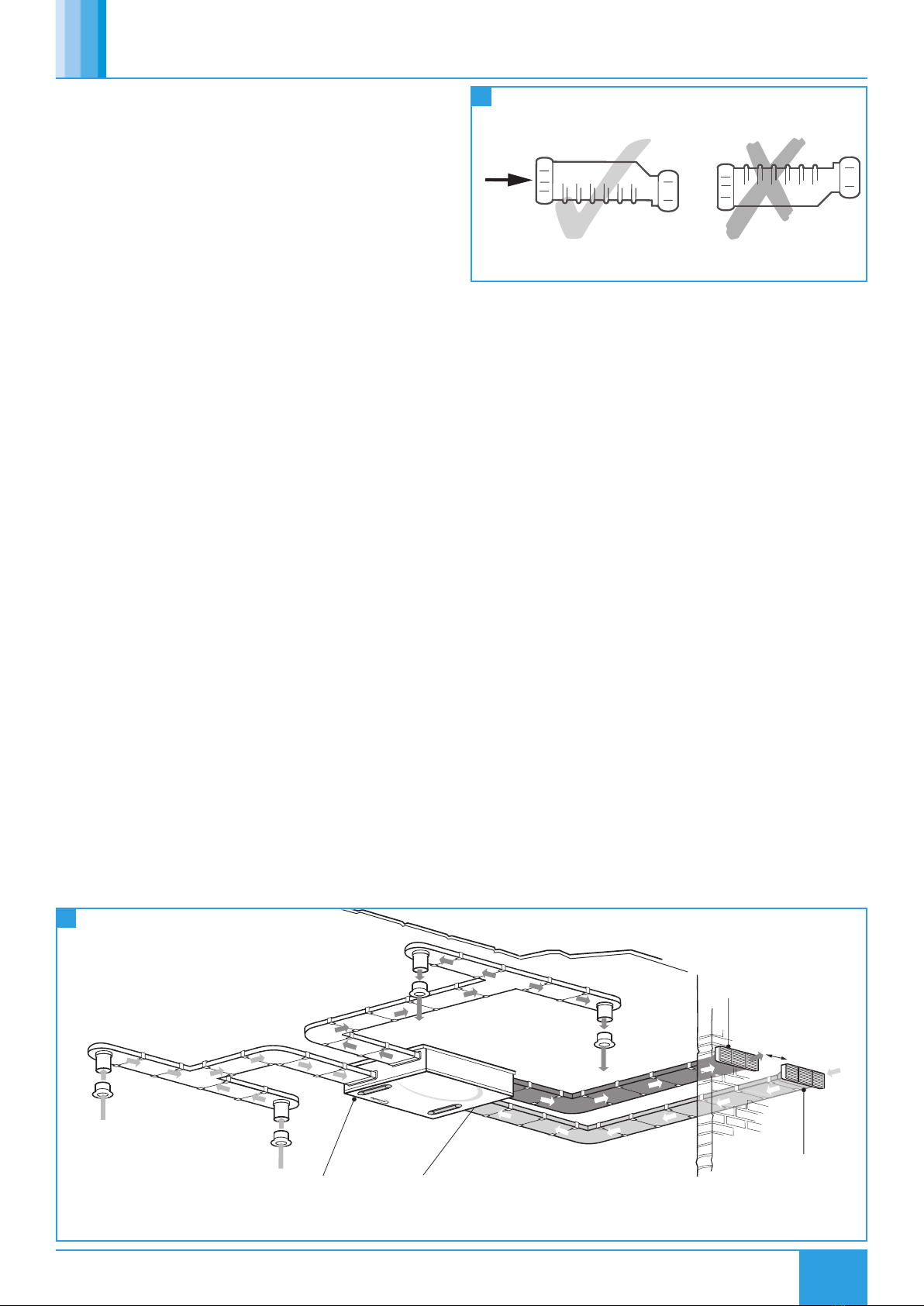

UNI-X units will be delivered to site in one section and will be labelled

with the direction of air flow. The direction convention must be

observed during assembly.

3.1.3 Storage

The equipment must be stored in a dry, internal location. Ductwork

connection apertures shall be sealed against the ingress of dust, water

and vermin. Do not stack units, modules or components.

Where fans are to be stored or bonded for extensive periods follow the

Warranty Guidance Notes found in our conditions of sale.

3.2 Unit Installation

Installation of the UNI-X units, including all external services and

controls should be installed in accordance with the appropriate site

procedures, and MUST conform to all governing regulations e.g.

CDM, CIBSE, IEE, and in strict accordance with the applicable Building

Regulations.

To aid in installation, dimensional templates including hole centres

for mounting points are provided with the units.