TTMC BS-315G User manual

0

METAL CUTTING BAND SAW

MODEL BS-315G

Operation Manual

1

Table of contents

Introduction……………………………………………………………………………………2

1. Accident prevention and safety instruction……………………………………………..3

1.1Advice for the operator…………………………………………………………………..3

1.2 The electric equipments according to European Standard “2006/42/EC” which

some integrating modifications……………………………………………………………..3

1.3 Emergencies according to European Standard “2006/42/EC”………………………4

2. Description of machine…………………………………………………………………...4

2.1 Description of machine and its components………………………………………….4

2.2 Intended and unsuitable uses of the machine………………………………………...5

3. Main technical date………………………………………………………………..………5

4. Handling and transportation……………………………………………………………...5

5. Machine installation……………………………………………………………………….6

5.1 Machine check…………………………………………………………………………...6

5.2 Fastening of the machine……………………………………………………………….6

5.3 Saw blade assembly…………………………………………………………………….6

5.4 Electrical connection to the mains……………………………………………………..6

5.5 Cutting coolant…………………………………………………………………………...7

6. Machine start up and operation………………………………………………………….7

6.1 Operation………………………………………………………………………………....7

6.2 Cutting operation…………………………………………………………………………7

6.3 Special safety checks…………………………………………………………………...8

6.4 Measures to prevent residual risks…………………………………………………….8

7. Maintenance and repairs…………………………………………………………………9

7.1 General safety measures……………………………………………………………….9

7.2 Description of routine maintenance…………………………………………………....9

8. Parts list…………………………………………………………………….…………….11

9. Parts drawing..…………………………………………………………………………...14

10. Electric drawing…………………………………………………………………………16

2

Introduction

This operation instruction manual conforms to the requirements of European Standard

2006/42/EC Machine Directives and subsequent amendments.

In the light of this,special attention has been given to safety aspects and accident

prevention in the work-place for each stage in the machine’s “life”. Information which

could be of particular assistance to the operator has been high lighted.

The “Operating instructions” are an integral part of the machine and should be

consulted before, during and after the start up of machine and whenever else required.

The content of these instructions should always be carefully observed.

The observance of the above is the only way to achieve the two fundamental aims of

this manual:

● Optimization of machine performance

● Prevent damage to the machine and injury to the operator

CAUTION: BEFORE INSTALLING THE MACHINE, READ THE OPERATING

INSTRUCIONS CAREFULLY

3

1. Accident prevention and safety instruction

This machine has been designed to comply with national and community

accident-prevention regulations, improper use and / or tampering with the safety

devices will relieve the manufacturer of all responsibility.

1.1Advice for the operator

A. Check that the voltage indicated on the machine motor is the same as the line

voltage.

B. Check the efficiency of your electric supply and grounding system; connect the

power cable of machine to the socket and the ground lead (yellow-green) to the

grounding system.

C. When the saw frame is in suspended mode (or raised), the blade must not move.

D. Only the blade section used for cutting must be kept unprotected. To remove

guards operate on the adjustable head.

E. It is forbidden to use the machine without its shields.

F. Always disconnect the machine from the power socket before blade change or

carrying out any maintenance job, even in the case of abnormal machine operation.

G. Always wear suitable eye protection.

H. Never put your hands or arms into the cutting area while the machine is operating.

I. Do not shift the machine while it is cutting.

J. Do not wear loose clothing like: shirts with sleeves that are too long, gloves that are

too big, bracelets, chains or any other objects that could get caught in the machine

during operation. Tie back long hair.

K. Keep the area free of equipment, tools, or any other objects.

L. Perform only one operation at a time. Never have several objects in your hands at

the same time.

M. Keep your hands as clean as possible.

N. All internal operations, maintenance or repairs, must be performed in a well-lit area

or where is sufficient light from extra sources so as to avoid the risk of even slight

accidents.

1.2 The electric equipments according to European Standard “2006/42/EC”

which some integrating modifications.

A. The electric equipment ensures protection against electric shock as a result of

direct contact.

B. The active parts of this equipment are housed in a box to which access is limited by

screws that can only be removed with special tools; the parts are fed with

4

alternating current as low voltage (24V). The equipment is protected against

splashes of water and dust.

C. Protection of the system against short circuits is ensured by means of rapid fuses

and grounding; in the event of a motor overload, protection is provided by a thermal

probe.

D. In the event of a power cut, the specific start-up button must be reset.

E. The machine has been tested in conformity with European Standard.

1.3 Emergencies according to European Standard “2006/42/EC”.

In the event of incorrect operation of danger conditions, the machine may be stopped

immediately by pressing the red emergency button.

The casual or voluntary removal of the blade cover of the flywheels causes the

stepping-in of a interlock switch that automatically stops all machine functions.

Note: resetting of machine operation after each emergency stop require specific

restart button.

2. Description of machine

2.1 Description of machine and its components

The band sawing machine produced by us has a sturdy frame made from welded and

painted sheet-steel. The upper surface is designed to allow the complete draining

away of the cutting fluid. The band holding bow is made of cast-iron and has generous

dimensions,providing the cutting unit with the necessary strength and precision. The

vice unit is made of cast-iron and clamps the material to be cut securely. The bar-stop

device allows the length required to be preset and a constant level of performance for

repeated cuts. The blade-holding bow is firmly attached to a reduction unit built onto

the motor and to the base by means of a joint which allows 60°and 45°rotation to the

right and left. This joint also allows the cutting movement to advance manually or by

falling.

The coolant pump is fitted to the machine base. The main switch is located on the

front panel. The choice of one of the two motor rotation speeds and therefore cutting

speed is carried out by the main switch. The front panel is also fitted with an

emergency stop button and a START button. The control lever,fitted with an

ergonomic hand-grip and activation button with safety release action, reduces fatigue

during operation to a minimum. The blade is protected by a guard with interlock which

covers the upper area and the hand wheels and by two adjustable lower guards which

protect the operator from ejected shavings and coolant. The machine is supplied with

5

a set of service spanners.

2.2 Intended and unsuitable uses of machine

The band sawing machine has been designed and built to cut bars, structural steel

and ferrous metal pipes in accordance with the instructions contained in this manual.

Therefore, the cutting of other materials is not permitted: if the above

recommendations are not observed,the machine could be damaged and the health

and safety of the operator put at risk. Cutting is not permitted, if the bar has not been

first locked in the vice.

3. Main technical date

Under no circumstances should the following data be altered, this is in order to protect

the correct functioning of the machine and to avoid creating safety risks for the

operator.

Motor

Motor Power

Three-phase or single-phase

0.75/1.1 kw

Capacity

Circular @90°

Rectangular @90°

Circular @60°

Rectangular @60°

Circular @45°

Rectangular @45°

230mm

315 x 170 mm

130 mm

130 x 130 mm

210 mm

210 x 170 mm

Blade size (length ×width ×thick)

2825×27×0.9 mm

Cutting speed

40 / 80 rpm

Cutting angle

60°/ 45°right

Piece locking vice: max opening

315 mm

Packing size

163 x 87 x 153 cm

Net weight / gross weight

350 / 390 kg

4. Handling and transportation

For safe handling and transportation use a lift truck for movement indoors. Keep the

machine in its normal position and avoid turning it upside down. If the machine is

fastened to the pedestal, stability will be greatly reduced and therefore all the

necessary measures should be taken to stop the machine from tipping over.

6

All handing and transportation operations should be carried out by trained

staff.

5. Machine installation

5.1 Machine check

The machine should be checked to make sure that it has not been damaged during

transportation and handing. If the machine appears to have been damaged, contact

us immediately. Fit all the supplied accessories onto the machine such as #17 bar

stop and #33 roller arm.

5.2 Fastening of the machine

The machine will be able to operate in keeping with the technical parameters

supplied by us, if it is positioned correctly and fastened securely to the bench

or the factory floor so that vibrations are minimal during operation.

5.3 Saw blade assembly

Remove the #145 bow guard by unscrewing #149 screws and #64 Trifurcate handle.

Fit the band by inserting it first between the bearings of the blade guide heads and

then on the two pulleys, tighten the blade slightly by means of #64 Trifurcate handle

and install #145 bow guard. Check that the saw blade is fitted with the correct

direction of teeth. Make sure that the saw blade type (dimensions 2825×27×0.9 mm)

and its teeth pith are suited to the material to be cut.

5.4 Electrical connection to the mains

Install a differential thermo magnetic switch with characteristics suited to the

mains.

7

Make sure that the power supply voltage corresponds to the voltage on the motor

plate. Connect the cable to the power supply line observing the color codes of the

individual wires, pay particular attention to the earth wire. Connect the machine, make

sure that the rotation of circular blade is in the direction shown by the arrow on the

guard.

5.5 Cutting coolant

For the cooling of the circular blade,fill the tank with emulsible oil obtained from a

mixture of water and AGIP ULEX 260 EP oil with a percentage of 5-7%

6. Machine start up and operation

6.1 Operation

Checks to carry out before each cut

A Tension the saw blade by rotating #64 Trifurcate handle to the end of stroke

(mechanic stop). Remember at the end of the operation to loosen the hand wheel

to avoid the slackening of the band.

B Check that the hand indicates the required cutting angle (vice scale).

C Make sure that the bow and the vice are locked by means of #54 lock handle

D With the motor off, lower the bow and check that at the end of stroke, the band

does not touch the counter-vice.

E Make sure that the piece to be cut is properly secured in the vice.

F Make sure that the cooling liquid is circulating in the machine.

It is strictly forbidden to use the machine without cutting fluid

G When starting the motor, make sure that the band rotates in the direction of the

arrow

H To obtain maximum cutting accuracy,the unit must be located the nearest

possible to the work piece. Clamp the work piece with the vice. Release #86 blade

guide arm with clamping lever and move it near the vice jaw so that it doesn’t

touch it during the cutting operation, then secure it again. When carrying out this

operation, make sure that the blade guide does not come out of the bow guard

leaving a part of the blade exposed.

6.2 Cutting operation

A. Before cutting, check that the inclination is the one required. In order to correct or

change the inclination, place #54 Lock handle in position you expect and after

correction, move it back to the lock position.

B. Manual operation: Clamp the material to be cut with #2 Handle bar after having

positioned the clamp near the piece to be cut. Press main switch to “ON”position,

8

Change selector switch to “ ” position. Turn the speed switch to “1” position or

“2”position you like, take hold of #7 handle located at the end of head lever and

press the button. The blade will now start turning, position the blade carefully on

the piece to be cut. Then increase the pressure in order to accelerate the cutting

operation without using excessive force.

C. Automatic operation: Clamp the material to be cut with #2 Handle bar after having

positioned the clamp near the piece to be cut. Press main switch to “ON”position,

Change selector switch to “ ” position. Turn the speed switch to “1” position or

“2”position you like, after having started the unit by pressing the START push

button, the blade starts to rotate. The down stroke of the bow can be adjusted by

means of the appropriate regulator. Position the blade carefully on the piece to be

cut. Then increase the pressure with the regulator in order to accelerate the cutting

operation without using excessive force.

D. To make a series of cuts, position the bar stop in correspondence of the size

required. Fix it into position by using #19 Baffle block.

We strongly discourage the use of blades with ruined or insufficiently sharp

cutting edges

6.3 Special safety checks

A. Before using the machine, check carefully that the safety devices are in good

working order, that the mobile parts are not blocked, that no parts are damaged

and that all the components are installed correctly and are functioning properly.

B. Before operating the machine, make sure that the screws of the guards and other

protective devices are adequately secured, especially the screws of bow guard.

C. Check that the safety micro switches and the emergency button are functioning

correctly.

D. Make sure that the mobile guard does not leave uncovered an angle of more than

5°in order to prevent fingers from entering.

E. Pay attention to environmental conditions. Don’t expose the machine to rain, don’t

use it in damp environments, position the machine on a clean dry floor that has no

oil or grease stains.

F. Before using the machine, the operator should make sure that all tools and service

spanners used for maintenance or adjustment have been removed.

6.4 Measures to prevent residual risks

A. The removal of guards and tampering with the safety devices is strictly forbidden.

B. Gloves should always be worn.

9

C. Standard work clothing should be used and kept closed and should not have

flapping parts.

D. The machine should not be cleaned with liquids under pressure.

E. In the event of fire, extinguishers should not be used unless they are the powder

type. The electric power supply to the machine should always be disconnected in

these circumstances.

F. Do not insert foreign bodies into the motor cover and not supply the machine with

voltage by tampering with the safety micro switches or main switch.

G. Take the necessary precautions to avoid the machine being started by other

people during loading, adjustment, piece changing or cleaning.

7. Maintenance and repair

7.1 General safety measures

A. Lock main switch. Use the padlock in the event of machine failure or replacement

of the band. The padlock key should be entrusted to a responsible person.

B. Before carrying out any work on electrical equipment, remove the power supply

plug from the control pane (disconnect voltage).

C. Only use cables to supply power, which have a cross-section suited to the power

of the machine.

D. Authorized personnel should only carry out repairs. Only spare parts made by the

original manufacturer should be used, otherwise these could cause damage or

injury.

7.2 Description of routine maintenance

A. Adjustment of the blade guide bearings

Loosen #85 bolts, rotate #91 Hex. cap bolt, so that the blade guide bushings vertically

position the blade in axis. Tighten #85 bolts until the blade secured. The front blade

guides must be positioned the nearest possible to the piece to be cut. Check every 3

months the existing tolerance between the blade guides, making sure that it does not

exceed the blade thickness of one tenth of a millimeter, so as to avoid inexactnesses

in the cut squaring. Periodically check with mounted blade that the blade guide

bearings rotate freely.

B. Cleaning of the coolant tank

The coolant tank can be cleaned by simply removing #46A bolts. Empty the coolant

from the tank and collect the coolant in a container for future disposal. Clean away the

shavings and the metallic powder, taking care not to scatter this over the machine

especially around the motor and the box containing the electrical equipment. Fill the

10

tank with the amount and liquid stated earlier.

C. Checking of bench lever functioning

Check rotation release-locking lever is working properly regularly. In the event of the

lever not locking correctly, loosen #55 grub screw, tighten #56 nut and fasten #55 grub

screw again. Make sure that with the bench lever in right position, #26 rotating arm

which supports the bow can rotate freely.

11

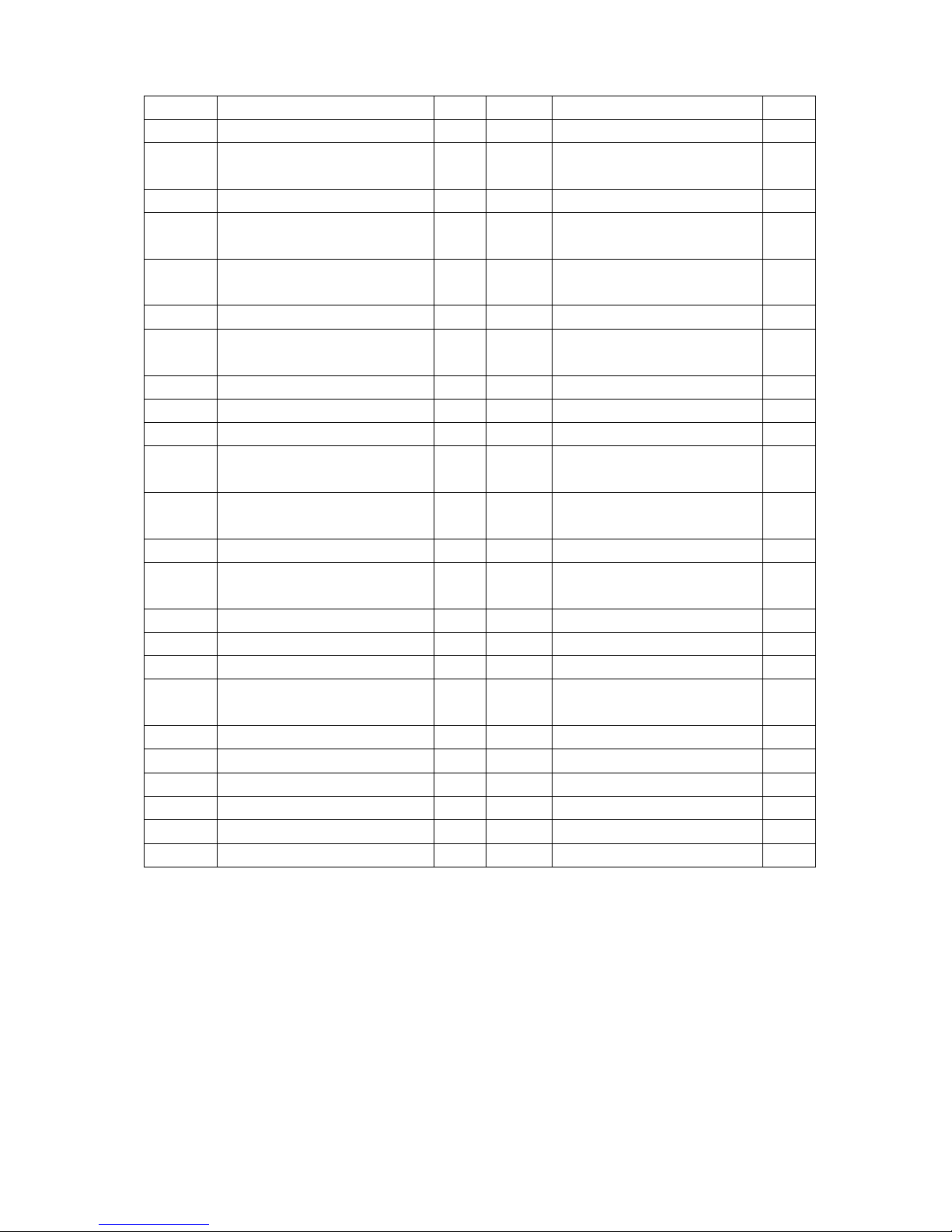

8. Part list

ITEM

DESCRIPTION

QTY

ITEM

DESCRIPTION

QTY

1

Handle glove M8X25

2

25

Block washer 10

2

2

Handle bar

1

26

rotating arm BS315G-0014

1

3

Handle axis

BS315G-0002

1

26A

Ruler

1

4

Thrust bearing AXK1730

1

26B

Limit block BS315G-0014

1

4A

Washer BS315G-0003

1

26C

Hexagon bolt M8x30

2

4B

Spring pin 6x30

1

26D

Nut M8

2

5

Lead screw

BS315G-0007

1

26E

Gasket BS315G-0038

1

6

Upper clamp

BS315G-0006

1

26F

Limit switch

1

7

Moving clamp board

BS315G-0008

1

27

Operating panel

1

8

Hexagon screw M10X20

3

27A

Operating panel

1

9

Adjusting handle

M12X100

1

28

Nut M6X16

2

10

Axis BS315G-0010

1

29

Mat 6

2

10A

Antenna BS315G-0011

1

30

Electrical box bracket

BS-315G-0031

1

11

clamp connecting seat

BS315G-0009

1

31

Mat 8

2

12

Lower clamp

BS315G-0012

1

32

Bolt M8X20

2

13

clamp fixed board 1

1

33

Roller BS315G-0025

1

14

Clamp fixed board 2

1

34

Holder shaft BS315G-0027

1

15

Hexagon screw M10X25

6

35

Mat 12

4

16

Hexagon screw M8x10

1

36

Bolt M12X20

4

17

Fixing bar

1

37

Sheath BS315G-0026

2

17A

Ruler

1

38

Block washer 17

2

18

Baffle shaft

1

39

Bracket BS315G-0028

1

19

Baffle block

1

40

Mat 10

4

20

Pentacle handle M8X16

1

41

Hexagon screw M10X25

4

21

Sleeve fixing shaft

BS315G-0019

1

42

Bracket BS315G-0013

1

22

Hexagon screw M6X20

4

43

Handle ball M10X32A

2

23

Hydraulic fixing seat

1

44

Shaft

1

24

Hydraulic fixing shaft

1

45

Cooling pump

1

12

ITEM

DESCRIPTION

QTY

ITEM

DESCRIPTION

QTY

46

Cover board

BS315G-0018

1

74

Hexagon screw M8X16

6

46A

Hexagon screw M10X25

6

75

Handle switch

1

46B

Mat 5

6

76

Pressure handle

1

47

Under pan BS315G-0015

1

77

Hexagon screw M10X12

1

47A

Nut M10

2

78

Moving seat

1

47B

Hexagon bolt M10X45

2

79

Driven wheel

BS315G-0033

1

47C

Hexagon screw M10X45

4

80

Bearing 6207-2Z

2

48

Preventing board

1

81

Sheath

1

49

Leg BS315G-0016

1

82

Block washer 72

1

50

Hexagon screw M8X25

3

83

Mat

2

51

Mat 8

3

84

Hexagon bolt M12X25

2

52

Connecting shaft

1

85

Bolt M6X12

1

53

Lock seat

1

86

blade guide arm

1

54

Lock handle

1

87

Board

1

55

Grub screw M8X10

1

88

Flat washer 6

2

56

Nut M30X1.5

1

89

Hexagon screw M6X10

2

57

Mat 10

4

90

Pressure board

BS315G-0001

1

58

Hexagon screw M10X25

4

91

Hexagon bolt M12X35

1

59

Nut M8

4

92

Hexagon screw M5X8

2

60

Mat 8

8

93

Guard board

1

61

Hexagon screw M8X16

4

94

Rear adjusting seat

1

62

Door BS315G-0017

1

95

Hexagon head screw

M8x25

2

63

Lock MS802

1

96

Clamp

4

64

Trifurcate handle

∮70X∮18

1

97

Bearing 6208-2Z

4

65

Sheath

1

98

Hexagon eccentric cover

2

66

Spring pin 8X35

1

99

Hexagon eccentric cover

2

67

Adjusting pole

BS315G-0021

1

100

Flat washer 8

4

68

Dishing spring 4X20.5X2

12

101

Hexagon screw M6X30

2

69

Thrusting bearing

AXK2035

1

102

Hexagon screw M6X25

2

70

Saw bow BS315G-0020

1

103

Front adjusting seat

1

71

Blade adjusting switch

1

104

Driving wheel BS315G-0032

1

72

Hexagon screw M4X30

2

104.1

Saw blade

2825X27X0.9X5/8

1

73

Pressure board

2

105

Output shaft

1

13

ITEM

DESCRIPTION

QTY

ITEM

DESCRIPTION

QTY

106

Block washer 40

2

129

Bearing cover

BS315G-0035

2

107

Bearing 6208-2Z

1

130

Bearing 32009X2

2

108

Cooling water separation

block

1

131

Sheath BS315G-0034

1

108A

Hexagon screw M4X25

4

132

Rotary shaft

BS315G-0036

1

109

Cylinder

1

133

Hexagon screw M10X25

4

110

Cylinder bracket

BS315G-0023

1

134

Hexagon screw M12X45

1

111

Hexagon M12X25

2

135

Pressure pad

1

112

sheath

2

136

Pressure spring Ⅱ

1

113

Hexagon screw M10X25

2

137

Pressure spring Ⅱ

1

114

Connecting board

BS315G-0030

1

138

Shaft

1

115

Shield board

BS315G-0029

1

139

Block washer 12

2

116

Wire brush ∮50

140

Shaft

1

117

Wire brush bracket

BS315G-0024

1

141

Sleeve

1

117.1

Hexagon screw M10X25

2

142

Block washer 15

1

118

Shaft sheath

1

143

Hexagon screw M8X20

4

119

Hexagon screw M6X6

1

144

axis seat

1

120

Slowdown box

1

145

bow guard

BS315G-0022

1

121

Hexagon bolt M10X30

4

146

Bow shield switch

1

122

Motor

1

147

Route switch pad

1

123

Route switch stand

1

148

Key switch plate

1

124

Hexagon screw M6X6

2

149

Screw M6X12

2

125

Nut BS315G-0037

1

150

Flat washer 6

2

126

Hexagon screw M8X10

1

151

Hexagon screw M6X12

2

14

9. Part drawing

15

16

10. Electric drawing

17

Note: This manual is only for your reference. Owning to the continuous

improvement, changes may be made at any time with no obligation on

the part of machine. And please note the local voltage for operating

machine

Table of contents

Popular Saw manuals by other brands

Makita

Makita XSL01Z instruction manual

Gude

Gude GRK 210 BS Translation of the original instructions

Husqvarna

Husqvarna K 4000 Cut-n-Break Operator's manual

Dexter Power

Dexter Power CSC18LD.R Abridged user manual

DeWalt

DeWalt DC305-XE instruction manual

Diamond Products

Diamond Products CC2500 Operator's manual